Regasification in the oil & gas industry

Converting LNG to natural gas

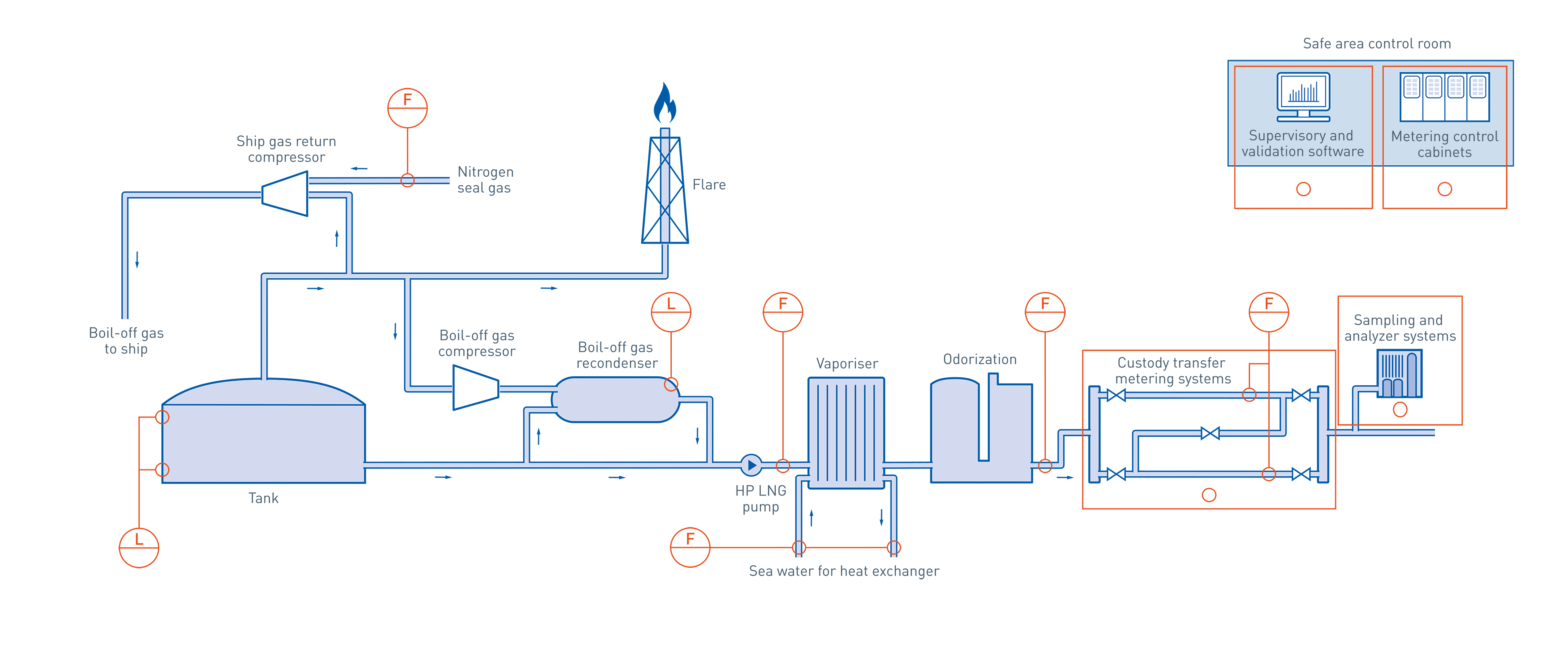

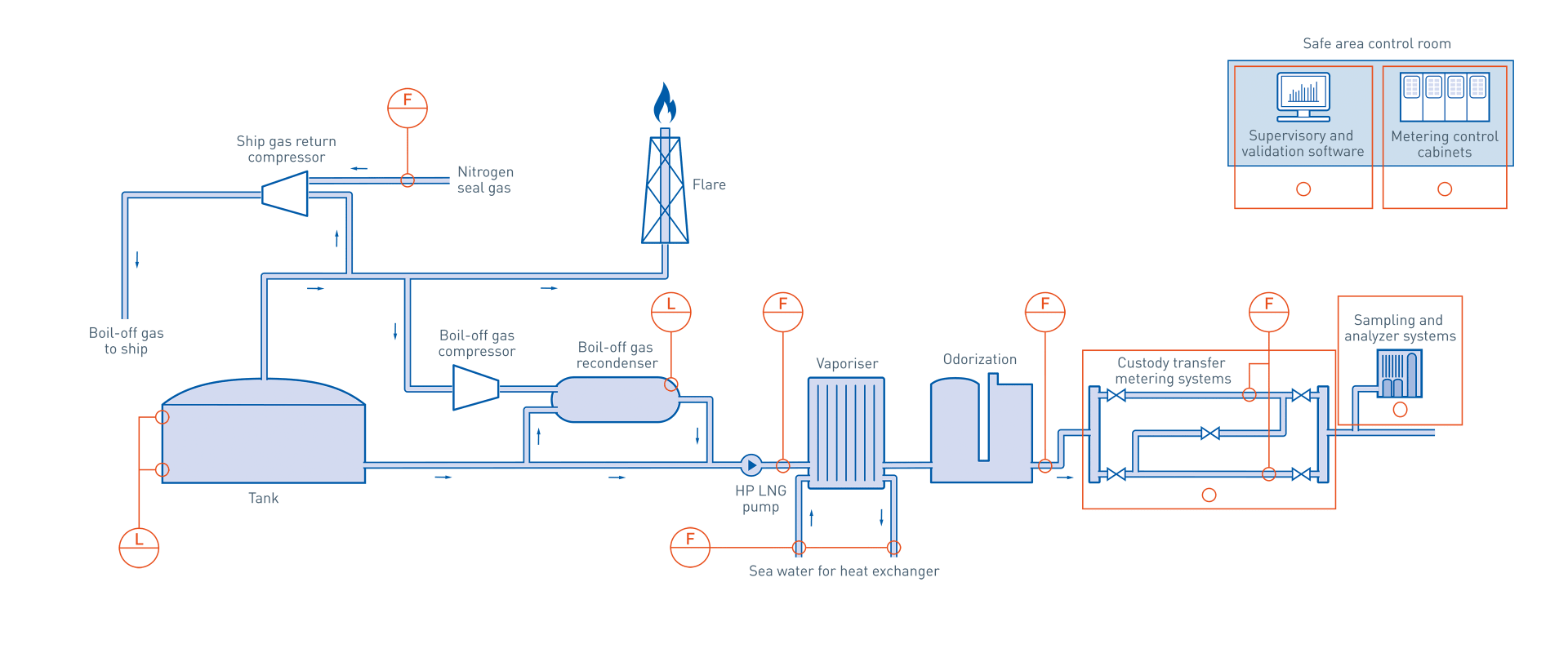

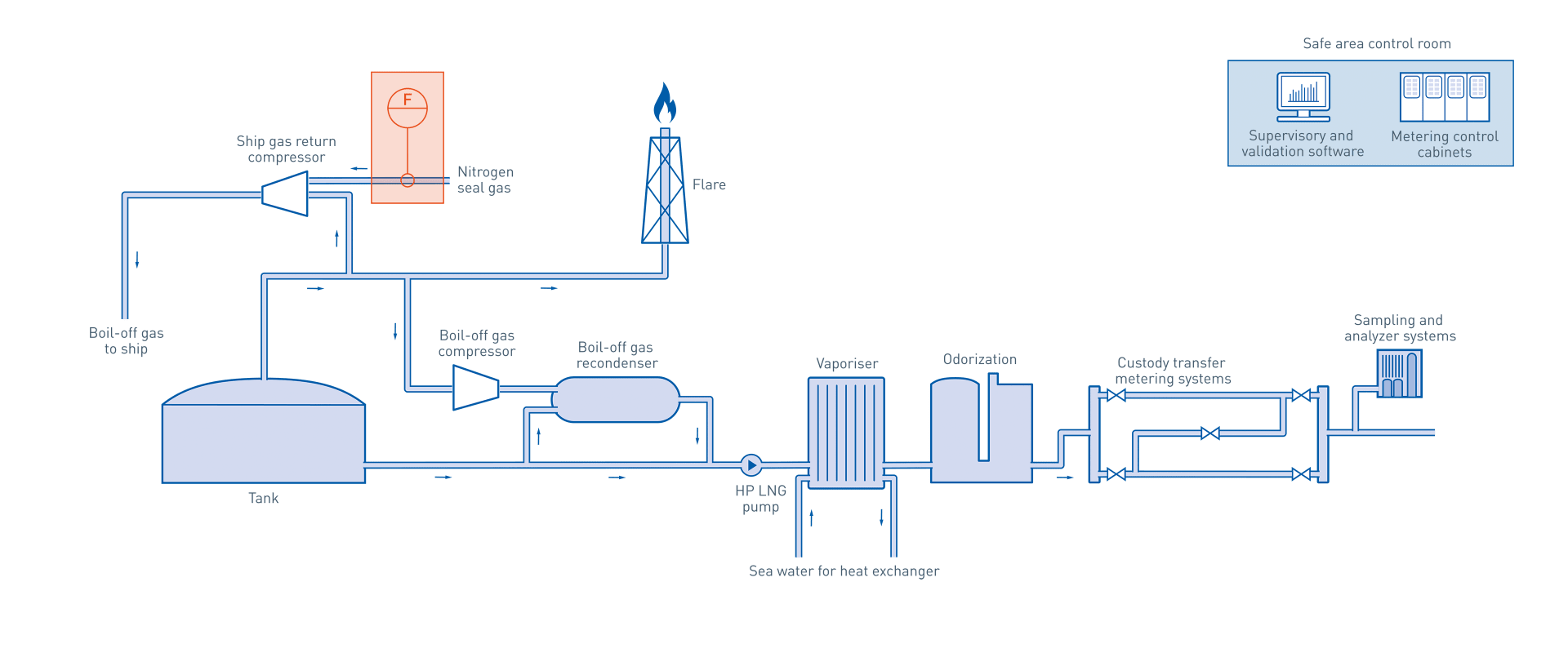

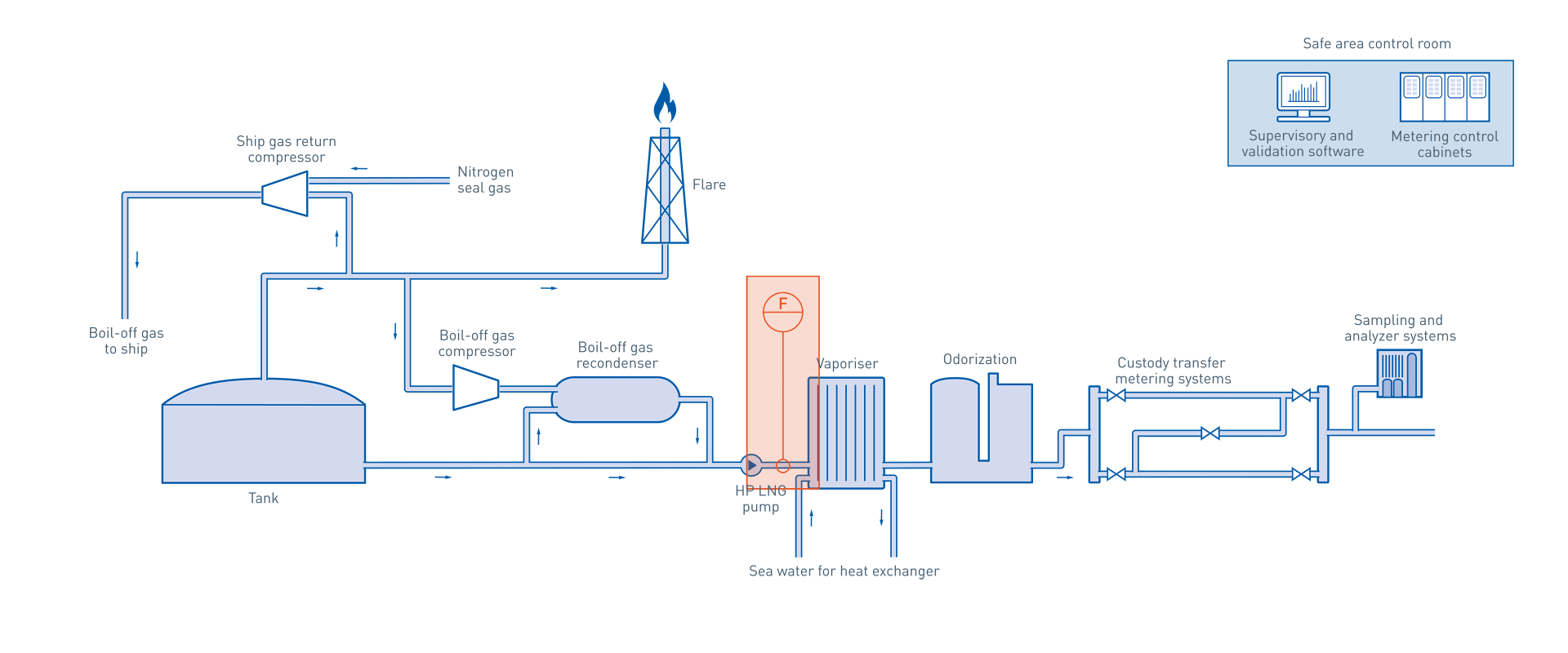

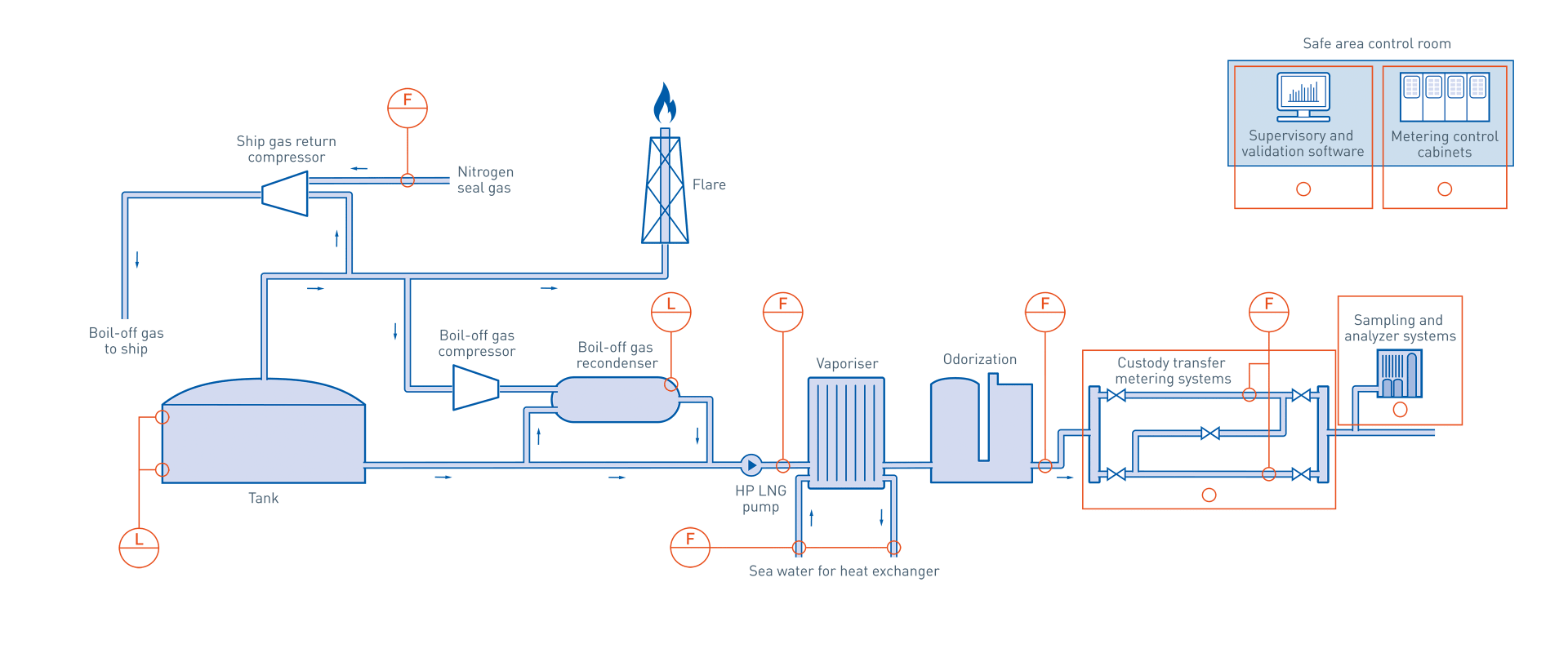

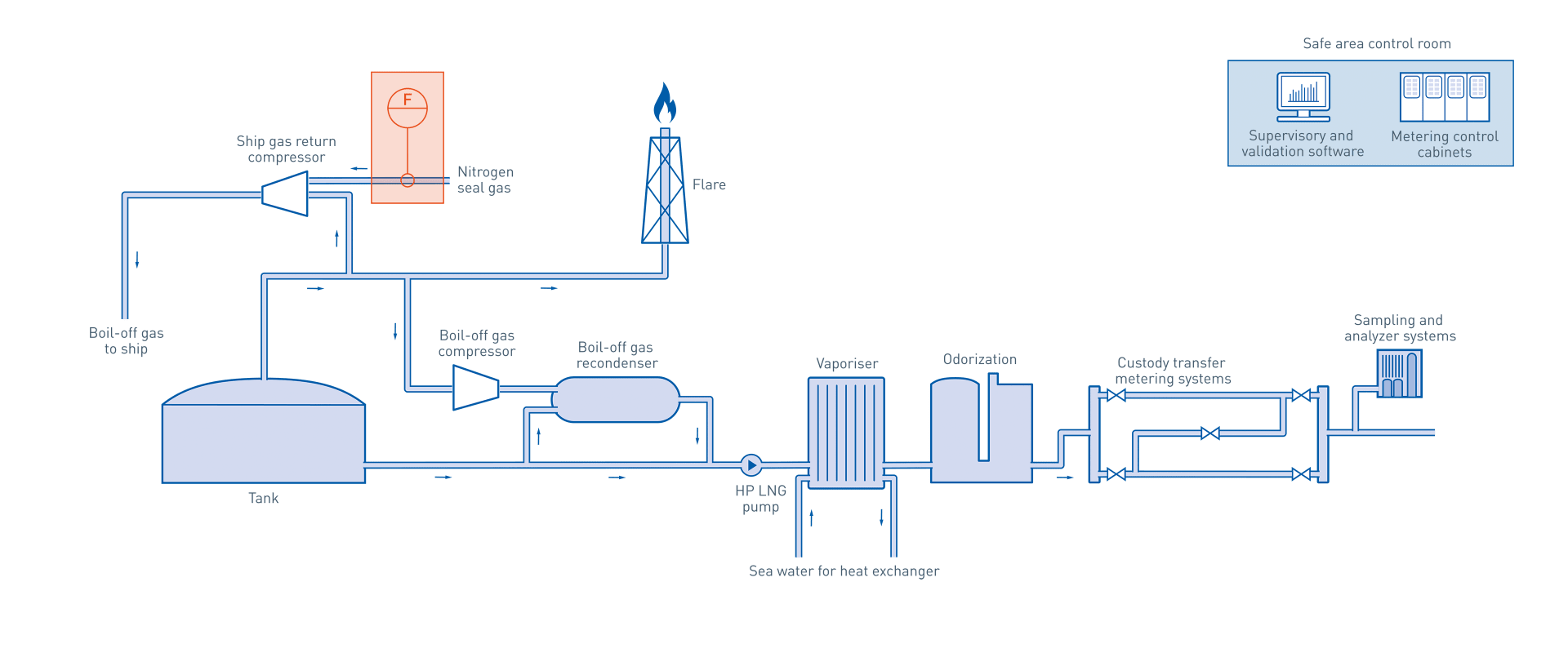

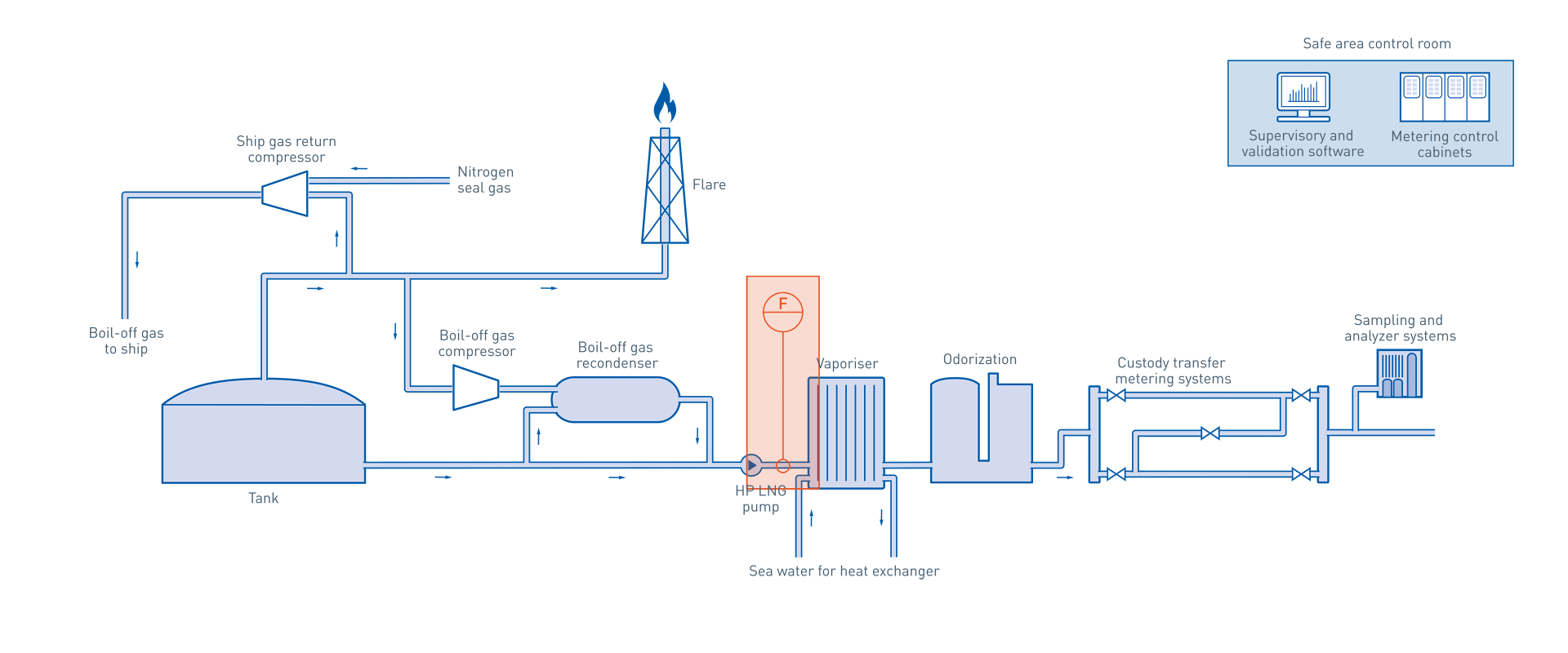

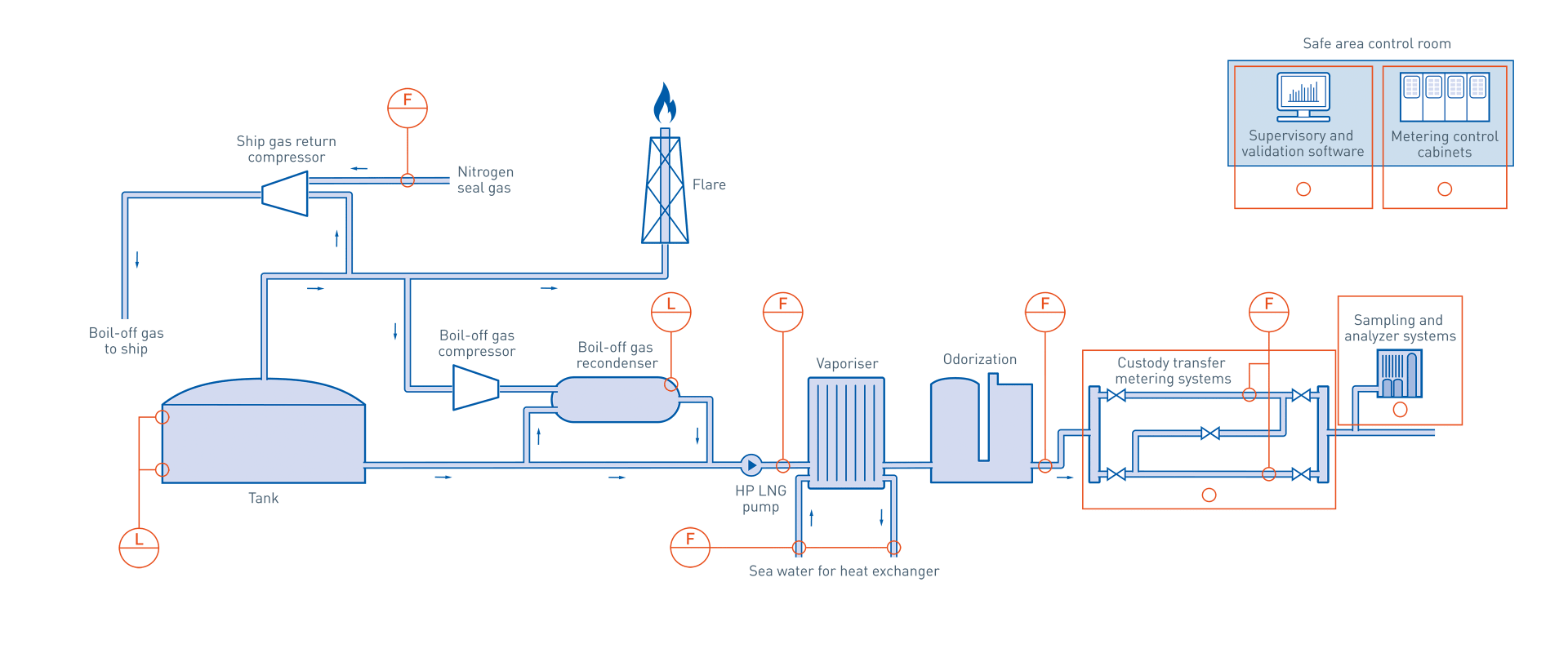

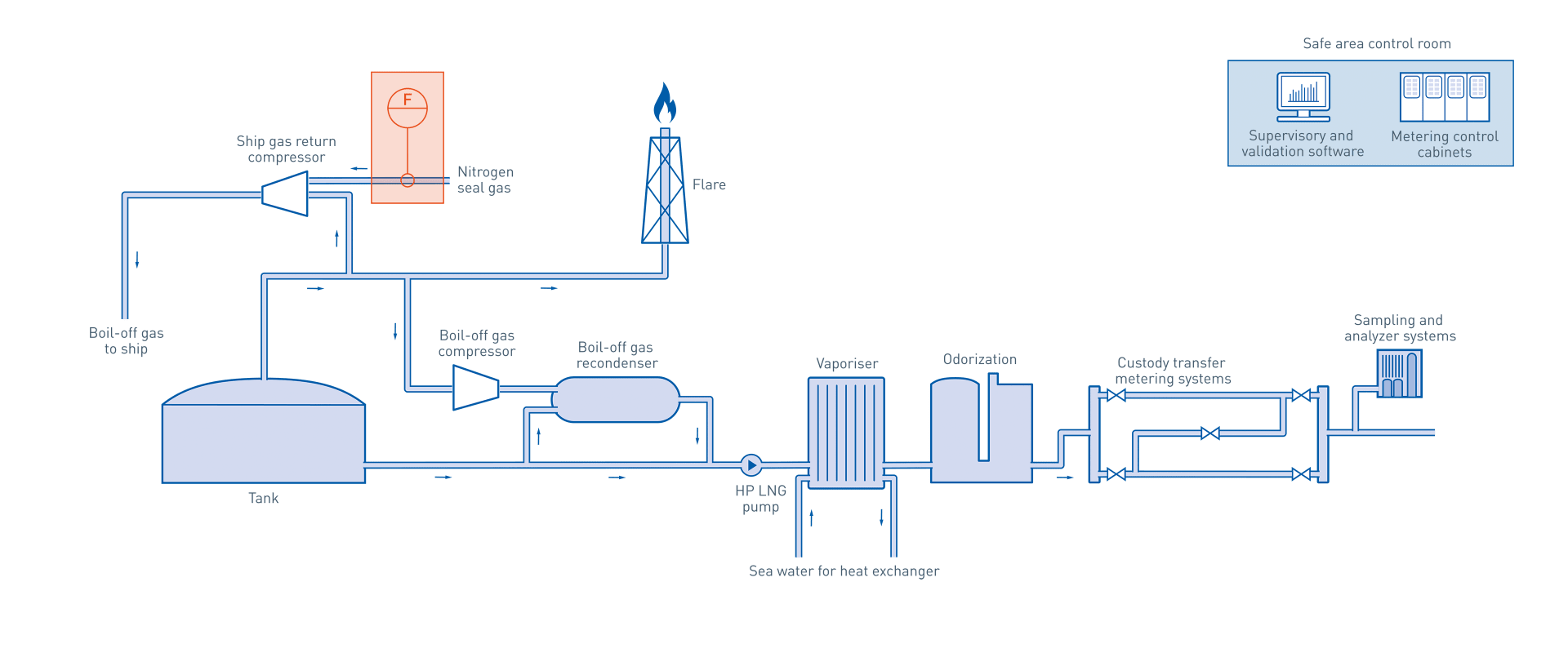

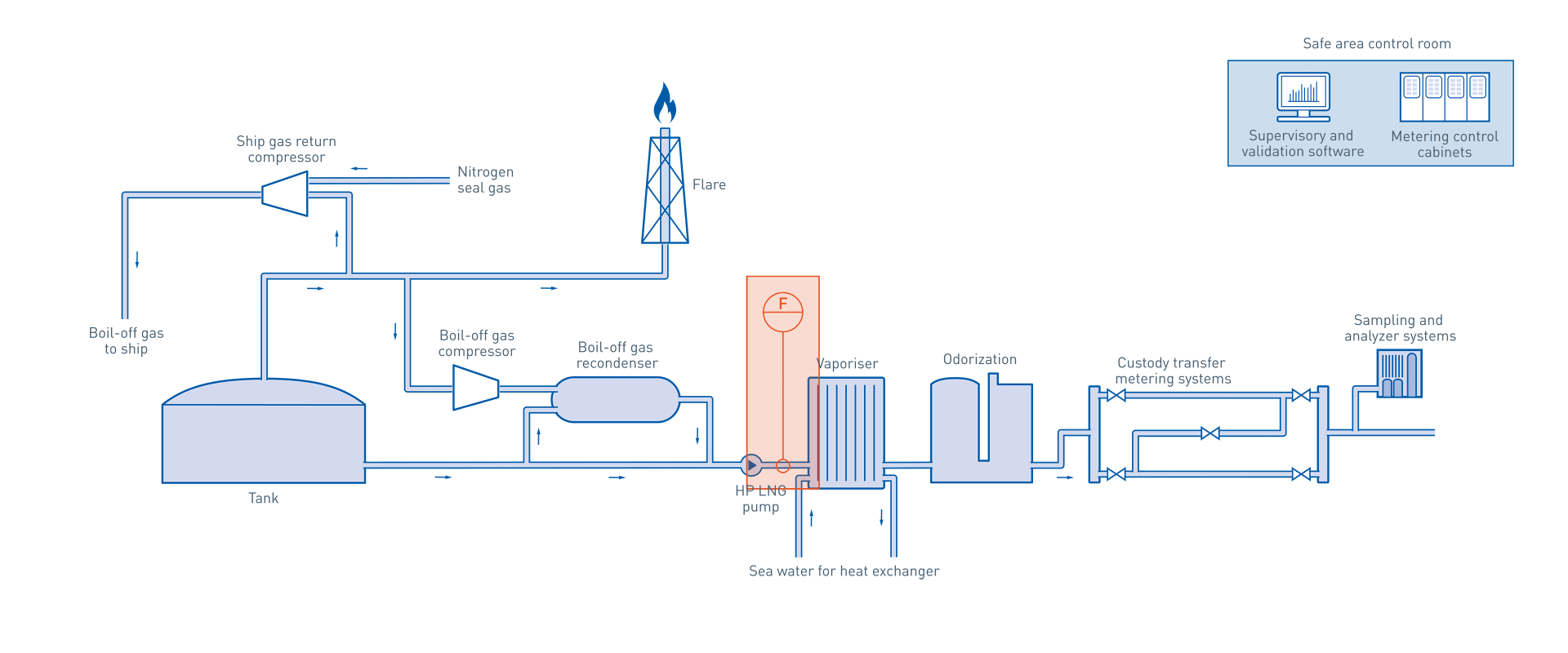

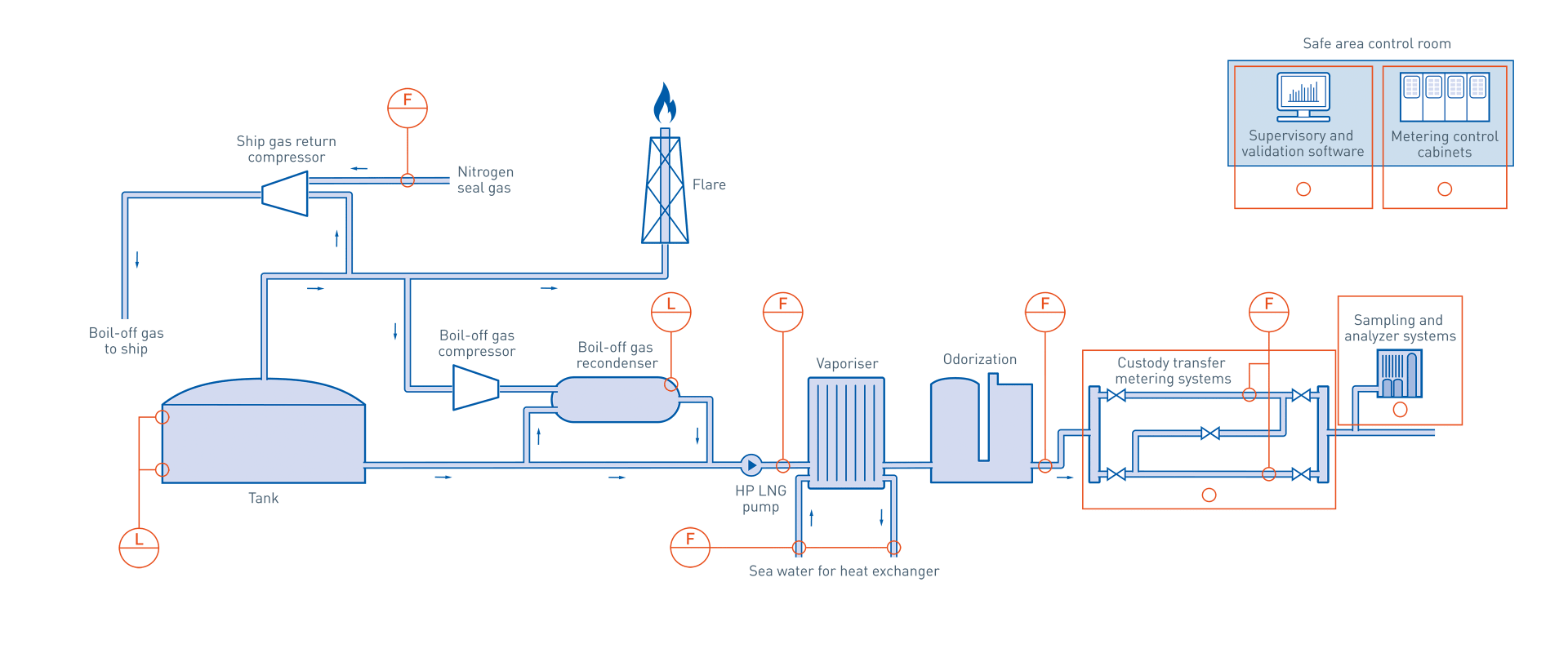

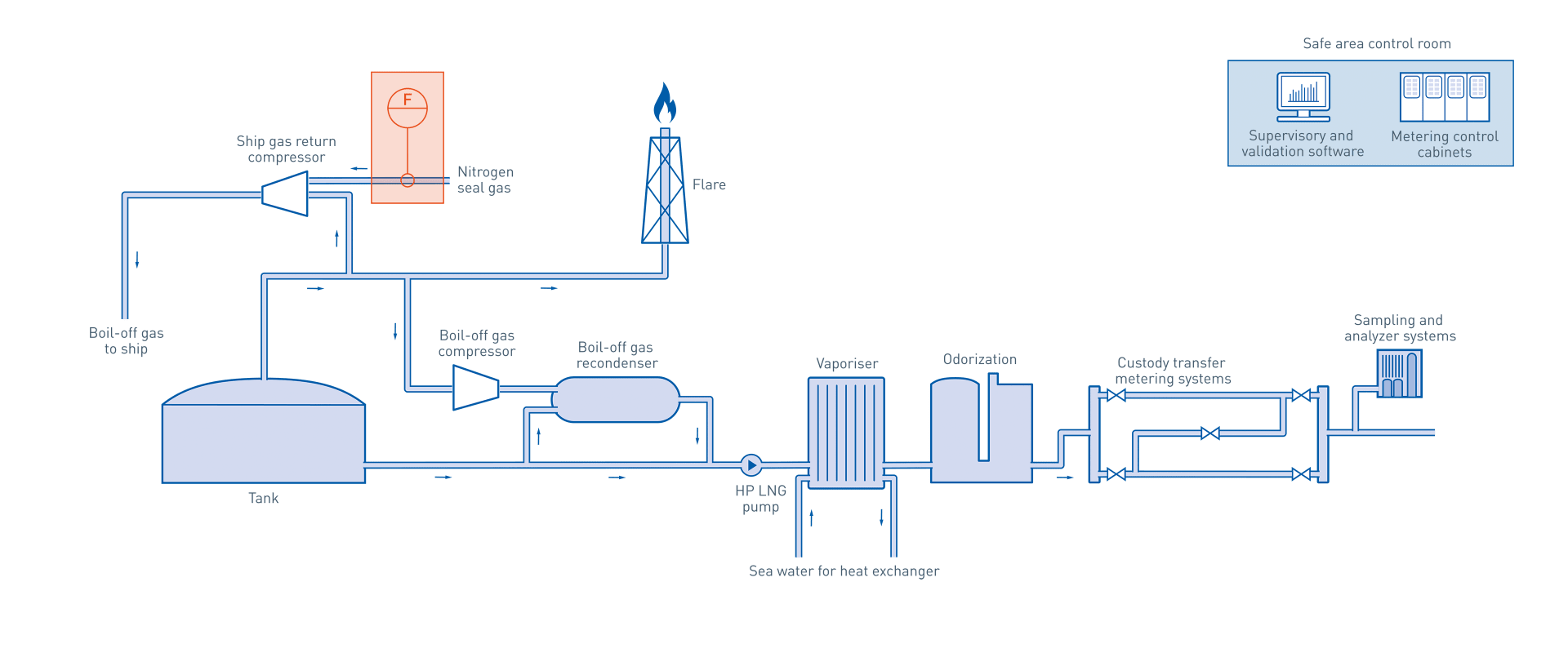

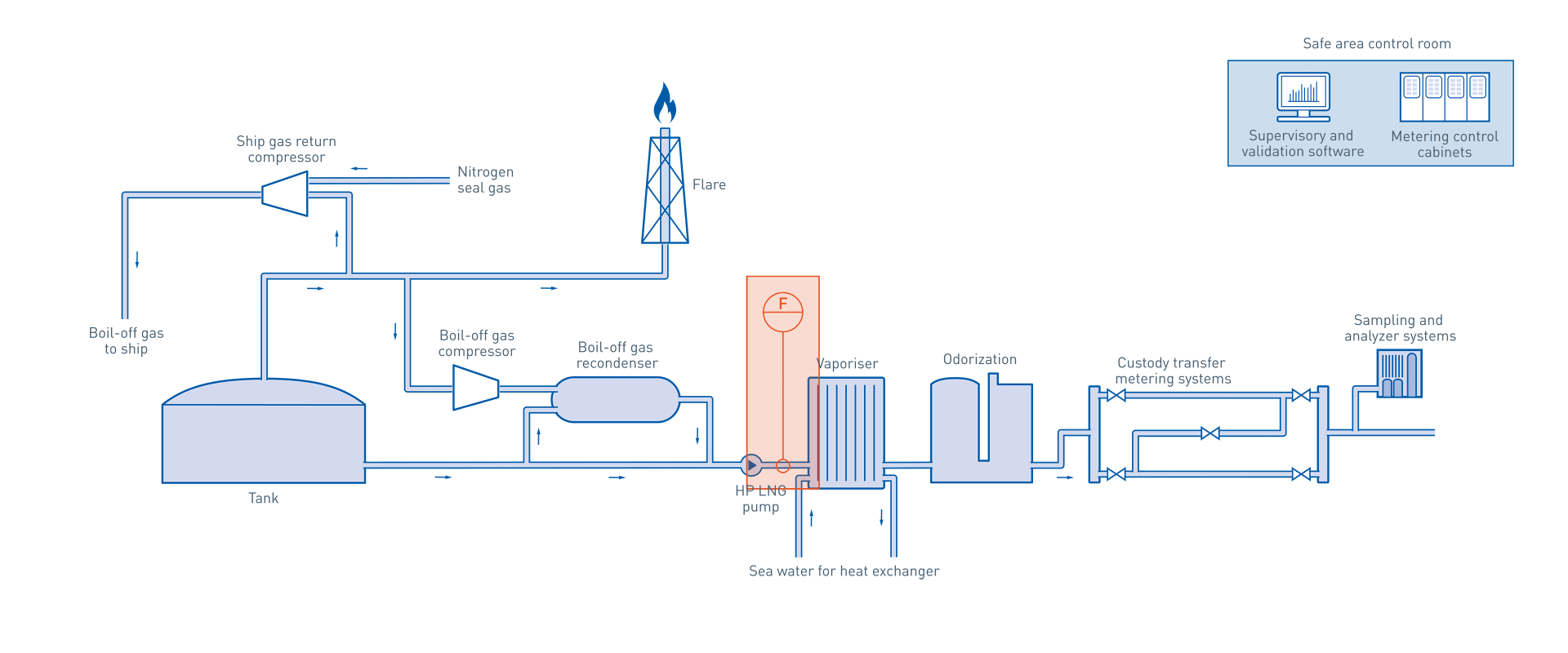

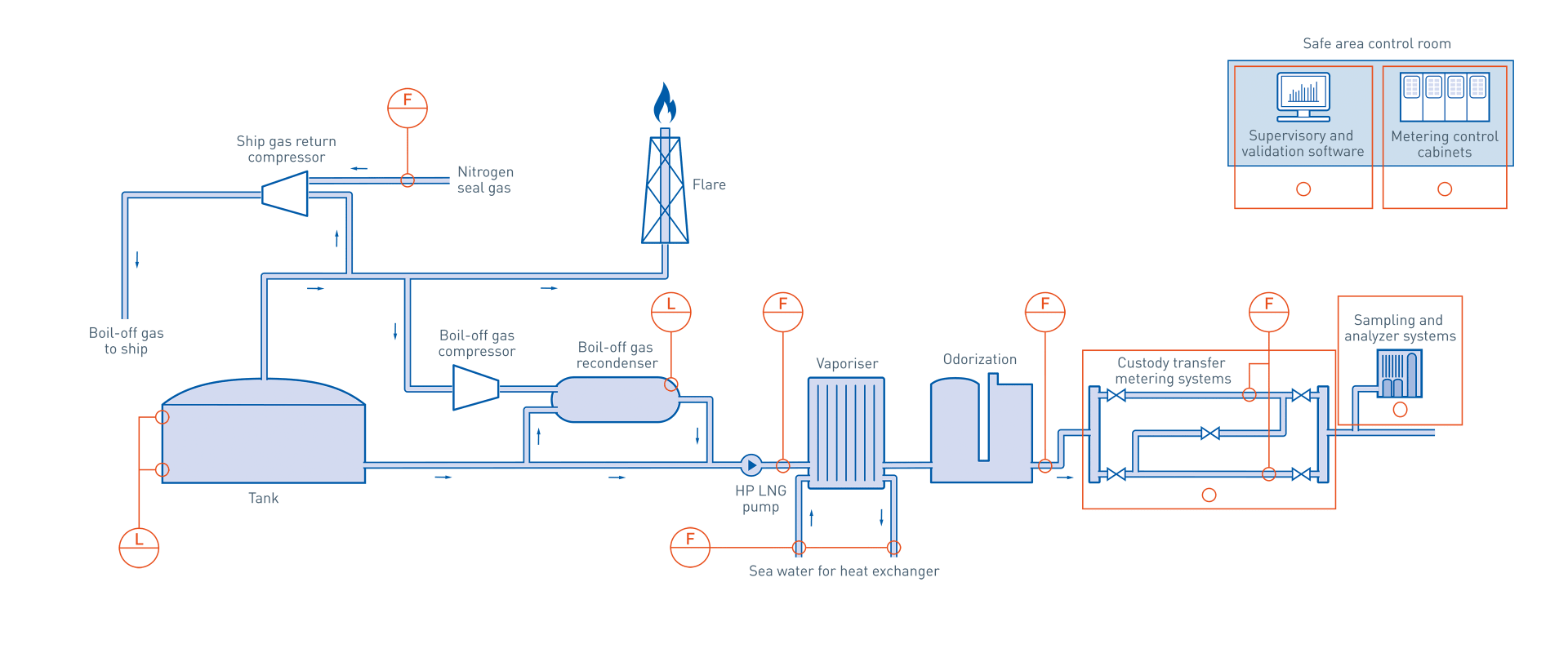

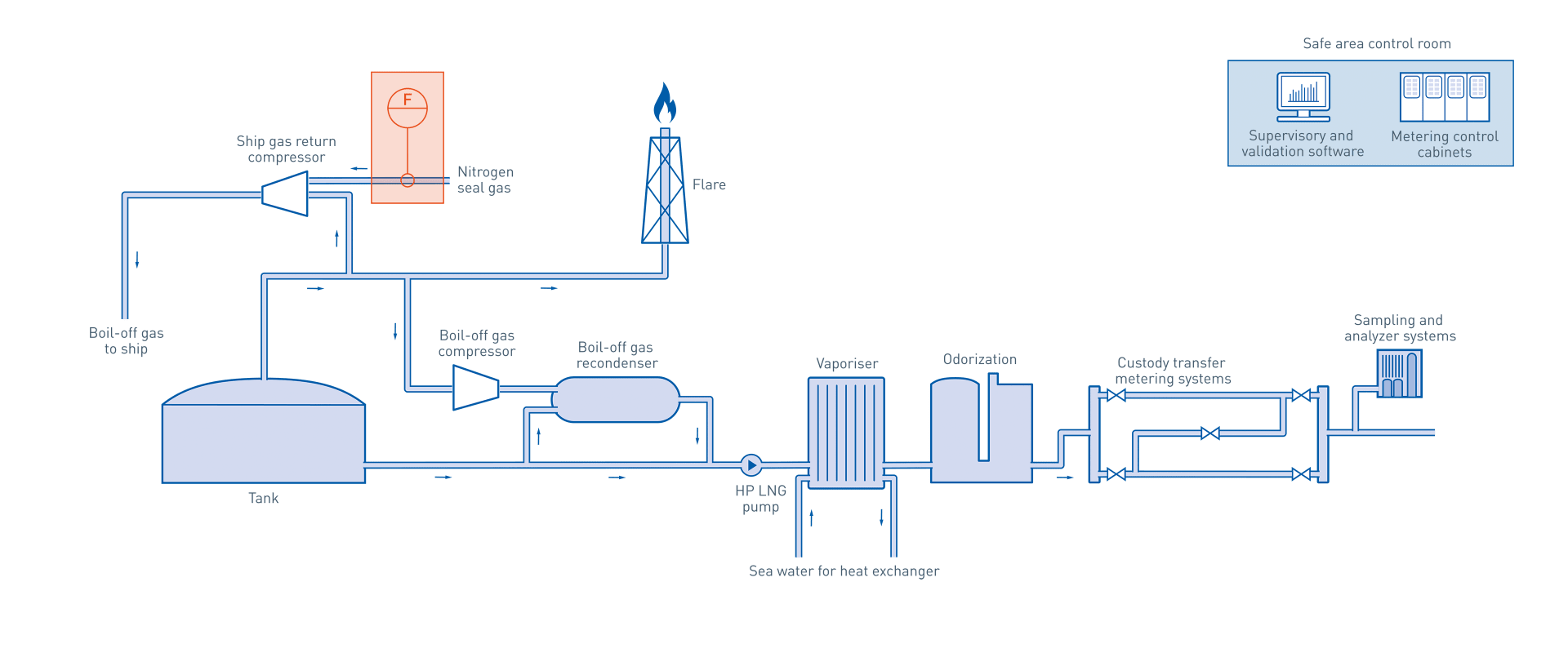

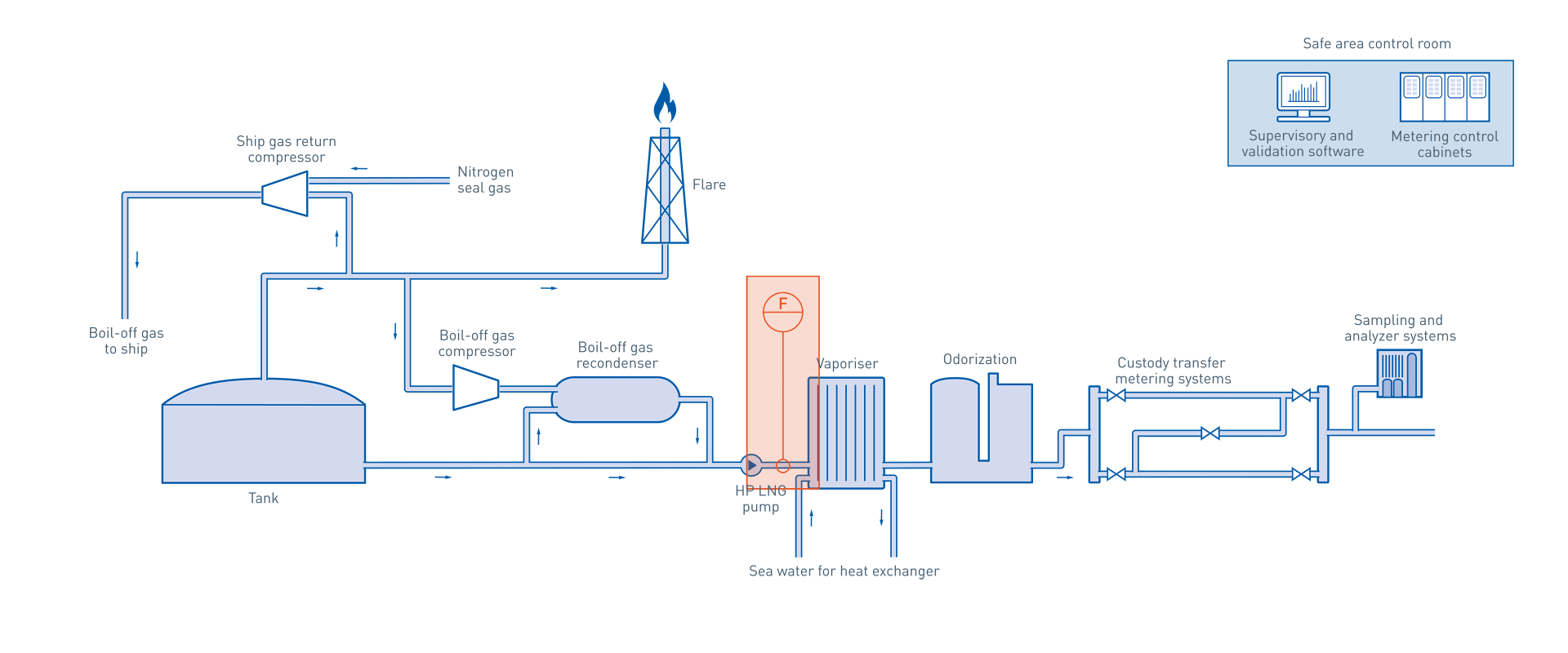

