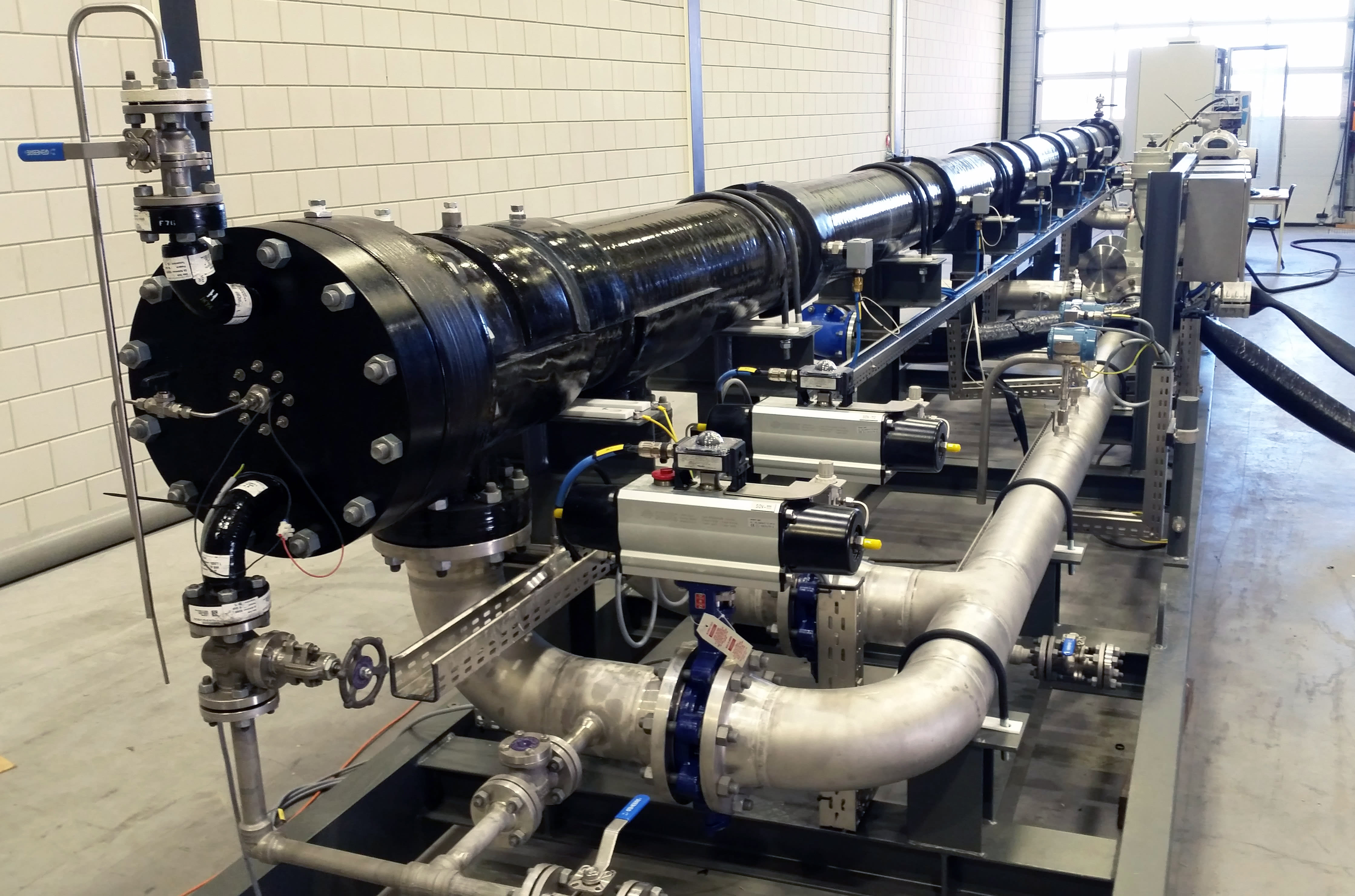

Ball provers

Standalone or fully integrated prover solution

- Engineered solutions optimised for the customer processes

- Stand alone or integrated into the metering skid

- Uni- and bi-directional, with diameters from 3" to 36"

Traditional mechanical flowmeters, such as turbines and PD meters, are usually calibrated in the field when the product properties change. The main reason is that product viscosity directly affects the measurement error of these mechanical flowmeters. To eliminate this viscosity dependency, mechanical meters are usually calibrated on the actual product and operational flow rate using an on-site ball prover.

