Catalytic reforming in the oil & gas industry

Cracking of heavy naphtha molecules

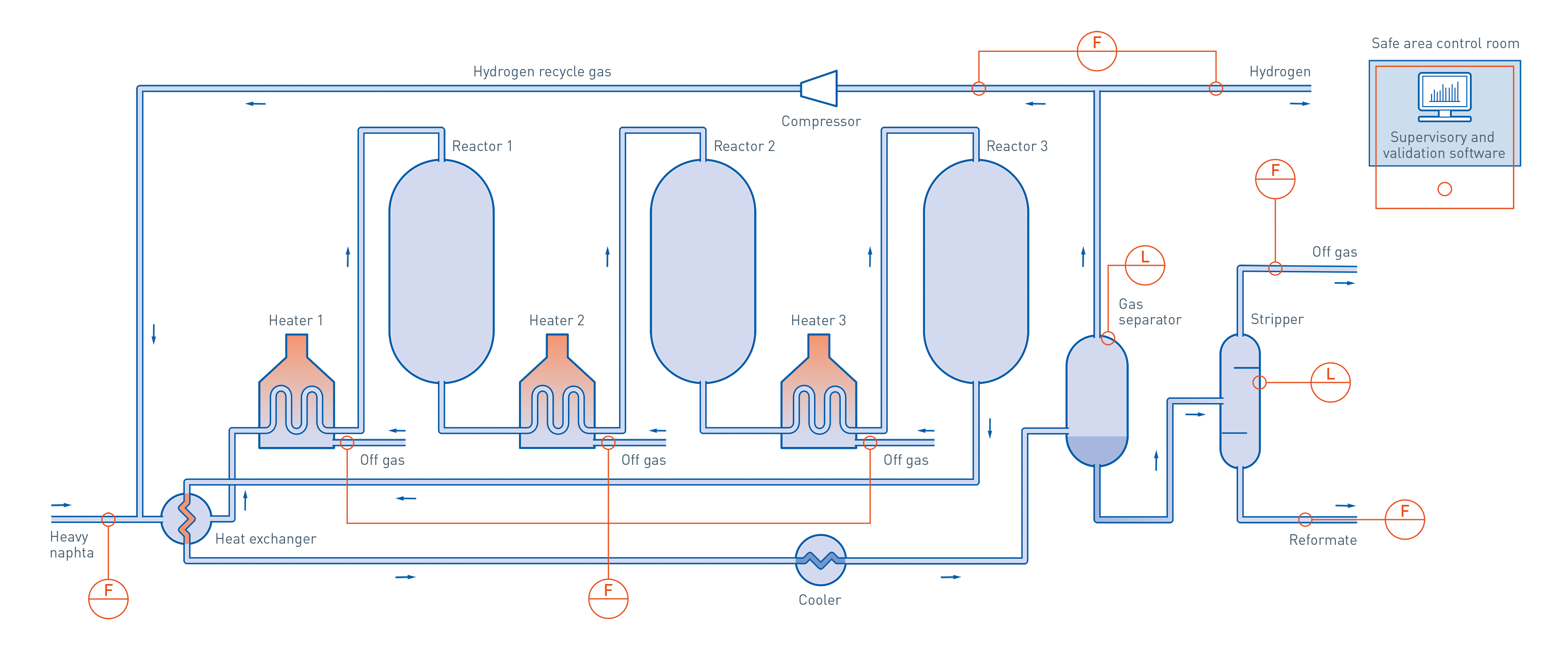

Catalytic reforming is a process that converts the heavy naphtha stream into liquid ‘Reformate’, which is a blending component for high-octane gasoline. As a by-product of this process, hydrogen gas is produced, which is a useful feedstock for other refinery processes, such as Hydrocracking.

In addition to its application as a blending component for gasoline, Reformate is a source of aromatic bulk chemicals that can be used as raw materials for the production of plastics.

The catalytic reforming instrumentation available from KROHNE includes several types of flowmeter for measurement of the different gas and liquid streams, and radar level measurement equipment to provide separator level control.

Process details

Catalytic reforming in the oil & gas industry

Requirements:

- Continuous measurement to adjust level in the degasser

Recommended products and solutions:

OPTIFLEX 2200

- Continuous measurement of level, distance, volume, mass or dielectric constant

- Measuring range: 0.6…40 m / 2…131 ft (liquids), 0.6…20 m / 2…65.5 ft (solids)

- -50…+300°C / -58…+572°F; -1…40 barg / -14.5…580 psig

BM 26 F2200

- Continuous, redundant measurement using two measurement principles in one device

- Measuring range: 0.3…5.5 / 1…18 ft (longer on request)

- Density: 0.5…3 kg/l / 31…187 lb/ft3

- -50…+300°C / -58…+570°F; -1…100 barg / -14.5…1450 psig

Requirements:

- Ensure optimized burner control

- Fluctuating operating conditions

Recommended products and solutions:

OPTISONIC 7300

- 2-path meter, for standard volume flow metering, independent of media properties

- No maintenance, no pressure loss, large dynamic range

- Flange: DN50…1000 / 2…40", max. PN450 / ASME Cl 2500; also weld-in connections

- 3 x 4…20 mA, HART®, Modbus, FF

OPTISWIRL 4200

- For liquids, (wet) gases, saturated and superheated steam (+240°C / +464°F)

- Integrated P+T measurement: direct output of mass, nominal flow, energy, gross/net heat