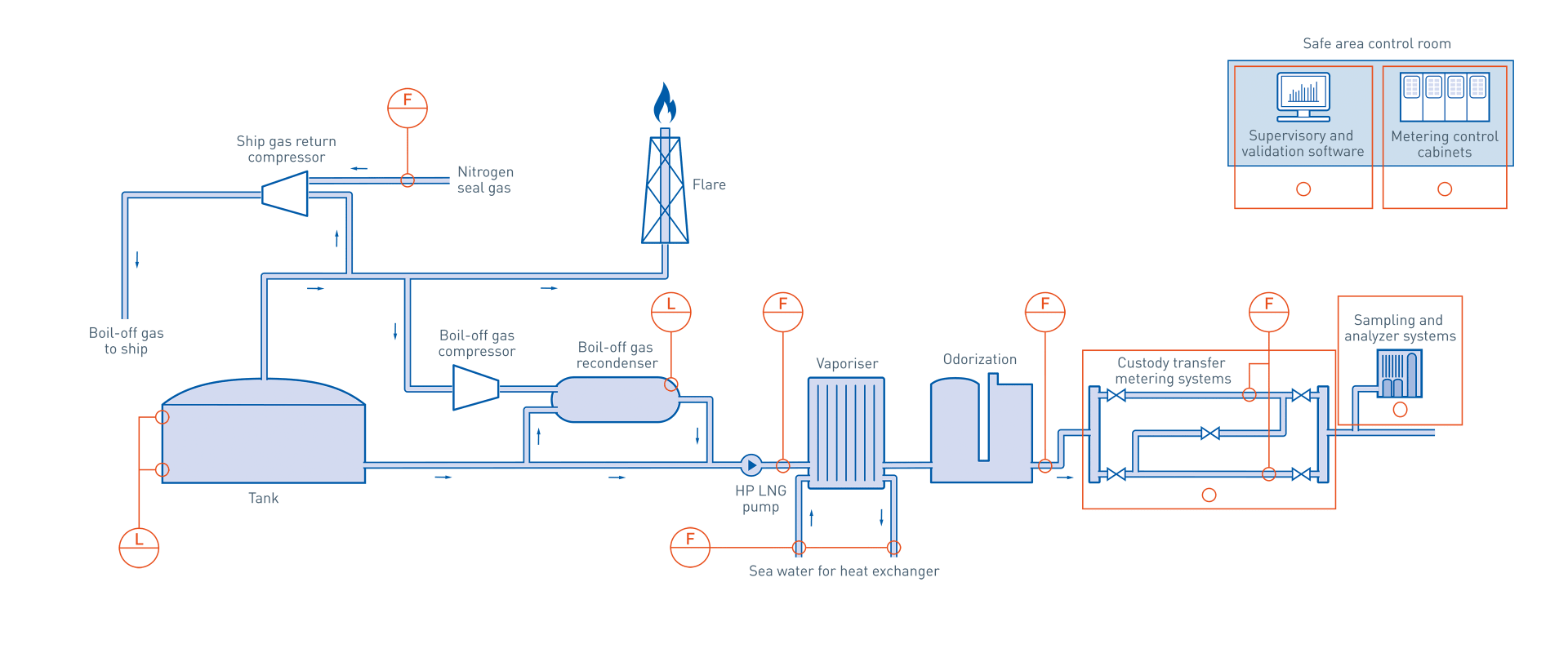

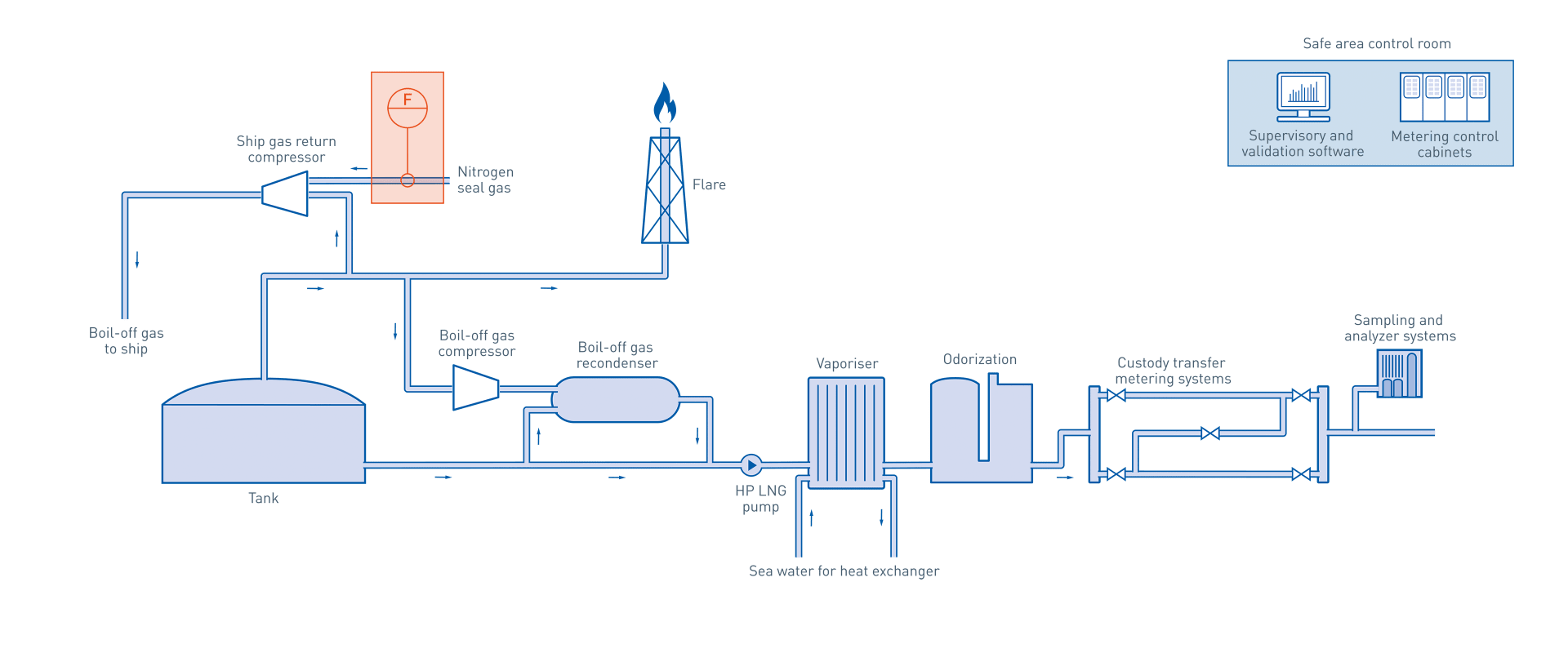

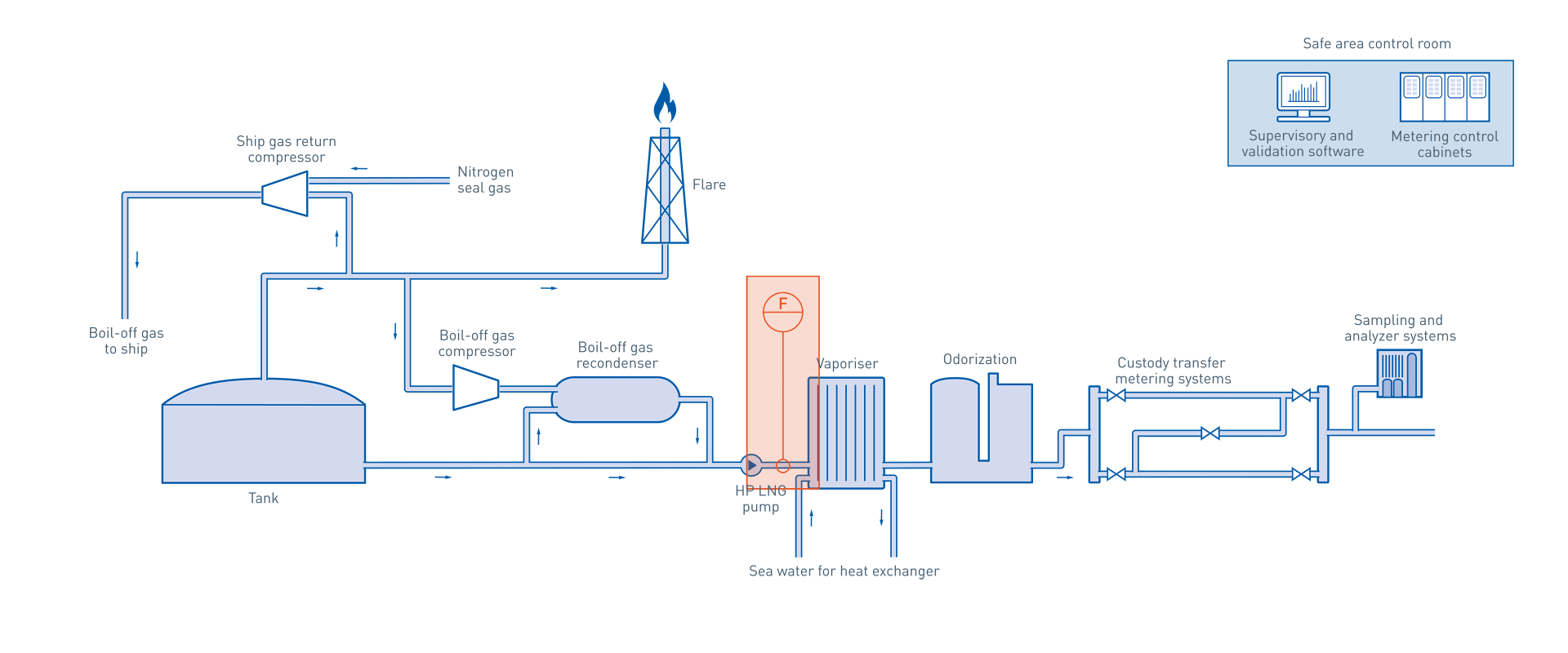

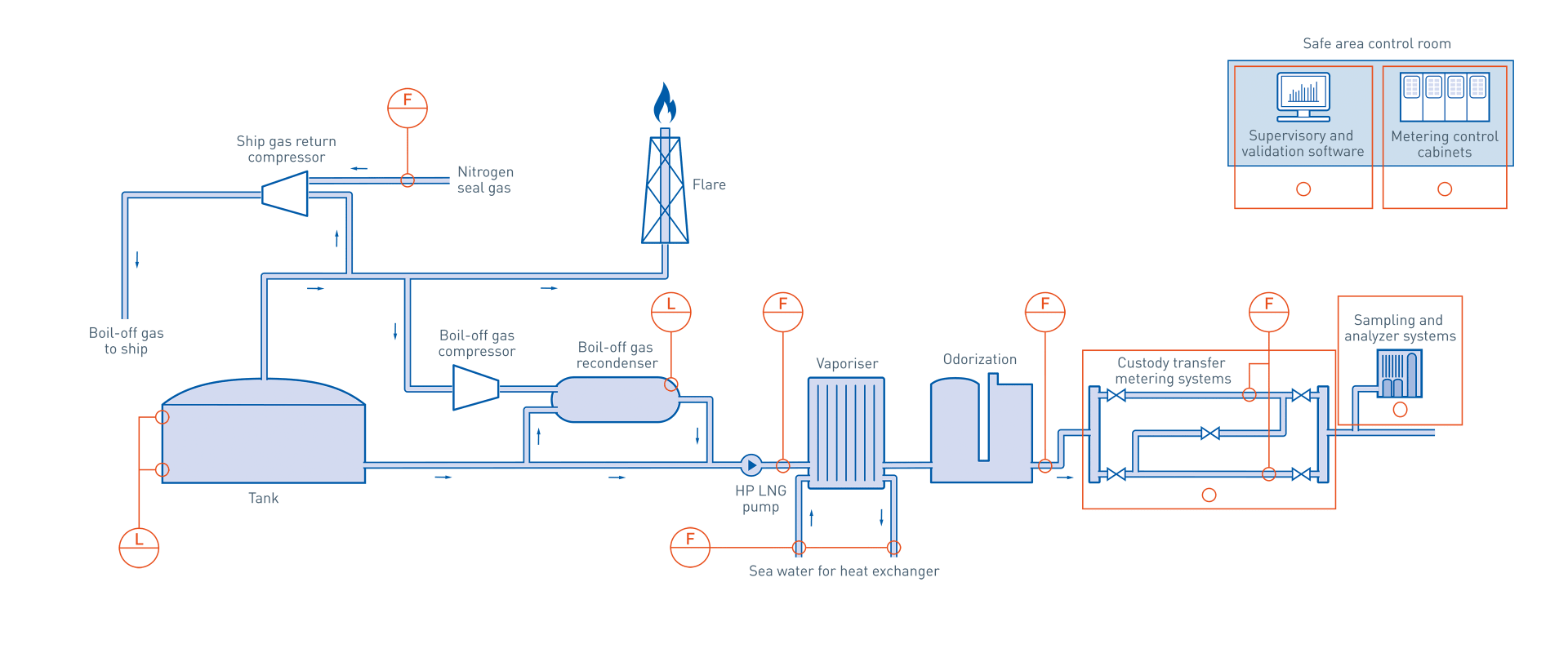

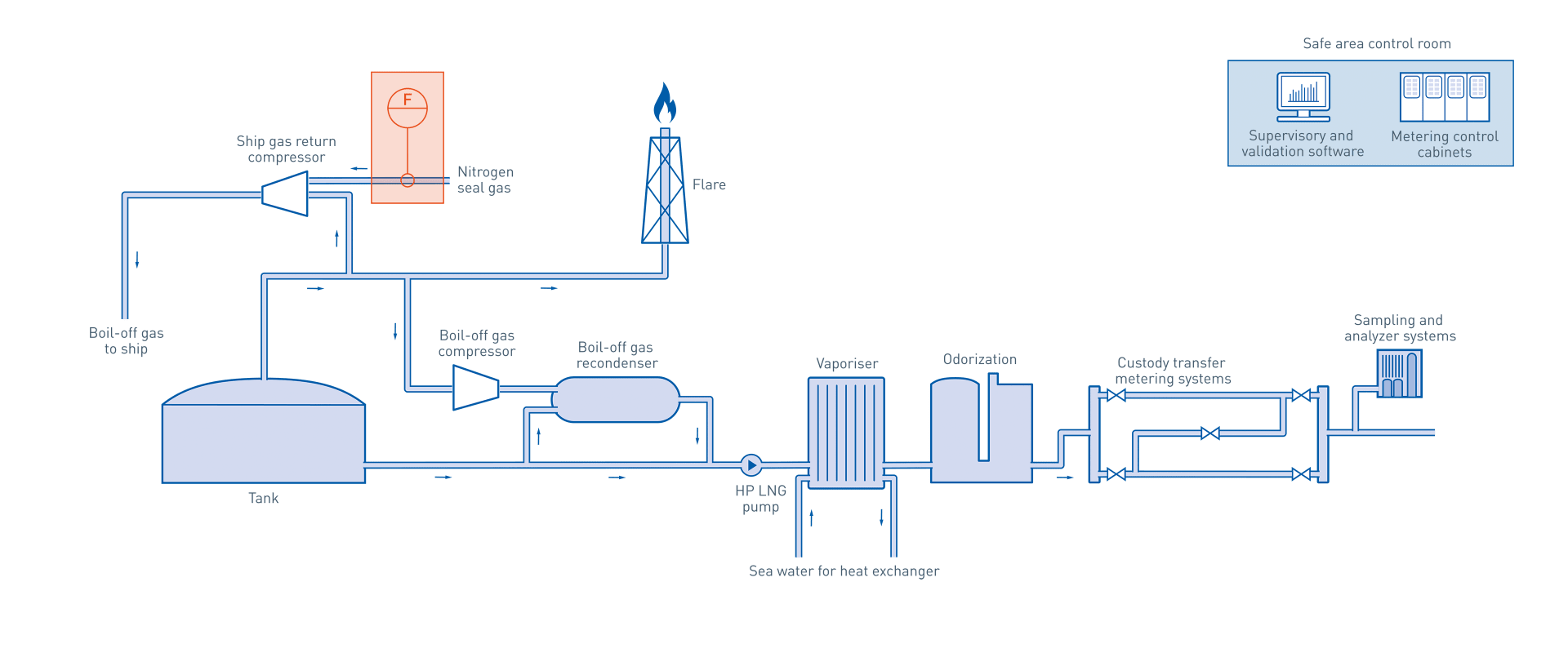

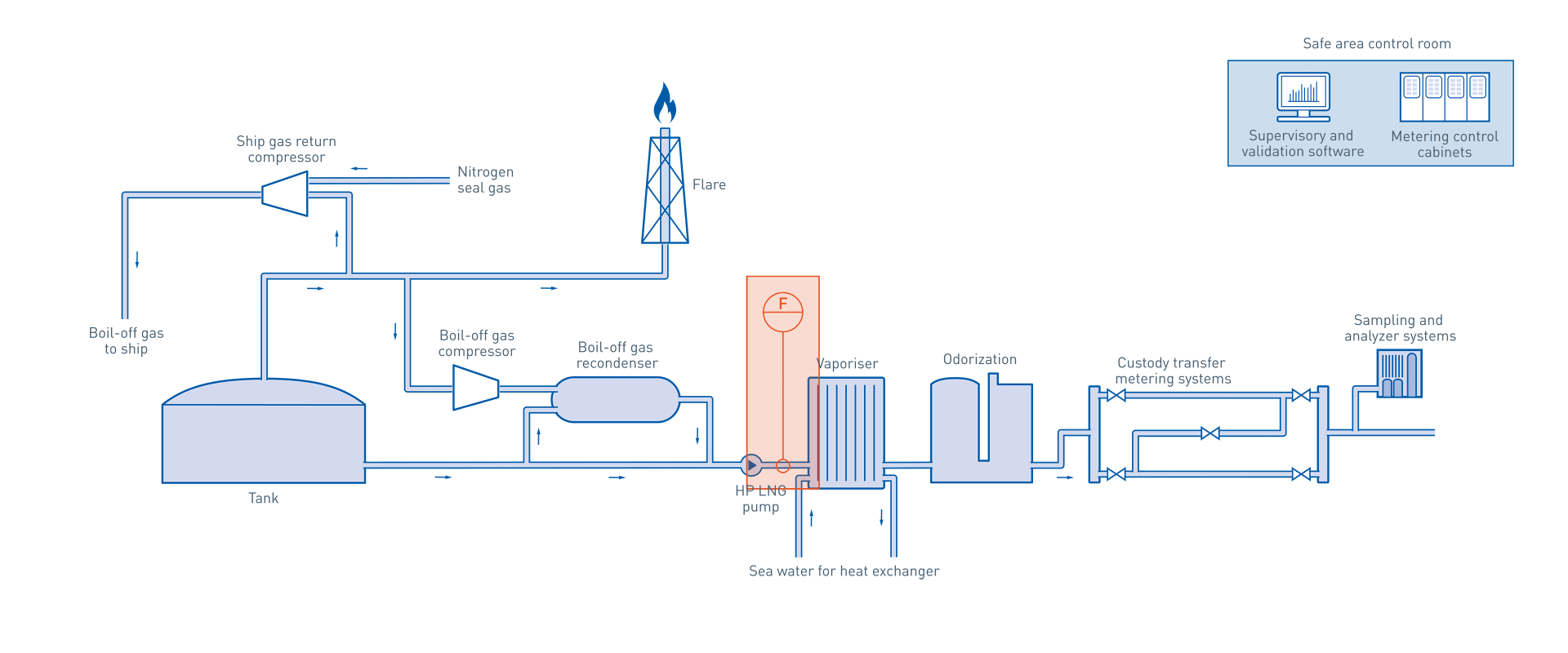

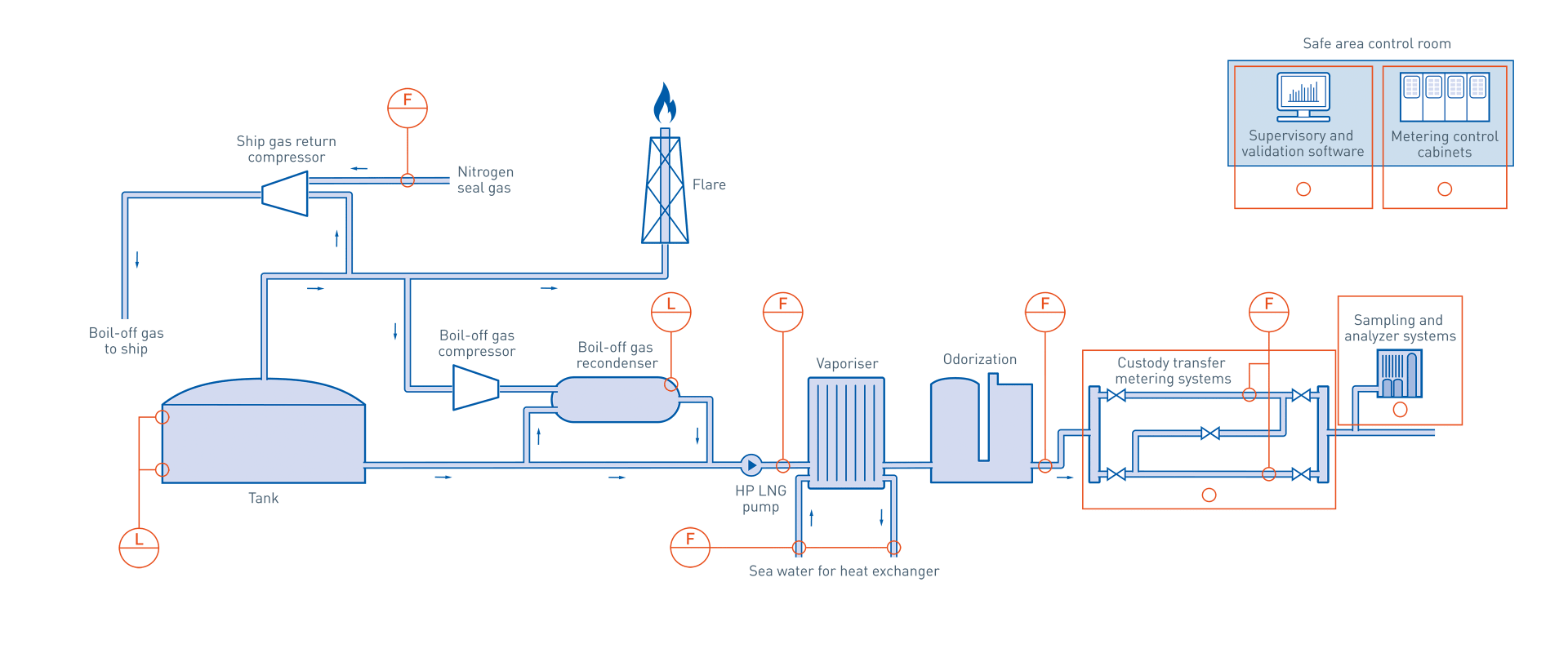

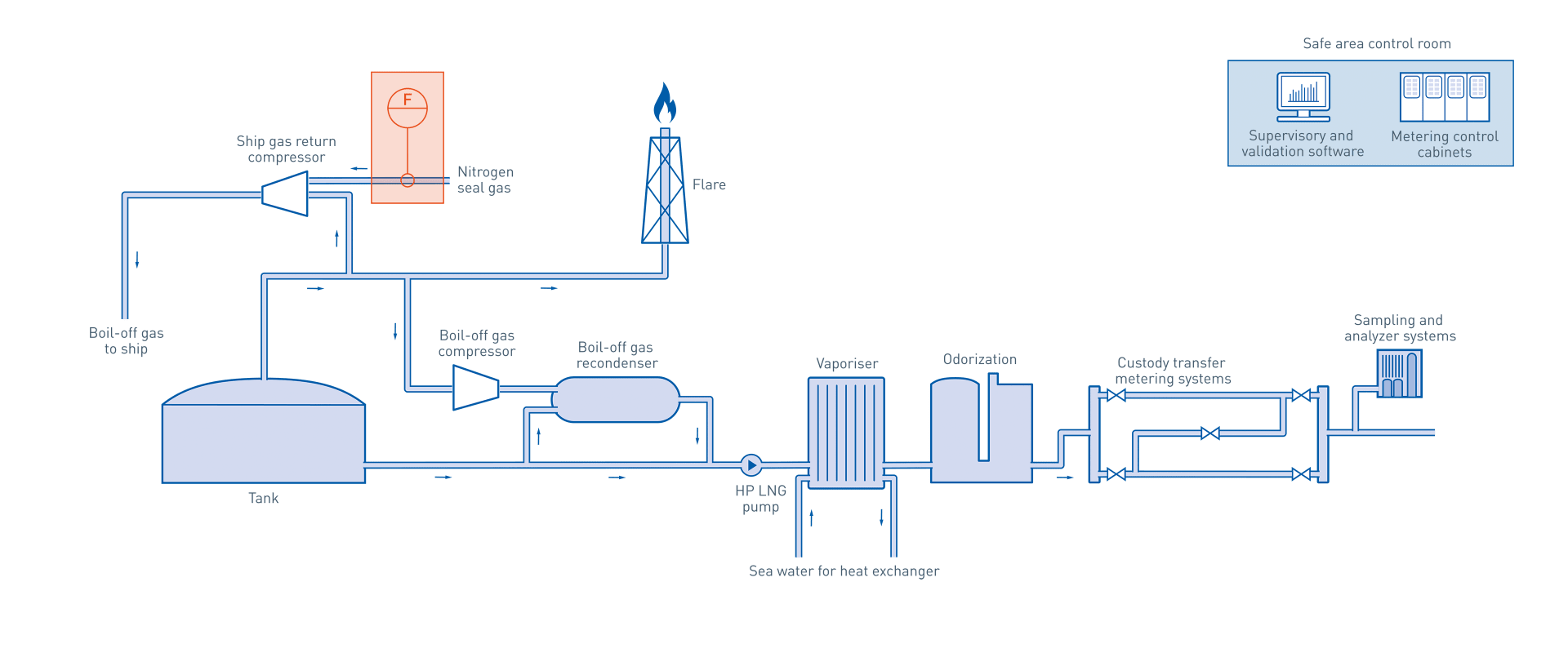

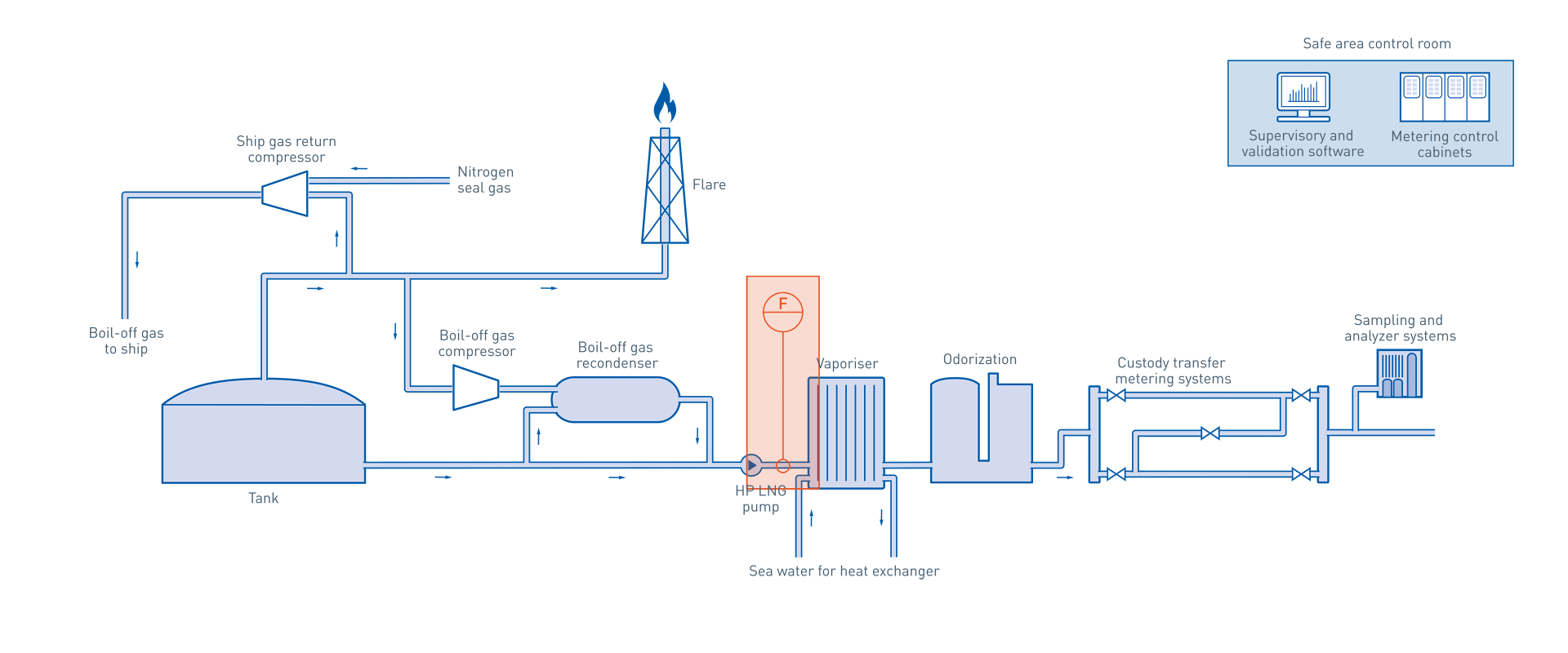

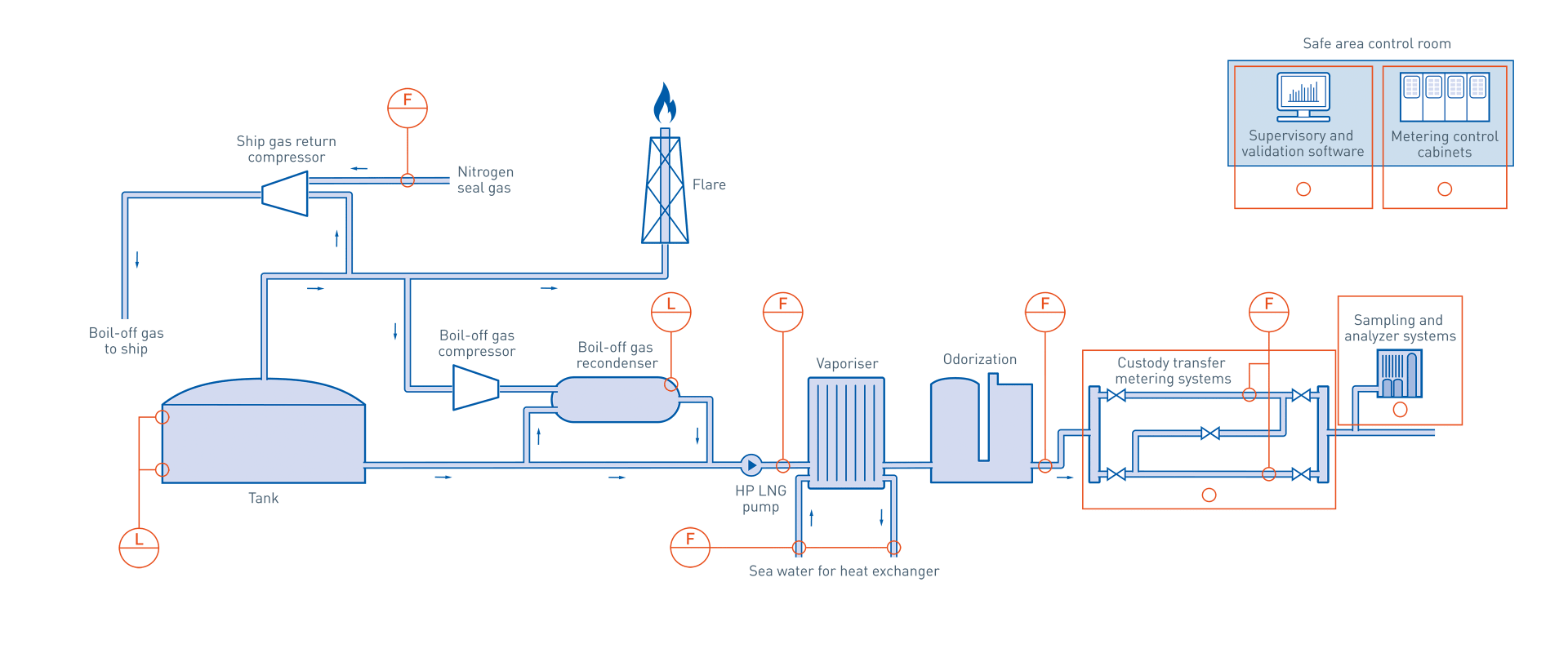

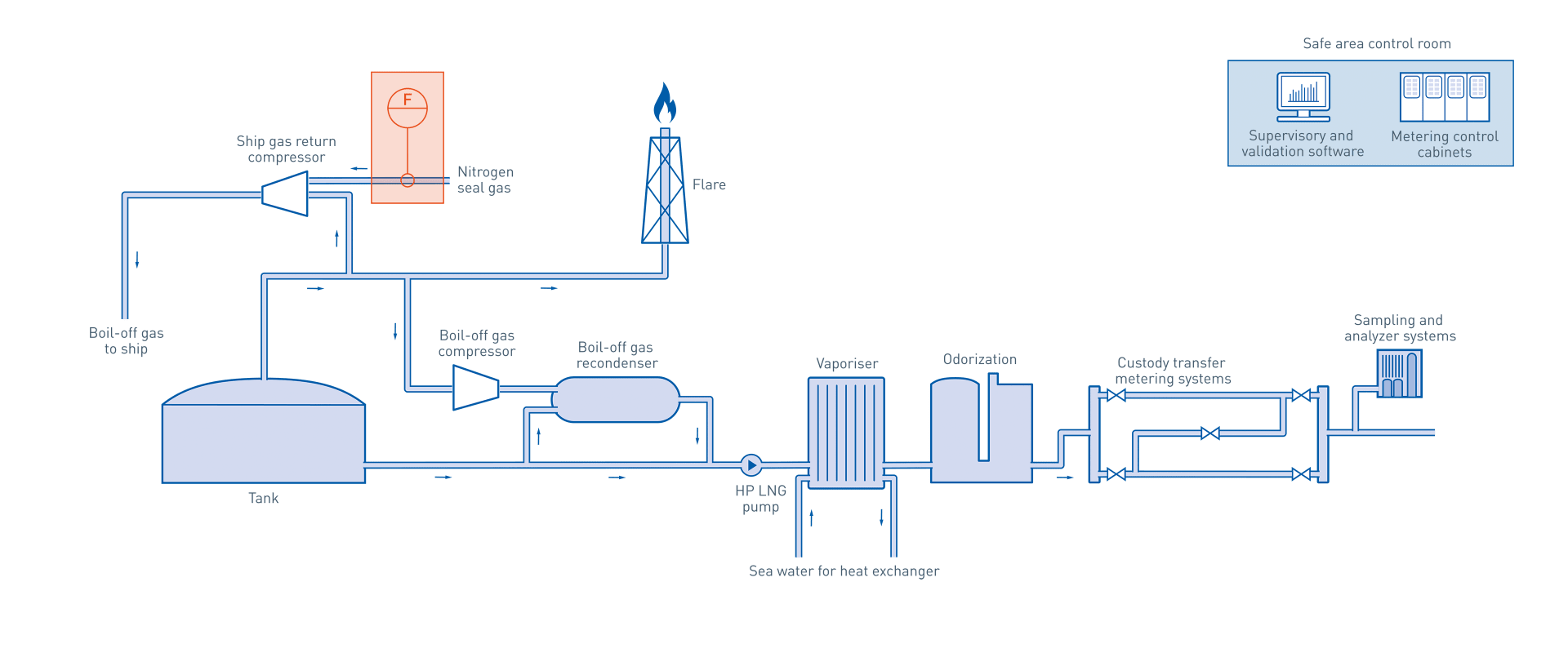

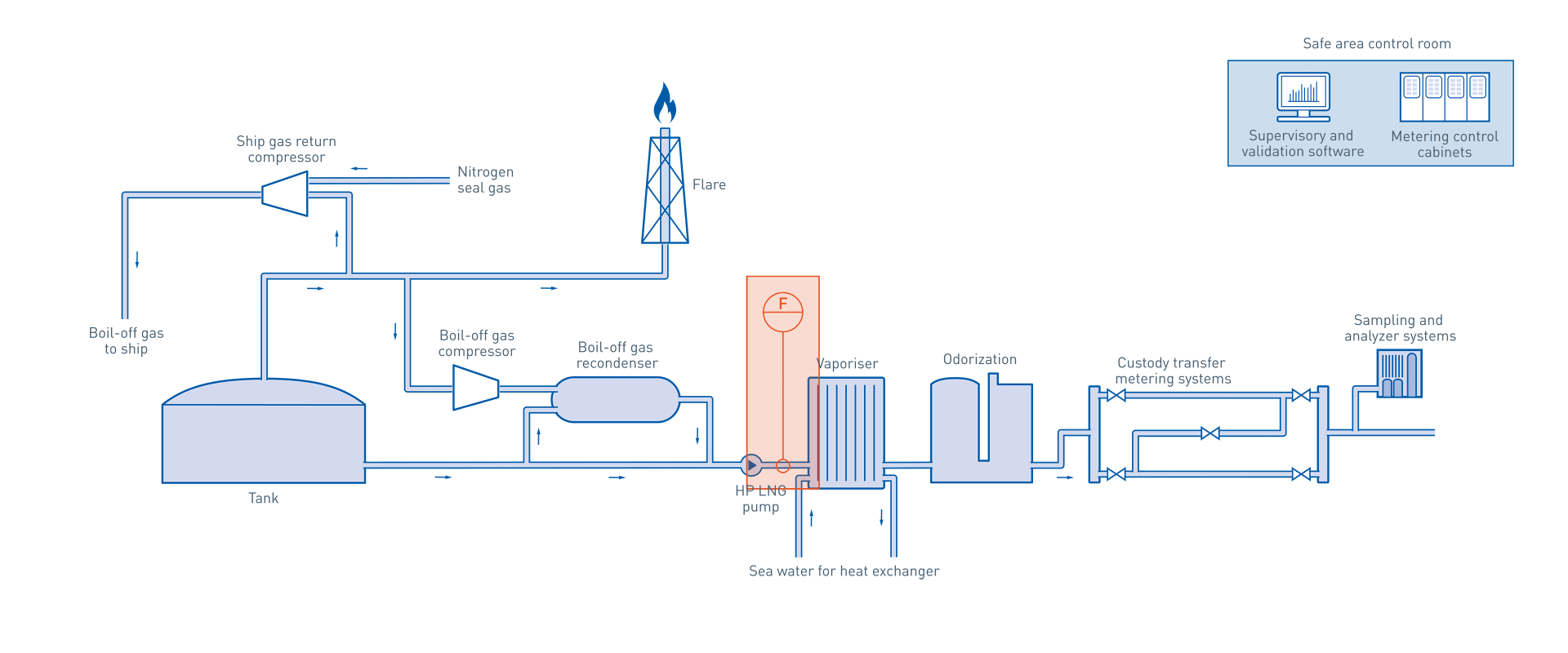

At the receiving terminal the LNG is stored within very large and extremely well insulated tanks. Custody transfer measurement systems on the delivered LNG and the boil off gas returned to the ship’s tanks to provide accurate accounting data on the received fuel into the terminal. Once the tanker has left, any boil off gas is compressed and re-liquefied in a condenser, or alternatively can be flared off, via a flowmeter.

To supply natural gas into the distribution system, for industrial and domestic use, the LNG must be heated to convert it back to a gas. Typically using the heat available from the sea-water around the terminal, the liquid LNG is evaporated in large heat exchangers fed by seawater. Then the gas frequently has some odour added, as methane has no smell. In the final process the gas is mixed with other gases, such as nitrogen, to adjust the calorific value to suit the local requirement.

On transfer into the high pressure natural gas transmission pipeline grid, the delivery is made via a custody transfer flow measurement skid, where the volume and calorific value again are measured for invoicing purposes.

KROHNE has vast experience with custody transfer and process measurements of natural gas in the gas phase, having provided many such metering installations. For LNG applications, KROHNE developed a series of ultrasonic flowmeters and Coriolis mass meters that can be installed fully insulated when used in cryogenic applications. Other KROHNE flow instrumentation is used in regasification plants to measure process gas flows, heat exchanger seawater flows, nitrogen seal gas flow on compressors, and LNG level control.

Process details

Regasification in the oil & gas industry

Requirements:

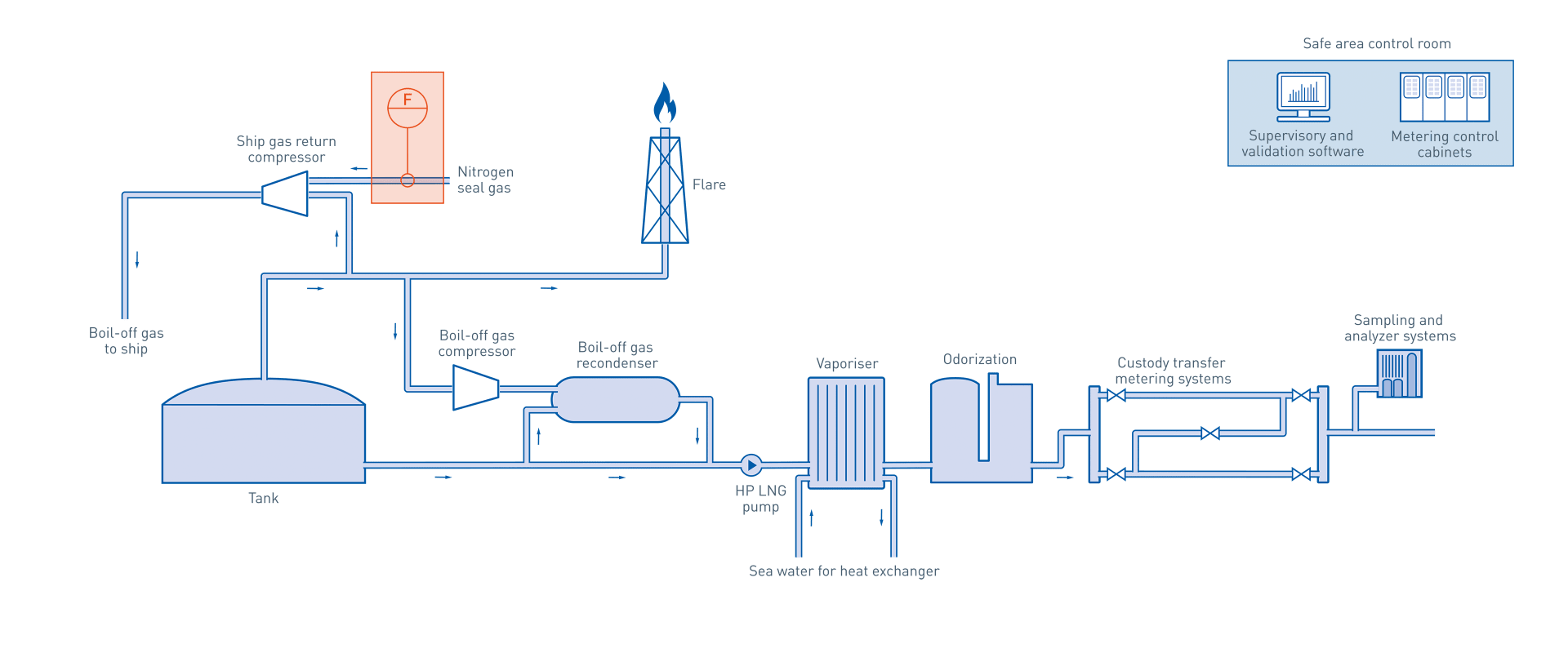

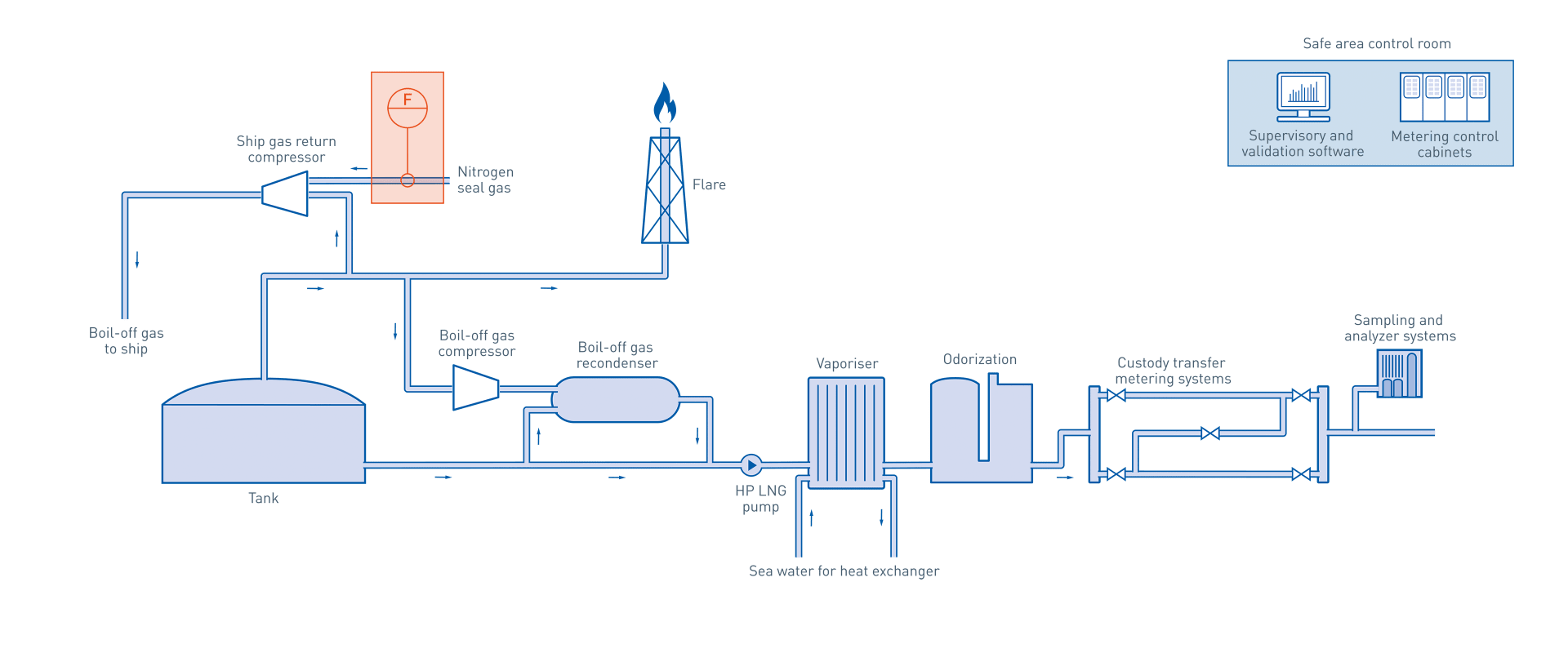

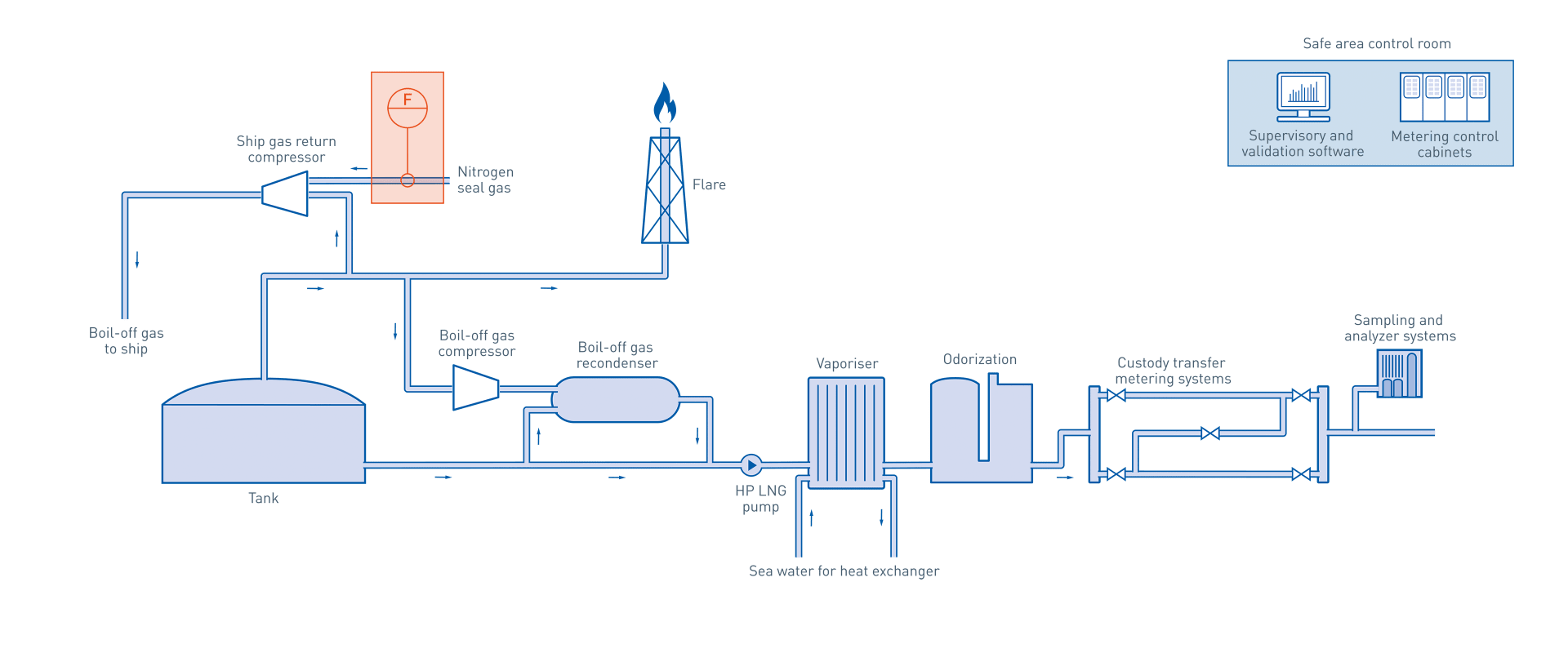

- Recognize leaks and defective seals quickly to prevent compressor damage

- Indication of the flow

Recommended products and solutions:

H250 M40

- Modular design: from mechanical indicator to 4…20 mA/HART®7, FF, Profibus-PA and totalizer

- Any installation position: vertical, horizontal or in fall pipes

- Flange: DN15…150 / ½…6"; also NPT, G, hygienic connections, etc.

- -196…+400°C / -320…+752°F; max. 1000 barg / 14500 psig

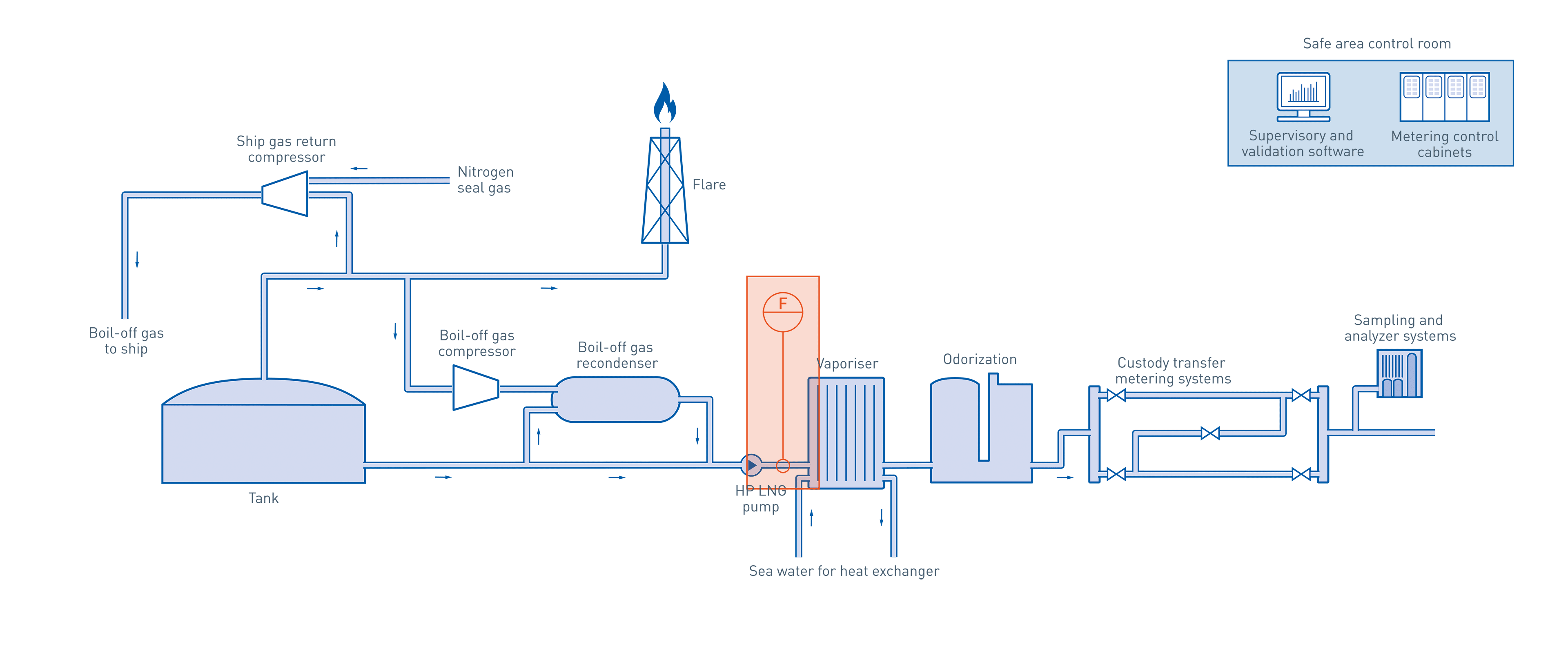

Requirements:

- Measurement of sea water for process control

- Energy balance of heat exchange process

Recommended products and solutions:

OPTISONIC 6300

- Stationary device, for installation at any location without process interruption or need to cut pipes

- Up to +200°C / +392°F

- Robust stainless steel sensor rail for pipes DN15…4000 / ½…160"

- 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP

OPTIFLUX 4000

- Full bore design: pipe cross-section without restrictions

- Connection sizes: DN2.5…3000 / ⅒…120" (depending on signal converter)

- Liner: PTFE, PFA, ETFE, PU, hard and soft rubber

OPTIFLUX 2000

- Full bore design: pipe cross-section without restrictions

- Connection sizes: DN25…1200 / 1…48"

- Liner: PP, PO or hard rubber

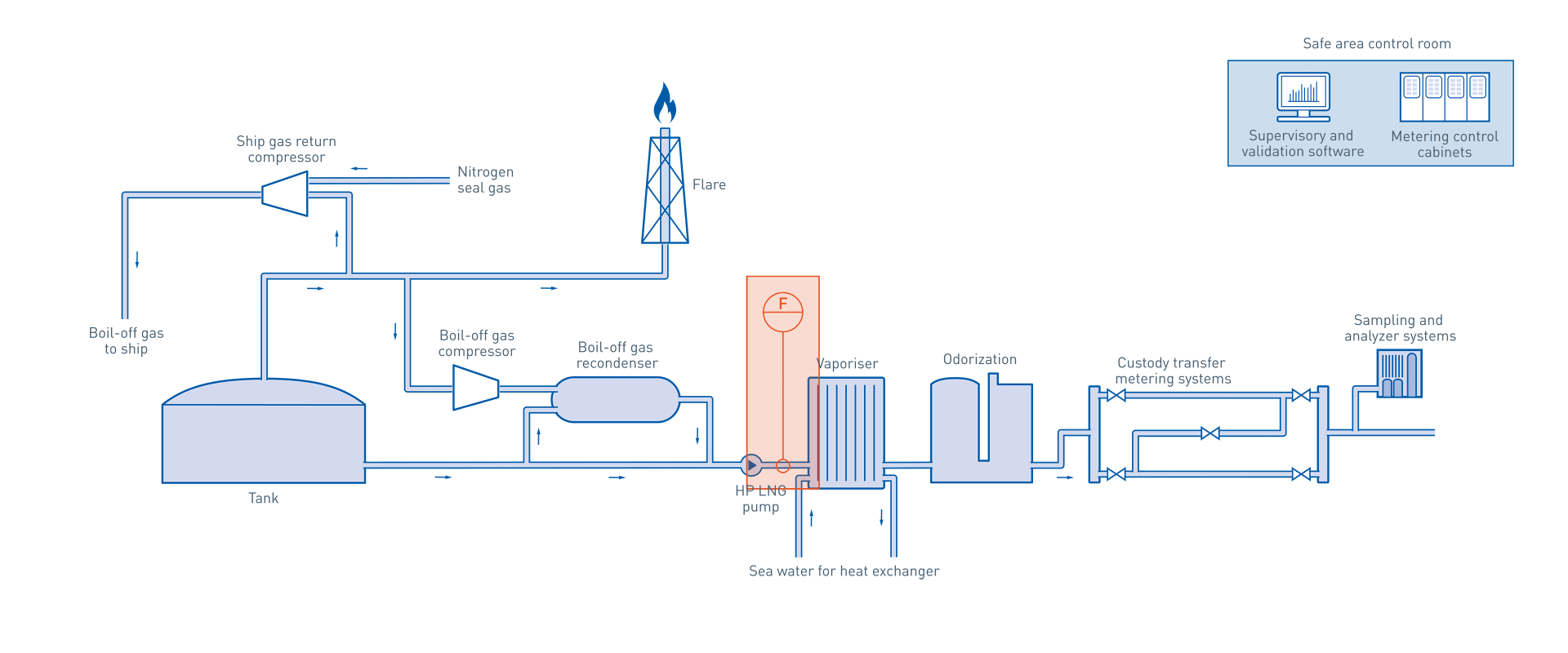

Requirements:

- Level measurement of gas and liquid in cryogenic conditions

- Cryogenic temperatures (<-162°C)

Recommended products and solutions:

BM 26 F2200

- Continuous, redundant measurement using two measurement principles in one device

- Measuring range: 0.3…5.5 / 1…18 ft (longer on request)

- Density: 0.5…3 kg/l / 31…187 lb/ft3

- -50…+300°C / -58…+570°F; -1…100 barg / -14.5…1450 psig

Requirements:

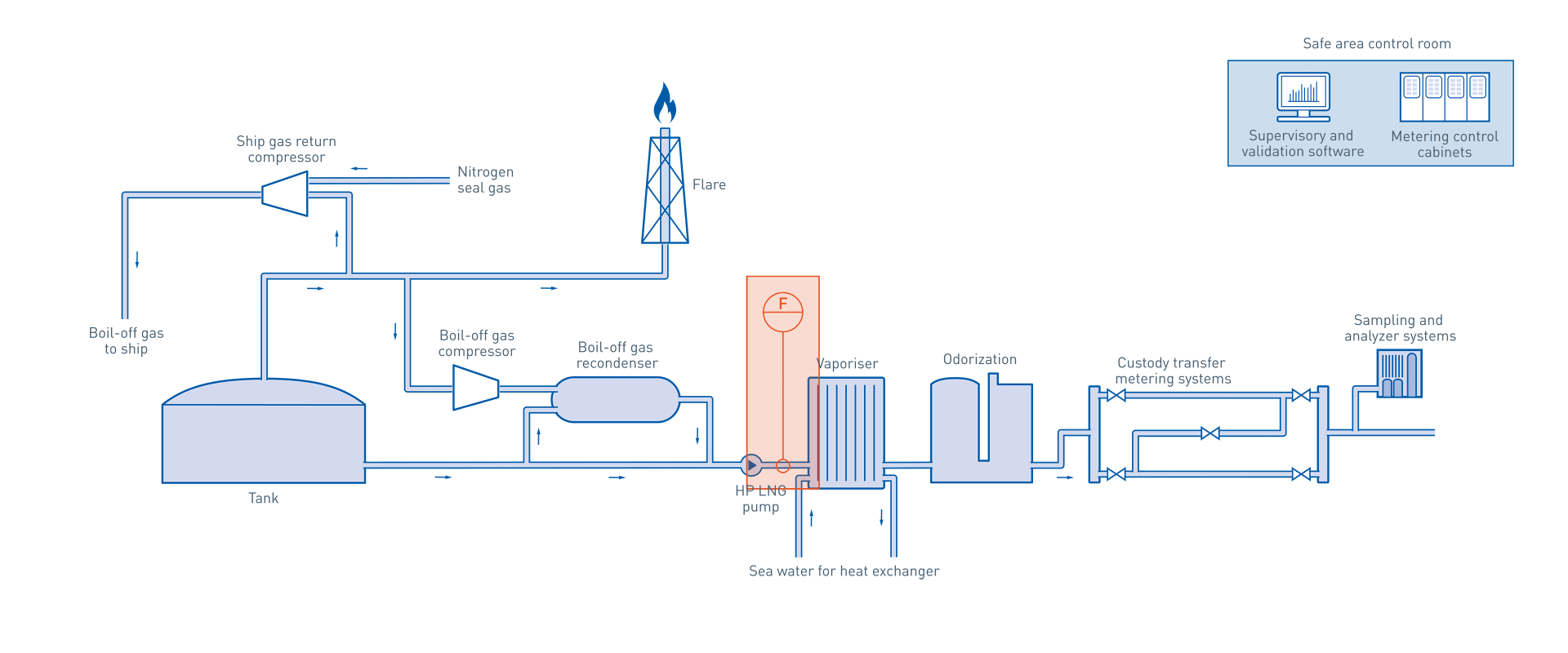

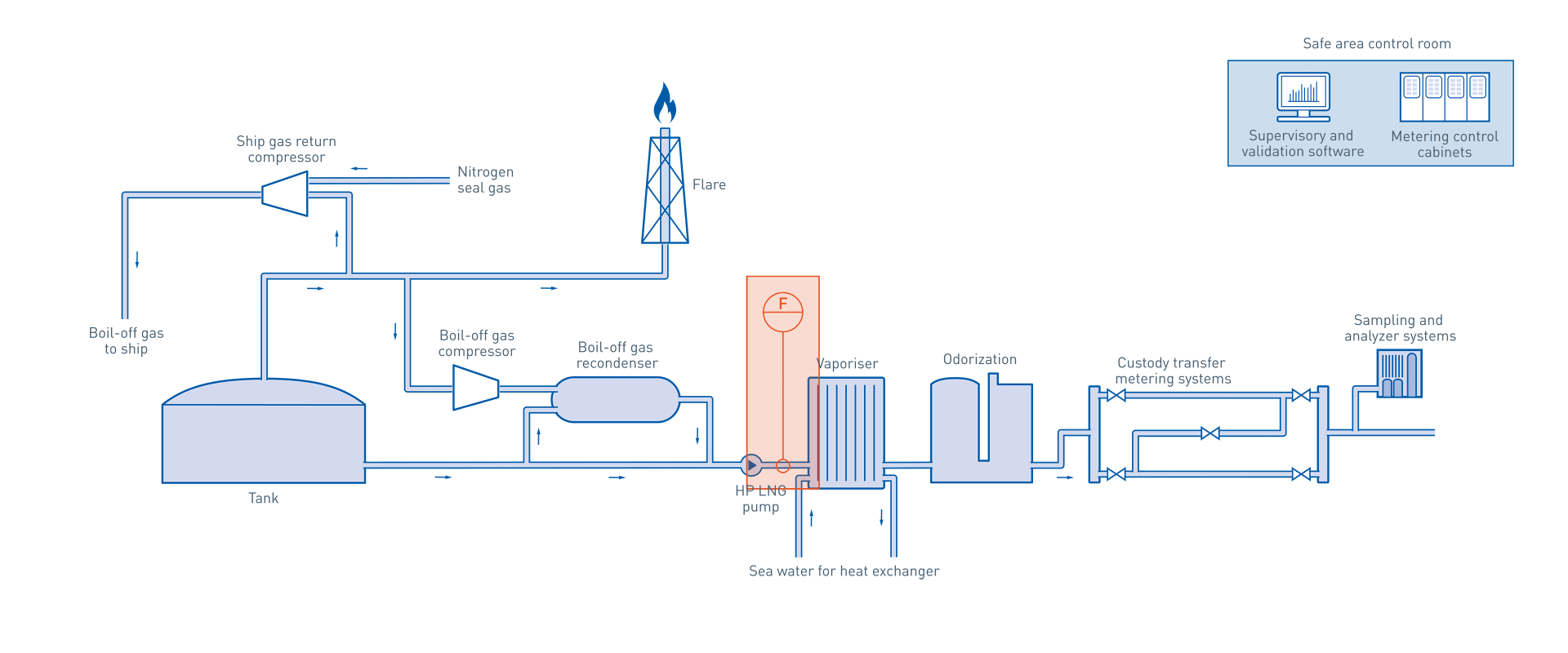

- Cryogenic temperatures (<-162°C)

- Accurate measurement for process control

Recommended products and solutions:

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

Requirements:

- Injection of odorant in natural gas

- Indication of the flow of chemicals

- Ensure continuous injection

Recommended products and solutions:

H250 M40

- Modular design: from mechanical indicator to 4…20 mA/HART®7, FF, Profibus-PA and totalizer

- Any installation position: vertical, horizontal or in fall pipes

- Flange: DN15…150 / ½…6"; also NPT, G, hygienic connections, etc.

- -196…+400°C / -320…+752°F; max. 1000 barg / 14500 psig

Requirements:

- High accuracy measurement of natural gas

- Need for diagnostics to ensure measurement accuracy

Recommended products and solutions:

OPTIMASS 6400

- High accuracy (±0.05% flat), for cryogenic to HT media (-200…+400°C / -328…+752°F); maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- SIL 2/3; CT: OIML R117, R137, MI-005, MI-002; API, AGA; hygienic certifications

- Flange: DN10…300 / ½…12", max. PN 160 / ASME Cl 1500

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

OPTIMASS 2400

- For gases and liquids up to 4,600 t/h; maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- CT: OIML R117, MI-005, MI-002; API and AGA compliant

- Flange: DN100…400 / 4…16", max. PN160 / ASME Cl 1500

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

ALTOSONIC V12

- 12-chord meter, for high accuracy flow metering of natural gas

- CT: OIML R137 (class 0.5), MI-002, AGA9 etc.