KROHNE Ball provers come fully equipped, including third party certification and training, and are used by many major oil companies and calibration providers. Ball provers are supplied as standalone systems or can be fully integrated into the metering system. Using a low-friction baked phenolic lining and a proprietary design of micro set sphere detector assures best-in-class prover performance with excellent chemical and abrasion resistance. KROHNE has been providing ball provers since more than 35 years. Modern flowmeters that have no moving parts do not have the same viscosity dependency as mechanical meters. Nevertheless specifications could still call for on-site proving. In this case a combination of KROHNE ultrasonic or Coriolis flowmeters can be provided, in combination with a ball prover.

Highlights

- Low-friction baked phenolic lining with excellent chemical and abrasion resistance

- Proprietary design of micro set sphere detector assures best-in-class performance

- Fully wired, pre-configured and tested

- KROHNE offers support during all project phases - from fundamental design choices during FEED, up to commissioning and on-site training and service

- Site installation coordinated through one of our 100 local offices

Typical applications

- Custody transfer flow metering systems

- Allocation and high-accuracy process measurement

Related products

OPTIMASS 6400

Coriolis mass flowmeter for advanced process applications

- High accuracy (±0.05% flat), for cryogenic to HT media (-200…+400°C / -328…+752°F); maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- SIL 2/3; CT: OIML R117, R137, MI-005, MI-002; API, AGA; hygienic certifications

- Flange: DN10…300 / ½…12", max. PN 160 / ASME Cl 1500

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

OPTIMASS 2400

Coriolis mass flowmeter for highest capacity bulk measurement

- For gases and liquids up to 4,600 t/h; maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- CT: OIML R117, MI-005, MI-002; API and AGA compliant

- Flange: DN100…400 / 4…16", max. PN160 / ASME Cl 1500

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

OPTIMASS 7400

Coriolis mass flowmeter for advanced process applications

- High accuracy (±0.1%), for viscous, aggressive or shear-sensitive media; maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- CT: OIML R117, MI-005; API; hygienic certifications

- Flange: DN10…100 / ½…4", max. PN100 / ASME Cl 600; others

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

ALTOSONIC 5

Ultrasonic flowmeter for custody transfer (CT) measurement in upstream and midstream applications

- Multipath inline meter for crudes, refined products, cryogenic media and chemicals

