Distillation in the oil & gas industry

Atmospheric and vacuum distillation measuring

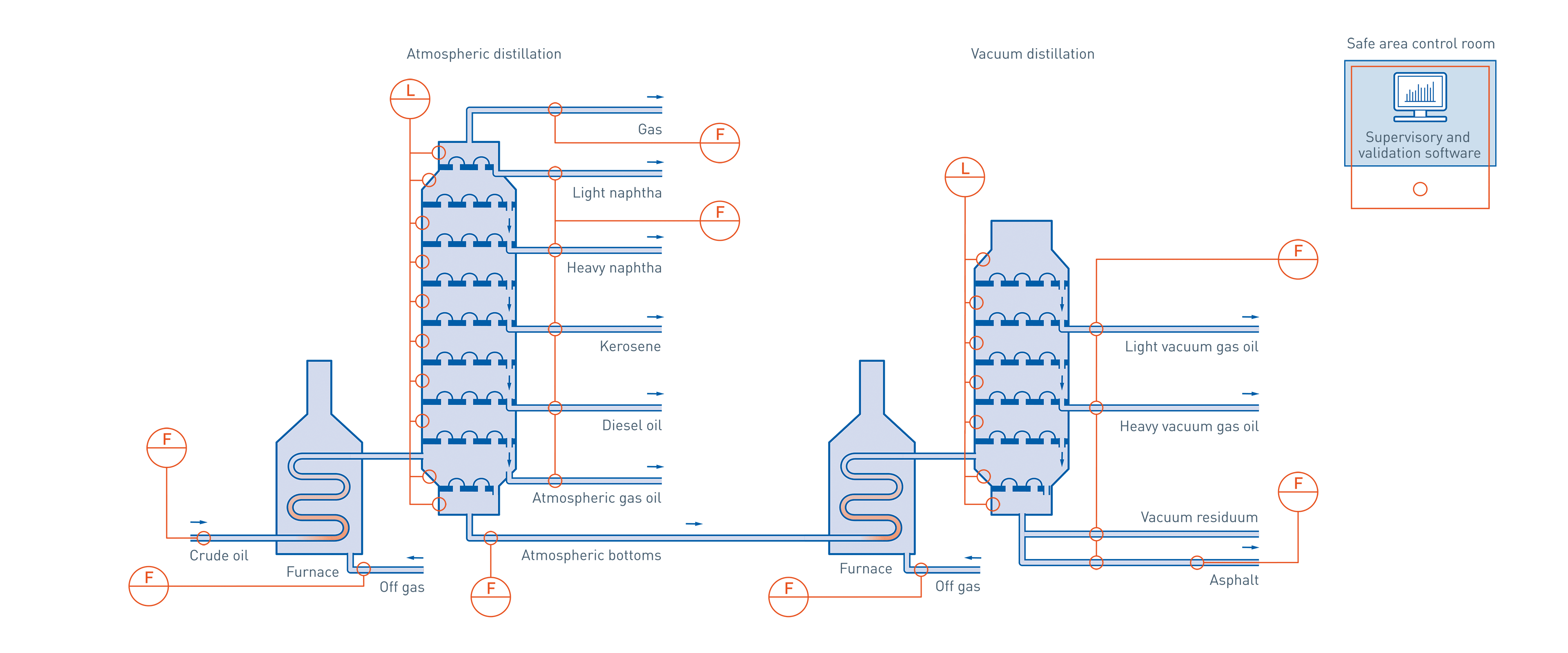

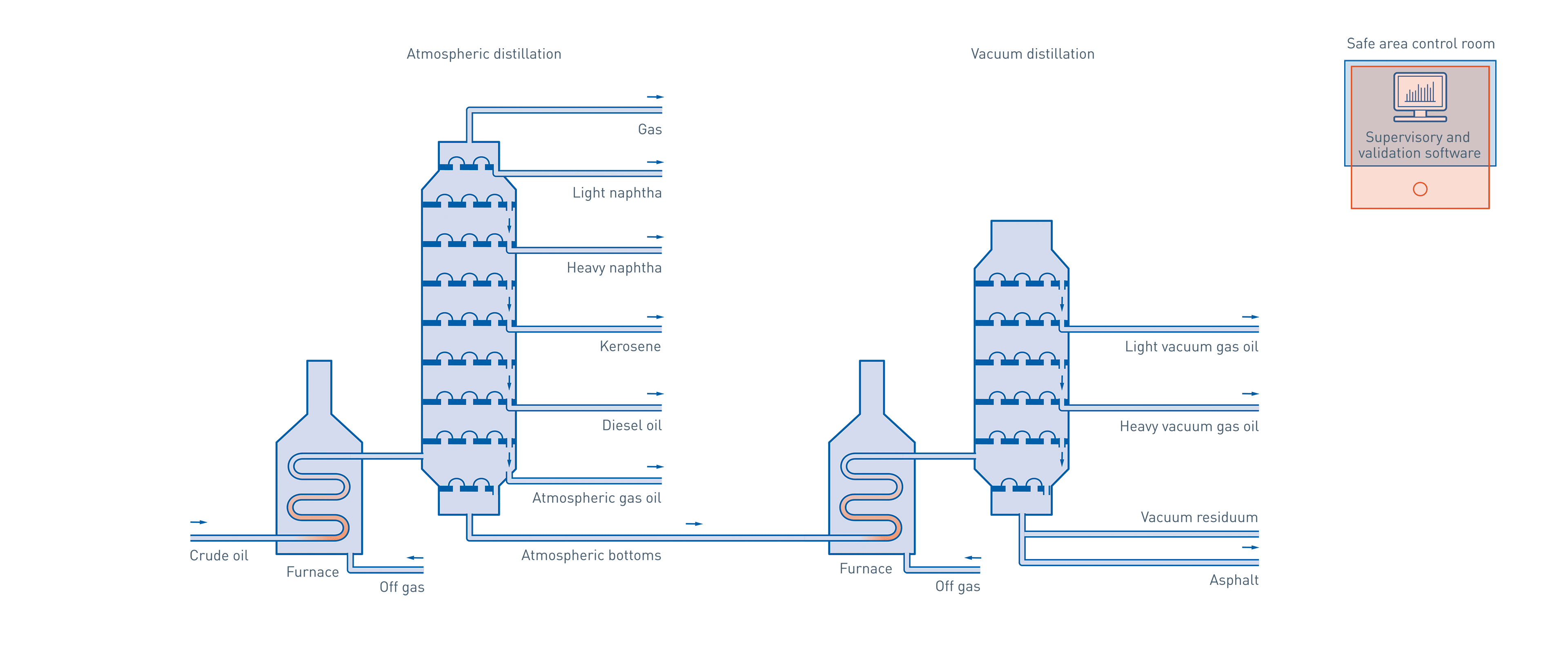

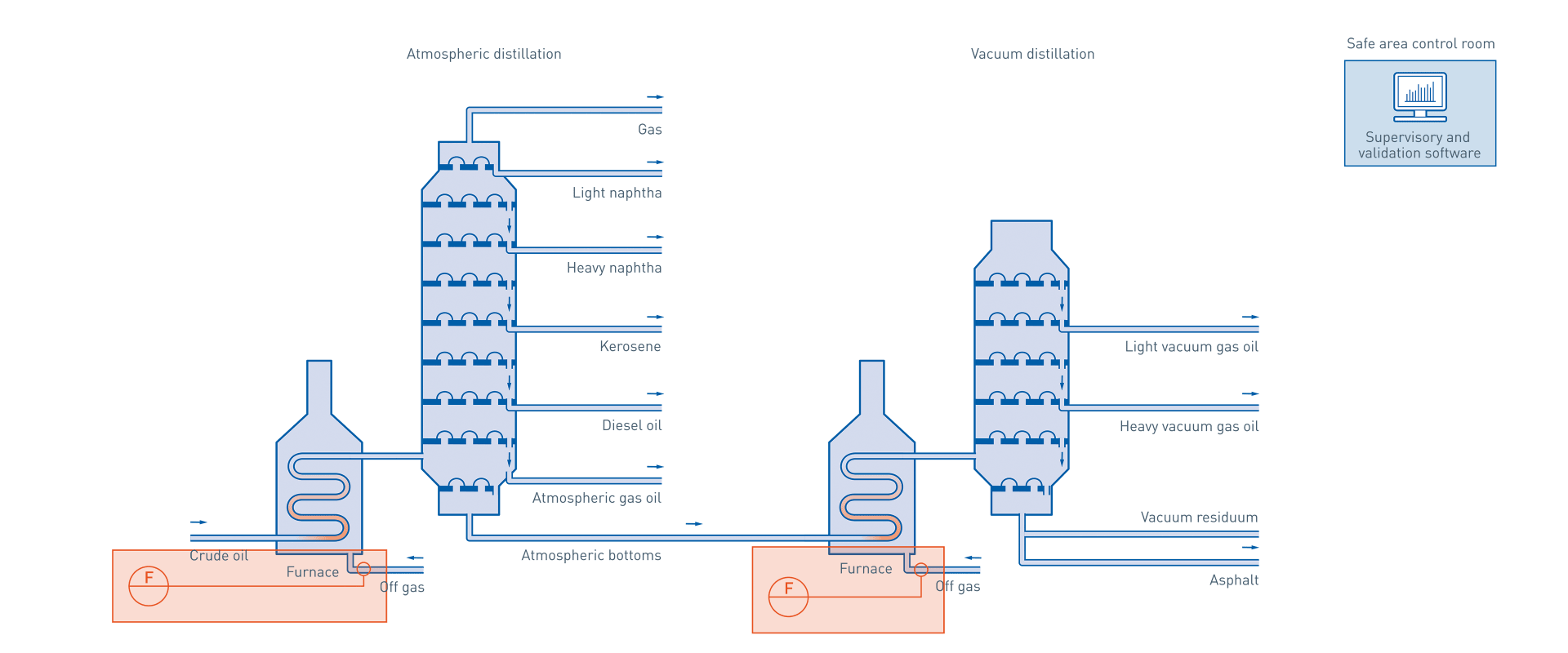

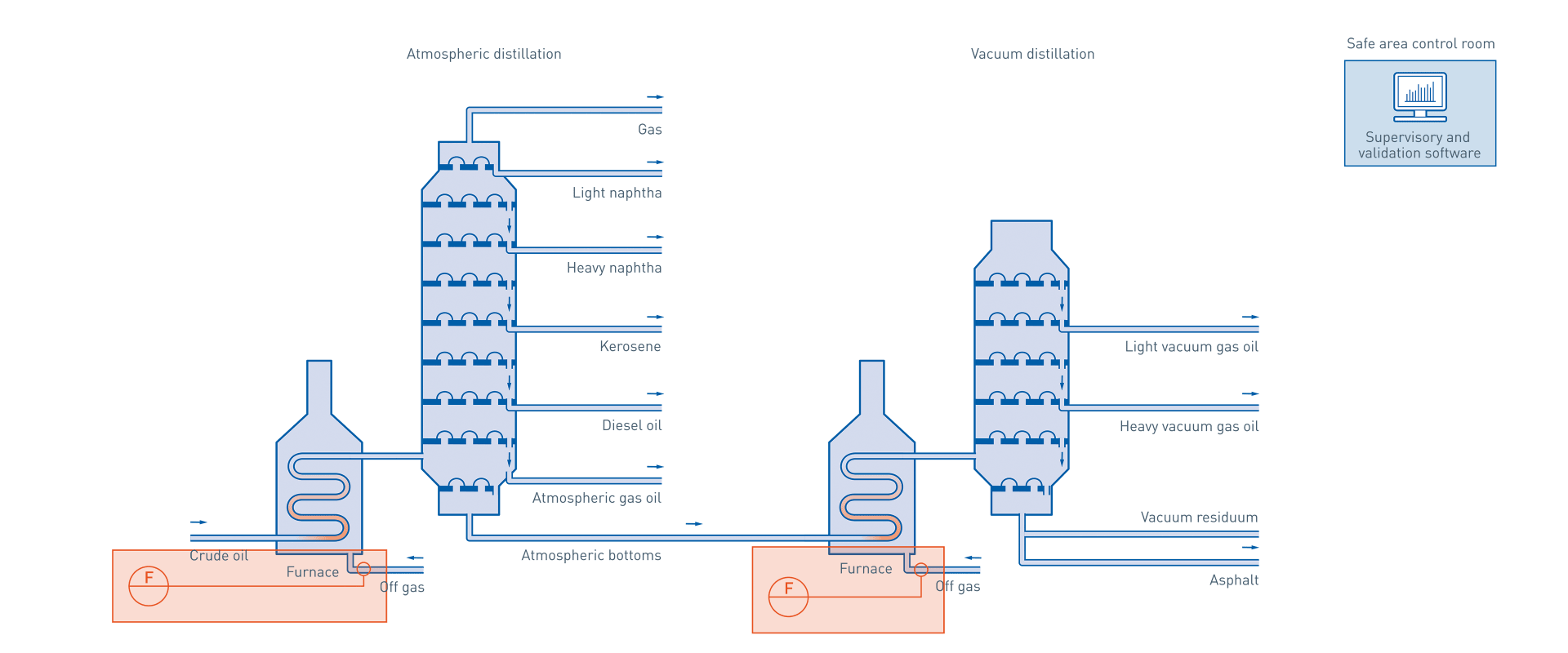

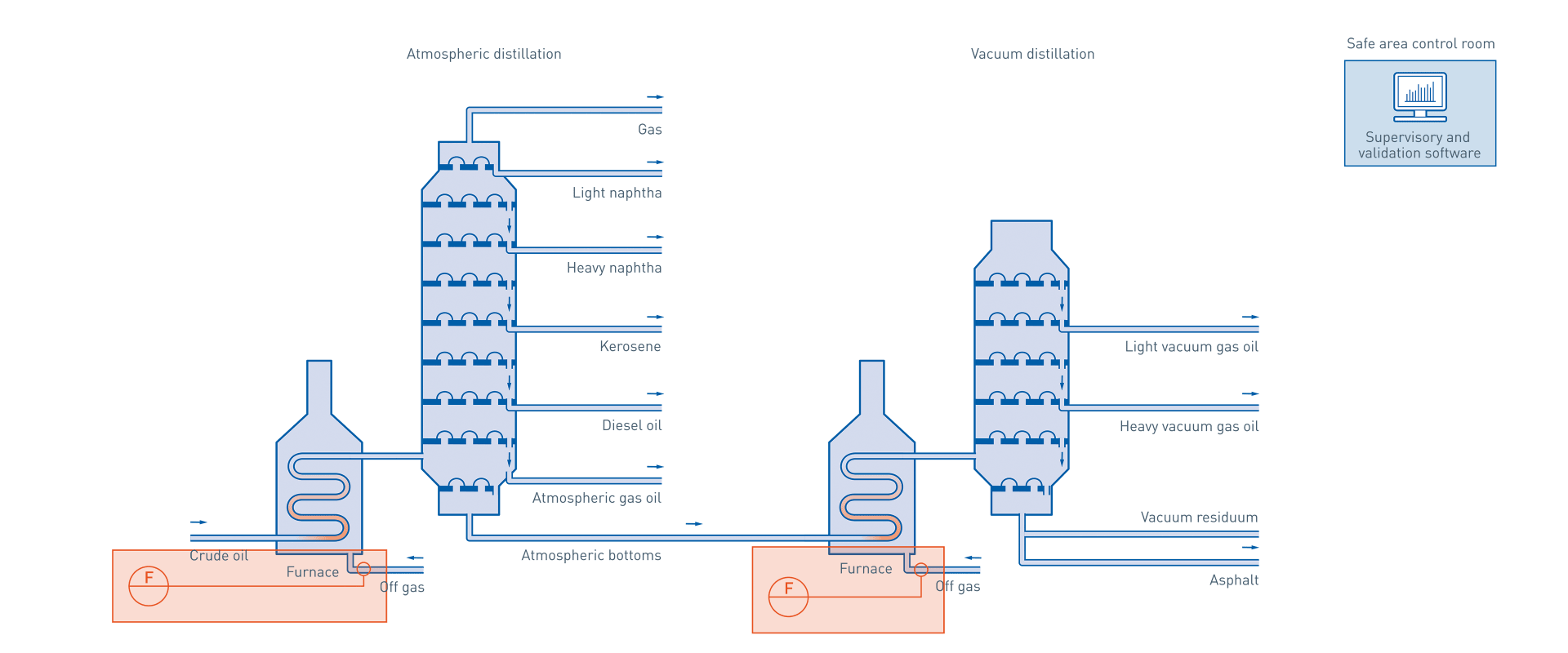

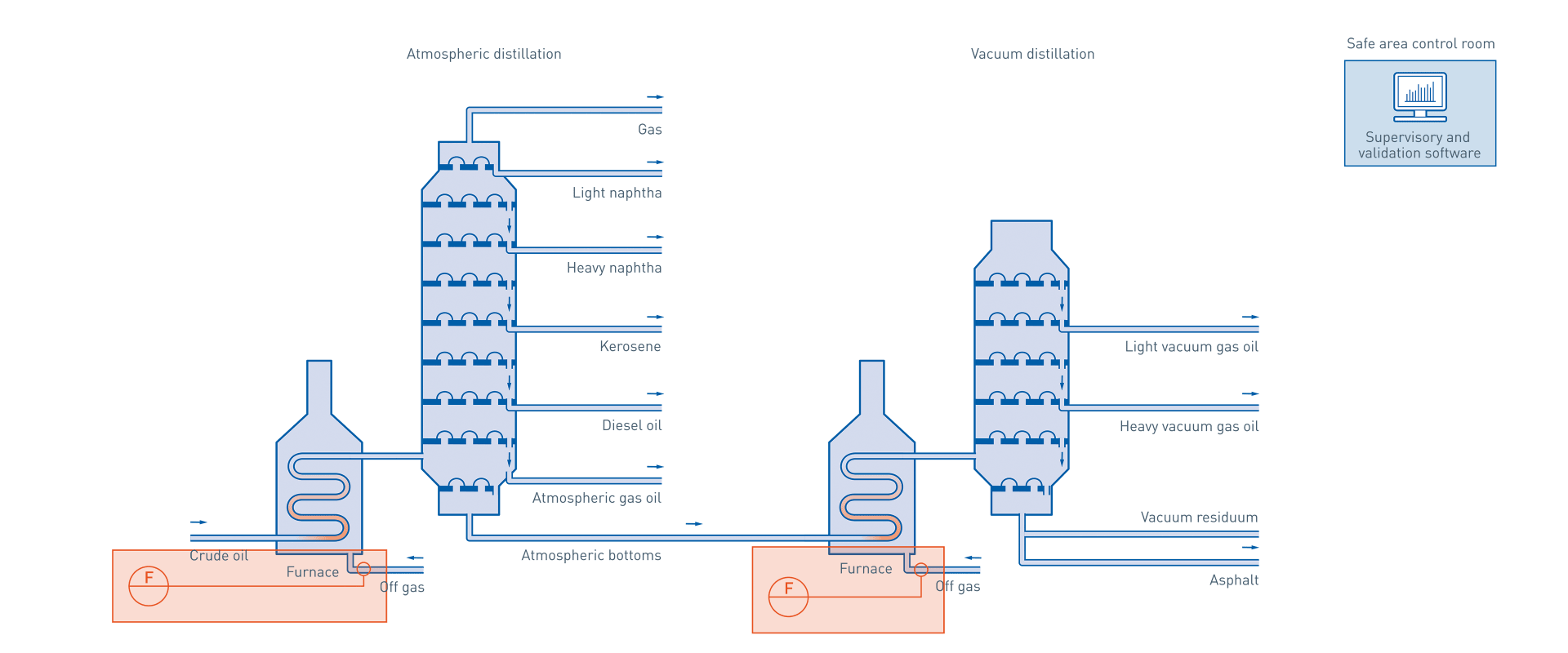

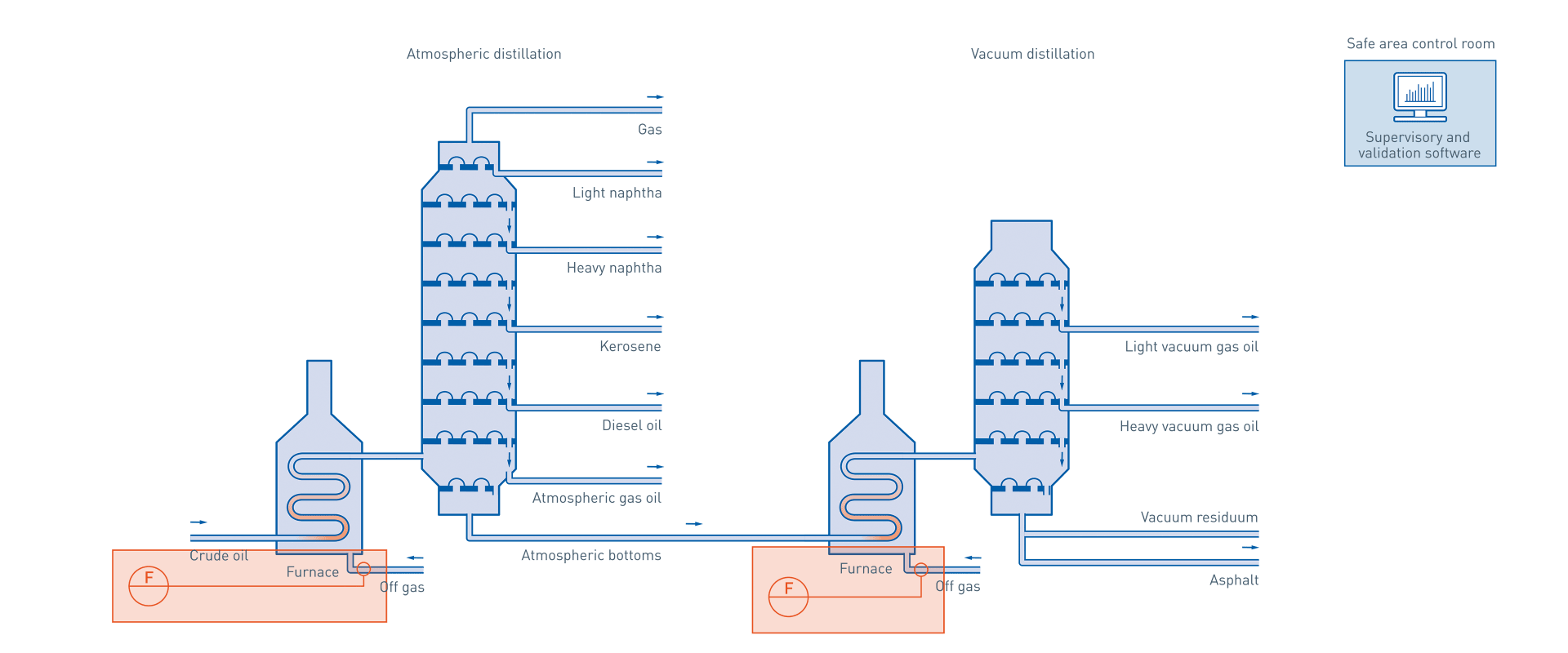

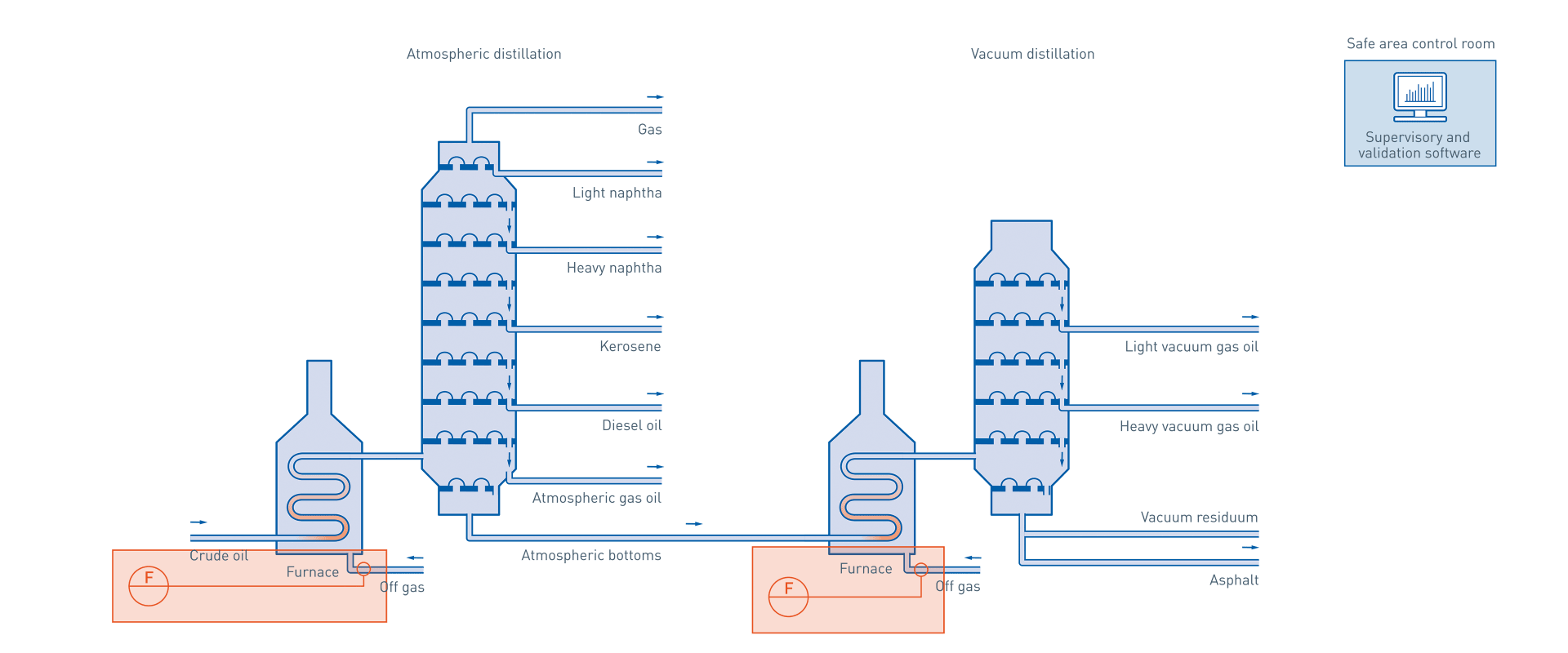

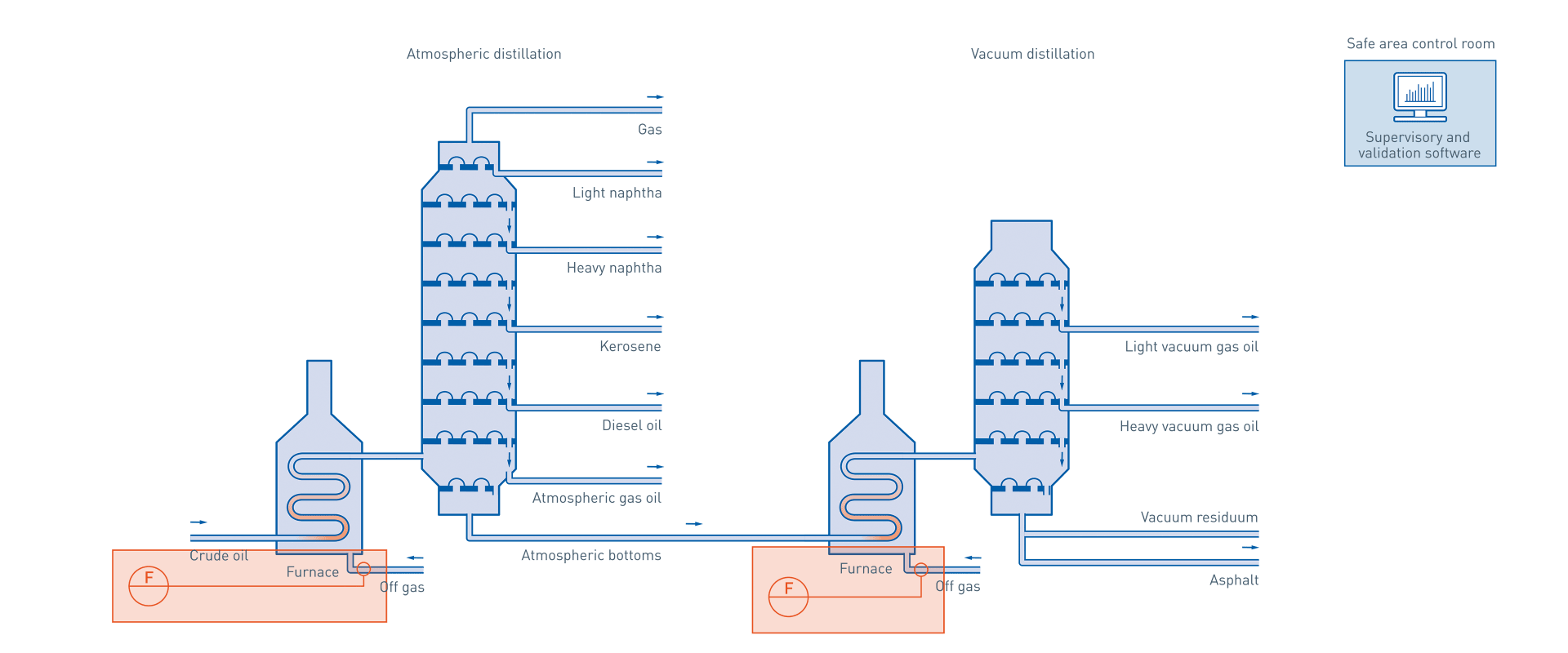

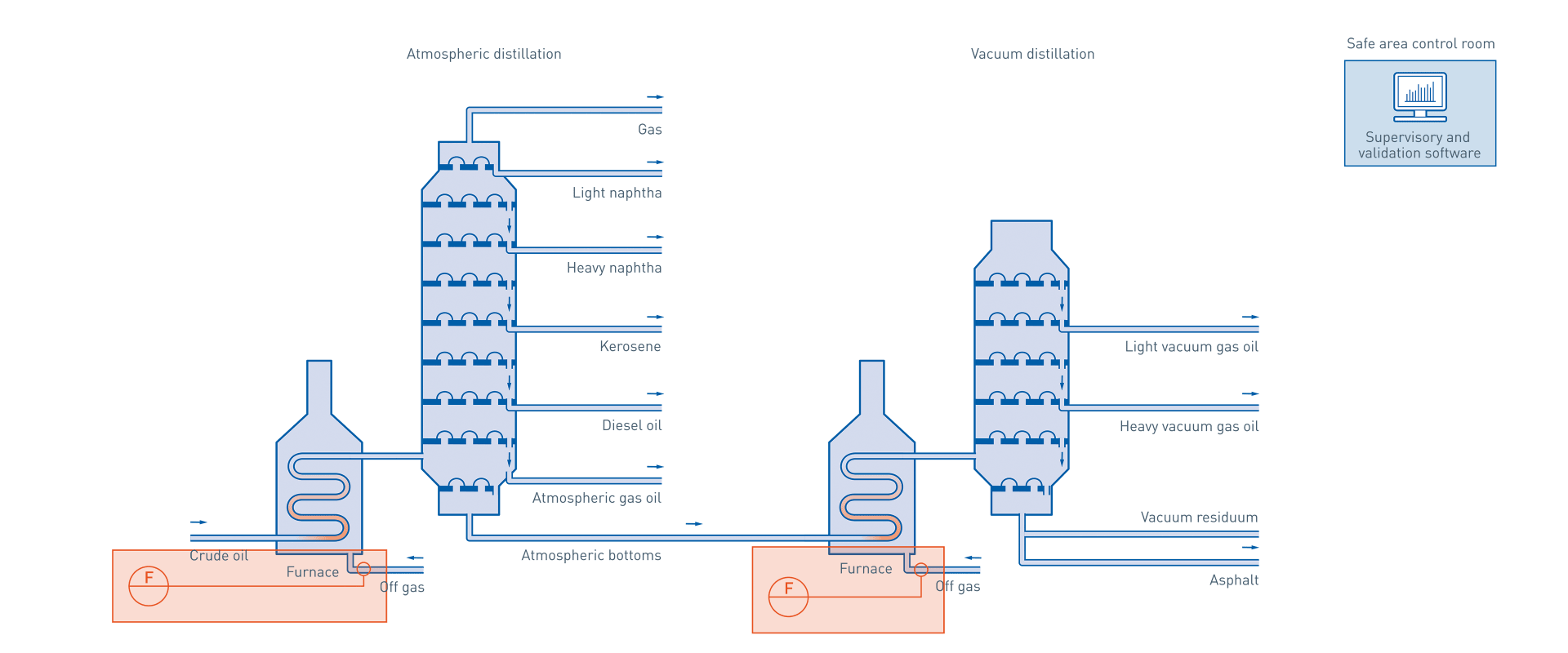

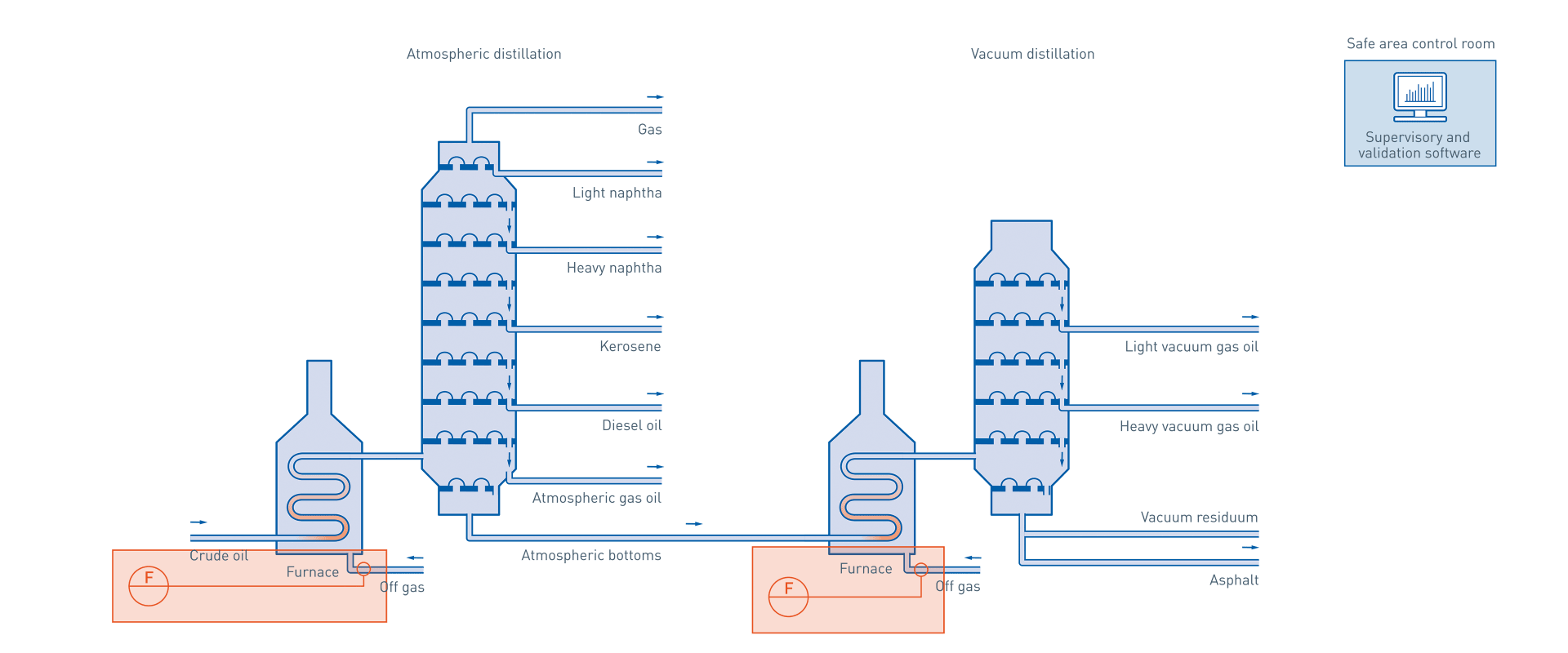

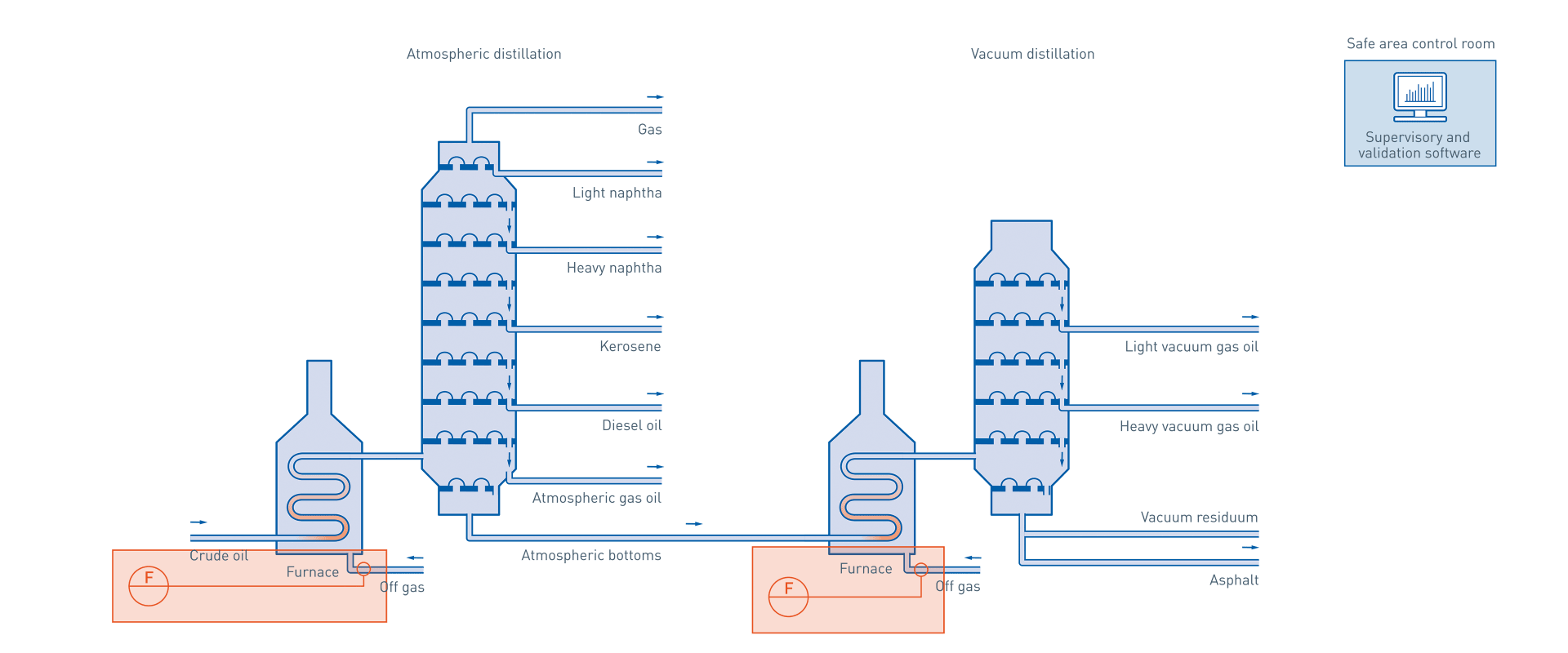

After desalting, the crude oil is further heated to around 375oC in a furnace. From here it flows into the bottom of an atmospheric