Storage and shipping in the oil & gas industry

Delivery flow monitoring of cryogenic LNG

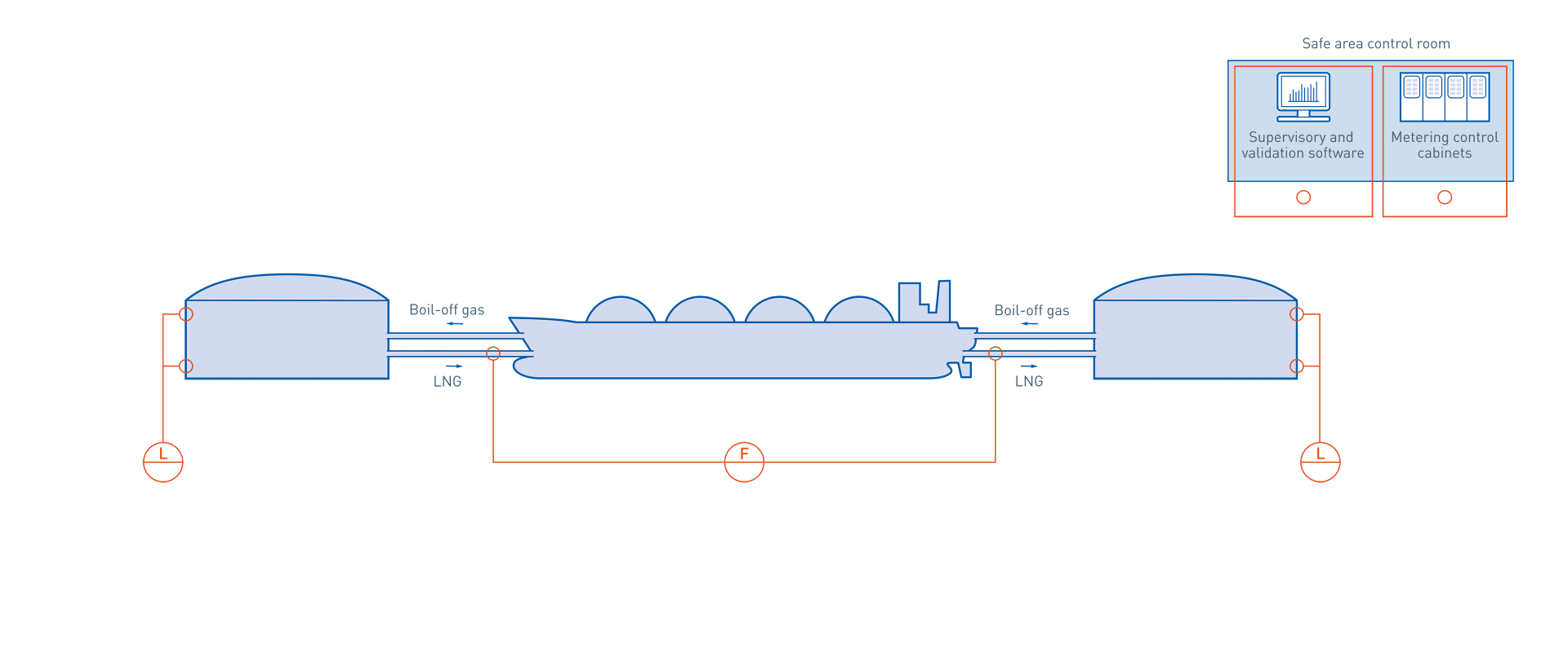

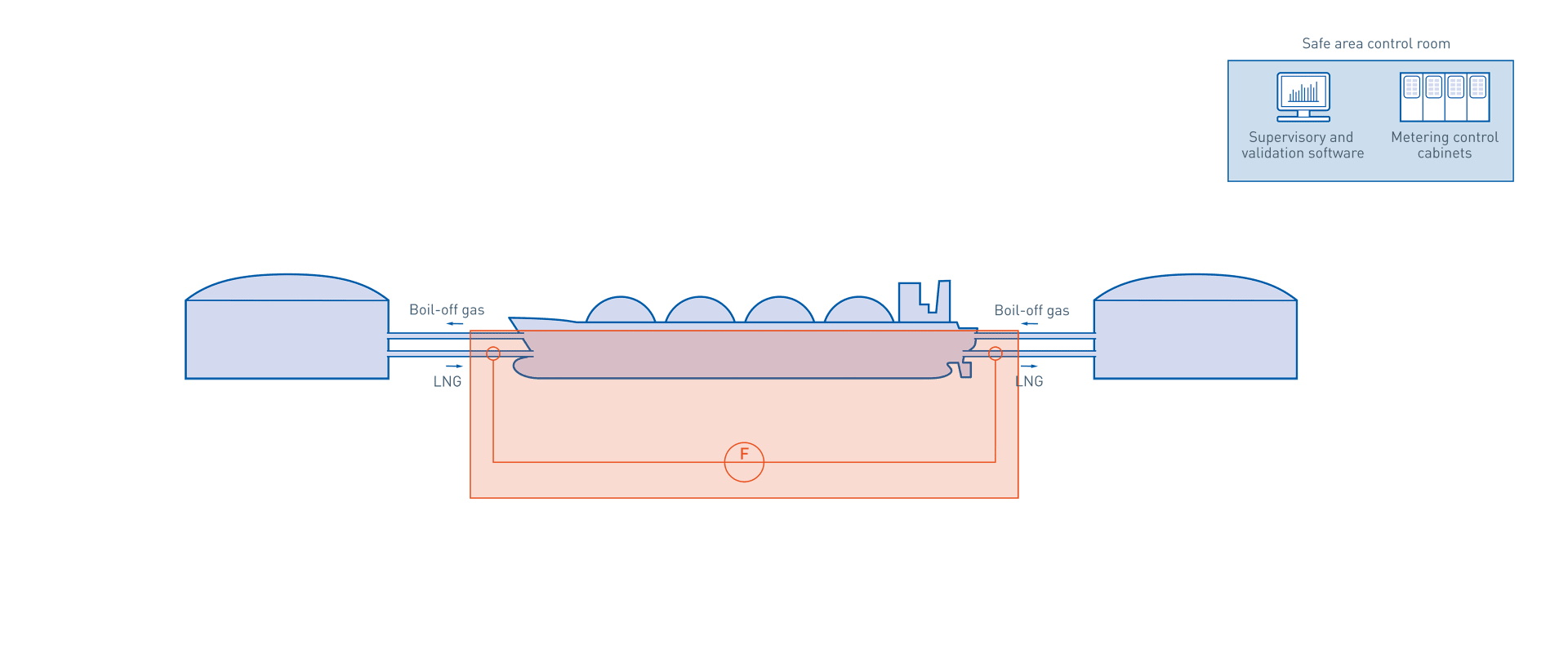

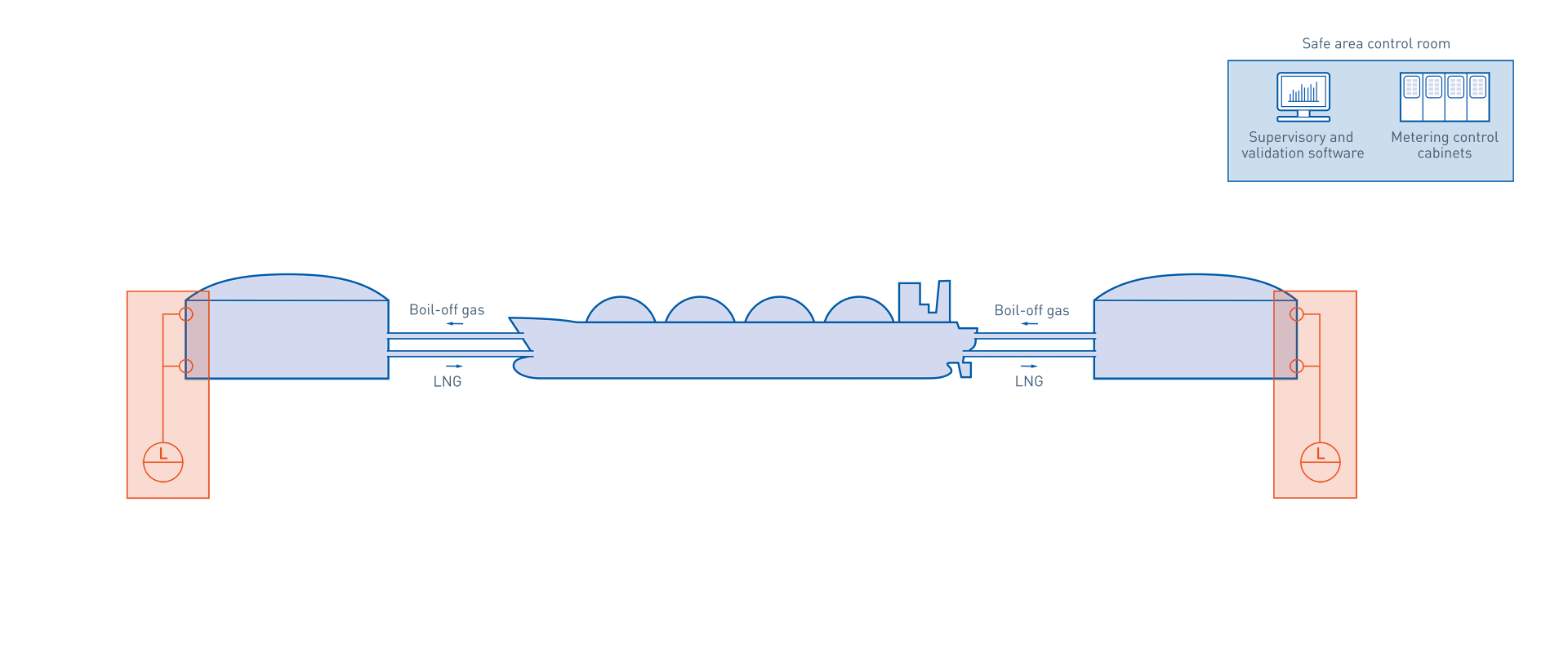

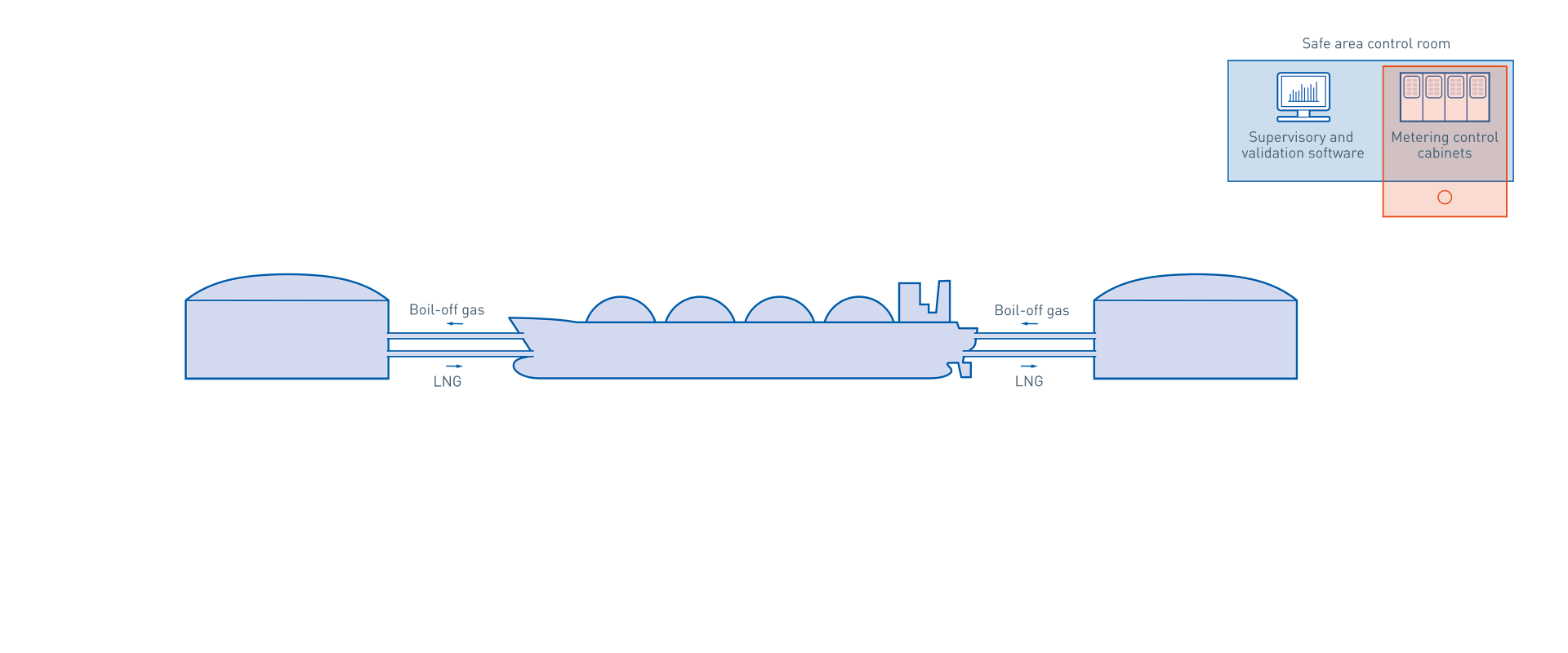

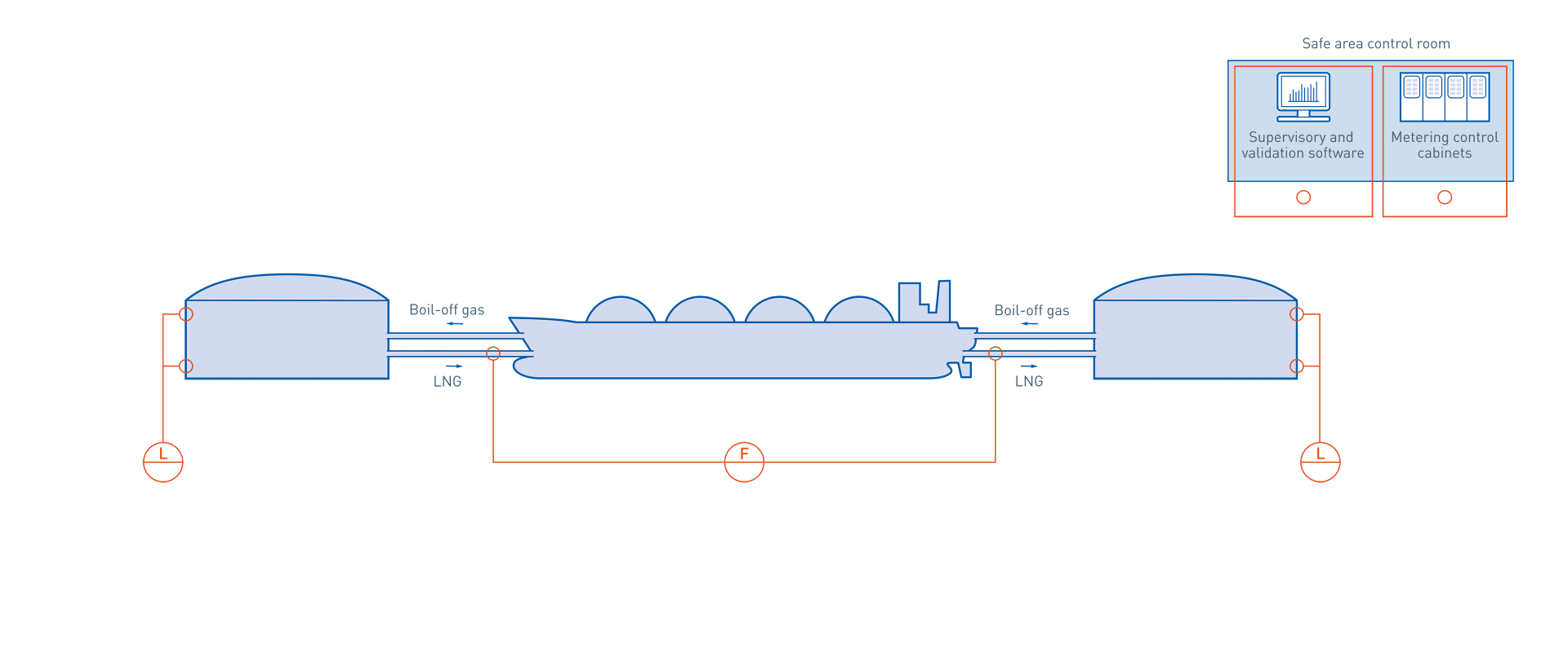

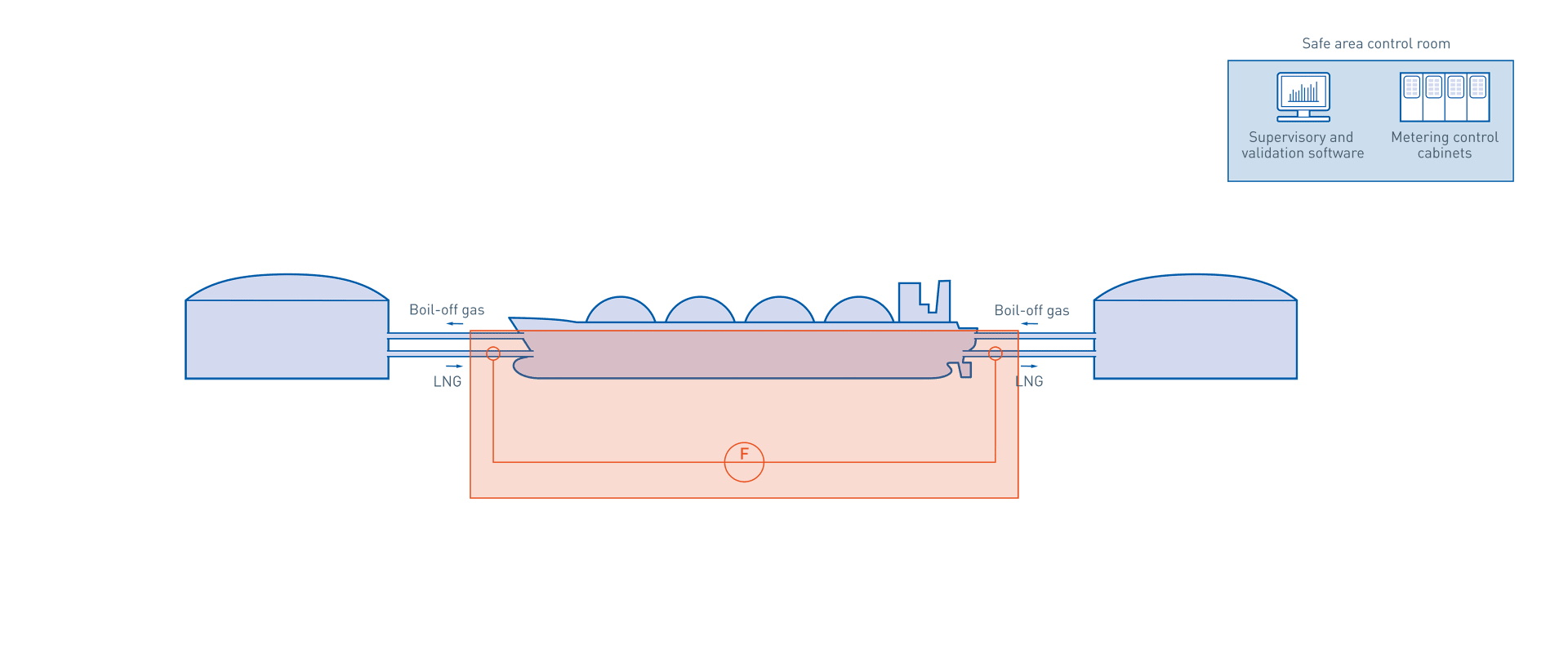

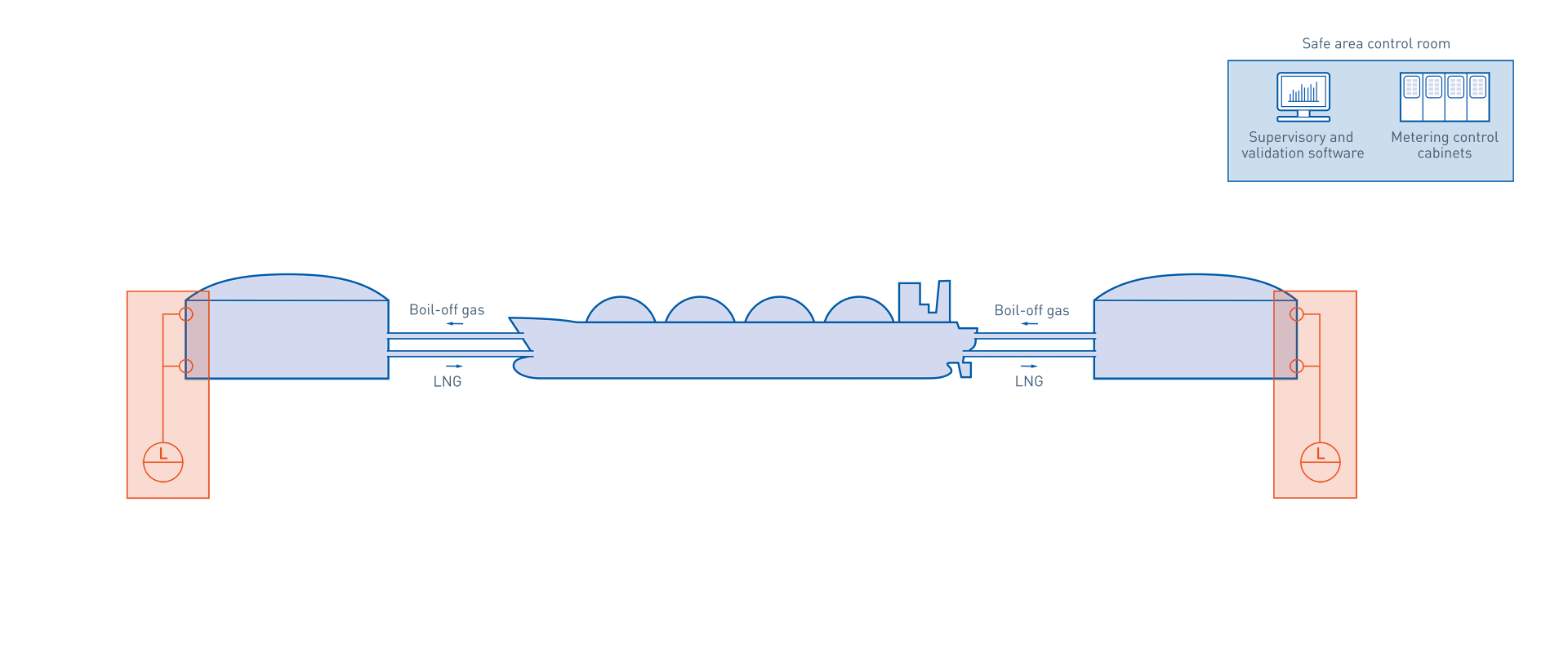

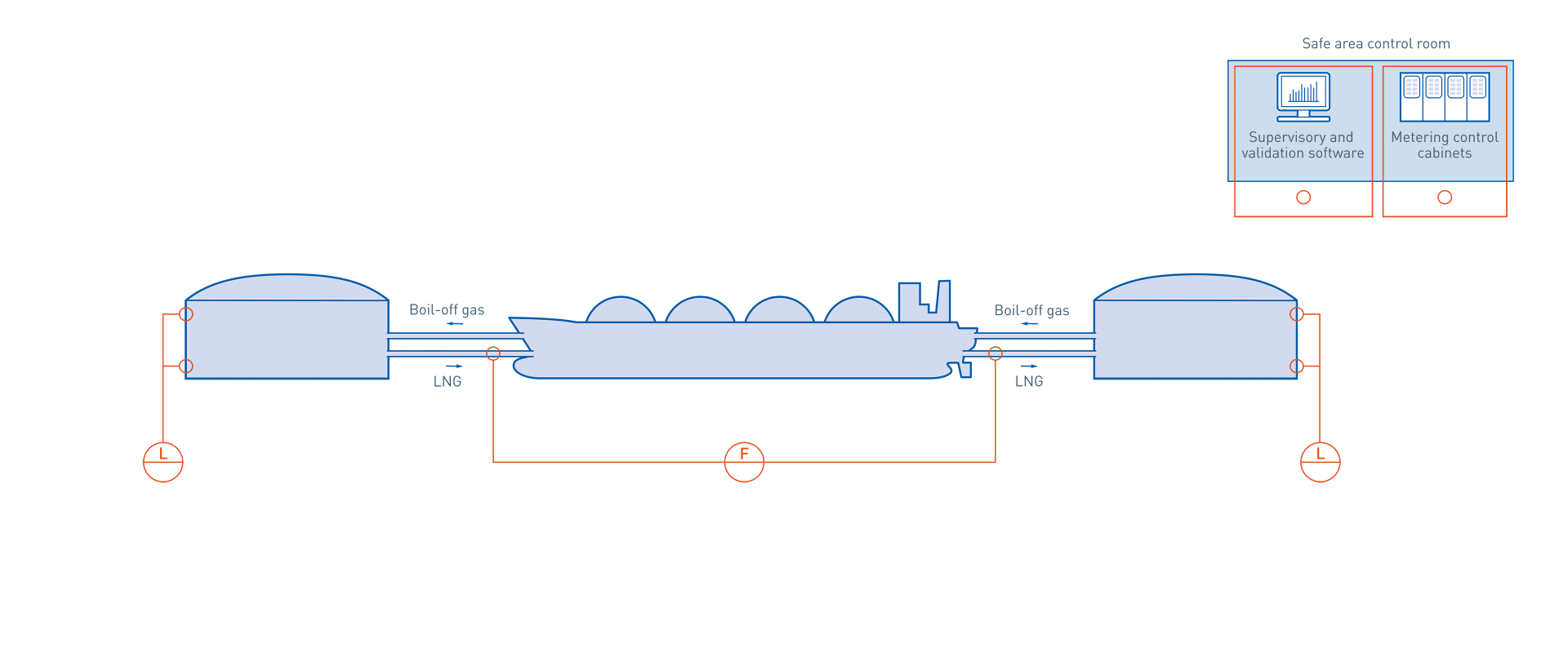

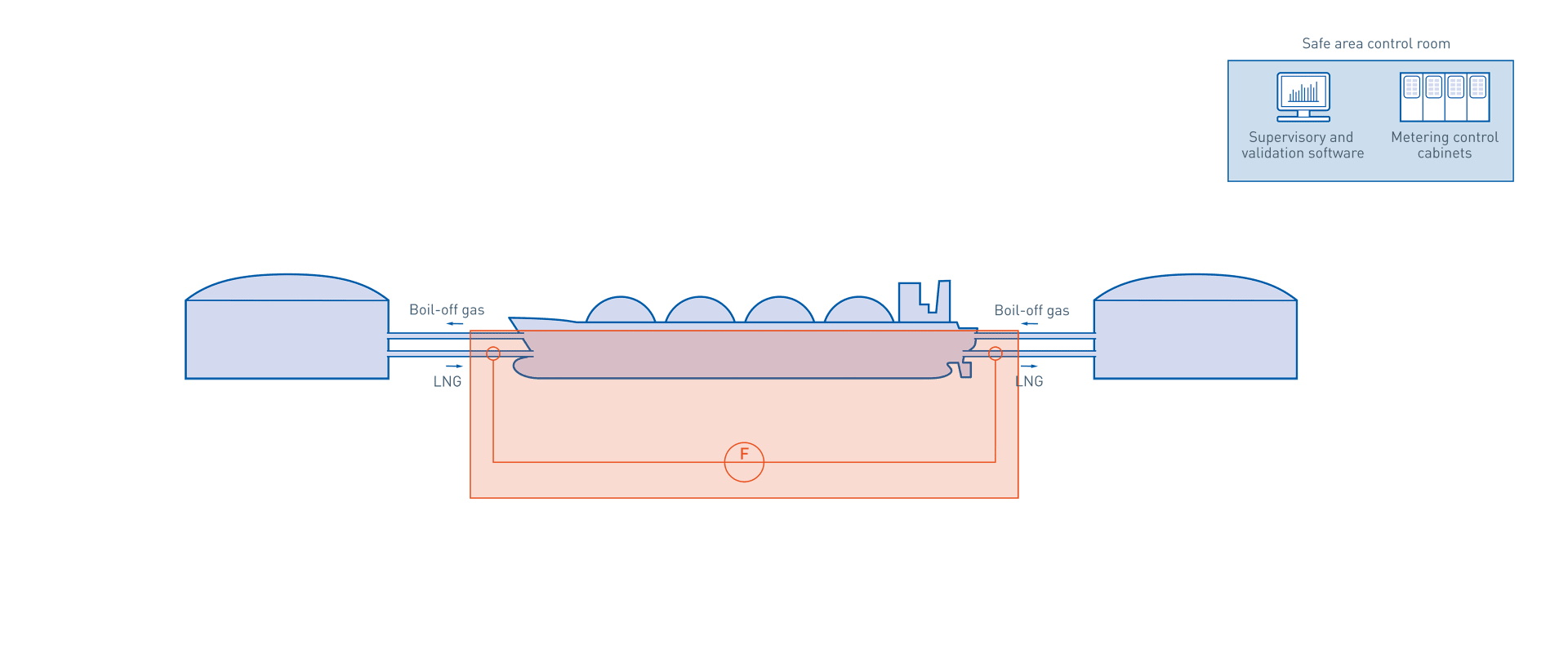

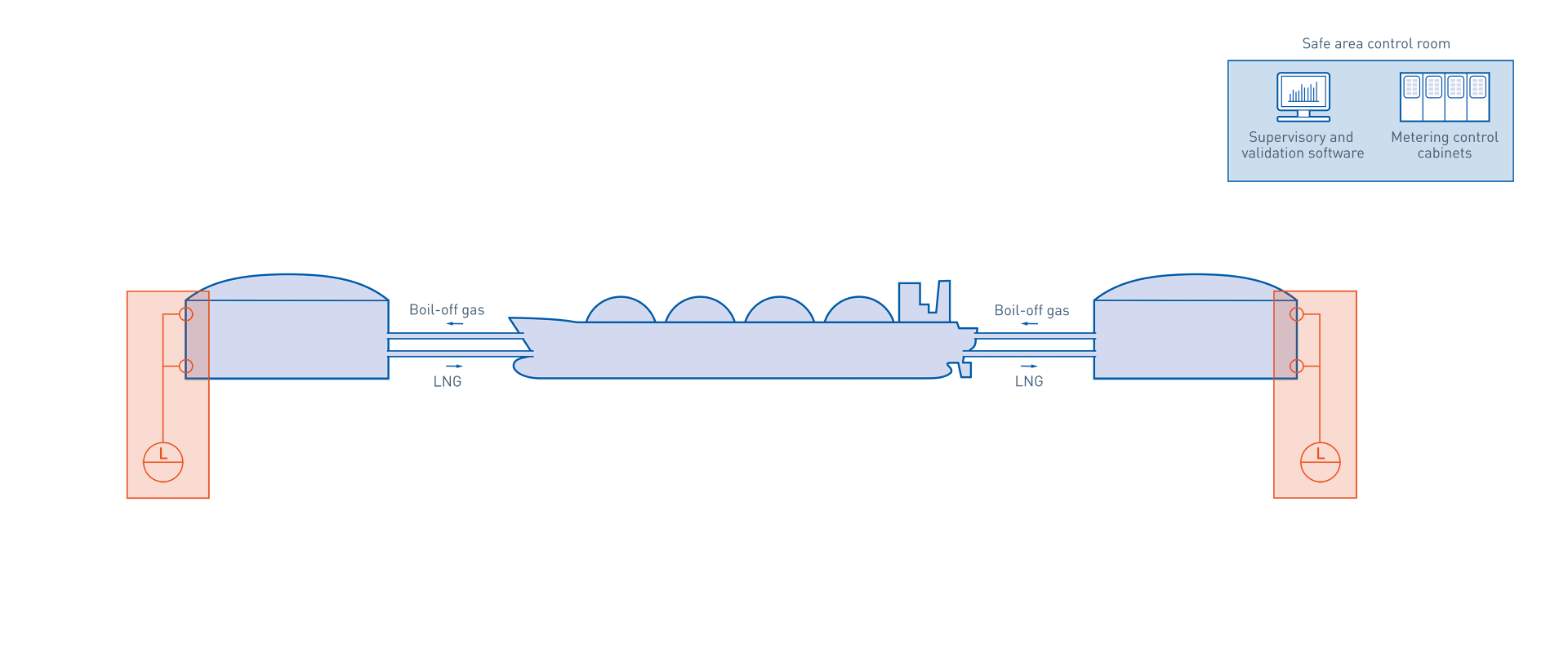

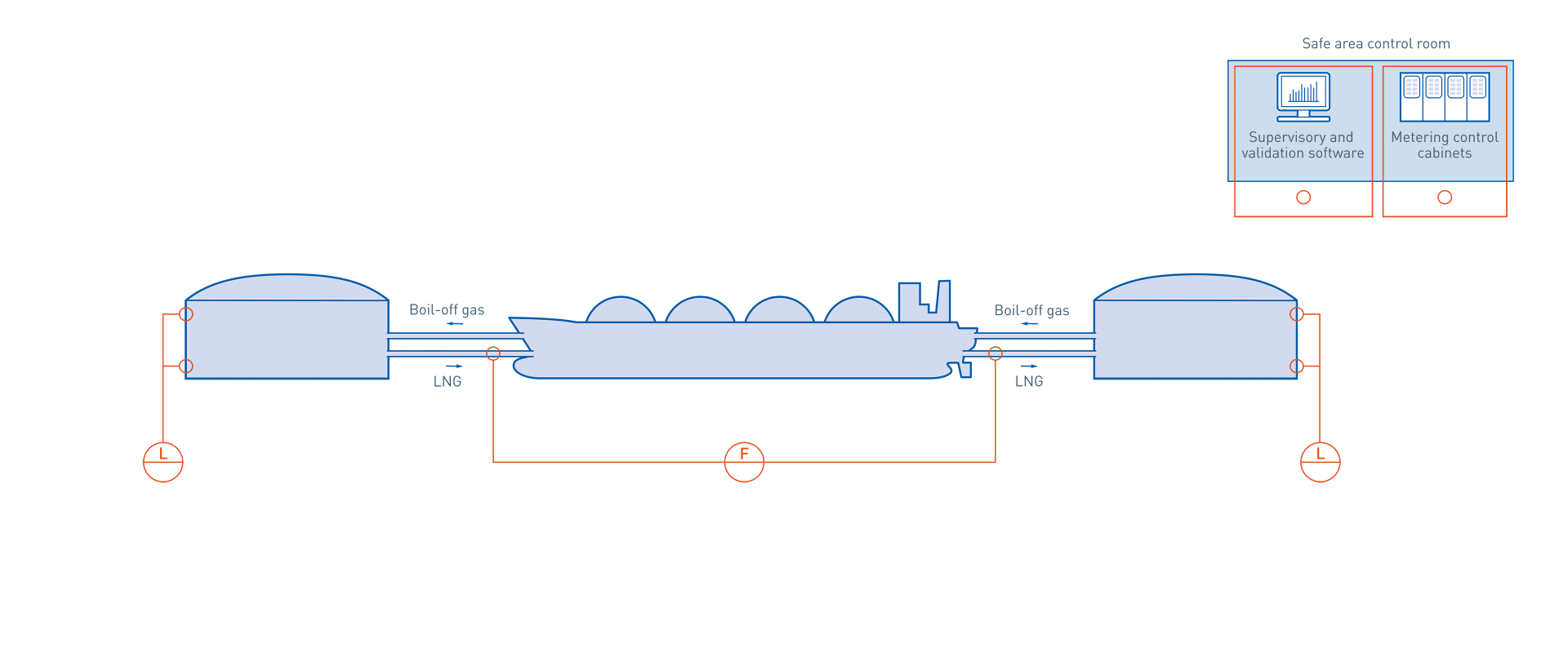

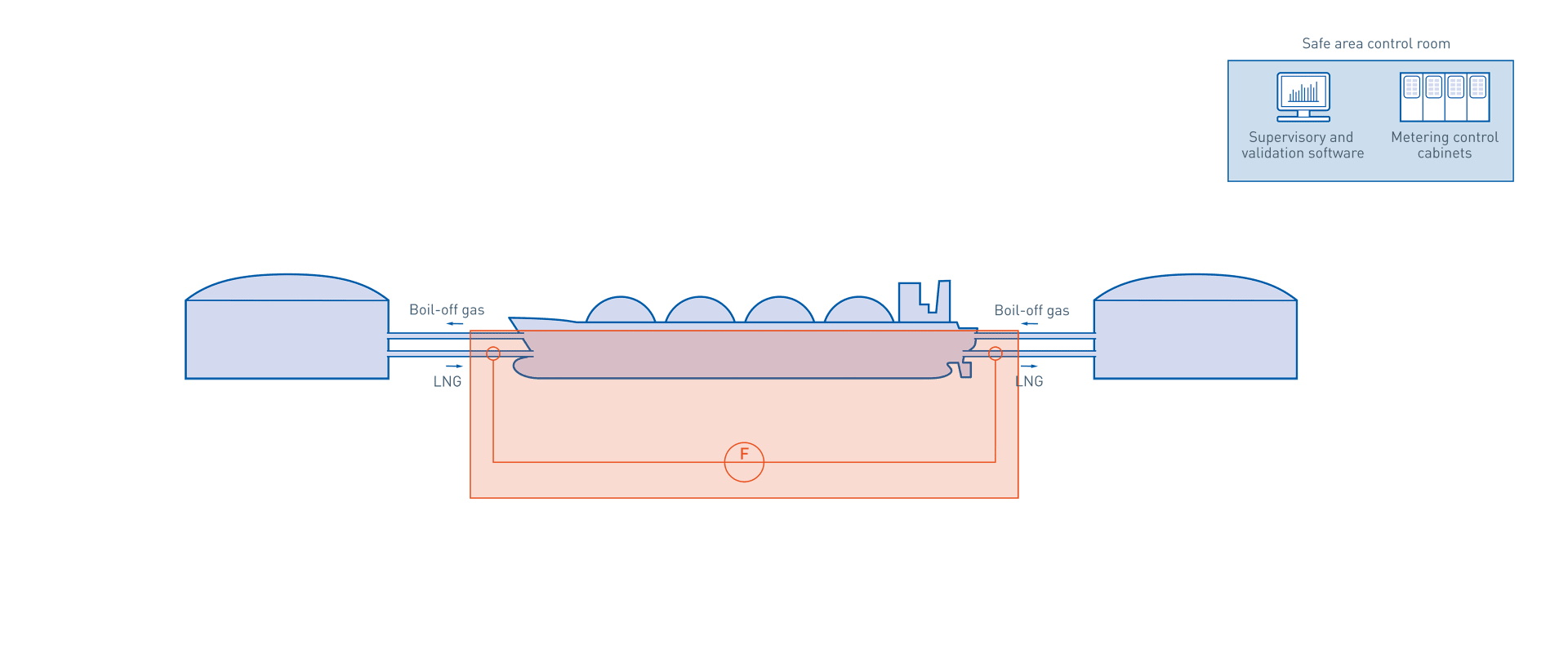

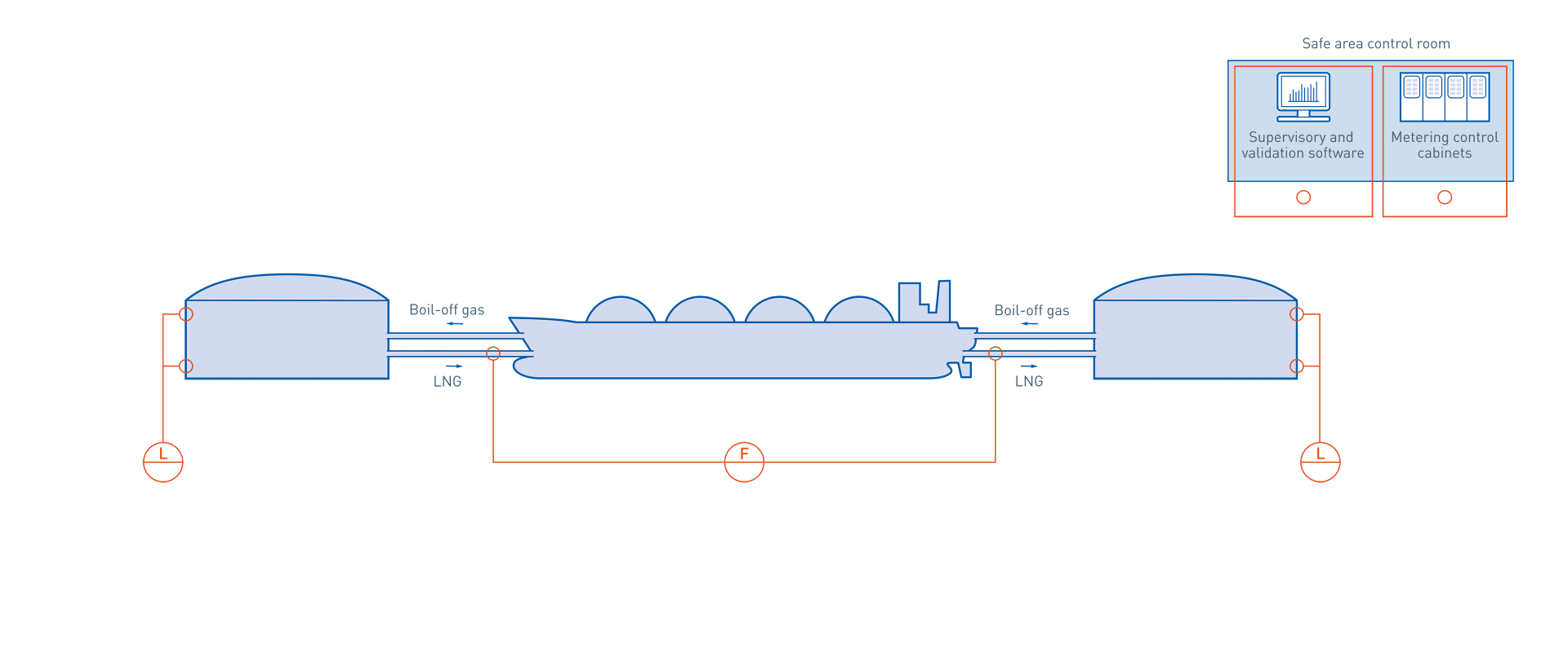

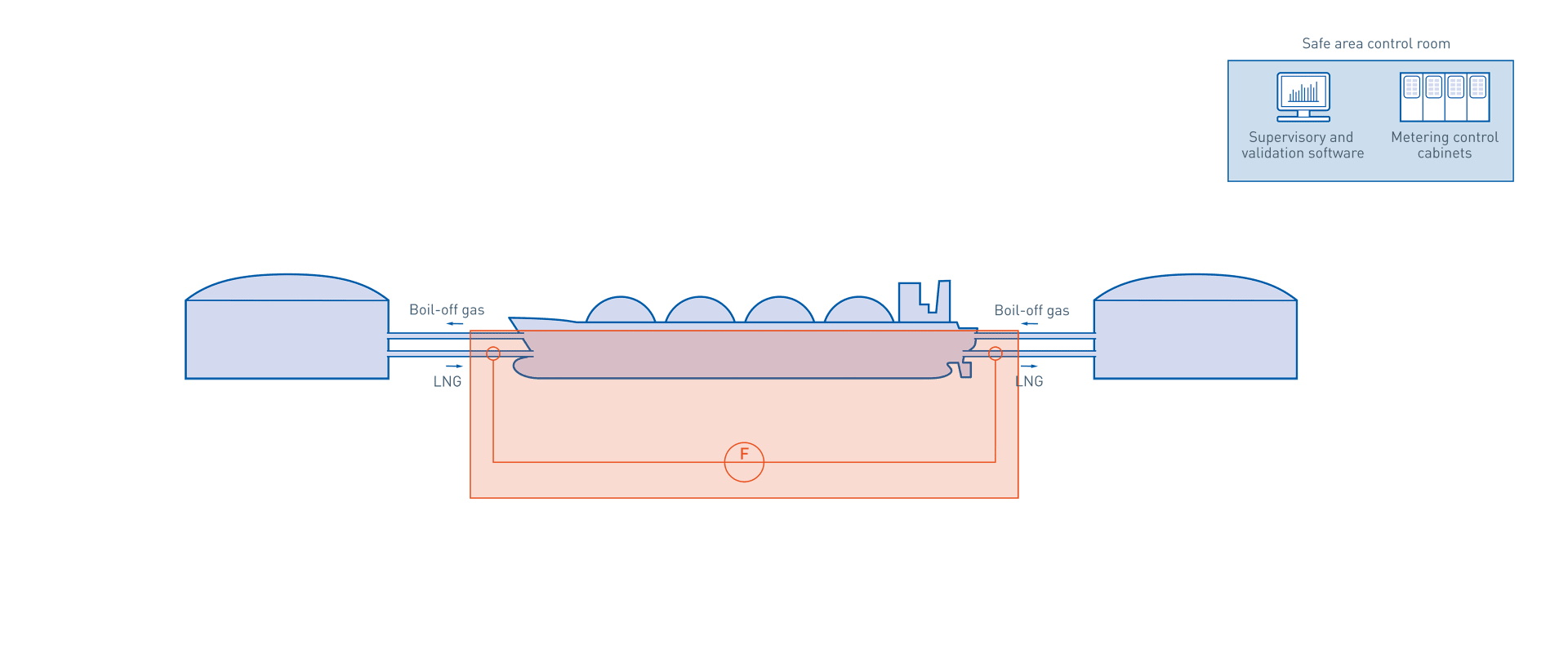

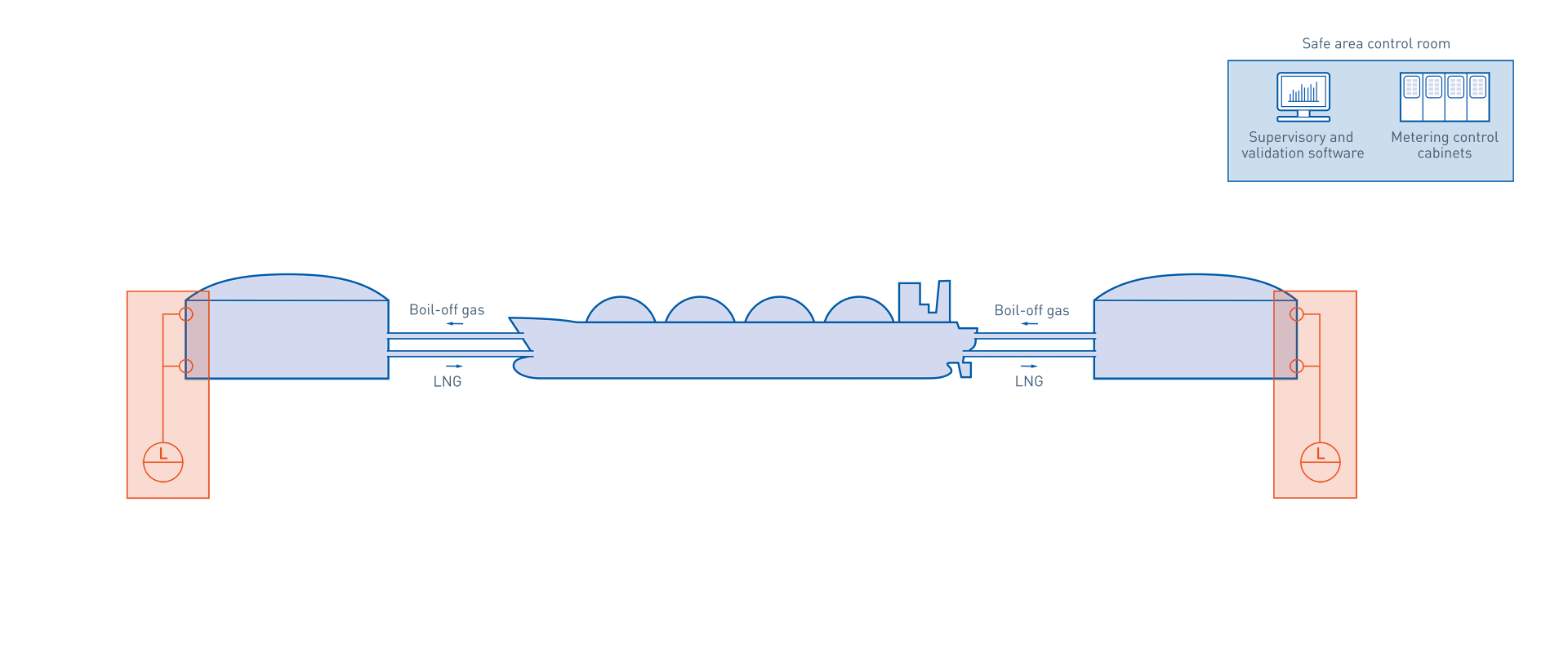

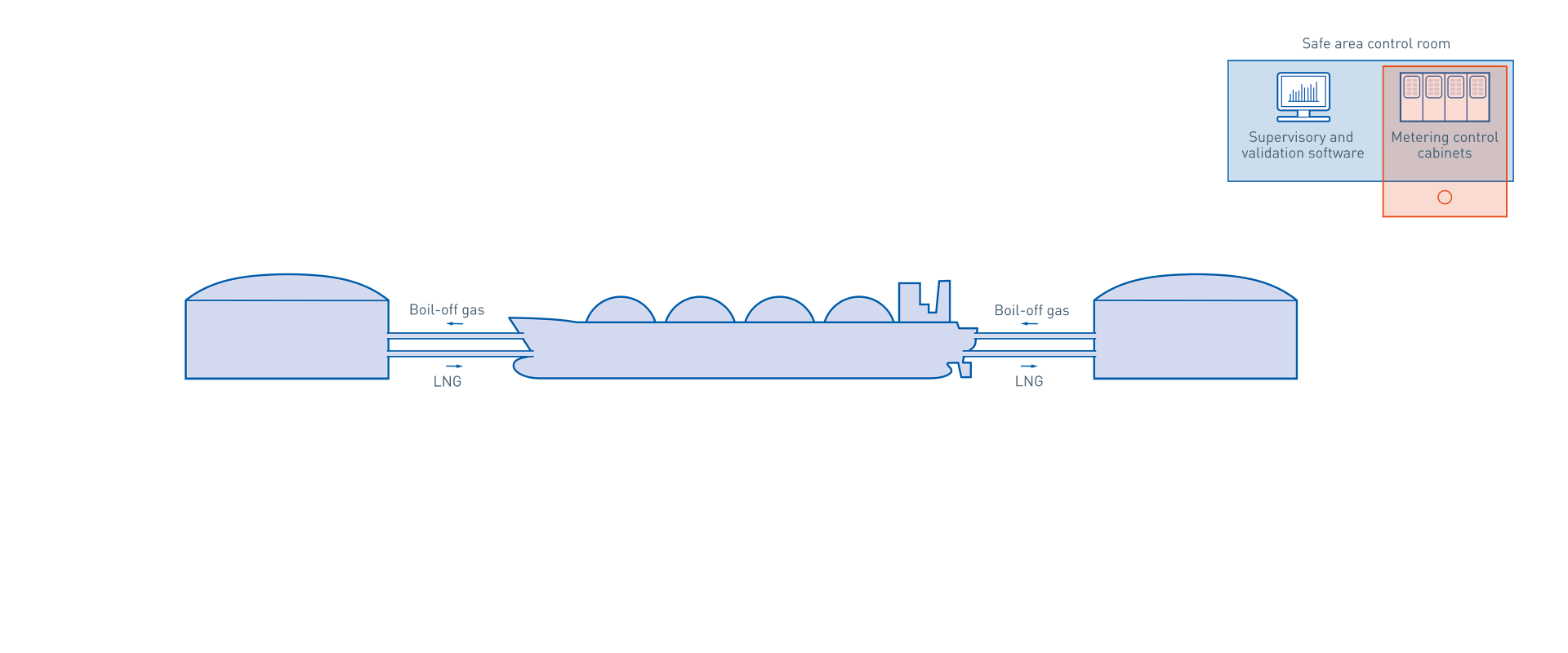