- CT: OIML R117, API compliant

- Flange: 4…24"; max. ASME Cl 600

- -200…+250°C / -328…+482°F

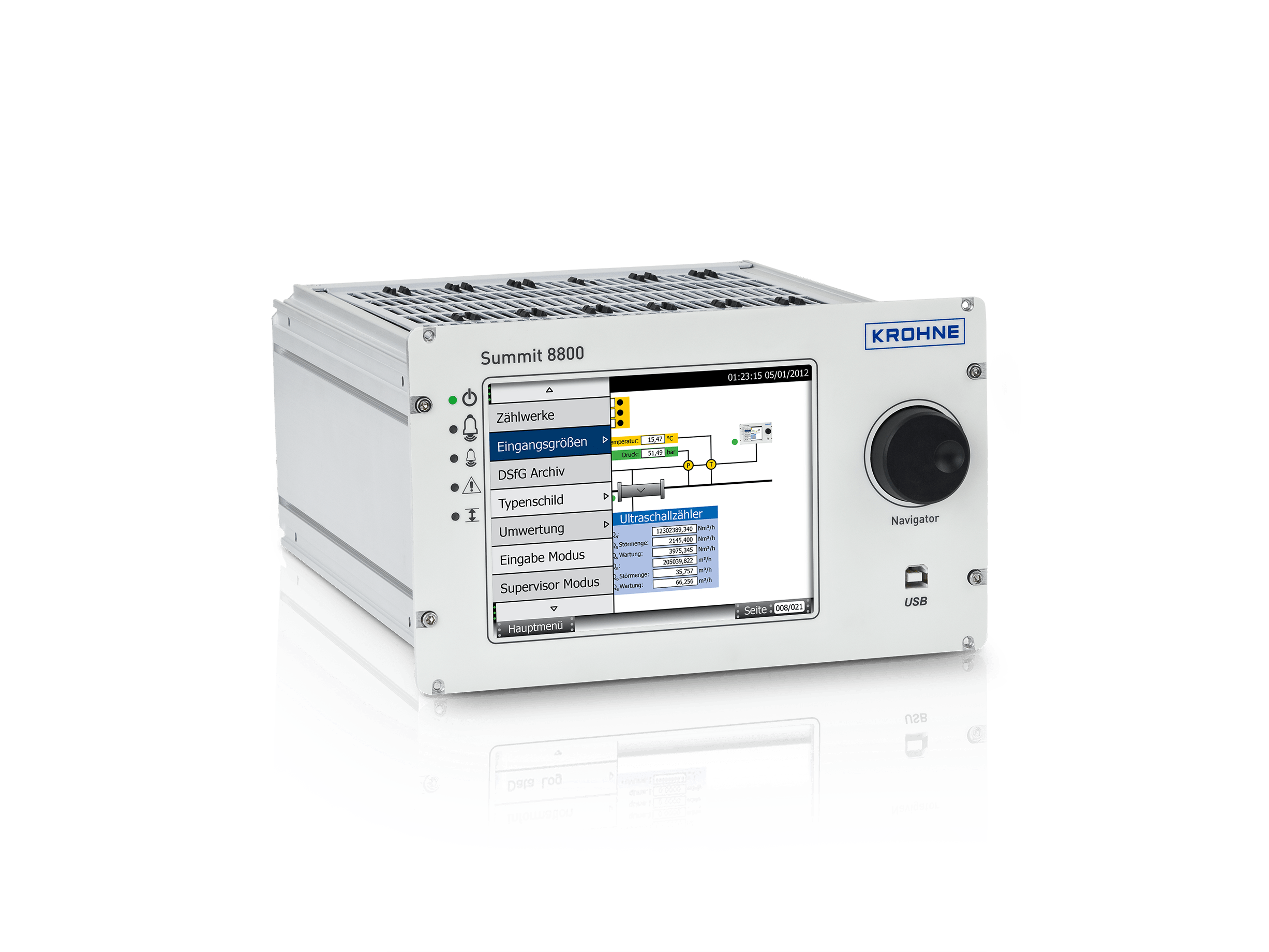

SUMMIT 8800

Flow computer for custody transfer (CT) measurement

- Cost effective solution due to modular hard- and software design

- Full colour graphical touch screen for maximum process transparency

- Easy operator access enabling time efficient maintenance

- Automatic Performance Monitoring extends recalibration interval

OPTIBAR PM 5060

Pressure transmitter for process pressure and level applications

- Rugged design with fully welded metallic diaphragm suited to high pressure ranges and hygienic requirements

- 100 mbar…1000 bar / 1.45…14500 psi

- Various threads, flanges, aseptic and other connections

- 2-wire 4…20 mA/HART®, FF, Profibus-PA, Bluetooth®

MICRO-SET MSD2

Prover sphere detector for the oil and gas industry

- Ball prover detector switch with enhanced repeatability in excess of API Chapter 4, for greater control on metering accuracy