distillation column, actually at slightly above atmospheric pressure. As the oil vapours rise up the column and cool, various fractions with different boiling temperatures condense into liquids, and are removed from the side of the column. These liquid fractions are known as sidecuts, and include naphtha, kerosene, light gas oil etc, as shown on the diagram. The liquids are cooled and process efficiency improved by exchanging their heat with the incoming oil feedstock. The gas remaining at the top of the column comprises the lightest fractions of the crude oil, those with the lowest boiling points. Typically the distillation column will be run in a continuous steady state, controlled by crude oil distillation instrumentation: here flow measurement and the consequent balancing of the fractions is important for control.

The residual oil that comes out of the bottom of this column, the ‘atmospheric bottoms’, has a boiling point above 375oC, and is fed into the subsequent vacuum distillation column. The vacuum conditions effectively lower the boiling points for these heavy fractions, avoiding any further increase in temperature, which could cause plugging, due to coke formation.

KROHNE has a range of atmospheric and vacuum distillation measurement solutions suitable for these harsh conditions. Special high temperature ultrasonic and Coriolis flowmeters and distillation column level transmitters have been developed for this duty. In addition KROHNE manufactures gas vortex and variable area flowmeters that are used for fuel gas, off gas and gas injection flow measurement and control.

Process details

Distillation in the oil & gas industry

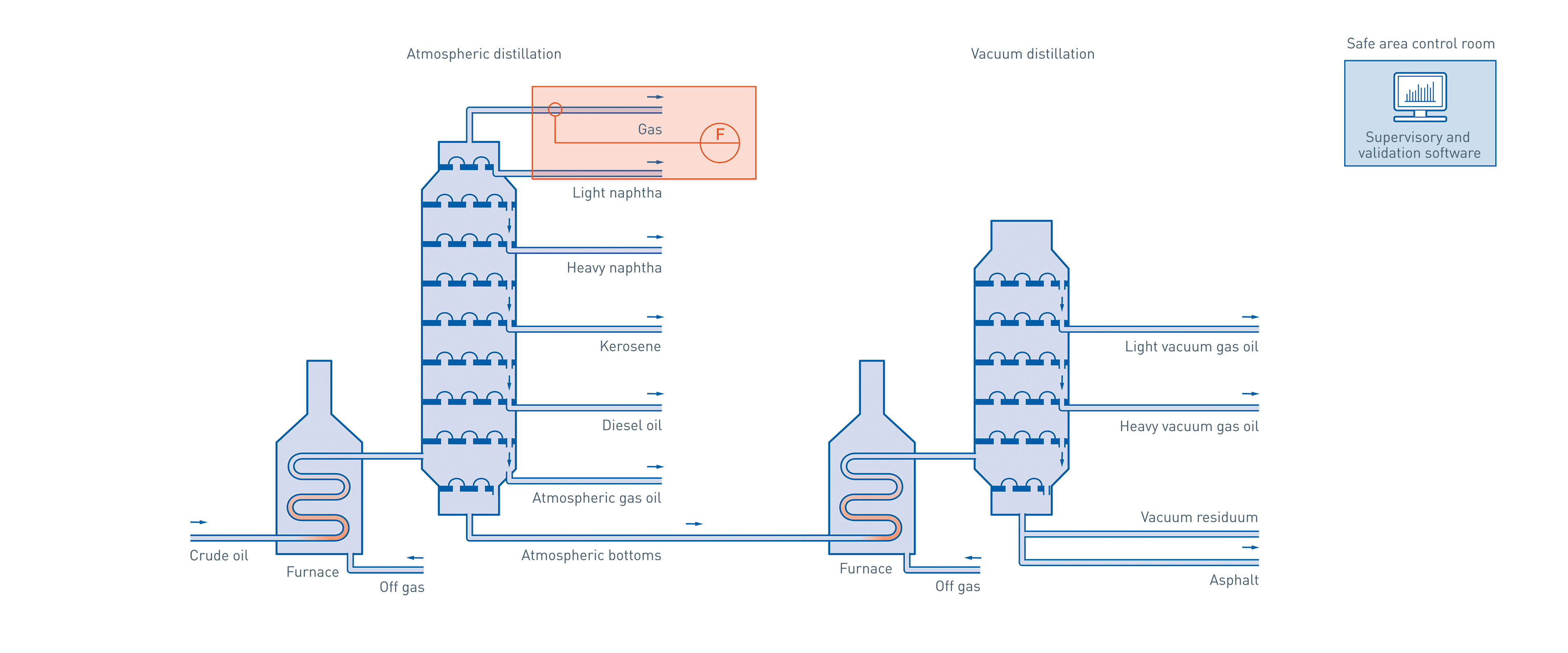

Requirements:

- Process Control

- Contamination of the crude oil could block mechanical meters

Recommended products and solutions:

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

Requirements:

- Improve efficiency of separation process

- Prevent overfill of distillation column

Recommended products and solutions:

BM 26 F2200

- Continuous, redundant measurement using two measurement principles in one device

- Measuring range: 0.3…5.5 / 1…18 ft (longer on request)