- Many variants, extensive CBM diagnostics free of charge

- Flange: DN100…1600 / 4…64"; max. PN450 / ASME Cl 2500

SUMMIT 8800

- Cost effective solution due to modular hard- and software design

- Full colour graphical touch screen for maximum process transparency

- Easy operator access enabling time efficient maintenance

- Automatic Performance Monitoring extends recalibration interval

Requirements:

- Cryogenic temperatures (<-162°C)

- Risk of overfill or dry run

- Inventory measurement

Recommended products and solutions:

OPTISWITCH 5300

- Point level detection of liquids under extreme conditions

- Probe length: up to 3000 mm / 118 ft

- ≥0.47 g/cm3 / 0.017 lb/in3 (optional: ≥0.42 g/cm3 or 0.015 lb/in3)

- -196…+450°C / -321…+842°F; -1…160 barg / -14.5…2321 psig

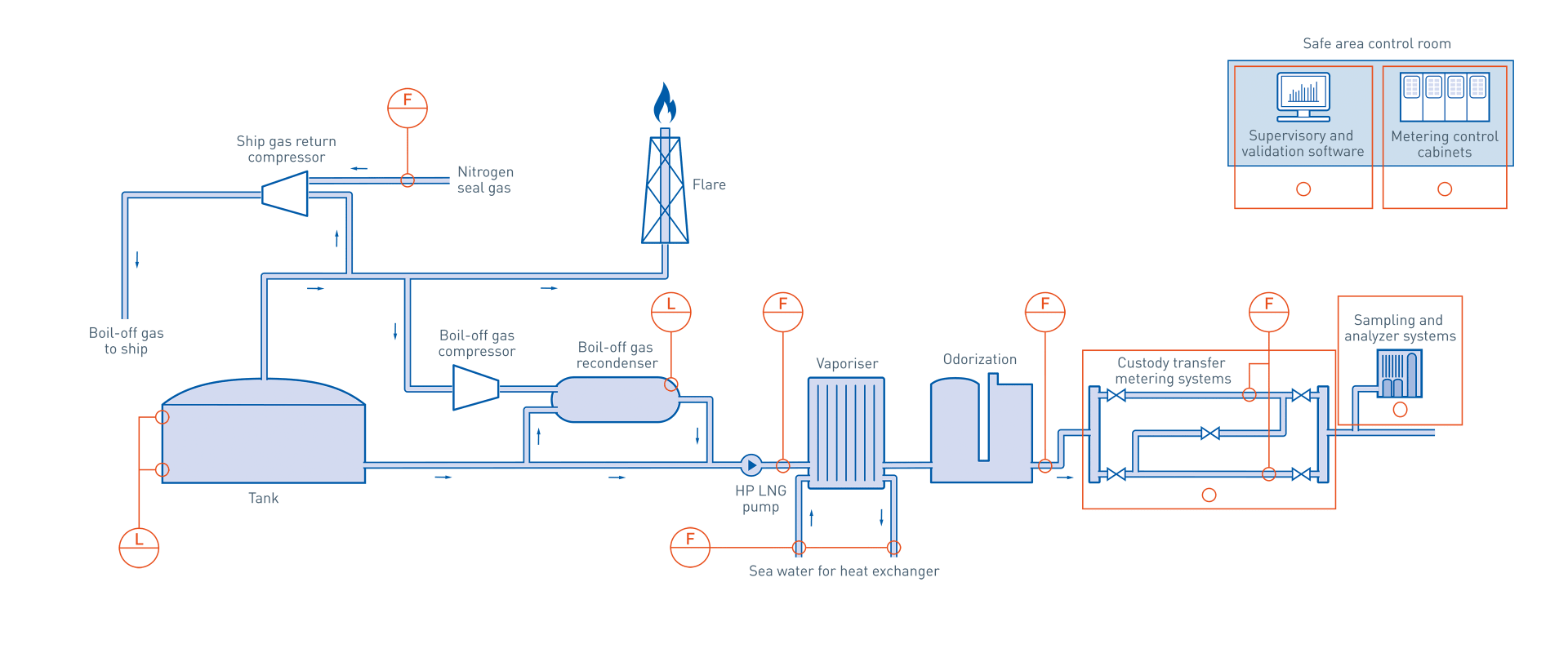

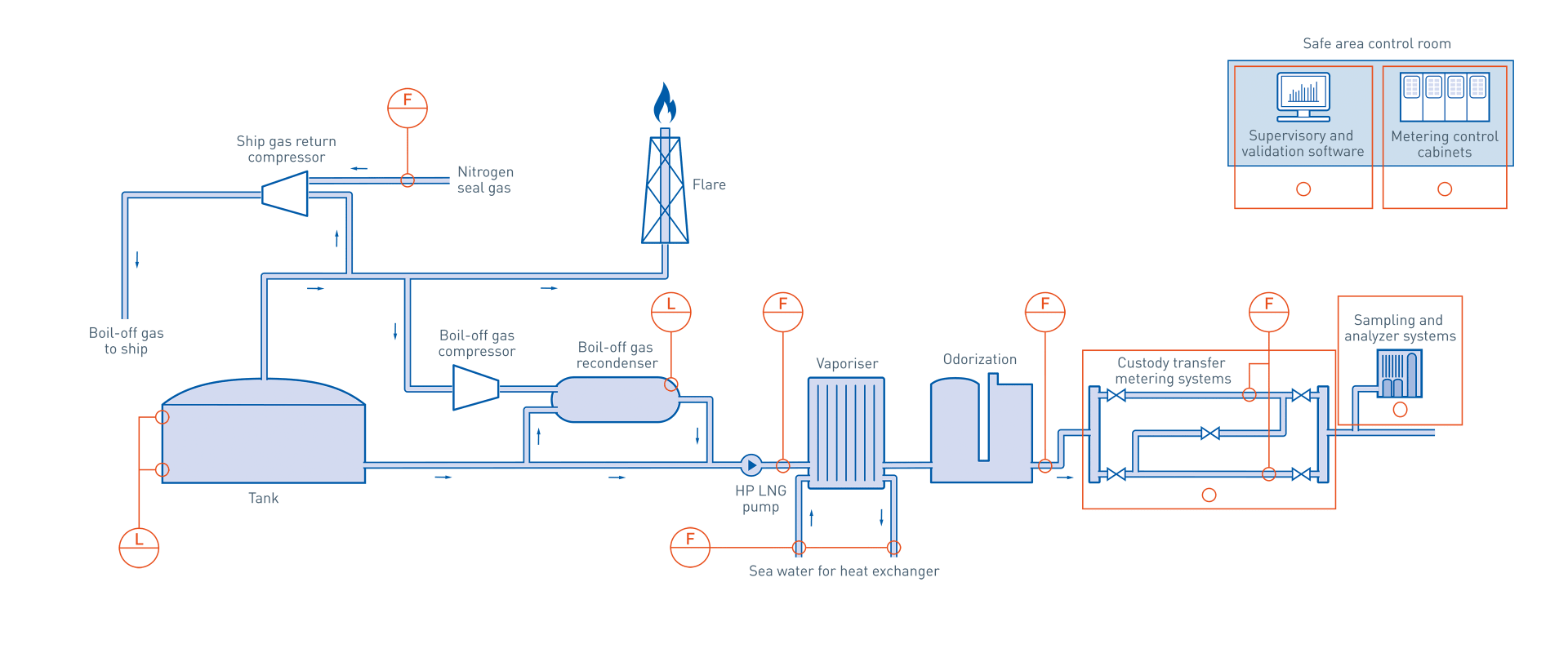

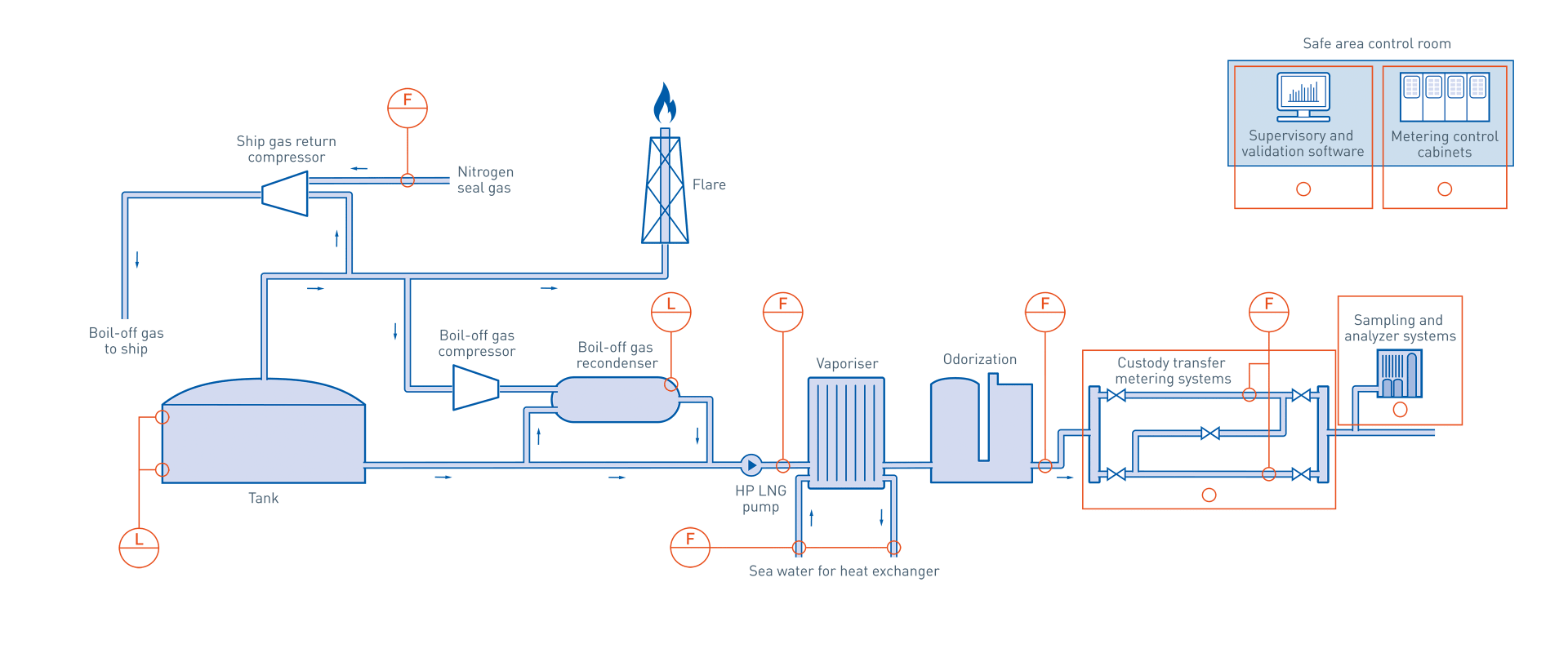

Requirements:

- Visualisation and monitoring of critical processes

- Control of reporting, trends and alarm handling

- Statistical evaluation of measurement data

Recommended products and solutions:

SynEnergy Supervisory and visualisation software

- HMI/SCADA software for measurement solutions

- State of the art HTML5 secure web technology

- Optimisation of operation results due to predictive maintenance

- Easy integration into existing DCS and ERP networks

CalSys Analyser Management software

- Effective performance monitoring of quality measurement instruments (QMI)

- Automated analyser validation and statistical process control

- Complies with international standards and methods (ASTM D3764, ASTM D6299, OP 97-30425 etc.)

- Increased availability of gas chromatographs and critical process analysers

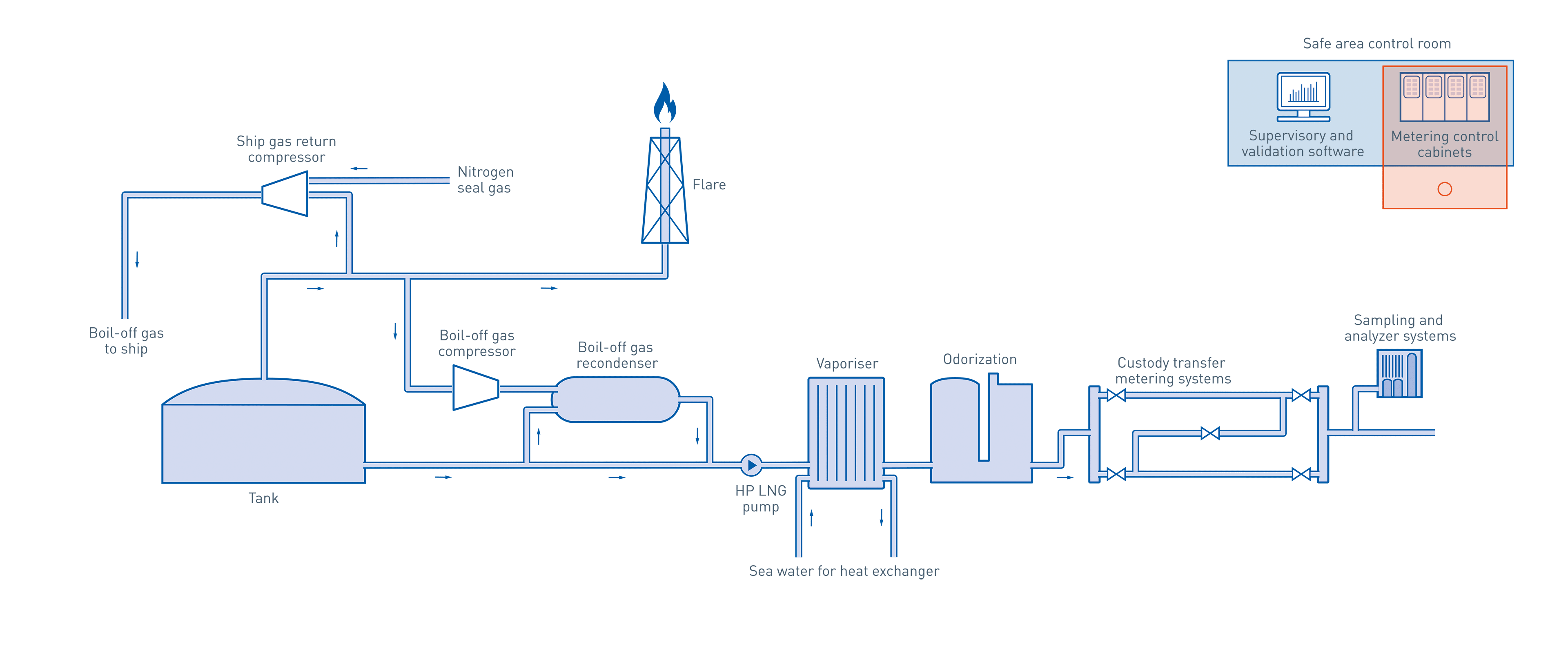

Requirements:

- Integration of flow computers, PLCs, supervisory computers and printers

- Installation of single flow computers up to fully redundant cabinet

- Complying with custody transfer requirements

Recommended products and solutions:

SUMMIT 8800

- Cost effective solution due to modular hard- and software design

- Full colour graphical touch screen for maximum process transparency

- Easy operator access enabling time efficient maintenance

- Automatic Performance Monitoring extends recalibration interval

Supervisory Control Cabinets

- Provides control of the metering system, including validation of field instrumentation

- Installed in a safe area, typically in a control room or dedicated building

- Supplied in combination with new metering systems, or for an upgrade to existing systems

Modular flow control and data transfer cabinets

- Cost effective, modular metering control solution

- Based on the SUMMIT 8800 flow computer

- Installed in a safe area, typically in a control room

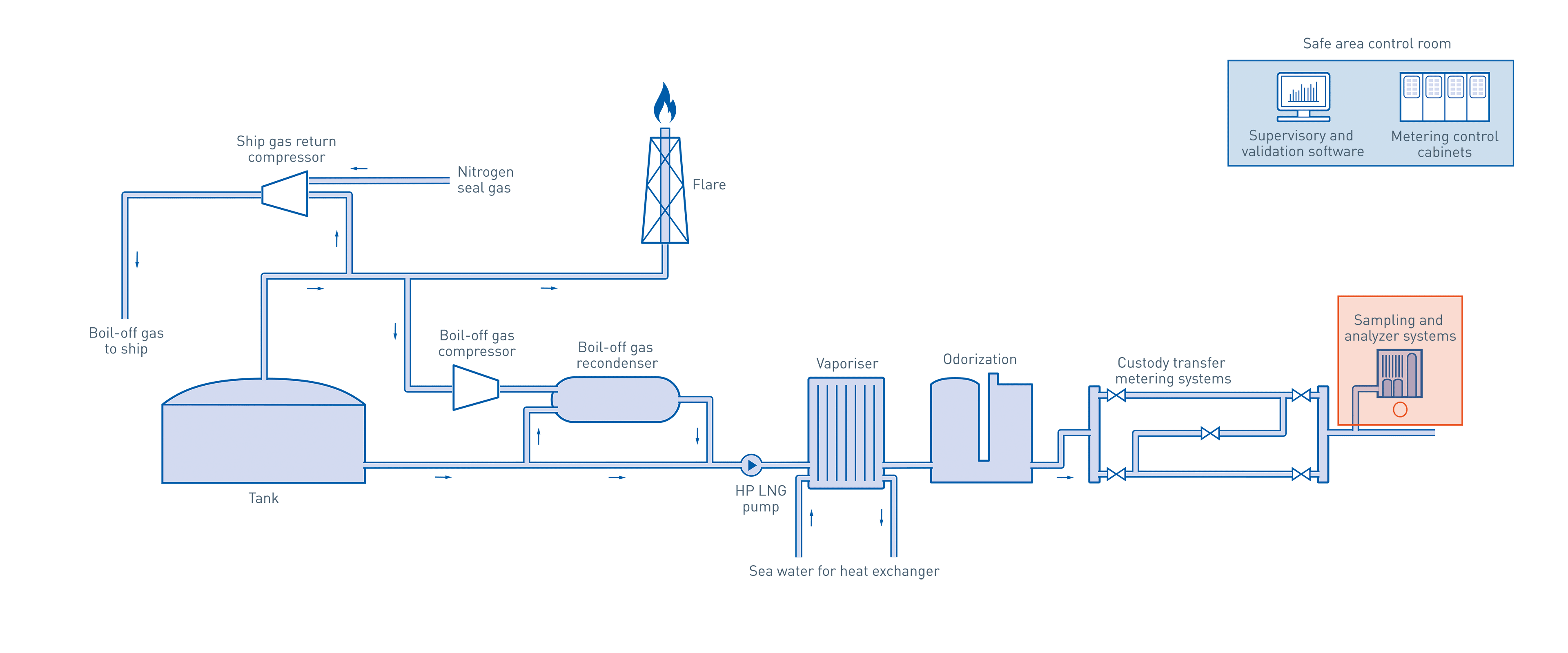

Requirements:

- Measurement of gas quality

- Control of gas mixing process

Recommended products and solutions:

Analyser houses and shelters

- Quality measurements of crude oil, refined products and natural gas

- Supplied with new metering systems, or as a stand-alone upgrade to existing systems

- Engineered solutions based on customer preferred brands

Requirements:

- High-accuracy measurement of gas volume and quality

- Traceable to international standards

- Complying with custody transfer requirements

- Master/duty configuration with flowmeter diagnostics

Recommended products and solutions:

Custody transfer metering systems for gases

- Based on ultrasonic, Coriolis, turbine or DP flowmeters

- From initial design phase up to on-site commissioning and training

- Comprising flow metering skid, metering control cabinets, sampling and analyser systems, and all supervisory and validation software

Custody transfer metering systems for LNG

- Based on ultrasonic or Coriolis cryogenic flow meters

- From large scale ship (un)loading to bunkering and truck loading

- Comprising flow metering skid, metering control cabinets, sampling and analyser systems, and all supervisory and validation software

Regasification in the oil & gas industry

Requirements:

- Recognize leaks and defective seals quickly to prevent compressor damage

- Indication of the flow

Recommended products and solutions:

H250 M40

- Modular design: from mechanical indicator to 4…20 mA/HART®7, FF, Profibus-PA and totalizer

- Any installation position: vertical, horizontal or in fall pipes

- Flange: DN15…150 / ½…6"; also NPT, G, hygienic connections, etc.

- -196…+400°C / -320…+752°F; max. 1000 barg / 14500 psig

Requirements:

- Measurement of sea water for process control

- Energy balance of heat exchange process

Recommended products and solutions:

OPTISONIC 6300

- Stationary device, for installation at any location without process interruption or need to cut pipes

- Up to +200°C / +392°F

- Robust stainless steel sensor rail for pipes DN15…4000 / ½…160"

- 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP

OPTIFLUX 4000

- Full bore design: pipe cross-section without restrictions

- Connection sizes: DN2.5…3000 / ⅒…120" (depending on signal converter)

- Liner: PTFE, PFA, ETFE, PU, hard and soft rubber

OPTIFLUX 2000

- Full bore design: pipe cross-section without restrictions

- Connection sizes: DN25…1200 / 1…48"

- Liner: PP, PO or hard rubber

Requirements:

- Level measurement of gas and liquid in cryogenic conditions

- Cryogenic temperatures (<-162°C)

Recommended products and solutions:

BM 26 F2200

- Continuous, redundant measurement using two measurement principles in one device

- Measuring range: 0.3…5.5 / 1…18 ft (longer on request)

- Density: 0.5…3 kg/l / 31…187 lb/ft3

- -50…+300°C / -58…+570°F; -1…100 barg / -14.5…1450 psig

Requirements:

- Cryogenic temperatures (<-162°C)

- Accurate measurement for process control

Recommended products and solutions:

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

Requirements:

- Injection of odorant in natural gas

- Indication of the flow of chemicals

- Ensure continuous injection

Recommended products and solutions:

H250 M40

- Modular design: from mechanical indicator to 4…20 mA/HART®7, FF, Profibus-PA and totalizer

- Any installation position: vertical, horizontal or in fall pipes

- Flange: DN15…150 / ½…6"; also NPT, G, hygienic connections, etc.

- -196…+400°C / -320…+752°F; max. 1000 barg / 14500 psig

Requirements:

- High accuracy measurement of natural gas

- Need for diagnostics to ensure measurement accuracy

Recommended products and solutions:

OPTIMASS 6400

- High accuracy (±0.05% flat), for cryogenic to HT media (-200…+400°C / -328…+752°F); maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- SIL 2/3; CT: OIML R117, R137, MI-005, MI-002; API, AGA; hygienic certifications

- Flange: DN10…300 / ½…12", max. PN 160 / ASME Cl 1500

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

OPTIMASS 2400

- For gases and liquids up to 4,600 t/h; maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- CT: OIML R117, MI-005, MI-002; API and AGA compliant

- Flange: DN100…400 / 4…16", max. PN160 / ASME Cl 1500

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

ALTOSONIC V12

- 12-chord meter, for high accuracy flow metering of natural gas

- CT: OIML R137 (class 0.5), MI-002, AGA9 etc.

- Many variants, extensive CBM diagnostics free of charge

- Flange: DN100…1600 / 4…64"; max. PN450 / ASME Cl 2500

SUMMIT 8800

- Cost effective solution due to modular hard- and software design

- Full colour graphical touch screen for maximum process transparency

- Easy operator access enabling time efficient maintenance

- Automatic Performance Monitoring extends recalibration interval

Requirements:

- Cryogenic temperatures (<-162°C)

- Risk of overfill or dry run

- Inventory measurement

Recommended products and solutions:

OPTISWITCH 5300

- Point level detection of liquids under extreme conditions

- Probe length: up to 3000 mm / 118 ft

- ≥0.47 g/cm3 / 0.017 lb/in3 (optional: ≥0.42 g/cm3 or 0.015 lb/in3)

- -196…+450°C / -321…+842°F; -1…160 barg / -14.5…2321 psig

Requirements:

- Visualisation and monitoring of critical processes

- Control of reporting, trends and alarm handling

- Statistical evaluation of measurement data

Recommended products and solutions:

SynEnergy Supervisory and visualisation software

- HMI/SCADA software for measurement solutions

- State of the art HTML5 secure web technology

- Optimisation of operation results due to predictive maintenance

- Easy integration into existing DCS and ERP networks

CalSys Analyser Management software

- Effective performance monitoring of quality measurement instruments (QMI)

- Automated analyser validation and statistical process control

- Complies with international standards and methods (ASTM D3764, ASTM D6299, OP 97-30425 etc.)

- Increased availability of gas chromatographs and critical process analysers

Requirements:

- Integration of flow computers, PLCs, supervisory computers and printers

- Installation of single flow computers up to fully redundant cabinet

- Complying with custody transfer requirements

Recommended products and solutions:

SUMMIT 8800

- Cost effective solution due to modular hard- and software design

- Full colour graphical touch screen for maximum process transparency

- Easy operator access enabling time efficient maintenance

- Automatic Performance Monitoring extends recalibration interval

Supervisory Control Cabinets

- Provides control of the metering system, including validation of field instrumentation

- Installed in a safe area, typically in a control room or dedicated building

- Supplied in combination with new metering systems, or for an upgrade to existing systems

Modular flow control and data transfer cabinets

- Cost effective, modular metering control solution

- Based on the SUMMIT 8800 flow computer

- Installed in a safe area, typically in a control room

Requirements:

- Measurement of gas quality

- Control of gas mixing process

Recommended products and solutions:

Analyser houses and shelters

- Quality measurements of crude oil, refined products and natural gas

- Supplied with new metering systems, or as a stand-alone upgrade to existing systems

- Engineered solutions based on customer preferred brands

Requirements:

- High-accuracy measurement of gas volume and quality

- Traceable to international standards

- Complying with custody transfer requirements

- Master/duty configuration with flowmeter diagnostics

Recommended products and solutions:

Custody transfer metering systems for gases

- Based on ultrasonic, Coriolis, turbine or DP flowmeters

- From initial design phase up to on-site commissioning and training

- Comprising flow metering skid, metering control cabinets, sampling and analyser systems, and all supervisory and validation software

Custody transfer metering systems for LNG

- Based on ultrasonic or Coriolis cryogenic flow meters

- From large scale ship (un)loading to bunkering and truck loading

- Comprising flow metering skid, metering control cabinets, sampling and analyser systems, and all supervisory and validation software

Requirements:

- Recognize leaks and defective seals quickly to prevent compressor damage

- Indication of the flow

Recommended products and solutions:

Regasification in the oil & gas industry

Requirements:

- Recognize leaks and defective seals quickly to prevent compressor damage

- Indication of the flow

Recommended products and solutions:

H250 M40

- Modular design: from mechanical indicator to 4…20 mA/HART®7, FF, Profibus-PA and totalizer

- Any installation position: vertical, horizontal or in fall pipes

- Flange: DN15…150 / ½…6"; also NPT, G, hygienic connections, etc.