- Flange: DN15…300 / ½…12"; wafer version: max. DN100 / 4"

- 2-wire, 4…20 mA, HART®, FF, Profibus-PA

Requirements:

- Process control

Recommended products and solutions:

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

Requirements:

- Process control

- Low density gas

Recommended products and solutions:

OPTISONIC 7300

- 2-path meter, for standard volume flow metering, independent of media properties

- No maintenance, no pressure loss, large dynamic range

- Flange: DN50…1000 / 2…40", max. PN450 / ASME Cl 2500; also weld-in connections

- 3 x 4…20 mA, HART®, Modbus, FF

OPTISWIRL 4200

- For liquids, (wet) gases, saturated and superheated steam (+240°C / +464°F)

- Integrated P+T measurement: direct output of mass, nominal flow, energy, gross/net heat

- Flange: DN15…300 / ½…12"; wafer version: max. DN100 / 4"

- 2-wire, 4…20 mA, HART®, FF, Profibus-PA

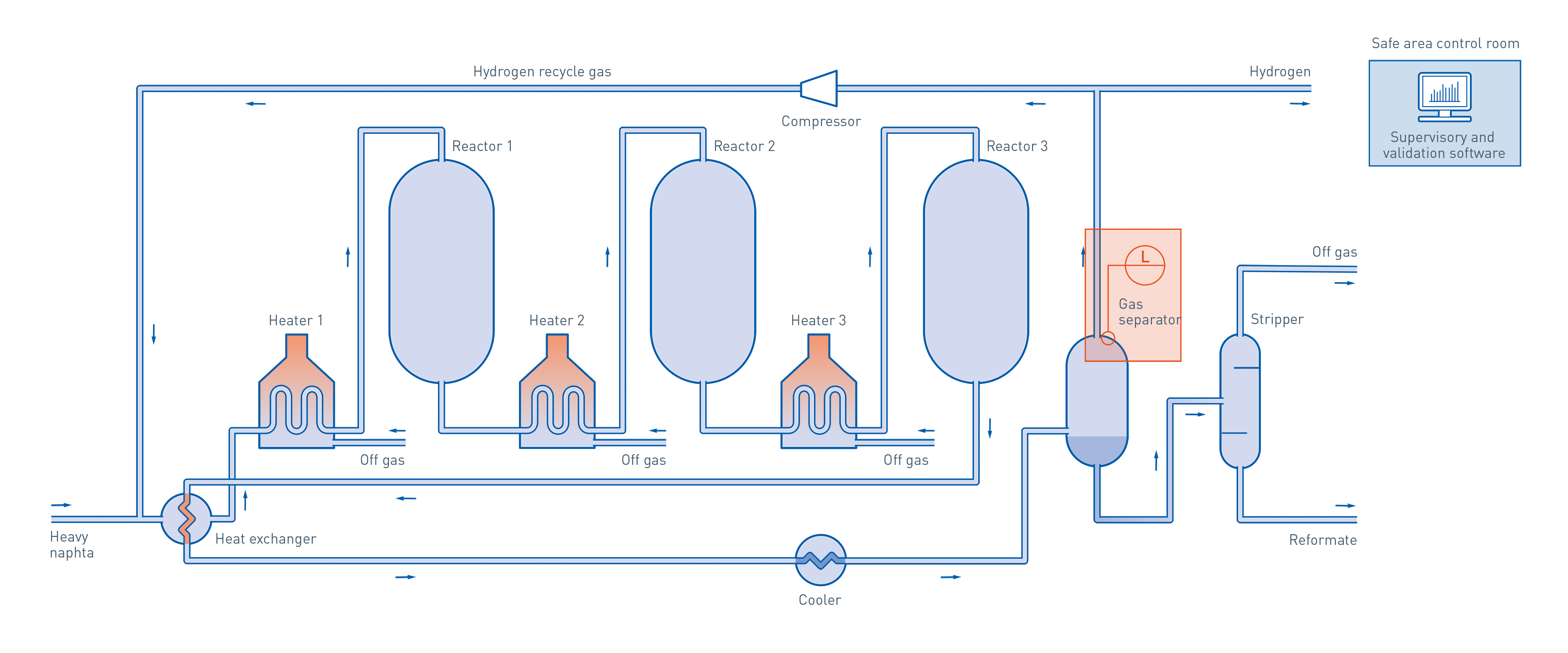

Requirements:

- Process control

- Prevent overfill

Recommended products and solutions:

OPTIFLEX 2200

- Continuous measurement of level, distance, volume, mass or dielectric constant

- Measuring range: 0.6…40 m / 2…131 ft (liquids), 0.6…20 m / 2…65.5 ft (solids)

- -50…+300°C / -58…+572°F; -1…40 barg / -14.5…580 psig

BM 26 F2200

- Continuous, redundant measurement using two measurement principles in one device

- Measuring range: 0.3…5.5 / 1…18 ft (longer on request)

- Density: 0.5…3 kg/l / 31…187 lb/ft3

- -50…+300°C / -58…+570°F; -1…100 barg / -14.5…1450 psig

Requirements:

- Maintain mass balance

- Process control

Recommended products and solutions:

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

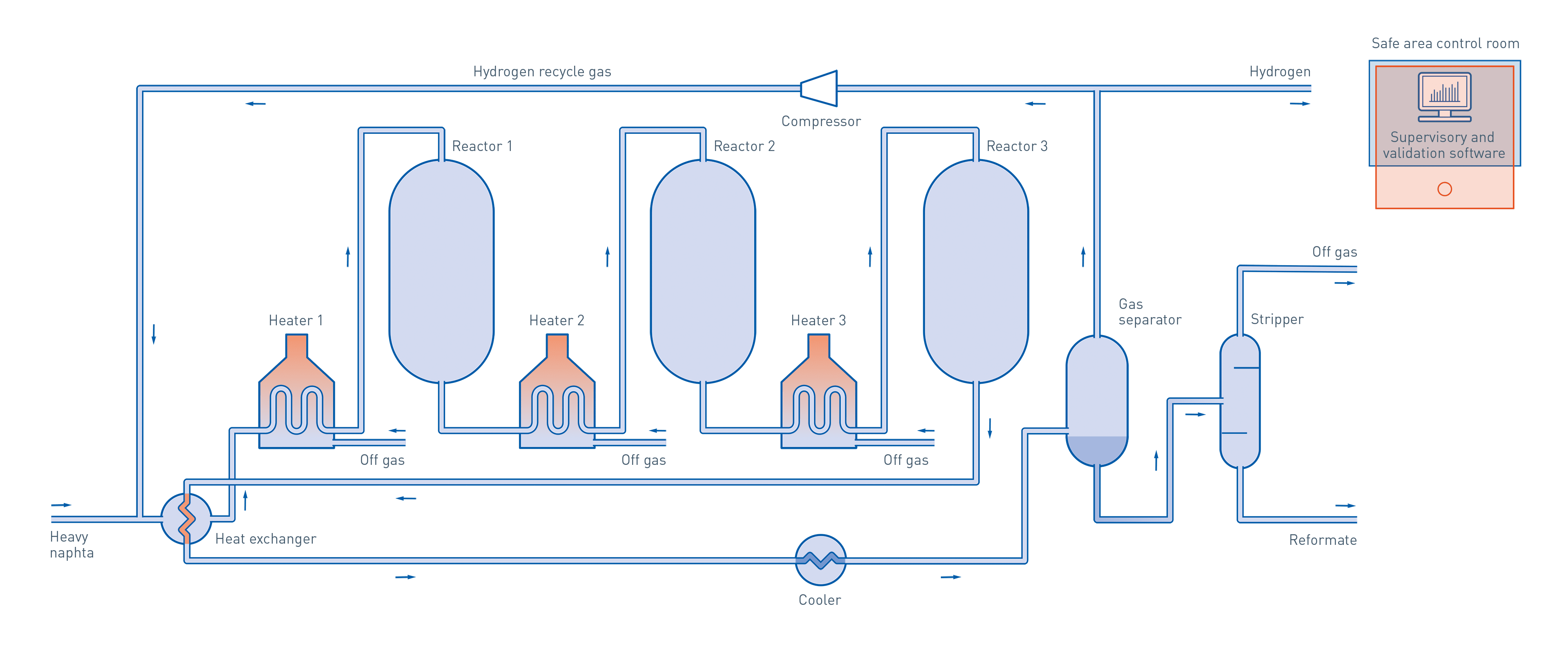

Requirements:

- Visualisation and monitoring of critical processes

- Control of reporting, trends and alarm handling

- Statistical evaluation of measurement data

Recommended products and solutions:

SynEnergy Supervisory and visualisation software

- HMI/SCADA software for measurement solutions

- State of the art HTML5 secure web technology

- Optimisation of operation results due to predictive maintenance

- Easy integration into existing DCS and ERP networks

CalSys Analyser Management software

- Effective performance monitoring of quality measurement instruments (QMI)

- Automated analyser validation and statistical process control

- Complies with international standards and methods (ASTM D3764, ASTM D6299, OP 97-30425 etc.)

- Increased availability of gas chromatographs and critical process analysers

Catalytic reforming in the oil & gas industry

Requirements:

- Continuous measurement to adjust level in the degasser

Recommended products and solutions:

OPTIFLEX 2200

- Continuous measurement of level, distance, volume, mass or dielectric constant

- Measuring range: 0.6…40 m / 2…131 ft (liquids), 0.6…20 m / 2…65.5 ft (solids)

- -50…+300°C / -58…+572°F; -1…40 barg / -14.5…580 psig

BM 26 F2200

- Continuous, redundant measurement using two measurement principles in one device

- Measuring range: 0.3…5.5 / 1…18 ft (longer on request)

- Density: 0.5…3 kg/l / 31…187 lb/ft3

- -50…+300°C / -58…+570°F; -1…100 barg / -14.5…1450 psig

Requirements:

- Ensure optimized burner control

- Fluctuating operating conditions

Recommended products and solutions:

OPTISONIC 7300

- 2-path meter, for standard volume flow metering, independent of media properties

- No maintenance, no pressure loss, large dynamic range

- Flange: DN50…1000 / 2…40", max. PN450 / ASME Cl 2500; also weld-in connections

- 3 x 4…20 mA, HART®, Modbus, FF

OPTISWIRL 4200

- For liquids, (wet) gases, saturated and superheated steam (+240°C / +464°F)

- Integrated P+T measurement: direct output of mass, nominal flow, energy, gross/net heat

- Flange: DN15…300 / ½…12"; wafer version: max. DN100 / 4"

- 2-wire, 4…20 mA, HART®, FF, Profibus-PA

Requirements:

- Process control

Recommended products and solutions:

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

Requirements:

- Process control

- Low density gas

Recommended products and solutions:

OPTISONIC 7300

- 2-path meter, for standard volume flow metering, independent of media properties

- No maintenance, no pressure loss, large dynamic range

- Flange: DN50…1000 / 2…40", max. PN450 / ASME Cl 2500; also weld-in connections

- 3 x 4…20 mA, HART®, Modbus, FF

OPTISWIRL 4200

- For liquids, (wet) gases, saturated and superheated steam (+240°C / +464°F)

- Integrated P+T measurement: direct output of mass, nominal flow, energy, gross/net heat

- Flange: DN15…300 / ½…12"; wafer version: max. DN100 / 4"

- 2-wire, 4…20 mA, HART®, FF, Profibus-PA

Requirements:

- Process control

- Prevent overfill

Recommended products and solutions:

OPTIFLEX 2200

- Continuous measurement of level, distance, volume, mass or dielectric constant

- Measuring range: 0.6…40 m / 2…131 ft (liquids), 0.6…20 m / 2…65.5 ft (solids)

- -50…+300°C / -58…+572°F; -1…40 barg / -14.5…580 psig

BM 26 F2200

- Continuous, redundant measurement using two measurement principles in one device

- Measuring range: 0.3…5.5 / 1…18 ft (longer on request)

- Density: 0.5…3 kg/l / 31…187 lb/ft3

- -50…+300°C / -58…+570°F; -1…100 barg / -14.5…1450 psig

Requirements:

- Maintain mass balance

- Process control

Recommended products and solutions:

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

Requirements:

- Visualisation and monitoring of critical processes

- Control of reporting, trends and alarm handling

- Statistical evaluation of measurement data

Recommended products and solutions:

SynEnergy Supervisory and visualisation software

- HMI/SCADA software for measurement solutions

- State of the art HTML5 secure web technology

- Optimisation of operation results due to predictive maintenance

- Easy integration into existing DCS and ERP networks

CalSys Analyser Management software

- Effective performance monitoring of quality measurement instruments (QMI)

- Automated analyser validation and statistical process control

- Complies with international standards and methods (ASTM D3764, ASTM D6299, OP 97-30425 etc.)

- Increased availability of gas chromatographs and critical process analysers

Requirements:

- Continuous measurement to adjust level in the degasser

Recommended products and solutions:

OPTIFLEX 2200

Guided radar (TDR) level transmitter for storage and process applications

BM 26 F2200

Magnetic bypass level indicator with guided radar (TDR) for liquid level applications

Catalytic reforming in the oil & gas industry

Requirements:

- Continuous measurement to adjust level in the degasser

Recommended products and solutions:

OPTIFLEX 2200

- Continuous measurement of level, distance, volume, mass or dielectric constant

- Measuring range: 0.6…40 m / 2…131 ft (liquids), 0.6…20 m / 2…65.5 ft (solids)

- -50…+300°C / -58…+572°F; -1…40 barg / -14.5…580 psig

BM 26 F2200

- Continuous, redundant measurement using two measurement principles in one device

- Measuring range: 0.3…5.5 / 1…18 ft (longer on request)

- Density: 0.5…3 kg/l / 31…187 lb/ft3

- -50…+300°C / -58…+570°F; -1…100 barg / -14.5…1450 psig

Requirements:

- Ensure optimized burner control

- Fluctuating operating conditions

Recommended products and solutions:

OPTISONIC 7300

- 2-path meter, for standard volume flow metering, independent of media properties

- No maintenance, no pressure loss, large dynamic range

- Flange: DN50…1000 / 2…40", max. PN450 / ASME Cl 2500; also weld-in connections

- 3 x 4…20 mA, HART®, Modbus, FF

OPTISWIRL 4200

- For liquids, (wet) gases, saturated and superheated steam (+240°C / +464°F)

- Integrated P+T measurement: direct output of mass, nominal flow, energy, gross/net heat

- Flange: DN15…300 / ½…12"; wafer version: max. DN100 / 4"

- 2-wire, 4…20 mA, HART®, FF, Profibus-PA

Requirements:

- Process control

Recommended products and solutions:

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

Requirements:

- Process control

- Low density gas

Recommended products and solutions:

OPTISONIC 7300

- 2-path meter, for standard volume flow metering, independent of media properties

- No maintenance, no pressure loss, large dynamic range

- Flange: DN50…1000 / 2…40", max. PN450 / ASME Cl 2500; also weld-in connections

- 3 x 4…20 mA, HART®, Modbus, FF

OPTISWIRL 4200

- For liquids, (wet) gases, saturated and superheated steam (+240°C / +464°F)

- Integrated P+T measurement: direct output of mass, nominal flow, energy, gross/net heat

- Flange: DN15…300 / ½…12"; wafer version: max. DN100 / 4"

- 2-wire, 4…20 mA, HART®, FF, Profibus-PA

Requirements:

- Process control

- Prevent overfill

Recommended products and solutions:

OPTIFLEX 2200

- Continuous measurement of level, distance, volume, mass or dielectric constant

- Measuring range: 0.6…40 m / 2…131 ft (liquids), 0.6…20 m / 2…65.5 ft (solids)

- -50…+300°C / -58…+572°F; -1…40 barg / -14.5…580 psig

BM 26 F2200

- Continuous, redundant measurement using two measurement principles in one device