- Density: 0.5…3 kg/l / 31…187 lb/ft3

- -50…+300°C / -58…+570°F; -1…100 barg / -14.5…1450 psig

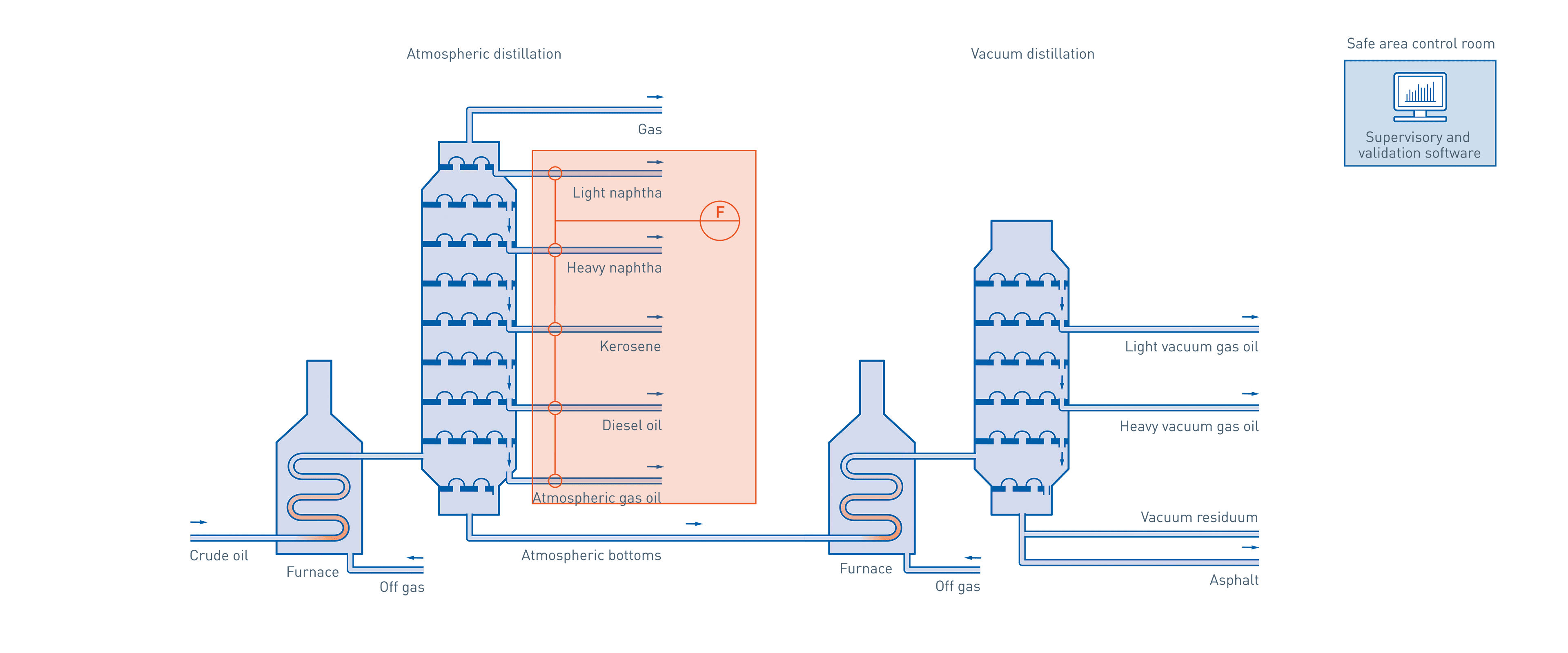

Requirements:

- Process control

- Agressive media

Recommended products and solutions:

OPTISONIC 7300

- 2-path meter, for standard volume flow metering, independent of media properties

- No maintenance, no pressure loss, large dynamic range

- Flange: DN50…1000 / 2…40", max. PN450 / ASME Cl 2500; also weld-in connections

- 3 x 4…20 mA, HART®, Modbus, FF

OPTISWIRL 4200

- For liquids, (wet) gases, saturated and superheated steam (+240°C / +464°F)

- Integrated P+T measurement: direct output of mass, nominal flow, energy, gross/net heat

- Flange: DN15…300 / ½…12"; wafer version: max. DN100 / 4"

- 2-wire, 4…20 mA, HART®, FF, Profibus-PA

Requirements:

- Process control

- Help to maintain mass balance

Recommended products and solutions:

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

OPTISONIC 6300

- Stationary device, for installation at any location without process interruption or need to cut pipes

- Up to +200°C / +392°F

- Robust stainless steel sensor rail for pipes DN15…4000 / ½…160"

- 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP

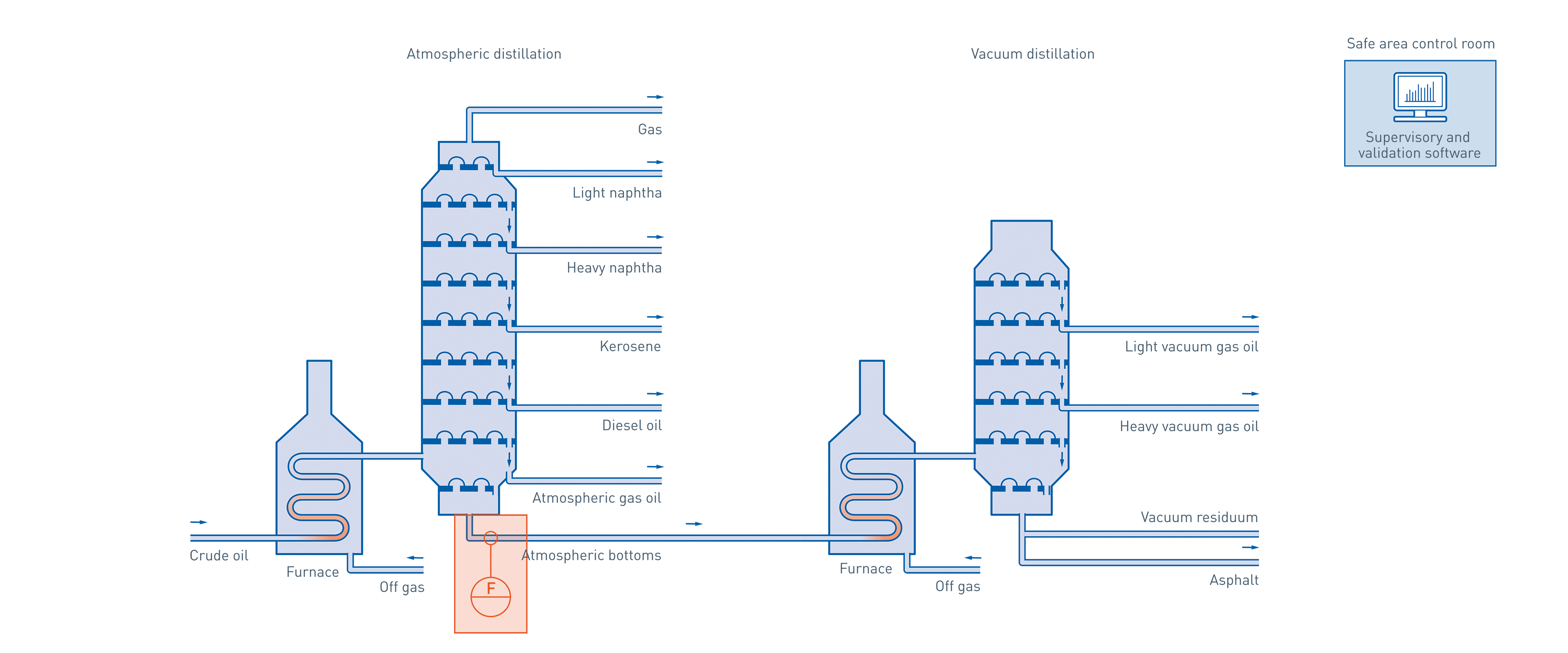

Requirements:

- High temperature

- High viscosity

- Risk of blockage

Recommended products and solutions:

OPTISONIC 4400 HT

- 2-path meter for flow measurement of thermal oil, boiler feed water, crudes and hot feed flows in refineries

- Up to +600°C / +1112°F

- Flange: max. DN1000 / 40"

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP

Requirements:

- High temperature

- Process control

- Help to maintain mass balance

Recommended products and solutions:

OPTISONIC 4400 HT

- 2-path meter for flow measurement of thermal oil, boiler feed water, crudes and hot feed flows in refineries

- Up to +600°C / +1112°F

- Flange: max. DN1000 / 40"

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP

Requirements:

- High temperature

- High viscosity

- Risk of blockage

Recommended products and solutions:

OPTIMASS 2400

- For gases and liquids up to 4,600 t/h; maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- CT: OIML R117, MI-005, MI-002; API and AGA compliant

- Flange: DN100…400 / 4…16", max. PN160 / ASME Cl 1500

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

Requirements:

- Ensure optimized burner control

- Fluctuating operating conditions

Recommended products and solutions:

OPTISONIC 7300

- 2-path meter, for standard volume flow metering, independent of media properties

- No maintenance, no pressure loss, large dynamic range

- Flange: DN50…1000 / 2…40", max. PN450 / ASME Cl 2500; also weld-in connections

- 3 x 4…20 mA, HART®, Modbus, FF

OPTISWIRL 4200

- For liquids, (wet) gases, saturated and superheated steam (+240°C / +464°F)

- Integrated P+T measurement: direct output of mass, nominal flow, energy, gross/net heat

- Flange: DN15…300 / ½…12"; wafer version: max. DN100 / 4"

- 2-wire, 4…20 mA, HART®, FF, Profibus-PA

Requirements:

- Visualisation and monitoring of critical processes

- Control of reporting, trends and alarm handling

- Statistical evaluation of measurement data

Recommended products and solutions:

SynEnergy Supervisory and visualisation software

- HMI/SCADA software for measurement solutions

- State of the art HTML5 secure web technology

- Optimisation of operation results due to predictive maintenance

- Easy integration into existing DCS and ERP networks

CalSys Analyser Management software

- Effective performance monitoring of quality measurement instruments (QMI)

- Automated analyser validation and statistical process control

- Complies with international standards and methods (ASTM D3764, ASTM D6299, OP 97-30425 etc.)

- Increased availability of gas chromatographs and critical process analysers

Distillation in the oil & gas industry

Requirements:

- Process Control

- Contamination of the crude oil could block mechanical meters

Recommended products and solutions:

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

Requirements:

- Improve efficiency of separation process

- Prevent overfill of distillation column

Recommended products and solutions:

BM 26 F2200

- Continuous, redundant measurement using two measurement principles in one device

- Measuring range: 0.3…5.5 / 1…18 ft (longer on request)

- Density: 0.5…3 kg/l / 31…187 lb/ft3

- -50…+300°C / -58…+570°F; -1…100 barg / -14.5…1450 psig

Requirements:

- Process control

- Agressive media

Recommended products and solutions:

OPTISONIC 7300

- 2-path meter, for standard volume flow metering, independent of media properties

- No maintenance, no pressure loss, large dynamic range

- Flange: DN50…1000 / 2…40", max. PN450 / ASME Cl 2500; also weld-in connections

- 3 x 4…20 mA, HART®, Modbus, FF

OPTISWIRL 4200

- For liquids, (wet) gases, saturated and superheated steam (+240°C / +464°F)

- Integrated P+T measurement: direct output of mass, nominal flow, energy, gross/net heat

- Flange: DN15…300 / ½…12"; wafer version: max. DN100 / 4"

- 2-wire, 4…20 mA, HART®, FF, Profibus-PA

Requirements:

- Process control

- Help to maintain mass balance

Recommended products and solutions:

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

OPTISONIC 6300

- Stationary device, for installation at any location without process interruption or need to cut pipes

- Up to +200°C / +392°F

- Robust stainless steel sensor rail for pipes DN15…4000 / ½…160"

- 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP

Requirements:

- High temperature

- High viscosity

- Risk of blockage

Recommended products and solutions:

OPTISONIC 4400 HT

- 2-path meter for flow measurement of thermal oil, boiler feed water, crudes and hot feed flows in refineries

- Up to +600°C / +1112°F

- Flange: max. DN1000 / 40"

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP

Requirements:

- High temperature

- Process control

- Help to maintain mass balance

Recommended products and solutions:

OPTISONIC 4400 HT

- 2-path meter for flow measurement of thermal oil, boiler feed water, crudes and hot feed flows in refineries

- Up to +600°C / +1112°F

- Flange: max. DN1000 / 40"

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP

Requirements:

- High temperature

- High viscosity

- Risk of blockage

Recommended products and solutions:

OPTIMASS 2400

- For gases and liquids up to 4,600 t/h; maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- CT: OIML R117, MI-005, MI-002; API and AGA compliant

- Flange: DN100…400 / 4…16", max. PN160 / ASME Cl 1500

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

Requirements:

- Ensure optimized burner control

- Fluctuating operating conditions

Recommended products and solutions:

OPTISONIC 7300

- 2-path meter, for standard volume flow metering, independent of media properties

- No maintenance, no pressure loss, large dynamic range

- Flange: DN50…1000 / 2…40", max. PN450 / ASME Cl 2500; also weld-in connections

- 3 x 4…20 mA, HART®, Modbus, FF

OPTISWIRL 4200

- For liquids, (wet) gases, saturated and superheated steam (+240°C / +464°F)

- Integrated P+T measurement: direct output of mass, nominal flow, energy, gross/net heat

- Flange: DN15…300 / ½…12"; wafer version: max. DN100 / 4"

- 2-wire, 4…20 mA, HART®, FF, Profibus-PA

Requirements:

- Visualisation and monitoring of critical processes

- Control of reporting, trends and alarm handling

- Statistical evaluation of measurement data

Recommended products and solutions:

SynEnergy Supervisory and visualisation software

- HMI/SCADA software for measurement solutions

- State of the art HTML5 secure web technology

- Optimisation of operation results due to predictive maintenance

- Easy integration into existing DCS and ERP networks

CalSys Analyser Management software

- Effective performance monitoring of quality measurement instruments (QMI)

- Automated analyser validation and statistical process control

- Complies with international standards and methods (ASTM D3764, ASTM D6299, OP 97-30425 etc.)

