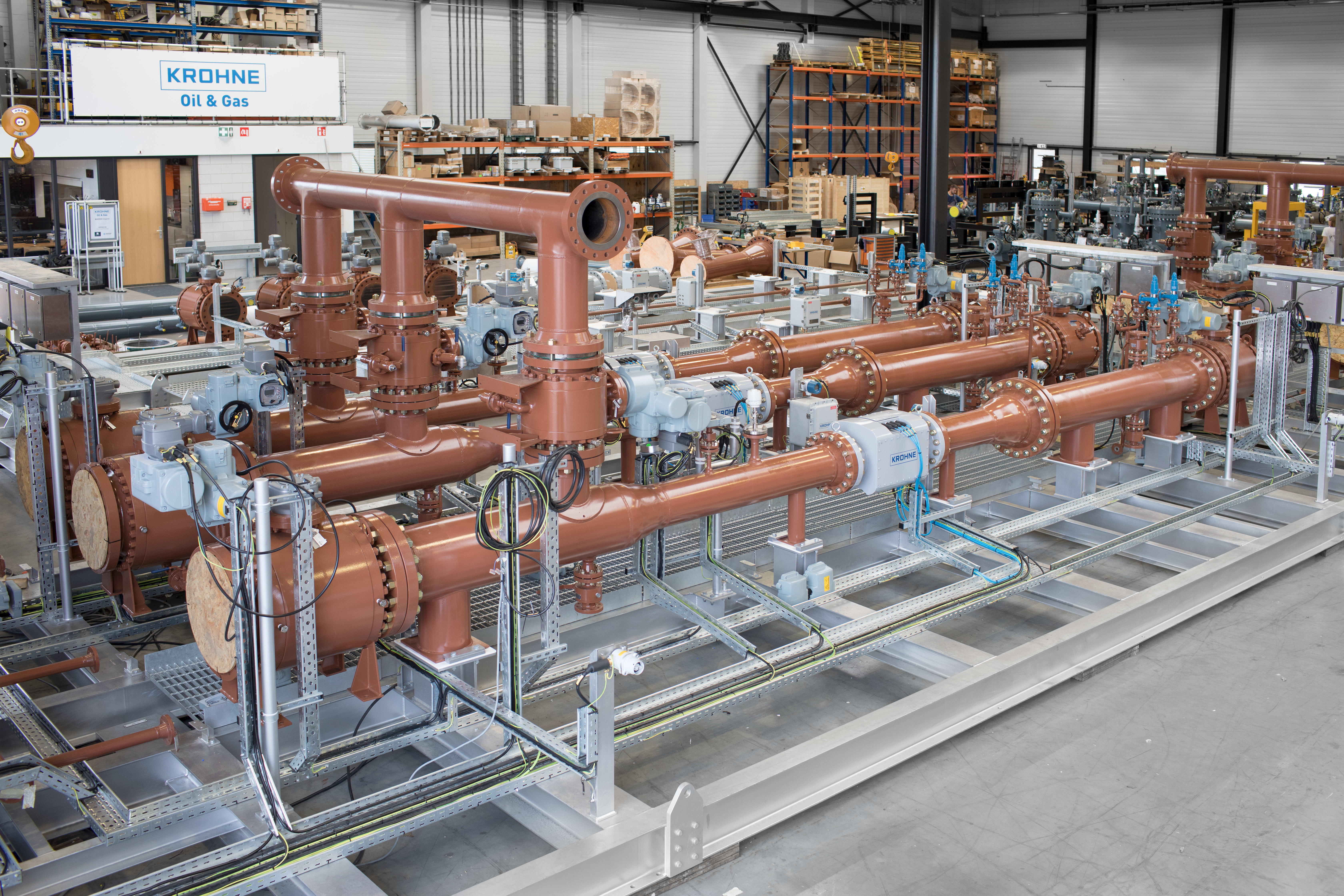

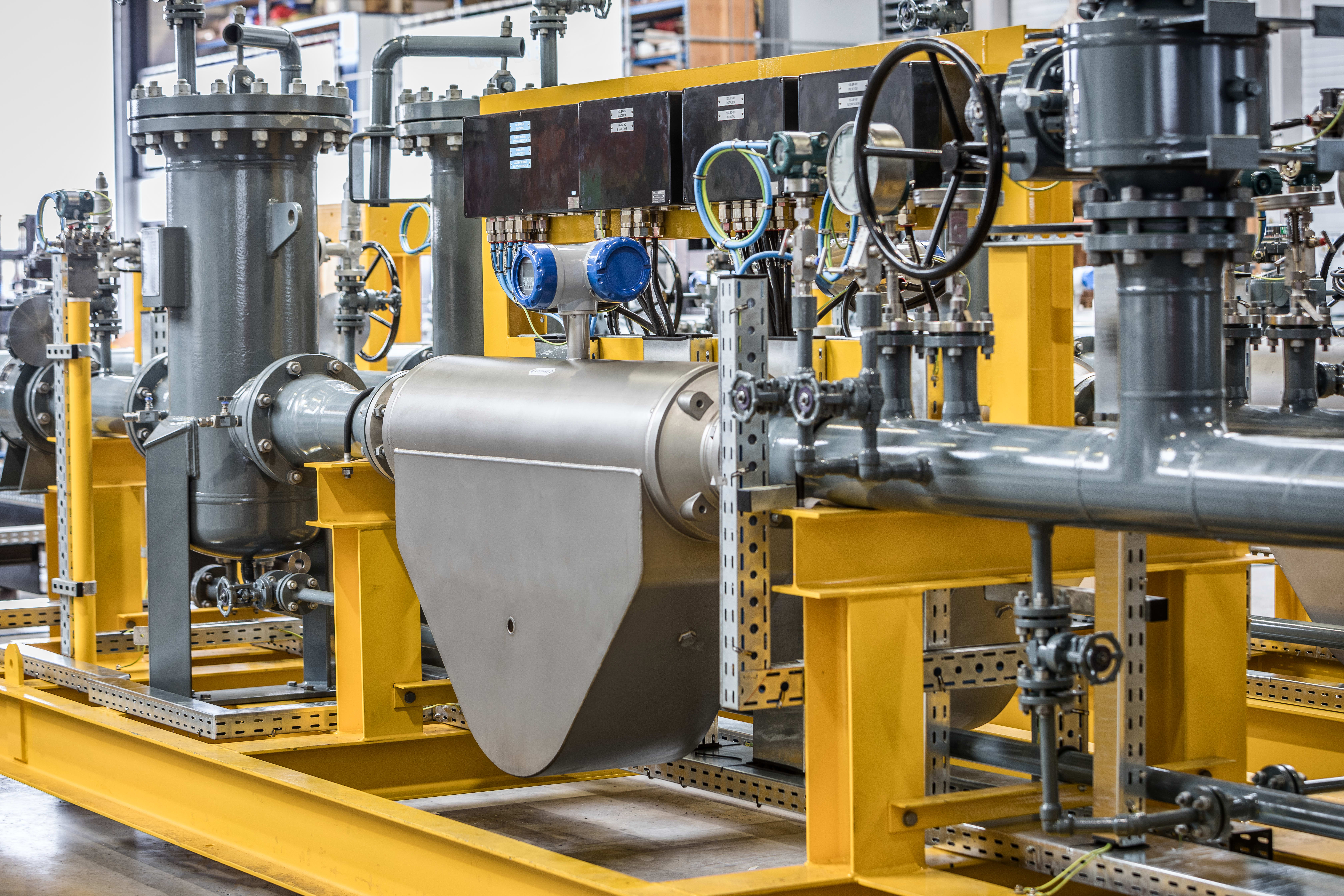

Custody transfer metering systems for crude oil and refined products

Metering solution for liquids

- Based on ultrasonic, Coriolis, turbine or PD flowmeters

- Covering the initial design phase through to on-site commissioning and training

- Comprising flow metering skid, flow control, metering control cabinets, sampling and analyser systems, including all supervisory and validation software

KROHNE metering systems are used throughout the entire oil & gas value chain, from allocation measurement during oil production up to truck and train loading of refined products at the refinery to guarantee an exact measurement. Also the downstream consumers of HFO or LFO like power plants make use of our metering systems. KROHNE takes full project responsibility for the system, including metering skids, analysers, and flow computers integrated into the metering control cabinet, with all supervisory and validation software.

