EcoMATE™ Bunker verification

Bunker verification solution for seagoing vessels

- For verification of bunker fuel quantities received through the bunkering line

- Enables data acquisition and logging, calculation and monitoring of bunkering operations

- Utilises the high accuracy mass flow measurement available from OPTIMASS bunker meters

- Allows checking of the fuel supplier delivery notes and the fuel oil costs billed

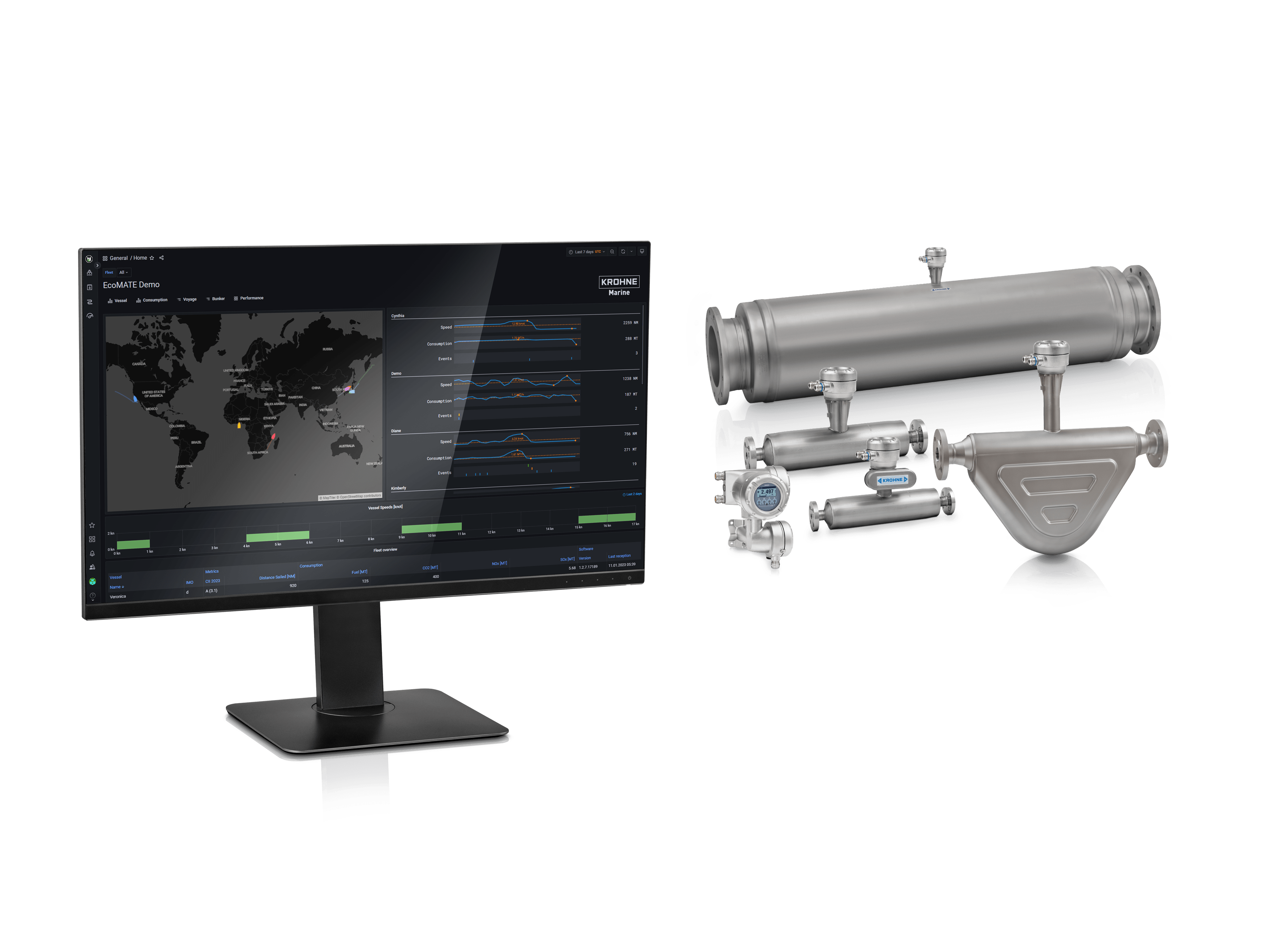

EcoMATE™, the electronic fuel management system (EFMS) from KROHNE, was specifically designed for real time monitoring of fuel consumption and bunkering and has become the solution of choice for many major shipping companies. Regardless of the vessel type, once implemented, EcoMATE™ provides the whole picture you need to gain full control of fuel consumption, emissions and bunkering.

The EcoMATE™ Bunker Verification module, one of the four software modules within the EcoMATE™ family, enables data acquisition and logging, calculation and monitoring of bunkering operations. In order to keep track of fuel oil costs and to be able to verify the amount of fuel oil received during a bunkering operation, the EcoMATE™ system also gives an overview of all corresponding flow readings.

A typical installation will consist of a flowmeter mounted in the bunkering line linked to an EcoMATE™ workstation, usually located in the control room. Supporting equipment like pressure sensors, venting and regulation valves may be recommended depending on the installation. During the bunkering process, trend graphs give you a good overview of all values. On the monitor, you can follow the exact amount of fuel oil taken on-board. Reports showing total bunker quantities received and verification of density (as delivered) can be printed and emailed to a shore station.

Highlights

- Enables ship-owners to monitor all types of vessel with a single integrated tool

- Generates reports on total fuel oil quantities delivered, including the fuel oil densities measured

- Conducts data quality checks and validations

- Continuous monitoring of mass flow rate, density and temperature throughout the entire bunkering operation

- Logging of historical data

- Full data integrity

- Automatically interfaced with a cloud solution accessible by onshore personnel

Typical applications

Marine industry

- Monitoring and reporting of bunker quantities as received, measured in the bunkering line

- For all types of vessels

Applications

Related products

OPTIMASS 2400

Marine version

Coriolis mass flowmeter for bunkering applications in the marine industry

- Measurement of mass and volume flow, density and temperature of high capacity flow rates in bunkering operations

- Bunker meter optimised for use with the EcoMATE™ Bunker verification solution for seagoing vessels

- Rugged Duplex or Super Duplex steel sensor material

- Marine approvals: DNV GL, CCS, LR, ABS, CCS, RINA, KR