- Increased availability of gas chromatographs and critical process analysers

Requirements:

- Process Control

- Contamination of the crude oil could block mechanical meters

Recommended products and solutions:

Distillation in the oil & gas industry

Requirements:

- Process Control

- Contamination of the crude oil could block mechanical meters

Recommended products and solutions:

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

Requirements:

- Improve efficiency of separation process

- Prevent overfill of distillation column

Recommended products and solutions:

BM 26 F2200

- Continuous, redundant measurement using two measurement principles in one device

- Measuring range: 0.3…5.5 / 1…18 ft (longer on request)

- Density: 0.5…3 kg/l / 31…187 lb/ft3

- -50…+300°C / -58…+570°F; -1…100 barg / -14.5…1450 psig

Requirements:

- Process control

- Agressive media

Recommended products and solutions:

OPTISONIC 7300

- 2-path meter, for standard volume flow metering, independent of media properties

- No maintenance, no pressure loss, large dynamic range

- Flange: DN50…1000 / 2…40", max. PN450 / ASME Cl 2500; also weld-in connections

- 3 x 4…20 mA, HART®, Modbus, FF

OPTISWIRL 4200

- For liquids, (wet) gases, saturated and superheated steam (+240°C / +464°F)

- Integrated P+T measurement: direct output of mass, nominal flow, energy, gross/net heat

- Flange: DN15…300 / ½…12"; wafer version: max. DN100 / 4"

- 2-wire, 4…20 mA, HART®, FF, Profibus-PA

Requirements:

- Process control

- Help to maintain mass balance

Recommended products and solutions:

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

OPTISONIC 6300

- Stationary device, for installation at any location without process interruption or need to cut pipes

- Up to +200°C / +392°F

- Robust stainless steel sensor rail for pipes DN15…4000 / ½…160"

- 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP

Requirements:

- High temperature

- High viscosity

- Risk of blockage

Recommended products and solutions:

OPTISONIC 4400 HT

- 2-path meter for flow measurement of thermal oil, boiler feed water, crudes and hot feed flows in refineries

- Up to +600°C / +1112°F

- Flange: max. DN1000 / 40"

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP

Requirements:

- High temperature

- Process control

- Help to maintain mass balance

Recommended products and solutions:

OPTISONIC 4400 HT

- 2-path meter for flow measurement of thermal oil, boiler feed water, crudes and hot feed flows in refineries

- Up to +600°C / +1112°F

- Flange: max. DN1000 / 40"

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP

Requirements:

- High temperature

- High viscosity

- Risk of blockage

Recommended products and solutions:

OPTIMASS 2400

- For gases and liquids up to 4,600 t/h; maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- CT: OIML R117, MI-005, MI-002; API and AGA compliant

- Flange: DN100…400 / 4…16", max. PN160 / ASME Cl 1500

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

Requirements:

- Ensure optimized burner control

- Fluctuating operating conditions

Recommended products and solutions:

OPTISONIC 7300

- 2-path meter, for standard volume flow metering, independent of media properties

- No maintenance, no pressure loss, large dynamic range

- Flange: DN50…1000 / 2…40", max. PN450 / ASME Cl 2500; also weld-in connections

- 3 x 4…20 mA, HART®, Modbus, FF

OPTISWIRL 4200

- For liquids, (wet) gases, saturated and superheated steam (+240°C / +464°F)

- Integrated P+T measurement: direct output of mass, nominal flow, energy, gross/net heat

- Flange: DN15…300 / ½…12"; wafer version: max. DN100 / 4"

- 2-wire, 4…20 mA, HART®, FF, Profibus-PA

Requirements:

- Visualisation and monitoring of critical processes

- Control of reporting, trends and alarm handling

- Statistical evaluation of measurement data

Recommended products and solutions:

SynEnergy Supervisory and visualisation software

- HMI/SCADA software for measurement solutions

- State of the art HTML5 secure web technology

- Optimisation of operation results due to predictive maintenance

- Easy integration into existing DCS and ERP networks

CalSys Analyser Management software

- Effective performance monitoring of quality measurement instruments (QMI)

- Automated analyser validation and statistical process control

- Complies with international standards and methods (ASTM D3764, ASTM D6299, OP 97-30425 etc.)

- Increased availability of gas chromatographs and critical process analysers

Requirements:

- Improve efficiency of separation process

- Prevent overfill of distillation column

Recommended products and solutions:

BM 26 F2200

Magnetic bypass level indicator with guided radar (TDR) for liquid level applications

Distillation in the oil & gas industry

Requirements:

- Process Control

- Contamination of the crude oil could block mechanical meters

Recommended products and solutions:

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

Requirements:

- Improve efficiency of separation process

- Prevent overfill of distillation column

Recommended products and solutions:

BM 26 F2200

- Continuous, redundant measurement using two measurement principles in one device

- Measuring range: 0.3…5.5 / 1…18 ft (longer on request)

- Density: 0.5…3 kg/l / 31…187 lb/ft3

- -50…+300°C / -58…+570°F; -1…100 barg / -14.5…1450 psig

Requirements:

- Process control

- Agressive media

Recommended products and solutions:

OPTISONIC 7300

- 2-path meter, for standard volume flow metering, independent of media properties

- No maintenance, no pressure loss, large dynamic range

- Flange: DN50…1000 / 2…40", max. PN450 / ASME Cl 2500; also weld-in connections

- 3 x 4…20 mA, HART®, Modbus, FF

OPTISWIRL 4200

- For liquids, (wet) gases, saturated and superheated steam (+240°C / +464°F)

- Integrated P+T measurement: direct output of mass, nominal flow, energy, gross/net heat

- Flange: DN15…300 / ½…12"; wafer version: max. DN100 / 4"

- 2-wire, 4…20 mA, HART®, FF, Profibus-PA

Requirements:

- Process control

- Help to maintain mass balance

Recommended products and solutions:

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

OPTISONIC 6300

- Stationary device, for installation at any location without process interruption or need to cut pipes

- Up to +200°C / +392°F

- Robust stainless steel sensor rail for pipes DN15…4000 / ½…160"

- 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP

Requirements:

- High temperature

- High viscosity

- Risk of blockage

Recommended products and solutions:

OPTISONIC 4400 HT

- 2-path meter for flow measurement of thermal oil, boiler feed water, crudes and hot feed flows in refineries

- Up to +600°C / +1112°F

- Flange: max. DN1000 / 40"

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP

Requirements:

- High temperature

- Process control

- Help to maintain mass balance

Recommended products and solutions:

OPTISONIC 4400 HT

- 2-path meter for flow measurement of thermal oil, boiler feed water, crudes and hot feed flows in refineries

- Up to +600°C / +1112°F

- Flange: max. DN1000 / 40"

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP

Requirements:

- High temperature

- High viscosity

- Risk of blockage

Recommended products and solutions:

OPTIMASS 2400

- For gases and liquids up to 4,600 t/h; maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- CT: OIML R117, MI-005, MI-002; API and AGA compliant

- Flange: DN100…400 / 4…16", max. PN160 / ASME Cl 1500

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

Requirements:

- Ensure optimized burner control

- Fluctuating operating conditions

Recommended products and solutions:

OPTISONIC 7300

- 2-path meter, for standard volume flow metering, independent of media properties

- No maintenance, no pressure loss, large dynamic range

- Flange: DN50…1000 / 2…40", max. PN450 / ASME Cl 2500; also weld-in connections

- 3 x 4…20 mA, HART®, Modbus, FF

OPTISWIRL 4200

- For liquids, (wet) gases, saturated and superheated steam (+240°C / +464°F)

- Integrated P+T measurement: direct output of mass, nominal flow, energy, gross/net heat

- Flange: DN15…300 / ½…12"; wafer version: max. DN100 / 4"

- 2-wire, 4…20 mA, HART®, FF, Profibus-PA

Requirements:

- Visualisation and monitoring of critical processes

- Control of reporting, trends and alarm handling

- Statistical evaluation of measurement data

Recommended products and solutions:

SynEnergy Supervisory and visualisation software

- HMI/SCADA software for measurement solutions

- State of the art HTML5 secure web technology

- Optimisation of operation results due to predictive maintenance

- Easy integration into existing DCS and ERP networks

CalSys Analyser Management software

- Effective performance monitoring of quality measurement instruments (QMI)

- Automated analyser validation and statistical process control

- Complies with international standards and methods (ASTM D3764, ASTM D6299, OP 97-30425 etc.)

- Increased availability of gas chromatographs and critical process analysers

Requirements:

- Process control

- Agressive media

Recommended products and solutions:

OPTISONIC 7300

Ultrasonic flowmeter for natural gas, process gas and utility gas applications

OPTISWIRL 4200

Vortex flowmeter for utility applications and energy management systems

Distillation in the oil & gas industry

Requirements:

- Process Control

- Contamination of the crude oil could block mechanical meters

Recommended products and solutions:

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

Requirements:

- Improve efficiency of separation process

- Prevent overfill of distillation column

Recommended products and solutions:

BM 26 F2200

- Continuous, redundant measurement using two measurement principles in one device

- Measuring range: 0.3…5.5 / 1…18 ft (longer on request)

- Density: 0.5…3 kg/l / 31…187 lb/ft3

- -50…+300°C / -58…+570°F; -1…100 barg / -14.5…1450 psig

Requirements:

- Process control

- Agressive media

Recommended products and solutions:

OPTISONIC 7300

- 2-path meter, for standard volume flow metering, independent of media properties

- No maintenance, no pressure loss, large dynamic range

- Flange: DN50…1000 / 2…40", max. PN450 / ASME Cl 2500; also weld-in connections

- 3 x 4…20 mA, HART®, Modbus, FF

OPTISWIRL 4200

- For liquids, (wet) gases, saturated and superheated steam (+240°C / +464°F)

- Integrated P+T measurement: direct output of mass, nominal flow, energy, gross/net heat

- Flange: DN15…300 / ½…12"; wafer version: max. DN100 / 4"

- 2-wire, 4…20 mA, HART®, FF, Profibus-PA

Requirements:

- Process control

- Help to maintain mass balance

Recommended products and solutions:

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

OPTISONIC 6300

- Stationary device, for installation at any location without process interruption or need to cut pipes

- Up to +200°C / +392°F

- Robust stainless steel sensor rail for pipes DN15…4000 / ½…160"

- 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP

Requirements:

- High temperature

- High viscosity

- Risk of blockage

Recommended products and solutions:

OPTISONIC 4400 HT

- 2-path meter for flow measurement of thermal oil, boiler feed water, crudes and hot feed flows in refineries

- Up to +600°C / +1112°F

- Flange: max. DN1000 / 40"