KROHNE metering systems are often designed as a master-duty configuration, where a Z-cross over allows periodical verification of the duty meters against the master meter. This set-up reduces costs, weight and footprint - as a high-end bulky prover is no longer required. KROHNE can offer a range of mobile and ball provers for custody transfer metering, in cases where an on-site prover is still requested. With instrumentation and metering system design from the same source, flow measurement relies on seamless integration of all components. KROHNE is established in the Oil & Gas industry since 1921 and has a local presence in over 100 countries to provide on-going support.

Highlights

- Straight tube Coriolis and ultrasonic flowmeters to minimise pressure drop

- In-house development of flowmeters, flow computers and supervisory software guarantees seamless integration of metering and diagnostics features

- Mobile and stationary master meter solutions to replace bulky provers

- Local support in local language available from over 100 offices worldwide

- Single source responsibility for the system

- Compliance with local and international standards e.g. OIML R117, API, MI-005

Typical applications

- Custody transfer metering systems and allocation measurement of crude oil

- Custody transfer measurement of refined products, LPG and (produced) water

- Ship, truck and tanker loading and unloading

- LACT measurements

- Power station fuel supply (HFO, LFO)

Related products

OPTIMASS 6400

Coriolis mass flowmeter for advanced process applications

- High accuracy (±0.05% flat), for cryogenic to HT media (-200…+400°C / -328…+752°F); maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- SIL 2/3; CT: OIML R117, R137, MI-005, MI-002; API, AGA; hygienic certifications

- Flange: DN10…300 / ½…12", max. PN 160 / ASME Cl 1500

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

OPTIMASS 2400

Coriolis mass flowmeter for highest capacity bulk measurement

- For gases and liquids up to 4,600 t/h; maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- CT: OIML R117, MI-005, MI-002; API and AGA compliant

- Flange: DN100…400 / 4…16", max. PN160 / ASME Cl 1500

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

OPTIMASS 7400

Coriolis mass flowmeter for advanced process applications

- High accuracy (±0.1%), for viscous, aggressive or shear-sensitive media; maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- CT: OIML R117, MI-005; API; hygienic certifications

- Flange: DN10…100 / ½…4", max. PN100 / ASME Cl 600; others

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

ALTOSONIC 5

Ultrasonic flowmeter for custody transfer (CT) measurement in upstream and midstream applications

- Multipath inline meter for crudes, refined products, cryogenic media and chemicals