Typically LNG is sold from the liquefaction plant and transported by sea using a specialized LNG tanker vessel. Custody transfer meters are used to measure the volume of the liquefied gas delivered, and this involves an analytical measurement of the LNG calorific value. The LNG tanker voyage takes some days, and the LNG tanks, while insulated, are not cooled, so some of the lightest fraction, the methane, boils off. Normally this is used to fuel the ship’s engines.

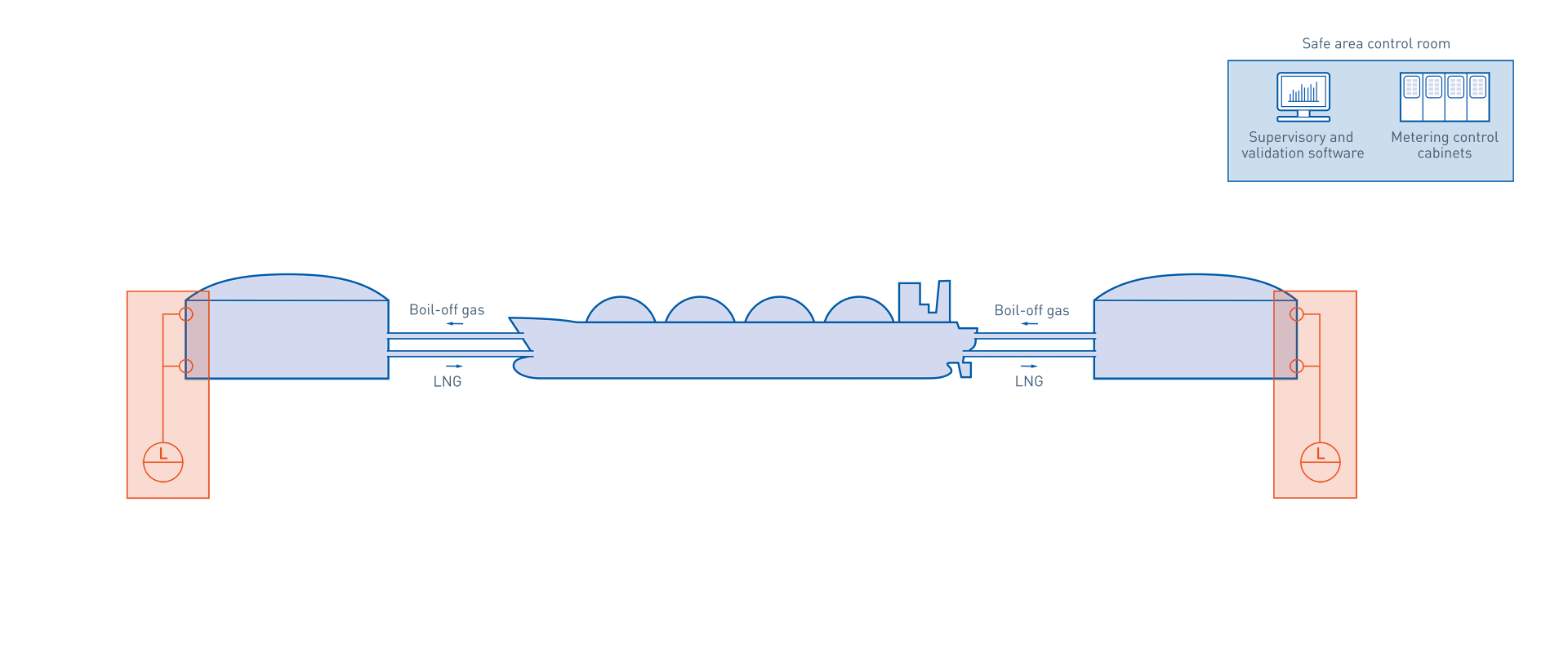

Upon arrival at the receiving terminal the volume of LNG available is slightly less than it was during the loading of the ship, so once again a custody transfer measurement of the delivered volume of LNG is essential, with the associated calorific value