- Measuring range: 0.3…5.5 / 1…18 ft (longer on request)

- Density: 0.5…3 kg/l / 31…187 lb/ft3

- -50…+300°C / -58…+570°F; -1…100 barg / -14.5…1450 psig

Requirements:

- Maintain mass balance

- Process control

Recommended products and solutions:

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

Requirements:

- Visualisation and monitoring of critical processes

- Control of reporting, trends and alarm handling

- Statistical evaluation of measurement data

Recommended products and solutions:

SynEnergy Supervisory and visualisation software

- HMI/SCADA software for measurement solutions

- State of the art HTML5 secure web technology

- Optimisation of operation results due to predictive maintenance

- Easy integration into existing DCS and ERP networks

CalSys Analyser Management software

- Effective performance monitoring of quality measurement instruments (QMI)

- Automated analyser validation and statistical process control

- Complies with international standards and methods (ASTM D3764, ASTM D6299, OP 97-30425 etc.)

- Increased availability of gas chromatographs and critical process analysers

Requirements:

- Ensure optimized burner control

- Fluctuating operating conditions

Recommended products and solutions:

OPTISONIC 7300

Ultrasonic flowmeter for natural gas, process gas and utility gas applications

OPTISWIRL 4200

Vortex flowmeter for utility applications and energy management systems

Catalytic reforming in the oil & gas industry

Requirements:

- Continuous measurement to adjust level in the degasser

Recommended products and solutions:

OPTIFLEX 2200

- Continuous measurement of level, distance, volume, mass or dielectric constant

- Measuring range: 0.6…40 m / 2…131 ft (liquids), 0.6…20 m / 2…65.5 ft (solids)

- -50…+300°C / -58…+572°F; -1…40 barg / -14.5…580 psig

BM 26 F2200

- Continuous, redundant measurement using two measurement principles in one device

- Measuring range: 0.3…5.5 / 1…18 ft (longer on request)

- Density: 0.5…3 kg/l / 31…187 lb/ft3

- -50…+300°C / -58…+570°F; -1…100 barg / -14.5…1450 psig

Requirements:

- Ensure optimized burner control

- Fluctuating operating conditions

Recommended products and solutions:

OPTISONIC 7300

- 2-path meter, for standard volume flow metering, independent of media properties

- No maintenance, no pressure loss, large dynamic range

- Flange: DN50…1000 / 2…40", max. PN450 / ASME Cl 2500; also weld-in connections

- 3 x 4…20 mA, HART®, Modbus, FF

OPTISWIRL 4200

- For liquids, (wet) gases, saturated and superheated steam (+240°C / +464°F)

- Integrated P+T measurement: direct output of mass, nominal flow, energy, gross/net heat

- Flange: DN15…300 / ½…12"; wafer version: max. DN100 / 4"

- 2-wire, 4…20 mA, HART®, FF, Profibus-PA

Requirements:

- Process control

Recommended products and solutions:

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

Requirements:

- Process control

- Low density gas

Recommended products and solutions:

OPTISONIC 7300

- 2-path meter, for standard volume flow metering, independent of media properties

- No maintenance, no pressure loss, large dynamic range

- Flange: DN50…1000 / 2…40", max. PN450 / ASME Cl 2500; also weld-in connections

- 3 x 4…20 mA, HART®, Modbus, FF

OPTISWIRL 4200

- For liquids, (wet) gases, saturated and superheated steam (+240°C / +464°F)

- Integrated P+T measurement: direct output of mass, nominal flow, energy, gross/net heat

- Flange: DN15…300 / ½…12"; wafer version: max. DN100 / 4"

- 2-wire, 4…20 mA, HART®, FF, Profibus-PA

Requirements:

- Process control

- Prevent overfill

Recommended products and solutions:

OPTIFLEX 2200

- Continuous measurement of level, distance, volume, mass or dielectric constant

- Measuring range: 0.6…40 m / 2…131 ft (liquids), 0.6…20 m / 2…65.5 ft (solids)

- -50…+300°C / -58…+572°F; -1…40 barg / -14.5…580 psig

BM 26 F2200

- Continuous, redundant measurement using two measurement principles in one device

- Measuring range: 0.3…5.5 / 1…18 ft (longer on request)

- Density: 0.5…3 kg/l / 31…187 lb/ft3

- -50…+300°C / -58…+570°F; -1…100 barg / -14.5…1450 psig

Requirements:

- Maintain mass balance

- Process control

Recommended products and solutions:

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

Requirements:

- Visualisation and monitoring of critical processes

- Control of reporting, trends and alarm handling

- Statistical evaluation of measurement data

Recommended products and solutions:

SynEnergy Supervisory and visualisation software

- HMI/SCADA software for measurement solutions

- State of the art HTML5 secure web technology

- Optimisation of operation results due to predictive maintenance

- Easy integration into existing DCS and ERP networks

CalSys Analyser Management software

- Effective performance monitoring of quality measurement instruments (QMI)

- Automated analyser validation and statistical process control

- Complies with international standards and methods (ASTM D3764, ASTM D6299, OP 97-30425 etc.)