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP

Requirements:

- High temperature

- Process control

- Help to maintain mass balance

Recommended products and solutions:

OPTISONIC 4400 HT

- 2-path meter for flow measurement of thermal oil, boiler feed water, crudes and hot feed flows in refineries

- Up to +600°C / +1112°F

- Flange: max. DN1000 / 40"

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP

Requirements:

- High temperature

- High viscosity

- Risk of blockage

Recommended products and solutions:

OPTIMASS 2400

- For gases and liquids up to 4,600 t/h; maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- CT: OIML R117, MI-005, MI-002; API and AGA compliant

- Flange: DN100…400 / 4…16", max. PN160 / ASME Cl 1500

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

Requirements:

- Ensure optimized burner control

- Fluctuating operating conditions

Recommended products and solutions:

OPTISONIC 7300

- 2-path meter, for standard volume flow metering, independent of media properties

- No maintenance, no pressure loss, large dynamic range

- Flange: DN50…1000 / 2…40", max. PN450 / ASME Cl 2500; also weld-in connections

- 3 x 4…20 mA, HART®, Modbus, FF

OPTISWIRL 4200

- For liquids, (wet) gases, saturated and superheated steam (+240°C / +464°F)

- Integrated P+T measurement: direct output of mass, nominal flow, energy, gross/net heat

- Flange: DN15…300 / ½…12"; wafer version: max. DN100 / 4"

- 2-wire, 4…20 mA, HART®, FF, Profibus-PA

Requirements:

- Visualisation and monitoring of critical processes

- Control of reporting, trends and alarm handling

- Statistical evaluation of measurement data

Recommended products and solutions:

SynEnergy Supervisory and visualisation software

- HMI/SCADA software for measurement solutions

- State of the art HTML5 secure web technology

- Optimisation of operation results due to predictive maintenance

- Easy integration into existing DCS and ERP networks

CalSys Analyser Management software

- Effective performance monitoring of quality measurement instruments (QMI)

- Automated analyser validation and statistical process control

- Complies with international standards and methods (ASTM D3764, ASTM D6299, OP 97-30425 etc.)

- Increased availability of gas chromatographs and critical process analysers

Requirements:

- Process control

- Help to maintain mass balance

Recommended products and solutions:

Distillation in the oil & gas industry

Requirements:

- Process Control

- Contamination of the crude oil could block mechanical meters

Recommended products and solutions:

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

Requirements:

- Improve efficiency of separation process

- Prevent overfill of distillation column

Recommended products and solutions:

BM 26 F2200

- Continuous, redundant measurement using two measurement principles in one device

- Measuring range: 0.3…5.5 / 1…18 ft (longer on request)

- Density: 0.5…3 kg/l / 31…187 lb/ft3

- -50…+300°C / -58…+570°F; -1…100 barg / -14.5…1450 psig

Requirements:

- Process control

- Agressive media

Recommended products and solutions:

OPTISONIC 7300

- 2-path meter, for standard volume flow metering, independent of media properties

- No maintenance, no pressure loss, large dynamic range

- Flange: DN50…1000 / 2…40", max. PN450 / ASME Cl 2500; also weld-in connections

- 3 x 4…20 mA, HART®, Modbus, FF

OPTISWIRL 4200

- For liquids, (wet) gases, saturated and superheated steam (+240°C / +464°F)

- Integrated P+T measurement: direct output of mass, nominal flow, energy, gross/net heat

- Flange: DN15…300 / ½…12"; wafer version: max. DN100 / 4"

- 2-wire, 4…20 mA, HART®, FF, Profibus-PA

Requirements:

- Process control

- Help to maintain mass balance

Recommended products and solutions:

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

OPTISONIC 6300

- Stationary device, for installation at any location without process interruption or need to cut pipes

- Up to +200°C / +392°F

- Robust stainless steel sensor rail for pipes DN15…4000 / ½…160"

- 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP

Requirements:

- High temperature

- High viscosity

- Risk of blockage

Recommended products and solutions:

OPTISONIC 4400 HT

- 2-path meter for flow measurement of thermal oil, boiler feed water, crudes and hot feed flows in refineries

- Up to +600°C / +1112°F

- Flange: max. DN1000 / 40"

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP

Requirements:

- High temperature

- Process control

- Help to maintain mass balance

Recommended products and solutions:

OPTISONIC 4400 HT

- 2-path meter for flow measurement of thermal oil, boiler feed water, crudes and hot feed flows in refineries

- Up to +600°C / +1112°F

- Flange: max. DN1000 / 40"

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP

Requirements:

- High temperature

- High viscosity

- Risk of blockage

Recommended products and solutions:

OPTIMASS 2400

- For gases and liquids up to 4,600 t/h; maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- CT: OIML R117, MI-005, MI-002; API and AGA compliant

- Flange: DN100…400 / 4…16", max. PN160 / ASME Cl 1500

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

Requirements:

- Ensure optimized burner control

- Fluctuating operating conditions

Recommended products and solutions:

OPTISONIC 7300

- 2-path meter, for standard volume flow metering, independent of media properties

- No maintenance, no pressure loss, large dynamic range

- Flange: DN50…1000 / 2…40", max. PN450 / ASME Cl 2500; also weld-in connections

- 3 x 4…20 mA, HART®, Modbus, FF

OPTISWIRL 4200

- For liquids, (wet) gases, saturated and superheated steam (+240°C / +464°F)

- Integrated P+T measurement: direct output of mass, nominal flow, energy, gross/net heat

- Flange: DN15…300 / ½…12"; wafer version: max. DN100 / 4"

- 2-wire, 4…20 mA, HART®, FF, Profibus-PA

Requirements:

- Visualisation and monitoring of critical processes

- Control of reporting, trends and alarm handling

- Statistical evaluation of measurement data

Recommended products and solutions:

SynEnergy Supervisory and visualisation software

- HMI/SCADA software for measurement solutions

- State of the art HTML5 secure web technology

- Optimisation of operation results due to predictive maintenance

- Easy integration into existing DCS and ERP networks

CalSys Analyser Management software

- Effective performance monitoring of quality measurement instruments (QMI)

- Automated analyser validation and statistical process control

- Complies with international standards and methods (ASTM D3764, ASTM D6299, OP 97-30425 etc.)

- Increased availability of gas chromatographs and critical process analysers

Requirements:

- High temperature

- High viscosity

- Risk of blockage

Recommended products and solutions:

Distillation in the oil & gas industry

Requirements:

- Process Control

- Contamination of the crude oil could block mechanical meters

Recommended products and solutions:

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

Requirements:

- Improve efficiency of separation process

- Prevent overfill of distillation column

Recommended products and solutions:

BM 26 F2200

- Continuous, redundant measurement using two measurement principles in one device

- Measuring range: 0.3…5.5 / 1…18 ft (longer on request)

- Density: 0.5…3 kg/l / 31…187 lb/ft3

- -50…+300°C / -58…+570°F; -1…100 barg / -14.5…1450 psig

Requirements:

- Process control

- Agressive media

Recommended products and solutions:

OPTISONIC 7300

- 2-path meter, for standard volume flow metering, independent of media properties

- No maintenance, no pressure loss, large dynamic range

- Flange: DN50…1000 / 2…40", max. PN450 / ASME Cl 2500; also weld-in connections

- 3 x 4…20 mA, HART®, Modbus, FF

OPTISWIRL 4200

- For liquids, (wet) gases, saturated and superheated steam (+240°C / +464°F)

- Integrated P+T measurement: direct output of mass, nominal flow, energy, gross/net heat

- Flange: DN15…300 / ½…12"; wafer version: max. DN100 / 4"

- 2-wire, 4…20 mA, HART®, FF, Profibus-PA

Requirements:

- Process control

- Help to maintain mass balance

Recommended products and solutions:

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

OPTISONIC 6300

- Stationary device, for installation at any location without process interruption or need to cut pipes

- Up to +200°C / +392°F

- Robust stainless steel sensor rail for pipes DN15…4000 / ½…160"

- 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP

Requirements:

- High temperature

- High viscosity

- Risk of blockage

Recommended products and solutions:

OPTISONIC 4400 HT

- 2-path meter for flow measurement of thermal oil, boiler feed water, crudes and hot feed flows in refineries

- Up to +600°C / +1112°F

- Flange: max. DN1000 / 40"

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP

Requirements:

- High temperature

- Process control

- Help to maintain mass balance

Recommended products and solutions:

OPTISONIC 4400 HT

- 2-path meter for flow measurement of thermal oil, boiler feed water, crudes and hot feed flows in refineries

- Up to +600°C / +1112°F

- Flange: max. DN1000 / 40"

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP

Requirements:

- High temperature

- High viscosity

- Risk of blockage

Recommended products and solutions:

OPTIMASS 2400

- For gases and liquids up to 4,600 t/h; maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- CT: OIML R117, MI-005, MI-002; API and AGA compliant

- Flange: DN100…400 / 4…16", max. PN160 / ASME Cl 1500

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

Requirements:

- Ensure optimized burner control

- Fluctuating operating conditions

Recommended products and solutions:

OPTISONIC 7300

- 2-path meter, for standard volume flow metering, independent of media properties

- No maintenance, no pressure loss, large dynamic range

- Flange: DN50…1000 / 2…40", max. PN450 / ASME Cl 2500; also weld-in connections

- 3 x 4…20 mA, HART®, Modbus, FF

OPTISWIRL 4200

- For liquids, (wet) gases, saturated and superheated steam (+240°C / +464°F)

- Integrated P+T measurement: direct output of mass, nominal flow, energy, gross/net heat

- Flange: DN15…300 / ½…12"; wafer version: max. DN100 / 4"

- 2-wire, 4…20 mA, HART®, FF, Profibus-PA

Requirements:

- Visualisation and monitoring of critical processes

- Control of reporting, trends and alarm handling

- Statistical evaluation of measurement data

Recommended products and solutions:

SynEnergy Supervisory and visualisation software

- HMI/SCADA software for measurement solutions

- State of the art HTML5 secure web technology

- Optimisation of operation results due to predictive maintenance

- Easy integration into existing DCS and ERP networks

CalSys Analyser Management software

- Effective performance monitoring of quality measurement instruments (QMI)

- Automated analyser validation and statistical process control

- Complies with international standards and methods (ASTM D3764, ASTM D6299, OP 97-30425 etc.)