measurement. Traditionally, the volume of the LNG in the ship’s tanks was determined by level measurement, however more and more companies are installing flow measurement based systems to overcome the limitations of such cryogenic tank level measurement.

At the receiving terminal, the gas in the tanks that is displaced by the delivered LNG is frequently compressed and returned to the tanker, to equalize the system pressures. This returned volume is measured by another (gas phase) custody transfer flowmeter, to give accurate accounting.

KROHNE supplies flow metering instrumentation and systems for the custody transfer measurement of cryogenic LNG. For high volume applications - such as tanker loading and delivery flows - these are based on ultrasonic flowmeters. For lower flowrate applications these often use Coriolis mass flowmeters. Currently the calibration of these systems is achieved using water flow rigs, with an NMi certified correction method applied for the declared meter use on cryogenic LNG. For the future, the industry plans to establish a large scale LNG flow calibration facility. KROHNE cryogenic level switches are also used for LNG tank level measurement and control.

Process details

Storage and shipping in the oil & gas industry

Requirements:

- Cryogenic temperatures (<-162°C)

- High accuracy needed to prevent losses

- Custody transfer accuracy and approvals

Recommended products and solutions:

OPTIMASS 6400

- High accuracy (±0.05% flat), for cryogenic to HT media (-200…+400°C / -328…+752°F); maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- SIL 2/3; CT: OIML R117, R137, MI-005, MI-002; API, AGA; hygienic certifications

- Flange: DN10…300 / ½…12", max. PN 160 / ASME Cl 1500

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

ALTOSONIC 5

- Multipath inline meter for crudes, refined products, cryogenic media and chemicals

- CT: OIML R117, API compliant

- Flange: 4…24"; max. ASME Cl 600

- -200…+250°C / -328…+482°F

Requirements:

- Cryogenic temperatures (<-162°C)

- Risk of overfill or dry run

- Inventory measurement

Recommended products and solutions:

OPTISWITCH 5300

- Point level detection of liquids under extreme conditions

- Probe length: up to 3000 mm / 118 ft

- ≥0.47 g/cm3 / 0.017 lb/in3 (optional: ≥0.42 g/cm3 or 0.015 lb/in3)