- One model fits all prover pipes from diameters 3...36"

- Quick change-out, no need for prover re-calibration

- With stainless steel wetted parts, suitable for most products

Related solutions

Custody transfer metering systems for crude oil and refined products

Metering solution for liquids

- Based on ultrasonic, Coriolis, turbine or PD flowmeters

- Covering the initial design phase through to on-site commissioning and training

- Comprising flow metering skid, flow control, metering control cabinets, sampling and analyser systems, including all supervisory and validation software

Custody transfer metering systems for gases

Metering solution for natural gas

- Based on ultrasonic, Coriolis, turbine or DP flowmeters

- From initial design phase up to on-site commissioning and training

- Comprising flow metering skid, metering control cabinets, sampling and analyser systems, and all supervisory and validation software

Custody transfer metering systems for LNG

Metering solution for liquefied natural gas

- Based on ultrasonic or Coriolis cryogenic flow meters

- From large scale ship (un)loading to bunkering and truck loading

- Comprising flow metering skid, metering control cabinets, sampling and analyser systems, and all supervisory and validation software

Supervisory Control Cabinets

Complete solution for process control

- Provides control of the metering system, including validation of field instrumentation

- Installed in a safe area, typically in a control room or dedicated building

- Supplied in combination with new metering systems, or for an upgrade to existing systems

Modular flow control and data transfer cabinets

Basic flow control solution

- Cost effective, modular metering control solution

- Based on the SUMMIT 8800 flow computer

- Installed in a safe area, typically in a control room

Flow computing

Flow computer solution for the visualisation of measurements

- Graphical representation of all measurements

- Fully pre-configured and tested according to customer requirements

- Different liquid and gas streams measured and displayed on a single flow computer

Metering houses and shelters

Turnkey housing solution for the installation of electronic systems and cabinets on-site

- A safe area for the installation of electronic equipment and cabinets

- Integrated HVAC system where required

- Local operator supervisory work station can be included

SynEnergy Supervisory and visualisation software

Solution for continuous process monitoring and reporting

- HMI/SCADA software for measurement solutions

- State of the art HTML5 secure web technology

- Optimisation of operation results due to predictive maintenance

- Easy integration into existing DCS and ERP networks

CalSys Analyser Management software

Solution for analyser management and data acquisition (AMADAS)

- Effective performance monitoring of quality measurement instruments (QMI)

- Automated analyser validation and statistical process control

- Complies with international standards and methods (ASTM D3764, ASTM D6299, OP 97-30425 etc.)

- Increased availability of gas chromatographs and critical process analysers

Related services

Consultancy & engineering for provers and master meters

From metrology and engineering concepts, through to design and quality management

- Consultancy regarding local and international metrology requirements and certifications

- Cost effective engineering concepts tailored to the application and installation

- Detailed design of mechanical setup, instrumentation, E&I and software

- Project Management and quality assurance as ISO-9001, ISO-14001 & OHSAS-18001

Start-up & commissioning for provers and master meters

On-site commissioning services for on- and offshore installations

- Consultancy during the implementation of systems with KROHNE and non-KROHNE products

- Assurance of smooth and continuous operation in the field

- Site acceptance testing (SAT) to verify the system is working according to the requirements

System calibration & validation for provers and master meters

Periodic verification and re-calibrations

- KROHNE certified validation with full audit trail

- On-site or laboratory calibration of instruments

- Adjustments according to application requirements

- Uncertainty calculations with all parties involved

- Periodical inspection, including environmental and metrological certification

Operation & maintenance for provers and master meters

Support for site engineers in analysis of diagnostics and system maintenance

- Maintenance contracts and service level agreements

- Pre-defined service rates and response times

- 24/7 Customer support and emergency helpdesk

- Periodic health checks and software updates

Training for provers and master meters

Improve metrology knowledge and associated skills

- In-depth training on metrology expertise

- Theoretical and hands-on training

- From web-based seminars to extensive on-site workshops