- Increased availability of gas chromatographs and critical process analysers

Requirements:

- Process control

Recommended products and solutions:

Catalytic reforming in the oil & gas industry

Requirements:

- Continuous measurement to adjust level in the degasser

Recommended products and solutions:

OPTIFLEX 2200

- Continuous measurement of level, distance, volume, mass or dielectric constant

- Measuring range: 0.6…40 m / 2…131 ft (liquids), 0.6…20 m / 2…65.5 ft (solids)

- -50…+300°C / -58…+572°F; -1…40 barg / -14.5…580 psig

BM 26 F2200

- Continuous, redundant measurement using two measurement principles in one device

- Measuring range: 0.3…5.5 / 1…18 ft (longer on request)

- Density: 0.5…3 kg/l / 31…187 lb/ft3

- -50…+300°C / -58…+570°F; -1…100 barg / -14.5…1450 psig

Requirements:

- Ensure optimized burner control

- Fluctuating operating conditions

Recommended products and solutions:

OPTISONIC 7300

- 2-path meter, for standard volume flow metering, independent of media properties

- No maintenance, no pressure loss, large dynamic range

- Flange: DN50…1000 / 2…40", max. PN450 / ASME Cl 2500; also weld-in connections

- 3 x 4…20 mA, HART®, Modbus, FF

OPTISWIRL 4200

- For liquids, (wet) gases, saturated and superheated steam (+240°C / +464°F)

- Integrated P+T measurement: direct output of mass, nominal flow, energy, gross/net heat

- Flange: DN15…300 / ½…12"; wafer version: max. DN100 / 4"

- 2-wire, 4…20 mA, HART®, FF, Profibus-PA

Requirements:

- Process control

Recommended products and solutions:

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

Requirements:

- Process control

- Low density gas

Recommended products and solutions:

OPTISONIC 7300

- 2-path meter, for standard volume flow metering, independent of media properties

- No maintenance, no pressure loss, large dynamic range

- Flange: DN50…1000 / 2…40", max. PN450 / ASME Cl 2500; also weld-in connections

- 3 x 4…20 mA, HART®, Modbus, FF

OPTISWIRL 4200

- For liquids, (wet) gases, saturated and superheated steam (+240°C / +464°F)

- Integrated P+T measurement: direct output of mass, nominal flow, energy, gross/net heat

- Flange: DN15…300 / ½…12"; wafer version: max. DN100 / 4"

- 2-wire, 4…20 mA, HART®, FF, Profibus-PA

Requirements:

- Process control

- Prevent overfill

Recommended products and solutions:

OPTIFLEX 2200

- Continuous measurement of level, distance, volume, mass or dielectric constant

- Measuring range: 0.6…40 m / 2…131 ft (liquids), 0.6…20 m / 2…65.5 ft (solids)

- -50…+300°C / -58…+572°F; -1…40 barg / -14.5…580 psig

BM 26 F2200

- Continuous, redundant measurement using two measurement principles in one device

- Measuring range: 0.3…5.5 / 1…18 ft (longer on request)

- Density: 0.5…3 kg/l / 31…187 lb/ft3

- -50…+300°C / -58…+570°F; -1…100 barg / -14.5…1450 psig

Requirements:

- Maintain mass balance

- Process control

Recommended products and solutions:

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

Requirements:

- Visualisation and monitoring of critical processes

- Control of reporting, trends and alarm handling

- Statistical evaluation of measurement data

Recommended products and solutions:

SynEnergy Supervisory and visualisation software

- HMI/SCADA software for measurement solutions

- State of the art HTML5 secure web technology

- Optimisation of operation results due to predictive maintenance

- Easy integration into existing DCS and ERP networks

CalSys Analyser Management software

- Effective performance monitoring of quality measurement instruments (QMI)

- Automated analyser validation and statistical process control

- Complies with international standards and methods (ASTM D3764, ASTM D6299, OP 97-30425 etc.)

- Increased availability of gas chromatographs and critical process analysers

Requirements:

- Process control

- Low density gas

Recommended products and solutions:

OPTISONIC 7300

Ultrasonic flowmeter for natural gas, process gas and utility gas applications

OPTISWIRL 4200

Vortex flowmeter for utility applications and energy management systems

Catalytic reforming in the oil & gas industry

Requirements:

- Continuous measurement to adjust level in the degasser

Recommended products and solutions:

OPTIFLEX 2200

- Continuous measurement of level, distance, volume, mass or dielectric constant

- Measuring range: 0.6…40 m / 2…131 ft (liquids), 0.6…20 m / 2…65.5 ft (solids)

- -50…+300°C / -58…+572°F; -1…40 barg / -14.5…580 psig

BM 26 F2200

- Continuous, redundant measurement using two measurement principles in one device

- Measuring range: 0.3…5.5 / 1…18 ft (longer on request)

- Density: 0.5…3 kg/l / 31…187 lb/ft3

- -50…+300°C / -58…+570°F; -1…100 barg / -14.5…1450 psig

Requirements:

- Ensure optimized burner control

- Fluctuating operating conditions

Recommended products and solutions:

OPTISONIC 7300

- 2-path meter, for standard volume flow metering, independent of media properties

- No maintenance, no pressure loss, large dynamic range

- Flange: DN50…1000 / 2…40", max. PN450 / ASME Cl 2500; also weld-in connections

- 3 x 4…20 mA, HART®, Modbus, FF

OPTISWIRL 4200

- For liquids, (wet) gases, saturated and superheated steam (+240°C / +464°F)

- Integrated P+T measurement: direct output of mass, nominal flow, energy, gross/net heat

- Flange: DN15…300 / ½…12"; wafer version: max. DN100 / 4"