- -196…+400°C / -320…+752°F; max. 1000 barg / 14500 psig

Requirements:

- Measurement of sea water for process control

- Energy balance of heat exchange process

Recommended products and solutions:

OPTISONIC 6300

- Stationary device, for installation at any location without process interruption or need to cut pipes

- Up to +200°C / +392°F

- Robust stainless steel sensor rail for pipes DN15…4000 / ½…160"

- 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP

OPTIFLUX 4000

- Full bore design: pipe cross-section without restrictions

- Connection sizes: DN2.5…3000 / ⅒…120" (depending on signal converter)

- Liner: PTFE, PFA, ETFE, PU, hard and soft rubber

OPTIFLUX 2000

- Full bore design: pipe cross-section without restrictions

- Connection sizes: DN25…1200 / 1…48"

- Liner: PP, PO or hard rubber

Requirements:

- Level measurement of gas and liquid in cryogenic conditions

- Cryogenic temperatures (<-162°C)

Recommended products and solutions:

BM 26 F2200

- Continuous, redundant measurement using two measurement principles in one device

- Measuring range: 0.3…5.5 / 1…18 ft (longer on request)

- Density: 0.5…3 kg/l / 31…187 lb/ft3

- -50…+300°C / -58…+570°F; -1…100 barg / -14.5…1450 psig

Requirements:

- Cryogenic temperatures (<-162°C)

- Accurate measurement for process control

Recommended products and solutions:

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

Requirements:

- Injection of odorant in natural gas

- Indication of the flow of chemicals

- Ensure continuous injection

Recommended products and solutions:

H250 M40

- Modular design: from mechanical indicator to 4…20 mA/HART®7, FF, Profibus-PA and totalizer

- Any installation position: vertical, horizontal or in fall pipes

- Flange: DN15…150 / ½…6"; also NPT, G, hygienic connections, etc.

- -196…+400°C / -320…+752°F; max. 1000 barg / 14500 psig

Requirements:

- High accuracy measurement of natural gas

- Need for diagnostics to ensure measurement accuracy

Recommended products and solutions:

OPTIMASS 6400

- High accuracy (±0.05% flat), for cryogenic to HT media (-200…+400°C / -328…+752°F); maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- SIL 2/3; CT: OIML R117, R137, MI-005, MI-002; API, AGA; hygienic certifications

- Flange: DN10…300 / ½…12", max. PN 160 / ASME Cl 1500

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

OPTIMASS 2400

- For gases and liquids up to 4,600 t/h; maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- CT: OIML R117, MI-005, MI-002; API and AGA compliant

- Flange: DN100…400 / 4…16", max. PN160 / ASME Cl 1500

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

ALTOSONIC V12

- 12-chord meter, for high accuracy flow metering of natural gas

- CT: OIML R137 (class 0.5), MI-002, AGA9 etc.

- Many variants, extensive CBM diagnostics free of charge

- Flange: DN100…1600 / 4…64"; max. PN450 / ASME Cl 2500

SUMMIT 8800

- Cost effective solution due to modular hard- and software design

- Full colour graphical touch screen for maximum process transparency

- Easy operator access enabling time efficient maintenance

- Automatic Performance Monitoring extends recalibration interval

Requirements:

- Cryogenic temperatures (<-162°C)

- Risk of overfill or dry run

- Inventory measurement

Recommended products and solutions:

OPTISWITCH 5300

- Point level detection of liquids under extreme conditions

- Probe length: up to 3000 mm / 118 ft

- ≥0.47 g/cm3 / 0.017 lb/in3 (optional: ≥0.42 g/cm3 or 0.015 lb/in3)

- -196…+450°C / -321…+842°F; -1…160 barg / -14.5…2321 psig

Requirements:

- Visualisation and monitoring of critical processes

- Control of reporting, trends and alarm handling

- Statistical evaluation of measurement data

Recommended products and solutions:

SynEnergy Supervisory and visualisation software

- HMI/SCADA software for measurement solutions

- State of the art HTML5 secure web technology

- Optimisation of operation results due to predictive maintenance

- Easy integration into existing DCS and ERP networks

CalSys Analyser Management software

- Effective performance monitoring of quality measurement instruments (QMI)

- Automated analyser validation and statistical process control

- Complies with international standards and methods (ASTM D3764, ASTM D6299, OP 97-30425 etc.)

- Increased availability of gas chromatographs and critical process analysers

Requirements:

- Integration of flow computers, PLCs, supervisory computers and printers

- Installation of single flow computers up to fully redundant cabinet

- Complying with custody transfer requirements

Recommended products and solutions:

SUMMIT 8800

- Cost effective solution due to modular hard- and software design

- Full colour graphical touch screen for maximum process transparency

- Easy operator access enabling time efficient maintenance

- Automatic Performance Monitoring extends recalibration interval

Supervisory Control Cabinets

- Provides control of the metering system, including validation of field instrumentation

- Installed in a safe area, typically in a control room or dedicated building

- Supplied in combination with new metering systems, or for an upgrade to existing systems

Modular flow control and data transfer cabinets

- Cost effective, modular metering control solution

- Based on the SUMMIT 8800 flow computer

- Installed in a safe area, typically in a control room

Requirements:

- Measurement of gas quality

- Control of gas mixing process

Recommended products and solutions:

Analyser houses and shelters

- Quality measurements of crude oil, refined products and natural gas

- Supplied with new metering systems, or as a stand-alone upgrade to existing systems

- Engineered solutions based on customer preferred brands

Requirements:

- High-accuracy measurement of gas volume and quality

- Traceable to international standards

- Complying with custody transfer requirements

- Master/duty configuration with flowmeter diagnostics

Recommended products and solutions:

Custody transfer metering systems for gases

- Based on ultrasonic, Coriolis, turbine or DP flowmeters

- From initial design phase up to on-site commissioning and training

- Comprising flow metering skid, metering control cabinets, sampling and analyser systems, and all supervisory and validation software

Custody transfer metering systems for LNG

- Based on ultrasonic or Coriolis cryogenic flow meters

- From large scale ship (un)loading to bunkering and truck loading

- Comprising flow metering skid, metering control cabinets, sampling and analyser systems, and all supervisory and validation software

Requirements:

- Measurement of sea water for process control

- Energy balance of heat exchange process

Recommended products and solutions:

OPTIFLUX 4000

Electromagnetic flow sensor for combination with IFC 050, IFC 100, IFC 300 and IFC 400 signal converters

OPTIFLUX 2000

Electromagnetic flow sensor for combination with IFC 050, IFC 100 and IFC 300 signal converters

Regasification in the oil & gas industry

Requirements:

- Recognize leaks and defective seals quickly to prevent compressor damage

- Indication of the flow

Recommended products and solutions:

H250 M40

- Modular design: from mechanical indicator to 4…20 mA/HART®7, FF, Profibus-PA and totalizer

- Any installation position: vertical, horizontal or in fall pipes

- Flange: DN15…150 / ½…6"; also NPT, G, hygienic connections, etc.

- -196…+400°C / -320…+752°F; max. 1000 barg / 14500 psig

Requirements:

- Measurement of sea water for process control

- Energy balance of heat exchange process

Recommended products and solutions:

OPTISONIC 6300

- Stationary device, for installation at any location without process interruption or need to cut pipes

- Up to +200°C / +392°F

- Robust stainless steel sensor rail for pipes DN15…4000 / ½…160"

- 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP

OPTIFLUX 4000

- Full bore design: pipe cross-section without restrictions

- Connection sizes: DN2.5…3000 / ⅒…120" (depending on signal converter)

- Liner: PTFE, PFA, ETFE, PU, hard and soft rubber

OPTIFLUX 2000

- Full bore design: pipe cross-section without restrictions

- Connection sizes: DN25…1200 / 1…48"

- Liner: PP, PO or hard rubber

Requirements:

- Level measurement of gas and liquid in cryogenic conditions

- Cryogenic temperatures (<-162°C)

Recommended products and solutions:

BM 26 F2200

- Continuous, redundant measurement using two measurement principles in one device

- Measuring range: 0.3…5.5 / 1…18 ft (longer on request)

- Density: 0.5…3 kg/l / 31…187 lb/ft3

- -50…+300°C / -58…+570°F; -1…100 barg / -14.5…1450 psig

Requirements:

- Cryogenic temperatures (<-162°C)

- Accurate measurement for process control

Recommended products and solutions:

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

Requirements:

- Injection of odorant in natural gas

- Indication of the flow of chemicals

- Ensure continuous injection

Recommended products and solutions:

H250 M40

- Modular design: from mechanical indicator to 4…20 mA/HART®7, FF, Profibus-PA and totalizer

- Any installation position: vertical, horizontal or in fall pipes

- Flange: DN15…150 / ½…6"; also NPT, G, hygienic connections, etc.

- -196…+400°C / -320…+752°F; max. 1000 barg / 14500 psig

Requirements:

- High accuracy measurement of natural gas

- Need for diagnostics to ensure measurement accuracy

Recommended products and solutions:

OPTIMASS 6400

- High accuracy (±0.05% flat), for cryogenic to HT media (-200…+400°C / -328…+752°F); maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- SIL 2/3; CT: OIML R117, R137, MI-005, MI-002; API, AGA; hygienic certifications

- Flange: DN10…300 / ½…12", max. PN 160 / ASME Cl 1500

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

OPTIMASS 2400

- For gases and liquids up to 4,600 t/h; maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- CT: OIML R117, MI-005, MI-002; API and AGA compliant

- Flange: DN100…400 / 4…16", max. PN160 / ASME Cl 1500

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

ALTOSONIC V12

- 12-chord meter, for high accuracy flow metering of natural gas

- CT: OIML R137 (class 0.5), MI-002, AGA9 etc.

- Many variants, extensive CBM diagnostics free of charge

- Flange: DN100…1600 / 4…64"; max. PN450 / ASME Cl 2500

SUMMIT 8800

- Cost effective solution due to modular hard- and software design

- Full colour graphical touch screen for maximum process transparency

- Easy operator access enabling time efficient maintenance

- Automatic Performance Monitoring extends recalibration interval

Requirements:

- Cryogenic temperatures (<-162°C)

- Risk of overfill or dry run

- Inventory measurement

Recommended products and solutions:

OPTISWITCH 5300

- Point level detection of liquids under extreme conditions

- Probe length: up to 3000 mm / 118 ft

- ≥0.47 g/cm3 / 0.017 lb/in3 (optional: ≥0.42 g/cm3 or 0.015 lb/in3)

- -196…+450°C / -321…+842°F; -1…160 barg / -14.5…2321 psig

Requirements:

- Visualisation and monitoring of critical processes

- Control of reporting, trends and alarm handling

- Statistical evaluation of measurement data

Recommended products and solutions:

SynEnergy Supervisory and visualisation software

- HMI/SCADA software for measurement solutions

- State of the art HTML5 secure web technology

- Optimisation of operation results due to predictive maintenance

- Easy integration into existing DCS and ERP networks

CalSys Analyser Management software

- Effective performance monitoring of quality measurement instruments (QMI)

- Automated analyser validation and statistical process control

- Complies with international standards and methods (ASTM D3764, ASTM D6299, OP 97-30425 etc.)

- Increased availability of gas chromatographs and critical process analysers

Requirements:

- Integration of flow computers, PLCs, supervisory computers and printers

- Installation of single flow computers up to fully redundant cabinet

- Complying with custody transfer requirements

Recommended products and solutions:

SUMMIT 8800

- Cost effective solution due to modular hard- and software design

- Full colour graphical touch screen for maximum process transparency

- Easy operator access enabling time efficient maintenance

- Automatic Performance Monitoring extends recalibration interval

Supervisory Control Cabinets

- Provides control of the metering system, including validation of field instrumentation

- Installed in a safe area, typically in a control room or dedicated building

- Supplied in combination with new metering systems, or for an upgrade to existing systems

Modular flow control and data transfer cabinets

- Cost effective, modular metering control solution

- Based on the SUMMIT 8800 flow computer

- Installed in a safe area, typically in a control room

Requirements:

- Measurement of gas quality

- Control of gas mixing process

Recommended products and solutions:

Analyser houses and shelters

- Quality measurements of crude oil, refined products and natural gas

- Supplied with new metering systems, or as a stand-alone upgrade to existing systems

- Engineered solutions based on customer preferred brands

Requirements:

- High-accuracy measurement of gas volume and quality

- Traceable to international standards

- Complying with custody transfer requirements

- Master/duty configuration with flowmeter diagnostics

Recommended products and solutions:

Custody transfer metering systems for gases

- Based on ultrasonic, Coriolis, turbine or DP flowmeters

- From initial design phase up to on-site commissioning and training

- Comprising flow metering skid, metering control cabinets, sampling and analyser systems, and all supervisory and validation software

Custody transfer metering systems for LNG

- Based on ultrasonic or Coriolis cryogenic flow meters

- From large scale ship (un)loading to bunkering and truck loading

- Comprising flow metering skid, metering control cabinets, sampling and analyser systems, and all supervisory and validation software

Requirements:

- Level measurement of gas and liquid in cryogenic conditions

- Cryogenic temperatures (<-162°C)

Recommended products and solutions:

BM 26 F2200

Magnetic bypass level indicator with guided radar (TDR) for liquid level applications

Regasification in the oil & gas industry

Requirements:

- Recognize leaks and defective seals quickly to prevent compressor damage

- Indication of the flow

Recommended products and solutions:

H250 M40

- Modular design: from mechanical indicator to 4…20 mA/HART®7, FF, Profibus-PA and totalizer

- Any installation position: vertical, horizontal or in fall pipes

- Flange: DN15…150 / ½…6"; also NPT, G, hygienic connections, etc.

- -196…+400°C / -320…+752°F; max. 1000 barg / 14500 psig

Requirements:

- Measurement of sea water for process control

- Energy balance of heat exchange process

Recommended products and solutions:

OPTISONIC 6300

- Stationary device, for installation at any location without process interruption or need to cut pipes

- Up to +200°C / +392°F

- Robust stainless steel sensor rail for pipes DN15…4000 / ½…160"

- 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP

OPTIFLUX 4000

- Full bore design: pipe cross-section without restrictions

- Connection sizes: DN2.5…3000 / ⅒…120" (depending on signal converter)

- Liner: PTFE, PFA, ETFE, PU, hard and soft rubber

OPTIFLUX 2000

- Full bore design: pipe cross-section without restrictions

- Connection sizes: DN25…1200 / 1…48"

- Liner: PP, PO or hard rubber

Requirements:

- Level measurement of gas and liquid in cryogenic conditions

- Cryogenic temperatures (<-162°C)

Recommended products and solutions:

BM 26 F2200

- Continuous, redundant measurement using two measurement principles in one device

- Measuring range: 0.3…5.5 / 1…18 ft (longer on request)

- Density: 0.5…3 kg/l / 31…187 lb/ft3

- -50…+300°C / -58…+570°F; -1…100 barg / -14.5…1450 psig

Requirements:

- Cryogenic temperatures (<-162°C)

- Accurate measurement for process control

Recommended products and solutions:

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

Requirements:

- Injection of odorant in natural gas

- Indication of the flow of chemicals

- Ensure continuous injection

Recommended products and solutions:

H250 M40

- Modular design: from mechanical indicator to 4…20 mA/HART®7, FF, Profibus-PA and totalizer

- Any installation position: vertical, horizontal or in fall pipes

- Flange: DN15…150 / ½…6"; also NPT, G, hygienic connections, etc.

- -196…+400°C / -320…+752°F; max. 1000 barg / 14500 psig

Requirements:

- High accuracy measurement of natural gas

- Need for diagnostics to ensure measurement accuracy

Recommended products and solutions:

OPTIMASS 6400

- High accuracy (±0.05% flat), for cryogenic to HT media (-200…+400°C / -328…+752°F); maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- SIL 2/3; CT: OIML R117, R137, MI-005, MI-002; API, AGA; hygienic certifications

- Flange: DN10…300 / ½…12", max. PN 160 / ASME Cl 1500

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

OPTIMASS 2400

- For gases and liquids up to 4,600 t/h; maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- CT: OIML R117, MI-005, MI-002; API and AGA compliant

- Flange: DN100…400 / 4…16", max. PN160 / ASME Cl 1500

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

ALTOSONIC V12

- 12-chord meter, for high accuracy flow metering of natural gas

- CT: OIML R137 (class 0.5), MI-002, AGA9 etc.

- Many variants, extensive CBM diagnostics free of charge

- Flange: DN100…1600 / 4…64"; max. PN450 / ASME Cl 2500

SUMMIT 8800

- Cost effective solution due to modular hard- and software design

- Full colour graphical touch screen for maximum process transparency

- Easy operator access enabling time efficient maintenance

- Automatic Performance Monitoring extends recalibration interval

Requirements:

- Cryogenic temperatures (<-162°C)

- Risk of overfill or dry run

- Inventory measurement

Recommended products and solutions:

OPTISWITCH 5300

- Point level detection of liquids under extreme conditions

- Probe length: up to 3000 mm / 118 ft

- ≥0.47 g/cm3 / 0.017 lb/in3 (optional: ≥0.42 g/cm3 or 0.015 lb/in3)

- -196…+450°C / -321…+842°F; -1…160 barg / -14.5…2321 psig

Requirements:

- Visualisation and monitoring of critical processes

- Control of reporting, trends and alarm handling

- Statistical evaluation of measurement data

Recommended products and solutions:

SynEnergy Supervisory and visualisation software

- HMI/SCADA software for measurement solutions

- State of the art HTML5 secure web technology

- Optimisation of operation results due to predictive maintenance

- Easy integration into existing DCS and ERP networks

CalSys Analyser Management software

- Effective performance monitoring of quality measurement instruments (QMI)

- Automated analyser validation and statistical process control

- Complies with international standards and methods (ASTM D3764, ASTM D6299, OP 97-30425 etc.)

- Increased availability of gas chromatographs and critical process analysers

Requirements:

- Integration of flow computers, PLCs, supervisory computers and printers

- Installation of single flow computers up to fully redundant cabinet

- Complying with custody transfer requirements

Recommended products and solutions:

SUMMIT 8800

- Cost effective solution due to modular hard- and software design

- Full colour graphical touch screen for maximum process transparency

- Easy operator access enabling time efficient maintenance

- Automatic Performance Monitoring extends recalibration interval

Supervisory Control Cabinets

- Provides control of the metering system, including validation of field instrumentation

- Installed in a safe area, typically in a control room or dedicated building

- Supplied in combination with new metering systems, or for an upgrade to existing systems

Modular flow control and data transfer cabinets

- Cost effective, modular metering control solution

- Based on the SUMMIT 8800 flow computer

- Installed in a safe area, typically in a control room

Requirements:

- Measurement of gas quality

- Control of gas mixing process

Recommended products and solutions:

Analyser houses and shelters

- Quality measurements of crude oil, refined products and natural gas

- Supplied with new metering systems, or as a stand-alone upgrade to existing systems

- Engineered solutions based on customer preferred brands

Requirements:

- High-accuracy measurement of gas volume and quality

- Traceable to international standards

- Complying with custody transfer requirements

- Master/duty configuration with flowmeter diagnostics

Recommended products and solutions:

Custody transfer metering systems for gases

- Based on ultrasonic, Coriolis, turbine or DP flowmeters

- From initial design phase up to on-site commissioning and training

- Comprising flow metering skid, metering control cabinets, sampling and analyser systems, and all supervisory and validation software

Custody transfer metering systems for LNG

- Based on ultrasonic or Coriolis cryogenic flow meters

- From large scale ship (un)loading to bunkering and truck loading

- Comprising flow metering skid, metering control cabinets, sampling and analyser systems, and all supervisory and validation software

Requirements:

- Cryogenic temperatures (<-162°C)

- Accurate measurement for process control

Recommended products and solutions:

Regasification in the oil & gas industry

Requirements:

- Recognize leaks and defective seals quickly to prevent compressor damage

- Indication of the flow

Recommended products and solutions:

H250 M40

- Modular design: from mechanical indicator to 4…20 mA/HART®7, FF, Profibus-PA and totalizer

- Any installation position: vertical, horizontal or in fall pipes

- Flange: DN15…150 / ½…6"; also NPT, G, hygienic connections, etc.

- -196…+400°C / -320…+752°F; max. 1000 barg / 14500 psig

Requirements:

- Measurement of sea water for process control

- Energy balance of heat exchange process

Recommended products and solutions:

OPTISONIC 6300

- Stationary device, for installation at any location without process interruption or need to cut pipes

- Up to +200°C / +392°F

- Robust stainless steel sensor rail for pipes DN15…4000 / ½…160"

- 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP

OPTIFLUX 4000

- Full bore design: pipe cross-section without restrictions

- Connection sizes: DN2.5…3000 / ⅒…120" (depending on signal converter)

- Liner: PTFE, PFA, ETFE, PU, hard and soft rubber

OPTIFLUX 2000

- Full bore design: pipe cross-section without restrictions

- Connection sizes: DN25…1200 / 1…48"

- Liner: PP, PO or hard rubber

Requirements:

- Level measurement of gas and liquid in cryogenic conditions

- Cryogenic temperatures (<-162°C)

Recommended products and solutions:

BM 26 F2200

- Continuous, redundant measurement using two measurement principles in one device

- Measuring range: 0.3…5.5 / 1…18 ft (longer on request)

- Density: 0.5…3 kg/l / 31…187 lb/ft3

- -50…+300°C / -58…+570°F; -1…100 barg / -14.5…1450 psig

Requirements:

- Cryogenic temperatures (<-162°C)

- Accurate measurement for process control

Recommended products and solutions:

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

Requirements:

- Injection of odorant in natural gas

- Indication of the flow of chemicals

- Ensure continuous injection

Recommended products and solutions:

H250 M40

- Modular design: from mechanical indicator to 4…20 mA/HART®7, FF, Profibus-PA and totalizer

- Any installation position: vertical, horizontal or in fall pipes

- Flange: DN15…150 / ½…6"; also NPT, G, hygienic connections, etc.

- -196…+400°C / -320…+752°F; max. 1000 barg / 14500 psig

Requirements:

- High accuracy measurement of natural gas

- Need for diagnostics to ensure measurement accuracy

Recommended products and solutions:

OPTIMASS 6400

- High accuracy (±0.05% flat), for cryogenic to HT media (-200…+400°C / -328…+752°F); maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- SIL 2/3; CT: OIML R117, R137, MI-005, MI-002; API, AGA; hygienic certifications

- Flange: DN10…300 / ½…12", max. PN 160 / ASME Cl 1500

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

OPTIMASS 2400

- For gases and liquids up to 4,600 t/h; maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- CT: OIML R117, MI-005, MI-002; API and AGA compliant

- Flange: DN100…400 / 4…16", max. PN160 / ASME Cl 1500

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

ALTOSONIC V12

- 12-chord meter, for high accuracy flow metering of natural gas

- CT: OIML R137 (class 0.5), MI-002, AGA9 etc.