- Increased availability of gas chromatographs and critical process analysers

Requirements:

- High temperature

- Process control

- Help to maintain mass balance

Recommended products and solutions:

Distillation in the oil & gas industry

Requirements:

- Process Control

- Contamination of the crude oil could block mechanical meters

Recommended products and solutions:

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

Requirements:

- Improve efficiency of separation process

- Prevent overfill of distillation column

Recommended products and solutions:

BM 26 F2200

- Continuous, redundant measurement using two measurement principles in one device

- Measuring range: 0.3…5.5 / 1…18 ft (longer on request)

- Density: 0.5…3 kg/l / 31…187 lb/ft3

- -50…+300°C / -58…+570°F; -1…100 barg / -14.5…1450 psig

Requirements:

- Process control

- Agressive media

Recommended products and solutions:

OPTISONIC 7300

- 2-path meter, for standard volume flow metering, independent of media properties

- No maintenance, no pressure loss, large dynamic range

- Flange: DN50…1000 / 2…40", max. PN450 / ASME Cl 2500; also weld-in connections

- 3 x 4…20 mA, HART®, Modbus, FF

OPTISWIRL 4200

- For liquids, (wet) gases, saturated and superheated steam (+240°C / +464°F)

- Integrated P+T measurement: direct output of mass, nominal flow, energy, gross/net heat

- Flange: DN15…300 / ½…12"; wafer version: max. DN100 / 4"

- 2-wire, 4…20 mA, HART®, FF, Profibus-PA

Requirements:

- Process control

- Help to maintain mass balance

Recommended products and solutions:

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

OPTISONIC 6300

- Stationary device, for installation at any location without process interruption or need to cut pipes

- Up to +200°C / +392°F

- Robust stainless steel sensor rail for pipes DN15…4000 / ½…160"

- 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP

Requirements:

- High temperature

- High viscosity

- Risk of blockage

Recommended products and solutions:

OPTISONIC 4400 HT

- 2-path meter for flow measurement of thermal oil, boiler feed water, crudes and hot feed flows in refineries

- Up to +600°C / +1112°F

- Flange: max. DN1000 / 40"

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP

Requirements:

- High temperature

- Process control

- Help to maintain mass balance

Recommended products and solutions:

OPTISONIC 4400 HT

- 2-path meter for flow measurement of thermal oil, boiler feed water, crudes and hot feed flows in refineries

- Up to +600°C / +1112°F

- Flange: max. DN1000 / 40"

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP

Requirements:

- High temperature

- High viscosity

- Risk of blockage

Recommended products and solutions:

OPTIMASS 2400

- For gases and liquids up to 4,600 t/h; maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- CT: OIML R117, MI-005, MI-002; API and AGA compliant

- Flange: DN100…400 / 4…16", max. PN160 / ASME Cl 1500

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

Requirements:

- Ensure optimized burner control

- Fluctuating operating conditions

Recommended products and solutions:

OPTISONIC 7300

- 2-path meter, for standard volume flow metering, independent of media properties

- No maintenance, no pressure loss, large dynamic range

- Flange: DN50…1000 / 2…40", max. PN450 / ASME Cl 2500; also weld-in connections

- 3 x 4…20 mA, HART®, Modbus, FF

OPTISWIRL 4200

- For liquids, (wet) gases, saturated and superheated steam (+240°C / +464°F)

- Integrated P+T measurement: direct output of mass, nominal flow, energy, gross/net heat

- Flange: DN15…300 / ½…12"; wafer version: max. DN100 / 4"

- 2-wire, 4…20 mA, HART®, FF, Profibus-PA

Requirements:

- Visualisation and monitoring of critical processes

- Control of reporting, trends and alarm handling

- Statistical evaluation of measurement data

Recommended products and solutions:

SynEnergy Supervisory and visualisation software

- HMI/SCADA software for measurement solutions

- State of the art HTML5 secure web technology

- Optimisation of operation results due to predictive maintenance

- Easy integration into existing DCS and ERP networks

CalSys Analyser Management software

- Effective performance monitoring of quality measurement instruments (QMI)

- Automated analyser validation and statistical process control

- Complies with international standards and methods (ASTM D3764, ASTM D6299, OP 97-30425 etc.)

- Increased availability of gas chromatographs and critical process analysers

Requirements:

- High temperature

- High viscosity

- Risk of blockage

Recommended products and solutions:

Distillation in the oil & gas industry

Requirements:

- Process Control

- Contamination of the crude oil could block mechanical meters

Recommended products and solutions:

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

Requirements:

- Improve efficiency of separation process

- Prevent overfill of distillation column

Recommended products and solutions:

BM 26 F2200

- Continuous, redundant measurement using two measurement principles in one device

- Measuring range: 0.3…5.5 / 1…18 ft (longer on request)

- Density: 0.5…3 kg/l / 31…187 lb/ft3

- -50…+300°C / -58…+570°F; -1…100 barg / -14.5…1450 psig

Requirements:

- Process control

- Agressive media

Recommended products and solutions:

OPTISONIC 7300

- 2-path meter, for standard volume flow metering, independent of media properties

- No maintenance, no pressure loss, large dynamic range

- Flange: DN50…1000 / 2…40", max. PN450 / ASME Cl 2500; also weld-in connections

- 3 x 4…20 mA, HART®, Modbus, FF

OPTISWIRL 4200

- For liquids, (wet) gases, saturated and superheated steam (+240°C / +464°F)

- Integrated P+T measurement: direct output of mass, nominal flow, energy, gross/net heat

- Flange: DN15…300 / ½…12"; wafer version: max. DN100 / 4"

- 2-wire, 4…20 mA, HART®, FF, Profibus-PA

Requirements:

- Process control

- Help to maintain mass balance

Recommended products and solutions:

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

OPTISONIC 6300

- Stationary device, for installation at any location without process interruption or need to cut pipes

- Up to +200°C / +392°F

- Robust stainless steel sensor rail for pipes DN15…4000 / ½…160"

- 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP

Requirements:

- High temperature

- High viscosity

- Risk of blockage

Recommended products and solutions:

OPTISONIC 4400 HT

- 2-path meter for flow measurement of thermal oil, boiler feed water, crudes and hot feed flows in refineries

- Up to +600°C / +1112°F

- Flange: max. DN1000 / 40"

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP

Requirements:

- High temperature

- Process control

- Help to maintain mass balance

Recommended products and solutions:

OPTISONIC 4400 HT

- 2-path meter for flow measurement of thermal oil, boiler feed water, crudes and hot feed flows in refineries

- Up to +600°C / +1112°F

- Flange: max. DN1000 / 40"

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP

Requirements:

- High temperature

- High viscosity

- Risk of blockage

Recommended products and solutions:

OPTIMASS 2400

- For gases and liquids up to 4,600 t/h; maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- CT: OIML R117, MI-005, MI-002; API and AGA compliant

- Flange: DN100…400 / 4…16", max. PN160 / ASME Cl 1500

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

Requirements:

- Ensure optimized burner control

- Fluctuating operating conditions

Recommended products and solutions:

OPTISONIC 7300

- 2-path meter, for standard volume flow metering, independent of media properties

- No maintenance, no pressure loss, large dynamic range

- Flange: DN50…1000 / 2…40", max. PN450 / ASME Cl 2500; also weld-in connections

- 3 x 4…20 mA, HART®, Modbus, FF

OPTISWIRL 4200

- For liquids, (wet) gases, saturated and superheated steam (+240°C / +464°F)

- Integrated P+T measurement: direct output of mass, nominal flow, energy, gross/net heat

- Flange: DN15…300 / ½…12"; wafer version: max. DN100 / 4"

- 2-wire, 4…20 mA, HART®, FF, Profibus-PA

Requirements:

- Visualisation and monitoring of critical processes

- Control of reporting, trends and alarm handling

- Statistical evaluation of measurement data

Recommended products and solutions:

SynEnergy Supervisory and visualisation software

- HMI/SCADA software for measurement solutions

- State of the art HTML5 secure web technology

- Optimisation of operation results due to predictive maintenance

- Easy integration into existing DCS and ERP networks

CalSys Analyser Management software

- Effective performance monitoring of quality measurement instruments (QMI)

- Automated analyser validation and statistical process control

- Complies with international standards and methods (ASTM D3764, ASTM D6299, OP 97-30425 etc.)

- Increased availability of gas chromatographs and critical process analysers

Requirements:

- Ensure optimized burner control

- Fluctuating operating conditions

Recommended products and solutions:

OPTISONIC 7300

Ultrasonic flowmeter for natural gas, process gas and utility gas applications

OPTISWIRL 4200

Vortex flowmeter for utility applications and energy management systems

Distillation in the oil & gas industry

Requirements:

- Process Control

- Contamination of the crude oil could block mechanical meters

Recommended products and solutions:

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

Requirements:

- Improve efficiency of separation process

- Prevent overfill of distillation column

Recommended products and solutions:

BM 26 F2200

- Continuous, redundant measurement using two measurement principles in one device

- Measuring range: 0.3…5.5 / 1…18 ft (longer on request)

- Density: 0.5…3 kg/l / 31…187 lb/ft3

- -50…+300°C / -58…+570°F; -1…100 barg / -14.5…1450 psig

Requirements:

- Process control

- Agressive media

Recommended products and solutions:

OPTISONIC 7300

- 2-path meter, for standard volume flow metering, independent of media properties

- No maintenance, no pressure loss, large dynamic range

- Flange: DN50…1000 / 2…40", max. PN450 / ASME Cl 2500; also weld-in connections

- 3 x 4…20 mA, HART®, Modbus, FF

OPTISWIRL 4200

- For liquids, (wet) gases, saturated and superheated steam (+240°C / +464°F)

- Integrated P+T measurement: direct output of mass, nominal flow, energy, gross/net heat

- Flange: DN15…300 / ½…12"; wafer version: max. DN100 / 4"

- 2-wire, 4…20 mA, HART®, FF, Profibus-PA

Requirements:

- Process control

- Help to maintain mass balance

Recommended products and solutions:

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

OPTISONIC 6300

- Stationary device, for installation at any location without process interruption or need to cut pipes

- Up to +200°C / +392°F

- Robust stainless steel sensor rail for pipes DN15…4000 / ½…160"

- 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP

Requirements:

- High temperature

- High viscosity

- Risk of blockage

Recommended products and solutions:

OPTISONIC 4400 HT

- 2-path meter for flow measurement of thermal oil, boiler feed water, crudes and hot feed flows in refineries

- Up to +600°C / +1112°F

- Flange: max. DN1000 / 40"

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP

Requirements:

- High temperature

- Process control

- Help to maintain mass balance

Recommended products and solutions:

OPTISONIC 4400 HT

- 2-path meter for flow measurement of thermal oil, boiler feed water, crudes and hot feed flows in refineries

- Up to +600°C / +1112°F

- Flange: max. DN1000 / 40"

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP

Requirements:

- High temperature

- High viscosity

- Risk of blockage

Recommended products and solutions:

OPTIMASS 2400

- For gases and liquids up to 4,600 t/h; maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- CT: OIML R117, MI-005, MI-002; API and AGA compliant

- Flange: DN100…400 / 4…16", max. PN160 / ASME Cl 1500

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

Requirements:

- Ensure optimized burner control

- Fluctuating operating conditions

Recommended products and solutions:

OPTISONIC 7300

- 2-path meter, for standard volume flow metering, independent of media properties

- No maintenance, no pressure loss, large dynamic range

- Flange: DN50…1000 / 2…40", max. PN450 / ASME Cl 2500; also weld-in connections

- 3 x 4…20 mA, HART®, Modbus, FF

OPTISWIRL 4200

- For liquids, (wet) gases, saturated and superheated steam (+240°C / +464°F)

- Integrated P+T measurement: direct output of mass, nominal flow, energy, gross/net heat

- Flange: DN15…300 / ½…12"; wafer version: max. DN100 / 4"

- 2-wire, 4…20 mA, HART®, FF, Profibus-PA

Requirements:

- Visualisation and monitoring of critical processes

- Control of reporting, trends and alarm handling

- Statistical evaluation of measurement data

Recommended products and solutions:

SynEnergy Supervisory and visualisation software

- HMI/SCADA software for measurement solutions

- State of the art HTML5 secure web technology

- Optimisation of operation results due to predictive maintenance

- Easy integration into existing DCS and ERP networks

CalSys Analyser Management software

- Effective performance monitoring of quality measurement instruments (QMI)

- Automated analyser validation and statistical process control

- Complies with international standards and methods (ASTM D3764, ASTM D6299, OP 97-30425 etc.)

- Increased availability of gas chromatographs and critical process analysers

Requirements:

- Visualisation and monitoring of critical processes

- Control of reporting, trends and alarm handling

- Statistical evaluation of measurement data

Recommended products and solutions:

SynEnergy Supervisory and visualisation software

Solution for continuous process monitoring and reporting

CalSys Analyser Management software

Solution for analyser management and data acquisition (AMADAS)