- CT: OIML R117, API compliant

- Flange: 4…24"; max. ASME Cl 600

- -200…+250°C / -328…+482°F

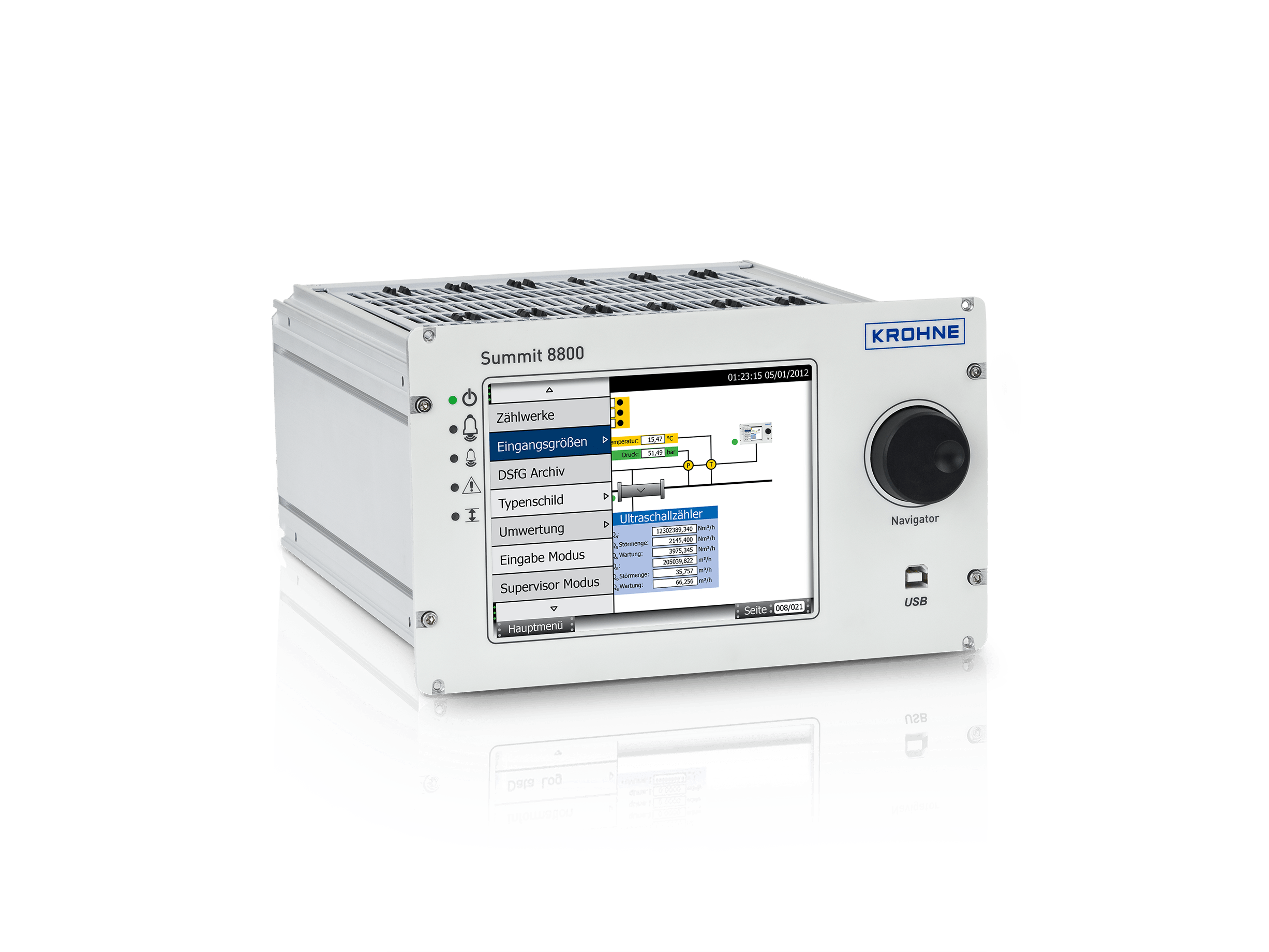

SUMMIT 8800

Flow computer for custody transfer (CT) measurement

- Cost effective solution due to modular hard- and software design

- Full colour graphical touch screen for maximum process transparency

- Easy operator access enabling time efficient maintenance

- Automatic Performance Monitoring extends recalibration interval

OPTIBAR PM 5060

Pressure transmitter for process pressure and level applications

- Rugged design with fully welded metallic diaphragm suited to high pressure ranges and hygienic requirements

- 100 mbar…1000 bar / 1.45…14500 psi

- Various threads, flanges, aseptic and other connections

- 2-wire 4…20 mA/HART®, FF, Profibus-PA, Bluetooth®

Related solutions

Supervisory Control Cabinets

Complete solution for process control

- Provides control of the metering system, including validation of field instrumentation

- Installed in a safe area, typically in a control room or dedicated building

- Supplied in combination with new metering systems, or for an upgrade to existing systems