- 2-wire, 4…20 mA, HART®, FF, Profibus-PA

Requirements:

- Process control

Recommended products and solutions:

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

Requirements:

- Process control

- Low density gas

Recommended products and solutions:

OPTISONIC 7300

- 2-path meter, for standard volume flow metering, independent of media properties

- No maintenance, no pressure loss, large dynamic range

- Flange: DN50…1000 / 2…40", max. PN450 / ASME Cl 2500; also weld-in connections

- 3 x 4…20 mA, HART®, Modbus, FF

OPTISWIRL 4200

- For liquids, (wet) gases, saturated and superheated steam (+240°C / +464°F)

- Integrated P+T measurement: direct output of mass, nominal flow, energy, gross/net heat

- Flange: DN15…300 / ½…12"; wafer version: max. DN100 / 4"

- 2-wire, 4…20 mA, HART®, FF, Profibus-PA

Requirements:

- Process control

- Prevent overfill

Recommended products and solutions:

OPTIFLEX 2200

- Continuous measurement of level, distance, volume, mass or dielectric constant

- Measuring range: 0.6…40 m / 2…131 ft (liquids), 0.6…20 m / 2…65.5 ft (solids)

- -50…+300°C / -58…+572°F; -1…40 barg / -14.5…580 psig

BM 26 F2200

- Continuous, redundant measurement using two measurement principles in one device

- Measuring range: 0.3…5.5 / 1…18 ft (longer on request)

- Density: 0.5…3 kg/l / 31…187 lb/ft3

- -50…+300°C / -58…+570°F; -1…100 barg / -14.5…1450 psig

Requirements:

- Maintain mass balance

- Process control

Recommended products and solutions:

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

Requirements:

- Visualisation and monitoring of critical processes

- Control of reporting, trends and alarm handling

- Statistical evaluation of measurement data

Recommended products and solutions:

SynEnergy Supervisory and visualisation software

- HMI/SCADA software for measurement solutions

- State of the art HTML5 secure web technology

- Optimisation of operation results due to predictive maintenance

- Easy integration into existing DCS and ERP networks

CalSys Analyser Management software

- Effective performance monitoring of quality measurement instruments (QMI)

- Automated analyser validation and statistical process control

- Complies with international standards and methods (ASTM D3764, ASTM D6299, OP 97-30425 etc.)

- Increased availability of gas chromatographs and critical process analysers

Requirements:

- Process control

- Prevent overfill

Recommended products and solutions:

OPTIFLEX 2200

Guided radar (TDR) level transmitter for storage and process applications

BM 26 F2200

Magnetic bypass level indicator with guided radar (TDR) for liquid level applications

Catalytic reforming in the oil & gas industry

Requirements:

- Continuous measurement to adjust level in the degasser

Recommended products and solutions:

OPTIFLEX 2200

- Continuous measurement of level, distance, volume, mass or dielectric constant

- Measuring range: 0.6…40 m / 2…131 ft (liquids), 0.6…20 m / 2…65.5 ft (solids)

- -50…+300°C / -58…+572°F; -1…40 barg / -14.5…580 psig

BM 26 F2200

- Continuous, redundant measurement using two measurement principles in one device

- Measuring range: 0.3…5.5 / 1…18 ft (longer on request)

- Density: 0.5…3 kg/l / 31…187 lb/ft3

- -50…+300°C / -58…+570°F; -1…100 barg / -14.5…1450 psig

Requirements:

- Ensure optimized burner control

- Fluctuating operating conditions

Recommended products and solutions:

OPTISONIC 7300

- 2-path meter, for standard volume flow metering, independent of media properties

- No maintenance, no pressure loss, large dynamic range

- Flange: DN50…1000 / 2…40", max. PN450 / ASME Cl 2500; also weld-in connections

- 3 x 4…20 mA, HART®, Modbus, FF

OPTISWIRL 4200

- For liquids, (wet) gases, saturated and superheated steam (+240°C / +464°F)

- Integrated P+T measurement: direct output of mass, nominal flow, energy, gross/net heat

- Flange: DN15…300 / ½…12"; wafer version: max. DN100 / 4"

- 2-wire, 4…20 mA, HART®, FF, Profibus-PA

Requirements:

- Process control

Recommended products and solutions:

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

Requirements:

- Process control

- Low density gas

Recommended products and solutions:

OPTISONIC 7300

- 2-path meter, for standard volume flow metering, independent of media properties

- No maintenance, no pressure loss, large dynamic range

- Flange: DN50…1000 / 2…40", max. PN450 / ASME Cl 2500; also weld-in connections

- 3 x 4…20 mA, HART®, Modbus, FF

OPTISWIRL 4200

- For liquids, (wet) gases, saturated and superheated steam (+240°C / +464°F)

- Integrated P+T measurement: direct output of mass, nominal flow, energy, gross/net heat

- Flange: DN15…300 / ½…12"; wafer version: max. DN100 / 4"

- 2-wire, 4…20 mA, HART®, FF, Profibus-PA

Requirements:

- Process control

- Prevent overfill

Recommended products and solutions:

OPTIFLEX 2200

- Continuous measurement of level, distance, volume, mass or dielectric constant

- Measuring range: 0.6…40 m / 2…131 ft (liquids), 0.6…20 m / 2…65.5 ft (solids)