- -196…+450°C / -321…+842°F; -1…160 barg / -14.5…2321 psig

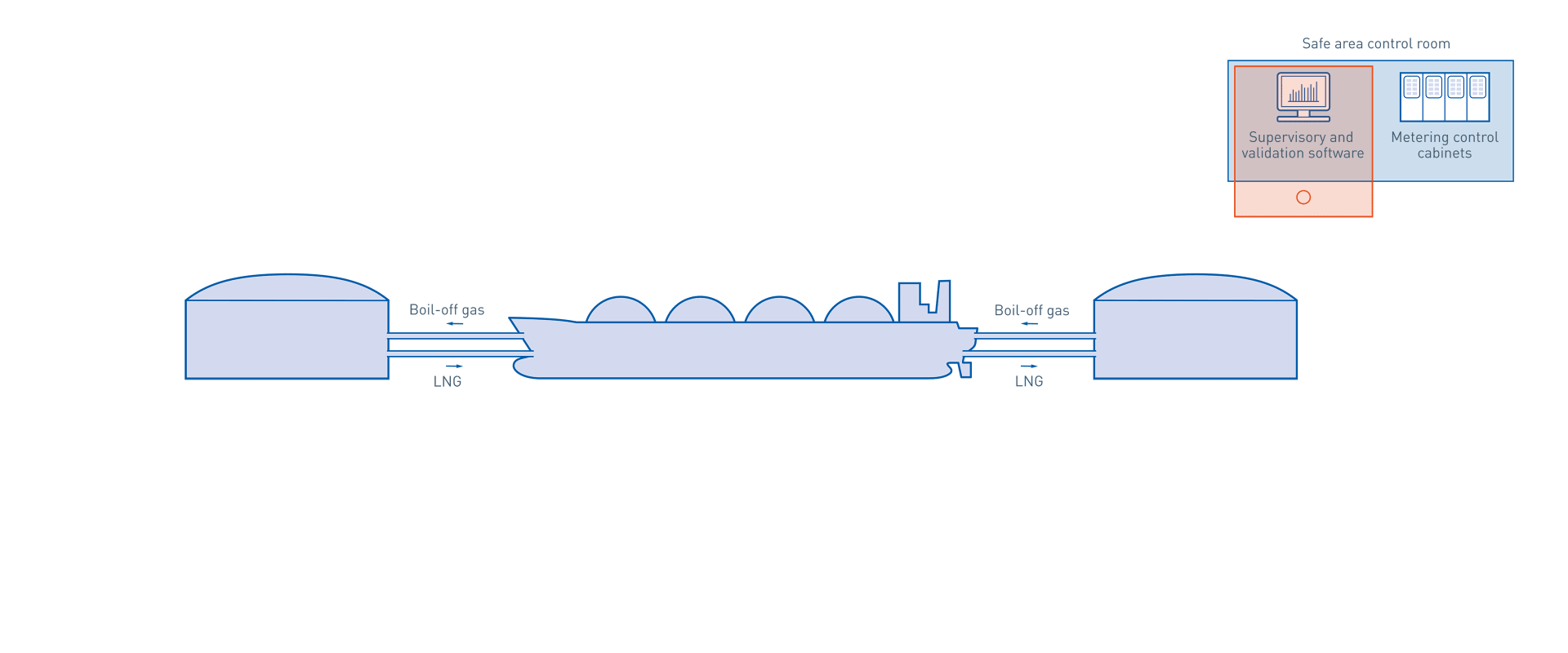

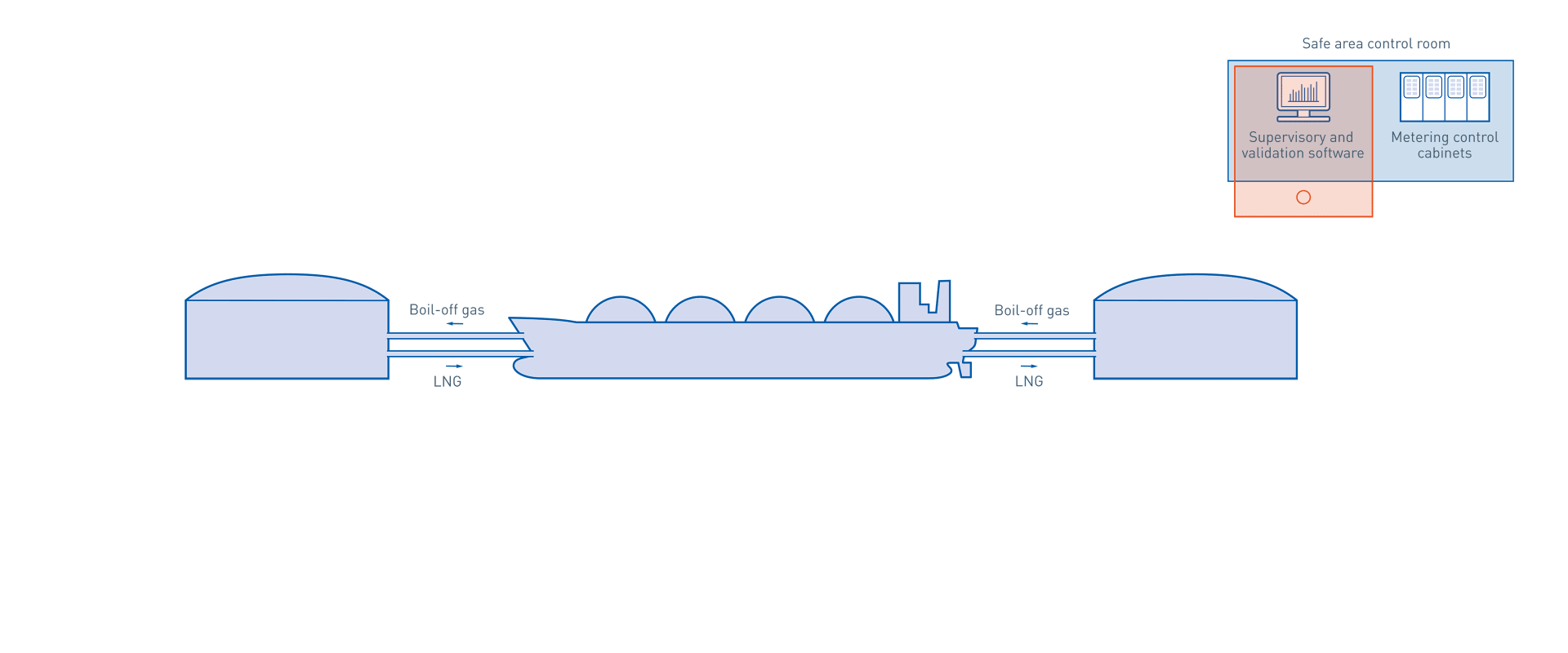

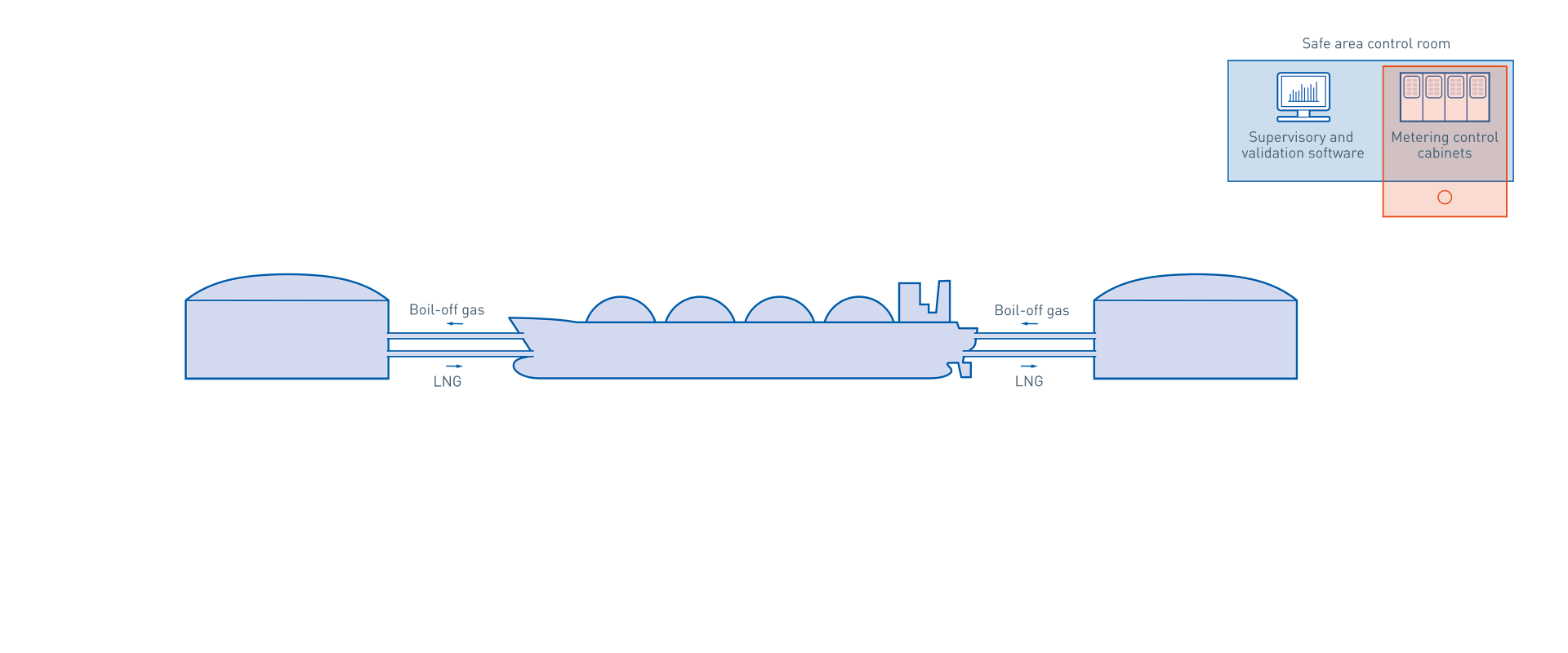

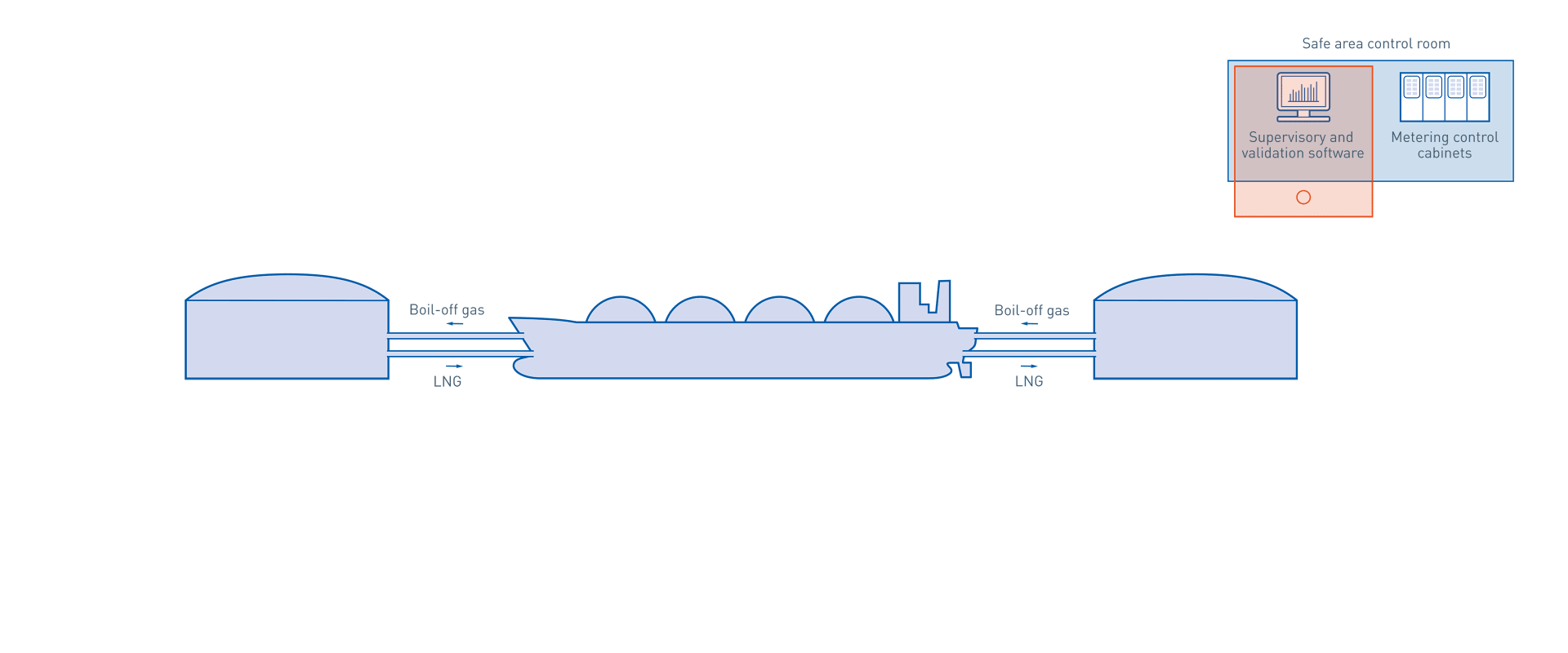

Requirements:

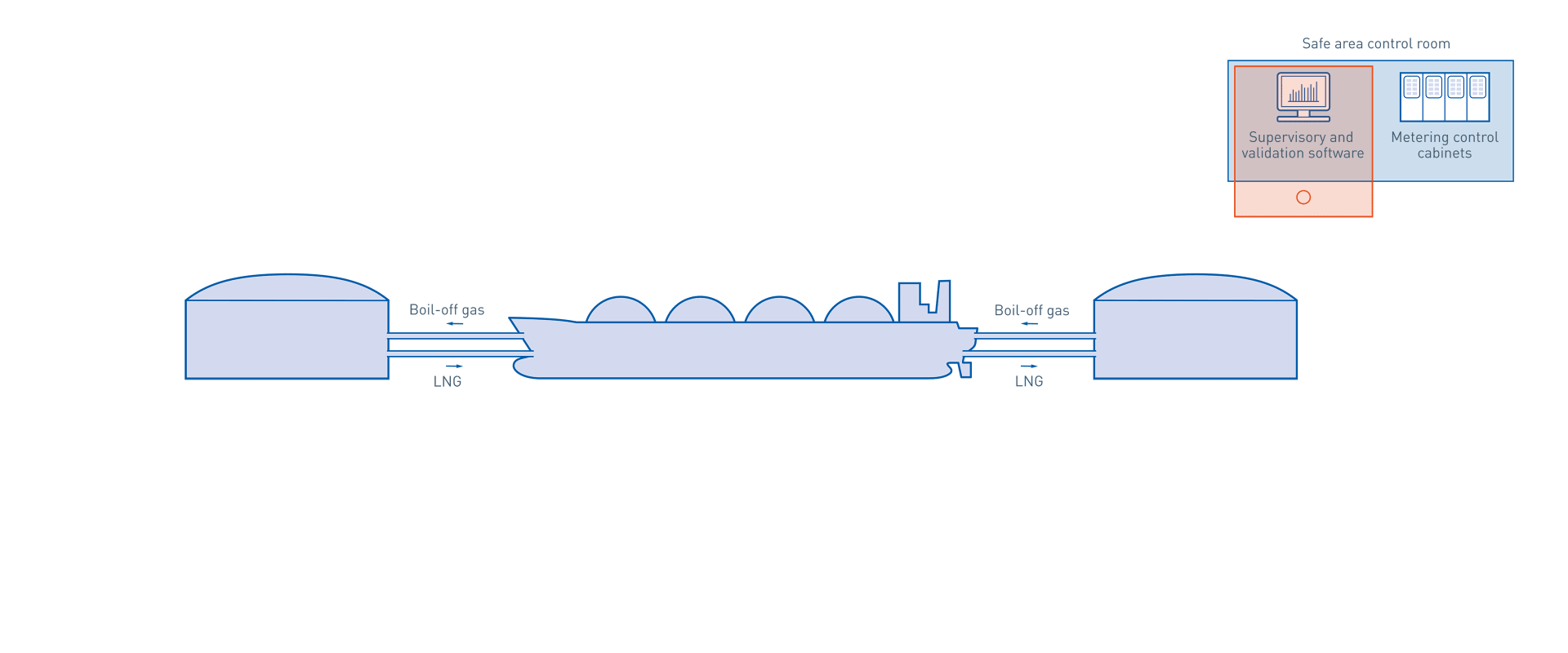

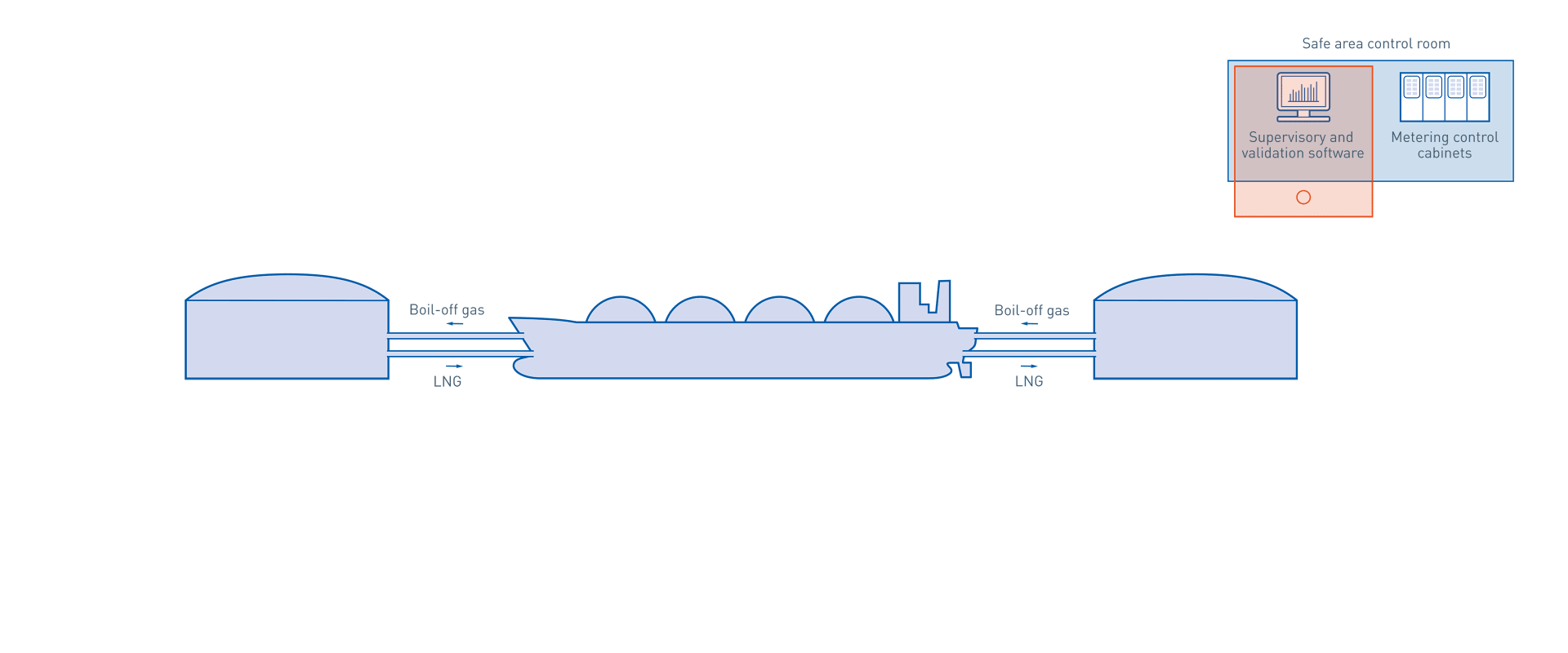

- Visualisation and monitoring of critical processes

- Control of reporting, trends and alarm handling

- Statistical evaluation of measurement data

Recommended products and solutions:

SynEnergy Supervisory and visualisation software

- HMI/SCADA software for measurement solutions

- State of the art HTML5 secure web technology

- Optimisation of operation results due to predictive maintenance

- Easy integration into existing DCS and ERP networks

CalSys Analyser Management software

- Effective performance monitoring of quality measurement instruments (QMI)

- Automated analyser validation and statistical process control

- Complies with international standards and methods (ASTM D3764, ASTM D6299, OP 97-30425 etc.)

- Increased availability of gas chromatographs and critical process analysers

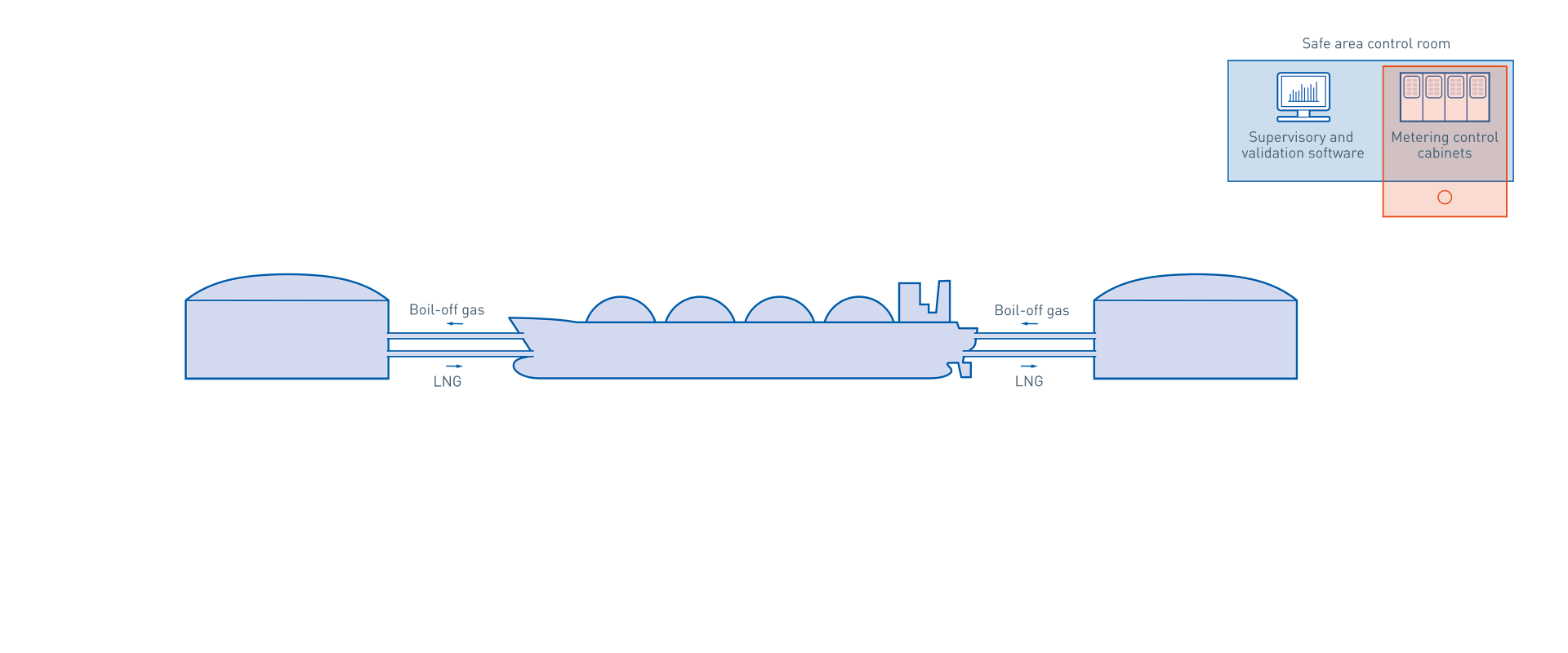

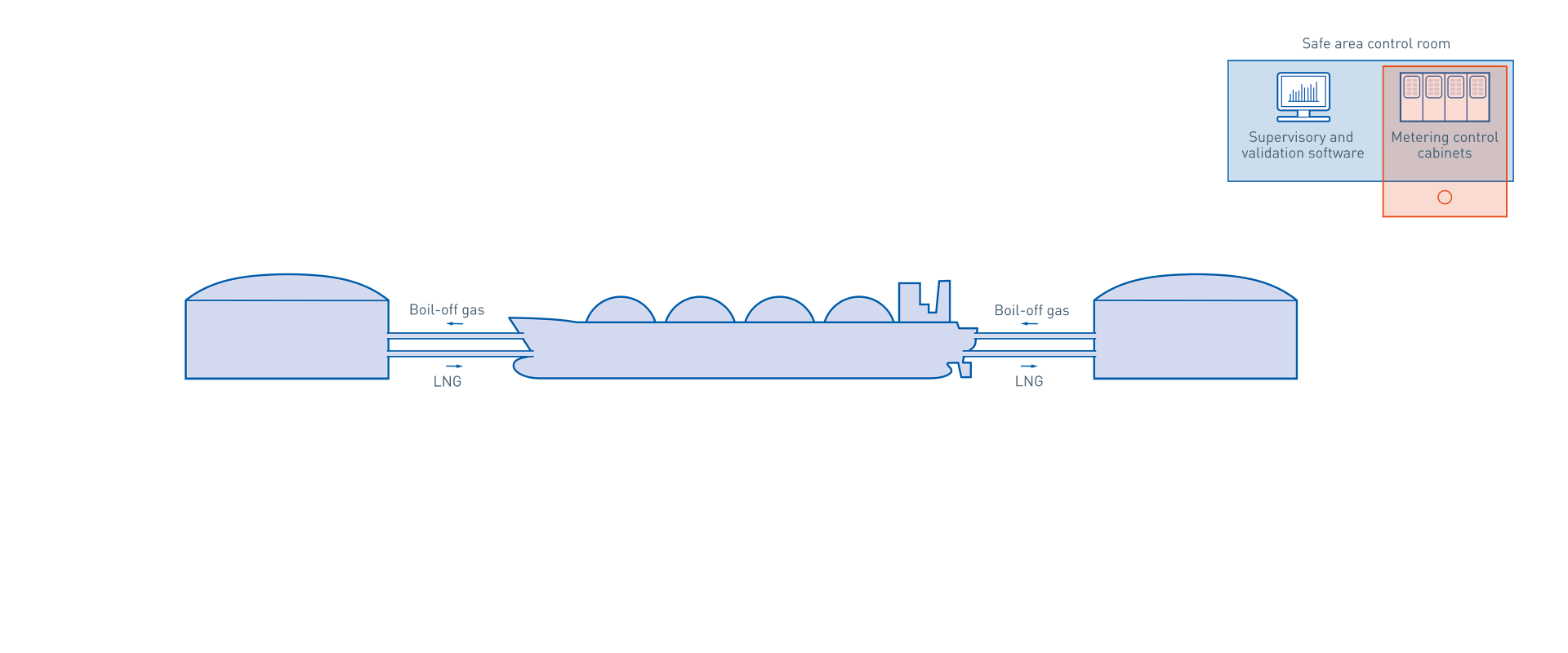

Requirements:

- Integration of flow computers, PLCs, supervisory computers and printers

- Installation of single flow computers up to fully redundant cabinet

- Complying with custody transfer requirements

Recommended products and solutions:

SUMMIT 8800

- Cost effective solution due to modular hard- and software design

- Full colour graphical touch screen for maximum process transparency

- Easy operator access enabling time efficient maintenance

- Automatic Performance Monitoring extends recalibration interval

Supervisory Control Cabinets

- Provides control of the metering system, including validation of field instrumentation

- Installed in a safe area, typically in a control room or dedicated building

- Supplied in combination with new metering systems, or for an upgrade to existing systems

Modular flow control and data transfer cabinets

- Cost effective, modular metering control solution

- Based on the SUMMIT 8800 flow computer

- Installed in a safe area, typically in a control room

Storage and shipping in the oil & gas industry

Requirements:

- Cryogenic temperatures (<-162°C)

- High accuracy needed to prevent losses

- Custody transfer accuracy and approvals

Recommended products and solutions:

OPTIMASS 6400

- High accuracy (±0.05% flat), for cryogenic to HT media (-200…+400°C / -328…+752°F); maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- SIL 2/3; CT: OIML R117, R137, MI-005, MI-002; API, AGA; hygienic certifications

- Flange: DN10…300 / ½…12", max. PN 160 / ASME Cl 1500

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

ALTOSONIC 5

- Multipath inline meter for crudes, refined products, cryogenic media and chemicals

- CT: OIML R117, API compliant

- Flange: 4…24"; max. ASME Cl 600

- -200…+250°C / -328…+482°F

Requirements:

- Cryogenic temperatures (<-162°C)

- Risk of overfill or dry run

- Inventory measurement

Recommended products and solutions:

OPTISWITCH 5300

- Point level detection of liquids under extreme conditions

- Probe length: up to 3000 mm / 118 ft

- ≥0.47 g/cm3 / 0.017 lb/in3 (optional: ≥0.42 g/cm3 or 0.015 lb/in3)

- -196…+450°C / -321…+842°F; -1…160 barg / -14.5…2321 psig

Requirements:

- Visualisation and monitoring of critical processes

- Control of reporting, trends and alarm handling

- Statistical evaluation of measurement data

Recommended products and solutions:

SynEnergy Supervisory and visualisation software

- HMI/SCADA software for measurement solutions

- State of the art HTML5 secure web technology

- Optimisation of operation results due to predictive maintenance

- Easy integration into existing DCS and ERP networks

CalSys Analyser Management software

- Effective performance monitoring of quality measurement instruments (QMI)

- Automated analyser validation and statistical process control

- Complies with international standards and methods (ASTM D3764, ASTM D6299, OP 97-30425 etc.)

- Increased availability of gas chromatographs and critical process analysers

Requirements:

- Integration of flow computers, PLCs, supervisory computers and printers

- Installation of single flow computers up to fully redundant cabinet

- Complying with custody transfer requirements

Recommended products and solutions:

SUMMIT 8800

- Cost effective solution due to modular hard- and software design

- Full colour graphical touch screen for maximum process transparency

- Easy operator access enabling time efficient maintenance

- Automatic Performance Monitoring extends recalibration interval

Supervisory Control Cabinets

- Provides control of the metering system, including validation of field instrumentation

- Installed in a safe area, typically in a control room or dedicated building

- Supplied in combination with new metering systems, or for an upgrade to existing systems

Modular flow control and data transfer cabinets

- Cost effective, modular metering control solution

- Based on the SUMMIT 8800 flow computer

- Installed in a safe area, typically in a control room

Requirements:

- Cryogenic temperatures (<-162°C)

- High accuracy needed to prevent losses

- Custody transfer accuracy and approvals

Recommended products and solutions:

ALTOSONIC 5

Ultrasonic flowmeter for custody transfer (CT) measurement in upstream and midstream applications

Storage and shipping in the oil & gas industry

Requirements:

- Cryogenic temperatures (<-162°C)

- High accuracy needed to prevent losses

- Custody transfer accuracy and approvals

Recommended products and solutions:

OPTIMASS 6400

- High accuracy (±0.05% flat), for cryogenic to HT media (-200…+400°C / -328…+752°F); maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- SIL 2/3; CT: OIML R117, R137, MI-005, MI-002; API, AGA; hygienic certifications

- Flange: DN10…300 / ½…12", max. PN 160 / ASME Cl 1500

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

ALTOSONIC 5

- Multipath inline meter for crudes, refined products, cryogenic media and chemicals

- CT: OIML R117, API compliant

- Flange: 4…24"; max. ASME Cl 600

- -200…+250°C / -328…+482°F

Requirements:

- Cryogenic temperatures (<-162°C)

- Risk of overfill or dry run

- Inventory measurement

Recommended products and solutions:

OPTISWITCH 5300

- Point level detection of liquids under extreme conditions

- Probe length: up to 3000 mm / 118 ft

- ≥0.47 g/cm3 / 0.017 lb/in3 (optional: ≥0.42 g/cm3 or 0.015 lb/in3)

- -196…+450°C / -321…+842°F; -1…160 barg / -14.5…2321 psig

Requirements:

- Visualisation and monitoring of critical processes

- Control of reporting, trends and alarm handling

- Statistical evaluation of measurement data

Recommended products and solutions:

SynEnergy Supervisory and visualisation software

- HMI/SCADA software for measurement solutions

- State of the art HTML5 secure web technology

- Optimisation of operation results due to predictive maintenance

- Easy integration into existing DCS and ERP networks

CalSys Analyser Management software

- Effective performance monitoring of quality measurement instruments (QMI)

- Automated analyser validation and statistical process control

- Complies with international standards and methods (ASTM D3764, ASTM D6299, OP 97-30425 etc.)

- Increased availability of gas chromatographs and critical process analysers

Requirements:

- Integration of flow computers, PLCs, supervisory computers and printers

- Installation of single flow computers up to fully redundant cabinet

- Complying with custody transfer requirements

Recommended products and solutions:

SUMMIT 8800

- Cost effective solution due to modular hard- and software design

- Full colour graphical touch screen for maximum process transparency

- Easy operator access enabling time efficient maintenance

- Automatic Performance Monitoring extends recalibration interval

Supervisory Control Cabinets

- Provides control of the metering system, including validation of field instrumentation

- Installed in a safe area, typically in a control room or dedicated building

- Supplied in combination with new metering systems, or for an upgrade to existing systems

Modular flow control and data transfer cabinets

- Cost effective, modular metering control solution

- Based on the SUMMIT 8800 flow computer

- Installed in a safe area, typically in a control room

Requirements:

- Cryogenic temperatures (<-162°C)

- Risk of overfill or dry run

- Inventory measurement

Recommended products and solutions:

Storage and shipping in the oil & gas industry

Requirements:

- Cryogenic temperatures (<-162°C)

- High accuracy needed to prevent losses

- Custody transfer accuracy and approvals

Recommended products and solutions:

OPTIMASS 6400

- High accuracy (±0.05% flat), for cryogenic to HT media (-200…+400°C / -328…+752°F); maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- SIL 2/3; CT: OIML R117, R137, MI-005, MI-002; API, AGA; hygienic certifications

- Flange: DN10…300 / ½…12", max. PN 160 / ASME Cl 1500

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

ALTOSONIC 5

- Multipath inline meter for crudes, refined products, cryogenic media and chemicals

- CT: OIML R117, API compliant

- Flange: 4…24"; max. ASME Cl 600

- -200…+250°C / -328…+482°F

Requirements:

- Cryogenic temperatures (<-162°C)

- Risk of overfill or dry run

- Inventory measurement

Recommended products and solutions:

OPTISWITCH 5300

- Point level detection of liquids under extreme conditions

- Probe length: up to 3000 mm / 118 ft

- ≥0.47 g/cm3 / 0.017 lb/in3 (optional: ≥0.42 g/cm3 or 0.015 lb/in3)

- -196…+450°C / -321…+842°F; -1…160 barg / -14.5…2321 psig

Requirements:

- Visualisation and monitoring of critical processes

- Control of reporting, trends and alarm handling

- Statistical evaluation of measurement data

Recommended products and solutions:

SynEnergy Supervisory and visualisation software

- HMI/SCADA software for measurement solutions

- State of the art HTML5 secure web technology

- Optimisation of operation results due to predictive maintenance

- Easy integration into existing DCS and ERP networks

CalSys Analyser Management software

- Effective performance monitoring of quality measurement instruments (QMI)

- Automated analyser validation and statistical process control

- Complies with international standards and methods (ASTM D3764, ASTM D6299, OP 97-30425 etc.)

- Increased availability of gas chromatographs and critical process analysers

Requirements:

- Integration of flow computers, PLCs, supervisory computers and printers

- Installation of single flow computers up to fully redundant cabinet

- Complying with custody transfer requirements

Recommended products and solutions:

SUMMIT 8800

- Cost effective solution due to modular hard- and software design

- Full colour graphical touch screen for maximum process transparency

- Easy operator access enabling time efficient maintenance

- Automatic Performance Monitoring extends recalibration interval

Supervisory Control Cabinets

- Provides control of the metering system, including validation of field instrumentation

- Installed in a safe area, typically in a control room or dedicated building

- Supplied in combination with new metering systems, or for an upgrade to existing systems

Modular flow control and data transfer cabinets

- Cost effective, modular metering control solution

- Based on the SUMMIT 8800 flow computer

- Installed in a safe area, typically in a control room

Requirements:

- Visualisation and monitoring of critical processes

- Control of reporting, trends and alarm handling

- Statistical evaluation of measurement data

Recommended products and solutions:

SynEnergy Supervisory and visualisation software

Solution for continuous process monitoring and reporting

CalSys Analyser Management software

Solution for analyser management and data acquisition (AMADAS)

Storage and shipping in the oil & gas industry

Requirements:

- Cryogenic temperatures (<-162°C)

- High accuracy needed to prevent losses

- Custody transfer accuracy and approvals

Recommended products and solutions:

OPTIMASS 6400

- High accuracy (±0.05% flat), for cryogenic to HT media (-200…+400°C / -328…+752°F); maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- SIL 2/3; CT: OIML R117, R137, MI-005, MI-002; API, AGA; hygienic certifications

- Flange: DN10…300 / ½…12", max. PN 160 / ASME Cl 1500

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

ALTOSONIC 5

- Multipath inline meter for crudes, refined products, cryogenic media and chemicals

- CT: OIML R117, API compliant

- Flange: 4…24"; max. ASME Cl 600

- -200…+250°C / -328…+482°F

Requirements:

- Cryogenic temperatures (<-162°C)

- Risk of overfill or dry run

- Inventory measurement

Recommended products and solutions:

OPTISWITCH 5300

- Point level detection of liquids under extreme conditions

- Probe length: up to 3000 mm / 118 ft

- ≥0.47 g/cm3 / 0.017 lb/in3 (optional: ≥0.42 g/cm3 or 0.015 lb/in3)

- -196…+450°C / -321…+842°F; -1…160 barg / -14.5…2321 psig

Requirements:

- Visualisation and monitoring of critical processes

- Control of reporting, trends and alarm handling

- Statistical evaluation of measurement data

Recommended products and solutions:

SynEnergy Supervisory and visualisation software

- HMI/SCADA software for measurement solutions

- State of the art HTML5 secure web technology

- Optimisation of operation results due to predictive maintenance

- Easy integration into existing DCS and ERP networks

CalSys Analyser Management software

- Effective performance monitoring of quality measurement instruments (QMI)

- Automated analyser validation and statistical process control

- Complies with international standards and methods (ASTM D3764, ASTM D6299, OP 97-30425 etc.)

- Increased availability of gas chromatographs and critical process analysers

Requirements:

- Integration of flow computers, PLCs, supervisory computers and printers

- Installation of single flow computers up to fully redundant cabinet

- Complying with custody transfer requirements

Recommended products and solutions:

SUMMIT 8800

- Cost effective solution due to modular hard- and software design

- Full colour graphical touch screen for maximum process transparency

- Easy operator access enabling time efficient maintenance

- Automatic Performance Monitoring extends recalibration interval

Supervisory Control Cabinets

- Provides control of the metering system, including validation of field instrumentation

- Installed in a safe area, typically in a control room or dedicated building

- Supplied in combination with new metering systems, or for an upgrade to existing systems

Modular flow control and data transfer cabinets

- Cost effective, modular metering control solution

- Based on the SUMMIT 8800 flow computer

- Installed in a safe area, typically in a control room

Requirements:

- Integration of flow computers, PLCs, supervisory computers and printers

- Installation of single flow computers up to fully redundant cabinet

- Complying with custody transfer requirements