Modular flow control and data transfer cabinets

Basic flow control solution

- Cost effective, modular metering control solution

- Based on the SUMMIT 8800 flow computer

- Installed in a safe area, typically in a control room

Flow computing

Flow computer solution for the visualisation of measurements

- Graphical representation of all measurements

- Fully pre-configured and tested according to customer requirements

- Different liquid and gas streams measured and displayed on a single flow computer

Metering houses and shelters

Turnkey housing solution for the installation of electronic systems and cabinets on-site

- A safe area for the installation of electronic equipment and cabinets

- Integrated HVAC system where required

- Local operator supervisory work station can be included

Sampling systems

Automatic sampling solution for liquid hydrocarbons

- Sampling systems for stand-alone use, or integrated into the flow metering systems

- In-house design, manufacturing, commissioning and testing

- Fully assembled and tested prior to shipping

- Engineered solution to meet any special project specifications

Analyser houses and shelters

Analyser solution for crude oil, refined products and natural gas

- Quality measurements of crude oil, refined products and natural gas

- Supplied with new metering systems, or as a stand-alone upgrade to existing systems

- Engineered solutions based on customer preferred brands

Ball provers

Standalone or fully integrated prover solution

- Engineered solutions optimised for the customer processes

- Stand alone or integrated into the metering skid

- Uni- and bi-directional, with diameters from 3" to 36"

Mobile provers

On-site master metering solution

- On-site meter verification against a mobile master meter

- Cost effective solution due to sharing between different locations

- Lowest measurement uncertainty by periodic verification of prover against national and international standards

- Engineered prover solution optimised for specific applications

Calibration runs and skids

Calibration solution for liquids and gases

- Comparable systems to those used during the manufacture of KROHNE flowmeters

- Flexible concept, with a design tailored to the requested application range of the flow control

- Available with calibration in accordance with national and international standards

SynEnergy Supervisory and visualisation software

Solution for continuous process monitoring and reporting

- HMI/SCADA software for measurement solutions

- State of the art HTML5 secure web technology

- Optimisation of operation results due to predictive maintenance

- Easy integration into existing DCS and ERP networks

CalSys Analyser Management software

Solution for analyser management and data acquisition (AMADAS)

- Effective performance monitoring of quality measurement instruments (QMI)

- Automated analyser validation and statistical process control

- Complies with international standards and methods (ASTM D3764, ASTM D6299, OP 97-30425 etc.)

- Increased availability of gas chromatographs and critical process analysers

Related services

Consultancy & engineering for metering systems

From metrology concepts through to design and testing

- Consultancy regarding local and international metrology requirements and certifications

- Cost effective engineering concepts tailored to application and installation

- Detailed design of mechanical setup, instrumentation, E&I and software

- Site survey and feasibility studies for specific process or technical requirements

- Assistance during project execution

Start-up & commissioning for metering systems

On-site support by dedicated KROHNE engineers

- Onsite commissioning services for on- and offshore metering systems

- Consultancy during the implementation of systems using KROHNE and non-KROHNE products

- Assurance of smooth and continuous operations in the field

- Site acceptance testing (SAT) to verify the system is working according to requirements

System calibration & validation for metering systems

Additional diagnostics and monitoring to achieve optimal performance of the system

- KROHNE certified validation with full audit trail

- On-site or laboratory calibration of instruments

- Adjustments according to application requirements

- Uncertainty calculations with all parties involved

- Periodical inspection, including environmental and metrological certification

Operation & maintenance for metering systems

Support for on-going diagnosis and system health checks

- Maintenance contracts and service level agreements

- Pre-defined service rates and response times

- 24/7 Customer support and emergency helpdesk

- Periodic health checks and software updates

- Troubleshooting using a remote link or by an engineer on-site

Training for metering systems

Full range of workshops and seminars related to products and measurement solutions

- Basic principles of metering systems

- Individual training sessions for operational, engineering and maintenance personnel

- Customised project training and engineering background