- -50…+300°C / -58…+572°F; -1…40 barg / -14.5…580 psig

BM 26 F2200

- Continuous, redundant measurement using two measurement principles in one device

- Measuring range: 0.3…5.5 / 1…18 ft (longer on request)

- Density: 0.5…3 kg/l / 31…187 lb/ft3

- -50…+300°C / -58…+570°F; -1…100 barg / -14.5…1450 psig

Requirements:

- Maintain mass balance

- Process control

Recommended products and solutions:

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

Requirements:

- Visualisation and monitoring of critical processes

- Control of reporting, trends and alarm handling

- Statistical evaluation of measurement data

Recommended products and solutions:

SynEnergy Supervisory and visualisation software

- HMI/SCADA software for measurement solutions

- State of the art HTML5 secure web technology

- Optimisation of operation results due to predictive maintenance

- Easy integration into existing DCS and ERP networks

CalSys Analyser Management software

- Effective performance monitoring of quality measurement instruments (QMI)

- Automated analyser validation and statistical process control

- Complies with international standards and methods (ASTM D3764, ASTM D6299, OP 97-30425 etc.)

- Increased availability of gas chromatographs and critical process analysers

Requirements:

- Maintain mass balance

- Process control

Recommended products and solutions:

Catalytic reforming in the oil & gas industry

Requirements:

- Continuous measurement to adjust level in the degasser

Recommended products and solutions:

OPTIFLEX 2200

- Continuous measurement of level, distance, volume, mass or dielectric constant

- Measuring range: 0.6…40 m / 2…131 ft (liquids), 0.6…20 m / 2…65.5 ft (solids)

- -50…+300°C / -58…+572°F; -1…40 barg / -14.5…580 psig

BM 26 F2200

- Continuous, redundant measurement using two measurement principles in one device

- Measuring range: 0.3…5.5 / 1…18 ft (longer on request)

- Density: 0.5…3 kg/l / 31…187 lb/ft3

- -50…+300°C / -58…+570°F; -1…100 barg / -14.5…1450 psig

Requirements:

- Ensure optimized burner control

- Fluctuating operating conditions

Recommended products and solutions:

OPTISONIC 7300

- 2-path meter, for standard volume flow metering, independent of media properties

- No maintenance, no pressure loss, large dynamic range

- Flange: DN50…1000 / 2…40", max. PN450 / ASME Cl 2500; also weld-in connections

- 3 x 4…20 mA, HART®, Modbus, FF

OPTISWIRL 4200

- For liquids, (wet) gases, saturated and superheated steam (+240°C / +464°F)

- Integrated P+T measurement: direct output of mass, nominal flow, energy, gross/net heat

- Flange: DN15…300 / ½…12"; wafer version: max. DN100 / 4"

- 2-wire, 4…20 mA, HART®, FF, Profibus-PA

Requirements:

- Process control

Recommended products and solutions:

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

Requirements:

- Process control

- Low density gas

Recommended products and solutions:

OPTISONIC 7300

- 2-path meter, for standard volume flow metering, independent of media properties

- No maintenance, no pressure loss, large dynamic range

- Flange: DN50…1000 / 2…40", max. PN450 / ASME Cl 2500; also weld-in connections

- 3 x 4…20 mA, HART®, Modbus, FF

OPTISWIRL 4200

- For liquids, (wet) gases, saturated and superheated steam (+240°C / +464°F)

- Integrated P+T measurement: direct output of mass, nominal flow, energy, gross/net heat

- Flange: DN15…300 / ½…12"; wafer version: max. DN100 / 4"

- 2-wire, 4…20 mA, HART®, FF, Profibus-PA

Requirements:

- Process control

- Prevent overfill

Recommended products and solutions:

OPTIFLEX 2200

- Continuous measurement of level, distance, volume, mass or dielectric constant

- Measuring range: 0.6…40 m / 2…131 ft (liquids), 0.6…20 m / 2…65.5 ft (solids)

- -50…+300°C / -58…+572°F; -1…40 barg / -14.5…580 psig

BM 26 F2200

- Continuous, redundant measurement using two measurement principles in one device

- Measuring range: 0.3…5.5 / 1…18 ft (longer on request)

- Density: 0.5…3 kg/l / 31…187 lb/ft3

- -50…+300°C / -58…+570°F; -1…100 barg / -14.5…1450 psig

Requirements:

- Maintain mass balance

- Process control

Recommended products and solutions:

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

Requirements:

- Visualisation and monitoring of critical processes

- Control of reporting, trends and alarm handling

- Statistical evaluation of measurement data

Recommended products and solutions:

SynEnergy Supervisory and visualisation software

- HMI/SCADA software for measurement solutions

- State of the art HTML5 secure web technology

- Optimisation of operation results due to predictive maintenance

- Easy integration into existing DCS and ERP networks

CalSys Analyser Management software

- Effective performance monitoring of quality measurement instruments (QMI)

- Automated analyser validation and statistical process control

- Complies with international standards and methods (ASTM D3764, ASTM D6299, OP 97-30425 etc.)

- Increased availability of gas chromatographs and critical process analysers

Requirements:

- Visualisation and monitoring of critical processes

- Control of reporting, trends and alarm handling

- Statistical evaluation of measurement data

Recommended products and solutions:

SynEnergy Supervisory and visualisation software

Solution for continuous process monitoring and reporting

CalSys Analyser Management software

Solution for analyser management and data acquisition (AMADAS)