- Many variants, extensive CBM diagnostics free of charge

- Flange: DN100…1600 / 4…64"; max. PN450 / ASME Cl 2500

SUMMIT 8800

- Cost effective solution due to modular hard- and software design

- Full colour graphical touch screen for maximum process transparency

- Easy operator access enabling time efficient maintenance

- Automatic Performance Monitoring extends recalibration interval

Requirements:

- Cryogenic temperatures (<-162°C)

- Risk of overfill or dry run

- Inventory measurement

Recommended products and solutions:

OPTISWITCH 5300

- Point level detection of liquids under extreme conditions

- Probe length: up to 3000 mm / 118 ft

- ≥0.47 g/cm3 / 0.017 lb/in3 (optional: ≥0.42 g/cm3 or 0.015 lb/in3)

- -196…+450°C / -321…+842°F; -1…160 barg / -14.5…2321 psig

Requirements:

- Visualisation and monitoring of critical processes

- Control of reporting, trends and alarm handling

- Statistical evaluation of measurement data

Recommended products and solutions:

SynEnergy Supervisory and visualisation software

- HMI/SCADA software for measurement solutions

- State of the art HTML5 secure web technology

- Optimisation of operation results due to predictive maintenance

- Easy integration into existing DCS and ERP networks

CalSys Analyser Management software

- Effective performance monitoring of quality measurement instruments (QMI)

- Automated analyser validation and statistical process control

- Complies with international standards and methods (ASTM D3764, ASTM D6299, OP 97-30425 etc.)

- Increased availability of gas chromatographs and critical process analysers

Requirements:

- Integration of flow computers, PLCs, supervisory computers and printers

- Installation of single flow computers up to fully redundant cabinet

- Complying with custody transfer requirements

Recommended products and solutions:

SUMMIT 8800

- Cost effective solution due to modular hard- and software design

- Full colour graphical touch screen for maximum process transparency

- Easy operator access enabling time efficient maintenance

- Automatic Performance Monitoring extends recalibration interval

Supervisory Control Cabinets

- Provides control of the metering system, including validation of field instrumentation

- Installed in a safe area, typically in a control room or dedicated building

- Supplied in combination with new metering systems, or for an upgrade to existing systems

Modular flow control and data transfer cabinets

- Cost effective, modular metering control solution

- Based on the SUMMIT 8800 flow computer

- Installed in a safe area, typically in a control room

Requirements:

- Measurement of gas quality

- Control of gas mixing process

Recommended products and solutions:

Analyser houses and shelters

- Quality measurements of crude oil, refined products and natural gas

- Supplied with new metering systems, or as a stand-alone upgrade to existing systems

- Engineered solutions based on customer preferred brands

Requirements:

- High-accuracy measurement of gas volume and quality

- Traceable to international standards

- Complying with custody transfer requirements

- Master/duty configuration with flowmeter diagnostics

Recommended products and solutions:

Custody transfer metering systems for gases

- Based on ultrasonic, Coriolis, turbine or DP flowmeters

- From initial design phase up to on-site commissioning and training

- Comprising flow metering skid, metering control cabinets, sampling and analyser systems, and all supervisory and validation software

Custody transfer metering systems for LNG

- Based on ultrasonic or Coriolis cryogenic flow meters

- From large scale ship (un)loading to bunkering and truck loading

- Comprising flow metering skid, metering control cabinets, sampling and analyser systems, and all supervisory and validation software

Requirements:

- Injection of odorant in natural gas

- Indication of the flow of chemicals

- Ensure continuous injection

Recommended products and solutions:

Regasification in the oil & gas industry

Requirements:

- Recognize leaks and defective seals quickly to prevent compressor damage

- Indication of the flow

Recommended products and solutions:

H250 M40

- Modular design: from mechanical indicator to 4…20 mA/HART®7, FF, Profibus-PA and totalizer

- Any installation position: vertical, horizontal or in fall pipes

- Flange: DN15…150 / ½…6"; also NPT, G, hygienic connections, etc.

- -196…+400°C / -320…+752°F; max. 1000 barg / 14500 psig

Requirements:

- Measurement of sea water for process control

- Energy balance of heat exchange process

Recommended products and solutions:

OPTISONIC 6300

- Stationary device, for installation at any location without process interruption or need to cut pipes

- Up to +200°C / +392°F

- Robust stainless steel sensor rail for pipes DN15…4000 / ½…160"

- 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP

OPTIFLUX 4000

- Full bore design: pipe cross-section without restrictions

- Connection sizes: DN2.5…3000 / ⅒…120" (depending on signal converter)

- Liner: PTFE, PFA, ETFE, PU, hard and soft rubber

OPTIFLUX 2000

- Full bore design: pipe cross-section without restrictions

- Connection sizes: DN25…1200 / 1…48"

- Liner: PP, PO or hard rubber

Requirements:

- Level measurement of gas and liquid in cryogenic conditions

- Cryogenic temperatures (<-162°C)

Recommended products and solutions:

BM 26 F2200

- Continuous, redundant measurement using two measurement principles in one device

- Measuring range: 0.3…5.5 / 1…18 ft (longer on request)

- Density: 0.5…3 kg/l / 31…187 lb/ft3

- -50…+300°C / -58…+570°F; -1…100 barg / -14.5…1450 psig

Requirements:

- Cryogenic temperatures (<-162°C)

- Accurate measurement for process control

Recommended products and solutions:

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

Requirements:

- Injection of odorant in natural gas

- Indication of the flow of chemicals

- Ensure continuous injection

Recommended products and solutions:

H250 M40

- Modular design: from mechanical indicator to 4…20 mA/HART®7, FF, Profibus-PA and totalizer

- Any installation position: vertical, horizontal or in fall pipes

- Flange: DN15…150 / ½…6"; also NPT, G, hygienic connections, etc.

- -196…+400°C / -320…+752°F; max. 1000 barg / 14500 psig

Requirements:

- High accuracy measurement of natural gas

- Need for diagnostics to ensure measurement accuracy

Recommended products and solutions:

OPTIMASS 6400

- High accuracy (±0.05% flat), for cryogenic to HT media (-200…+400°C / -328…+752°F); maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- SIL 2/3; CT: OIML R117, R137, MI-005, MI-002; API, AGA; hygienic certifications

- Flange: DN10…300 / ½…12", max. PN 160 / ASME Cl 1500

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

OPTIMASS 2400

- For gases and liquids up to 4,600 t/h; maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- CT: OIML R117, MI-005, MI-002; API and AGA compliant

- Flange: DN100…400 / 4…16", max. PN160 / ASME Cl 1500

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

ALTOSONIC V12

- 12-chord meter, for high accuracy flow metering of natural gas

- CT: OIML R137 (class 0.5), MI-002, AGA9 etc.

- Many variants, extensive CBM diagnostics free of charge

- Flange: DN100…1600 / 4…64"; max. PN450 / ASME Cl 2500

SUMMIT 8800

- Cost effective solution due to modular hard- and software design

- Full colour graphical touch screen for maximum process transparency

- Easy operator access enabling time efficient maintenance

- Automatic Performance Monitoring extends recalibration interval

Requirements:

- Cryogenic temperatures (<-162°C)

- Risk of overfill or dry run

- Inventory measurement

Recommended products and solutions:

OPTISWITCH 5300

- Point level detection of liquids under extreme conditions

- Probe length: up to 3000 mm / 118 ft

- ≥0.47 g/cm3 / 0.017 lb/in3 (optional: ≥0.42 g/cm3 or 0.015 lb/in3)

- -196…+450°C / -321…+842°F; -1…160 barg / -14.5…2321 psig

Requirements:

- Visualisation and monitoring of critical processes

- Control of reporting, trends and alarm handling

- Statistical evaluation of measurement data

Recommended products and solutions:

SynEnergy Supervisory and visualisation software

- HMI/SCADA software for measurement solutions

- State of the art HTML5 secure web technology

- Optimisation of operation results due to predictive maintenance

- Easy integration into existing DCS and ERP networks

CalSys Analyser Management software

- Effective performance monitoring of quality measurement instruments (QMI)

- Automated analyser validation and statistical process control

- Complies with international standards and methods (ASTM D3764, ASTM D6299, OP 97-30425 etc.)

- Increased availability of gas chromatographs and critical process analysers

Requirements:

- Integration of flow computers, PLCs, supervisory computers and printers

- Installation of single flow computers up to fully redundant cabinet

- Complying with custody transfer requirements

Recommended products and solutions:

SUMMIT 8800

- Cost effective solution due to modular hard- and software design

- Full colour graphical touch screen for maximum process transparency

- Easy operator access enabling time efficient maintenance

- Automatic Performance Monitoring extends recalibration interval

Supervisory Control Cabinets

- Provides control of the metering system, including validation of field instrumentation

- Installed in a safe area, typically in a control room or dedicated building

- Supplied in combination with new metering systems, or for an upgrade to existing systems

Modular flow control and data transfer cabinets

- Cost effective, modular metering control solution

- Based on the SUMMIT 8800 flow computer

- Installed in a safe area, typically in a control room

Requirements:

- Measurement of gas quality

- Control of gas mixing process

Recommended products and solutions:

Analyser houses and shelters

- Quality measurements of crude oil, refined products and natural gas

- Supplied with new metering systems, or as a stand-alone upgrade to existing systems

- Engineered solutions based on customer preferred brands

Requirements:

- High-accuracy measurement of gas volume and quality

- Traceable to international standards

- Complying with custody transfer requirements

- Master/duty configuration with flowmeter diagnostics

Recommended products and solutions:

Custody transfer metering systems for gases

- Based on ultrasonic, Coriolis, turbine or DP flowmeters

- From initial design phase up to on-site commissioning and training

- Comprising flow metering skid, metering control cabinets, sampling and analyser systems, and all supervisory and validation software

Custody transfer metering systems for LNG

- Based on ultrasonic or Coriolis cryogenic flow meters

- From large scale ship (un)loading to bunkering and truck loading

- Comprising flow metering skid, metering control cabinets, sampling and analyser systems, and all supervisory and validation software

Requirements:

- High accuracy measurement of natural gas

- Need for diagnostics to ensure measurement accuracy

Recommended products and solutions:

ALTOSONIC V12

Ultrasonic flowmeter for custody transfer (CT) measurement of gases

Regasification in the oil & gas industry

Requirements:

- Recognize leaks and defective seals quickly to prevent compressor damage

- Indication of the flow

Recommended products and solutions:

H250 M40

- Modular design: from mechanical indicator to 4…20 mA/HART®7, FF, Profibus-PA and totalizer

- Any installation position: vertical, horizontal or in fall pipes

- Flange: DN15…150 / ½…6"; also NPT, G, hygienic connections, etc.

- -196…+400°C / -320…+752°F; max. 1000 barg / 14500 psig

Requirements:

- Measurement of sea water for process control

- Energy balance of heat exchange process

Recommended products and solutions:

OPTISONIC 6300

- Stationary device, for installation at any location without process interruption or need to cut pipes

- Up to +200°C / +392°F

- Robust stainless steel sensor rail for pipes DN15…4000 / ½…160"

- 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP

OPTIFLUX 4000

- Full bore design: pipe cross-section without restrictions

- Connection sizes: DN2.5…3000 / ⅒…120" (depending on signal converter)

- Liner: PTFE, PFA, ETFE, PU, hard and soft rubber

OPTIFLUX 2000

- Full bore design: pipe cross-section without restrictions

- Connection sizes: DN25…1200 / 1…48"

- Liner: PP, PO or hard rubber

Requirements:

- Level measurement of gas and liquid in cryogenic conditions

- Cryogenic temperatures (<-162°C)

Recommended products and solutions:

BM 26 F2200

- Continuous, redundant measurement using two measurement principles in one device

- Measuring range: 0.3…5.5 / 1…18 ft (longer on request)

- Density: 0.5…3 kg/l / 31…187 lb/ft3

- -50…+300°C / -58…+570°F; -1…100 barg / -14.5…1450 psig

Requirements:

- Cryogenic temperatures (<-162°C)

- Accurate measurement for process control

Recommended products and solutions:

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

Requirements:

- Injection of odorant in natural gas

- Indication of the flow of chemicals

- Ensure continuous injection

Recommended products and solutions:

H250 M40

- Modular design: from mechanical indicator to 4…20 mA/HART®7, FF, Profibus-PA and totalizer

- Any installation position: vertical, horizontal or in fall pipes

- Flange: DN15…150 / ½…6"; also NPT, G, hygienic connections, etc.

- -196…+400°C / -320…+752°F; max. 1000 barg / 14500 psig

Requirements:

- High accuracy measurement of natural gas

- Need for diagnostics to ensure measurement accuracy

Recommended products and solutions:

OPTIMASS 6400

- High accuracy (±0.05% flat), for cryogenic to HT media (-200…+400°C / -328…+752°F); maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- SIL 2/3; CT: OIML R117, R137, MI-005, MI-002; API, AGA; hygienic certifications

- Flange: DN10…300 / ½…12", max. PN 160 / ASME Cl 1500

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

OPTIMASS 2400

- For gases and liquids up to 4,600 t/h; maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- CT: OIML R117, MI-005, MI-002; API and AGA compliant

- Flange: DN100…400 / 4…16", max. PN160 / ASME Cl 1500

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

ALTOSONIC V12

- 12-chord meter, for high accuracy flow metering of natural gas

- CT: OIML R137 (class 0.5), MI-002, AGA9 etc.

- Many variants, extensive CBM diagnostics free of charge

- Flange: DN100…1600 / 4…64"; max. PN450 / ASME Cl 2500

SUMMIT 8800

- Cost effective solution due to modular hard- and software design

- Full colour graphical touch screen for maximum process transparency

- Easy operator access enabling time efficient maintenance

- Automatic Performance Monitoring extends recalibration interval

Requirements:

- Cryogenic temperatures (<-162°C)

- Risk of overfill or dry run

- Inventory measurement

Recommended products and solutions:

OPTISWITCH 5300

- Point level detection of liquids under extreme conditions

- Probe length: up to 3000 mm / 118 ft

- ≥0.47 g/cm3 / 0.017 lb/in3 (optional: ≥0.42 g/cm3 or 0.015 lb/in3)

- -196…+450°C / -321…+842°F; -1…160 barg / -14.5…2321 psig

Requirements:

- Visualisation and monitoring of critical processes

- Control of reporting, trends and alarm handling

- Statistical evaluation of measurement data

Recommended products and solutions:

SynEnergy Supervisory and visualisation software

- HMI/SCADA software for measurement solutions

- State of the art HTML5 secure web technology

- Optimisation of operation results due to predictive maintenance

- Easy integration into existing DCS and ERP networks

CalSys Analyser Management software

- Effective performance monitoring of quality measurement instruments (QMI)

- Automated analyser validation and statistical process control

- Complies with international standards and methods (ASTM D3764, ASTM D6299, OP 97-30425 etc.)

- Increased availability of gas chromatographs and critical process analysers

Requirements:

- Integration of flow computers, PLCs, supervisory computers and printers

- Installation of single flow computers up to fully redundant cabinet

- Complying with custody transfer requirements

Recommended products and solutions:

SUMMIT 8800

- Cost effective solution due to modular hard- and software design

- Full colour graphical touch screen for maximum process transparency

- Easy operator access enabling time efficient maintenance

- Automatic Performance Monitoring extends recalibration interval

Supervisory Control Cabinets

- Provides control of the metering system, including validation of field instrumentation

- Installed in a safe area, typically in a control room or dedicated building

- Supplied in combination with new metering systems, or for an upgrade to existing systems

Modular flow control and data transfer cabinets

- Cost effective, modular metering control solution

- Based on the SUMMIT 8800 flow computer

- Installed in a safe area, typically in a control room

Requirements:

- Measurement of gas quality

- Control of gas mixing process

Recommended products and solutions:

Analyser houses and shelters

- Quality measurements of crude oil, refined products and natural gas

- Supplied with new metering systems, or as a stand-alone upgrade to existing systems

- Engineered solutions based on customer preferred brands

Requirements:

- High-accuracy measurement of gas volume and quality

- Traceable to international standards

- Complying with custody transfer requirements

- Master/duty configuration with flowmeter diagnostics

Recommended products and solutions:

Custody transfer metering systems for gases

- Based on ultrasonic, Coriolis, turbine or DP flowmeters

- From initial design phase up to on-site commissioning and training

- Comprising flow metering skid, metering control cabinets, sampling and analyser systems, and all supervisory and validation software

Custody transfer metering systems for LNG

- Based on ultrasonic or Coriolis cryogenic flow meters

- From large scale ship (un)loading to bunkering and truck loading

- Comprising flow metering skid, metering control cabinets, sampling and analyser systems, and all supervisory and validation software

Requirements:

- Cryogenic temperatures (<-162°C)

- Risk of overfill or dry run

- Inventory measurement

Recommended products and solutions:

Regasification in the oil & gas industry

Requirements:

- Recognize leaks and defective seals quickly to prevent compressor damage

- Indication of the flow

Recommended products and solutions:

H250 M40

- Modular design: from mechanical indicator to 4…20 mA/HART®7, FF, Profibus-PA and totalizer

- Any installation position: vertical, horizontal or in fall pipes

- Flange: DN15…150 / ½…6"; also NPT, G, hygienic connections, etc.

- -196…+400°C / -320…+752°F; max. 1000 barg / 14500 psig

Requirements:

- Measurement of sea water for process control

- Energy balance of heat exchange process

Recommended products and solutions:

OPTISONIC 6300

- Stationary device, for installation at any location without process interruption or need to cut pipes

- Up to +200°C / +392°F

- Robust stainless steel sensor rail for pipes DN15…4000 / ½…160"

- 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP

OPTIFLUX 4000

- Full bore design: pipe cross-section without restrictions

- Connection sizes: DN2.5…3000 / ⅒…120" (depending on signal converter)

- Liner: PTFE, PFA, ETFE, PU, hard and soft rubber

OPTIFLUX 2000

- Full bore design: pipe cross-section without restrictions

- Connection sizes: DN25…1200 / 1…48"

- Liner: PP, PO or hard rubber

Requirements:

- Level measurement of gas and liquid in cryogenic conditions

- Cryogenic temperatures (<-162°C)

Recommended products and solutions:

BM 26 F2200

- Continuous, redundant measurement using two measurement principles in one device

- Measuring range: 0.3…5.5 / 1…18 ft (longer on request)

- Density: 0.5…3 kg/l / 31…187 lb/ft3

- -50…+300°C / -58…+570°F; -1…100 barg / -14.5…1450 psig

Requirements:

- Cryogenic temperatures (<-162°C)

- Accurate measurement for process control

Recommended products and solutions:

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

Requirements:

- Injection of odorant in natural gas

- Indication of the flow of chemicals

- Ensure continuous injection

Recommended products and solutions:

H250 M40

- Modular design: from mechanical indicator to 4…20 mA/HART®7, FF, Profibus-PA and totalizer

- Any installation position: vertical, horizontal or in fall pipes

- Flange: DN15…150 / ½…6"; also NPT, G, hygienic connections, etc.

- -196…+400°C / -320…+752°F; max. 1000 barg / 14500 psig

Requirements:

- High accuracy measurement of natural gas

- Need for diagnostics to ensure measurement accuracy

Recommended products and solutions:

OPTIMASS 6400

- High accuracy (±0.05% flat), for cryogenic to HT media (-200…+400°C / -328…+752°F); maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- SIL 2/3; CT: OIML R117, R137, MI-005, MI-002; API, AGA; hygienic certifications

- Flange: DN10…300 / ½…12", max. PN 160 / ASME Cl 1500

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

OPTIMASS 2400

- For gases and liquids up to 4,600 t/h; maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- CT: OIML R117, MI-005, MI-002; API and AGA compliant

- Flange: DN100…400 / 4…16", max. PN160 / ASME Cl 1500

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

ALTOSONIC V12

- 12-chord meter, for high accuracy flow metering of natural gas

- CT: OIML R137 (class 0.5), MI-002, AGA9 etc.

- Many variants, extensive CBM diagnostics free of charge

- Flange: DN100…1600 / 4…64"; max. PN450 / ASME Cl 2500

SUMMIT 8800

- Cost effective solution due to modular hard- and software design

- Full colour graphical touch screen for maximum process transparency

- Easy operator access enabling time efficient maintenance

- Automatic Performance Monitoring extends recalibration interval

Requirements:

- Cryogenic temperatures (<-162°C)

- Risk of overfill or dry run

- Inventory measurement

Recommended products and solutions:

OPTISWITCH 5300

- Point level detection of liquids under extreme conditions

- Probe length: up to 3000 mm / 118 ft

- ≥0.47 g/cm3 / 0.017 lb/in3 (optional: ≥0.42 g/cm3 or 0.015 lb/in3)

- -196…+450°C / -321…+842°F; -1…160 barg / -14.5…2321 psig

Requirements:

- Visualisation and monitoring of critical processes

- Control of reporting, trends and alarm handling

- Statistical evaluation of measurement data

Recommended products and solutions:

SynEnergy Supervisory and visualisation software

- HMI/SCADA software for measurement solutions

- State of the art HTML5 secure web technology

- Optimisation of operation results due to predictive maintenance

- Easy integration into existing DCS and ERP networks

CalSys Analyser Management software

- Effective performance monitoring of quality measurement instruments (QMI)

- Automated analyser validation and statistical process control

- Complies with international standards and methods (ASTM D3764, ASTM D6299, OP 97-30425 etc.)

- Increased availability of gas chromatographs and critical process analysers

Requirements:

- Integration of flow computers, PLCs, supervisory computers and printers

- Installation of single flow computers up to fully redundant cabinet

- Complying with custody transfer requirements

Recommended products and solutions:

SUMMIT 8800

- Cost effective solution due to modular hard- and software design

- Full colour graphical touch screen for maximum process transparency

- Easy operator access enabling time efficient maintenance

- Automatic Performance Monitoring extends recalibration interval

Supervisory Control Cabinets

- Provides control of the metering system, including validation of field instrumentation

- Installed in a safe area, typically in a control room or dedicated building

- Supplied in combination with new metering systems, or for an upgrade to existing systems

Modular flow control and data transfer cabinets

- Cost effective, modular metering control solution

- Based on the SUMMIT 8800 flow computer

- Installed in a safe area, typically in a control room

Requirements:

- Measurement of gas quality

- Control of gas mixing process

Recommended products and solutions:

Analyser houses and shelters

- Quality measurements of crude oil, refined products and natural gas

- Supplied with new metering systems, or as a stand-alone upgrade to existing systems

- Engineered solutions based on customer preferred brands

Requirements:

- High-accuracy measurement of gas volume and quality

- Traceable to international standards

- Complying with custody transfer requirements

- Master/duty configuration with flowmeter diagnostics

Recommended products and solutions:

Custody transfer metering systems for gases

- Based on ultrasonic, Coriolis, turbine or DP flowmeters

- From initial design phase up to on-site commissioning and training

- Comprising flow metering skid, metering control cabinets, sampling and analyser systems, and all supervisory and validation software

Custody transfer metering systems for LNG

- Based on ultrasonic or Coriolis cryogenic flow meters

- From large scale ship (un)loading to bunkering and truck loading

- Comprising flow metering skid, metering control cabinets, sampling and analyser systems, and all supervisory and validation software

Requirements:

- Visualisation and monitoring of critical processes

- Control of reporting, trends and alarm handling

- Statistical evaluation of measurement data

Recommended products and solutions:

SynEnergy Supervisory and visualisation software

Solution for continuous process monitoring and reporting

CalSys Analyser Management software

Solution for analyser management and data acquisition (AMADAS)

Regasification in the oil & gas industry

Requirements:

- Recognize leaks and defective seals quickly to prevent compressor damage

- Indication of the flow

Recommended products and solutions:

H250 M40

- Modular design: from mechanical indicator to 4…20 mA/HART®7, FF, Profibus-PA and totalizer

- Any installation position: vertical, horizontal or in fall pipes

- Flange: DN15…150 / ½…6"; also NPT, G, hygienic connections, etc.

- -196…+400°C / -320…+752°F; max. 1000 barg / 14500 psig

Requirements:

- Measurement of sea water for process control

- Energy balance of heat exchange process

Recommended products and solutions:

OPTISONIC 6300

- Stationary device, for installation at any location without process interruption or need to cut pipes

- Up to +200°C / +392°F

- Robust stainless steel sensor rail for pipes DN15…4000 / ½…160"

- 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP

OPTIFLUX 4000

- Full bore design: pipe cross-section without restrictions

- Connection sizes: DN2.5…3000 / ⅒…120" (depending on signal converter)

- Liner: PTFE, PFA, ETFE, PU, hard and soft rubber

OPTIFLUX 2000

- Full bore design: pipe cross-section without restrictions

- Connection sizes: DN25…1200 / 1…48"

- Liner: PP, PO or hard rubber

Requirements:

- Level measurement of gas and liquid in cryogenic conditions

- Cryogenic temperatures (<-162°C)

Recommended products and solutions:

BM 26 F2200

- Continuous, redundant measurement using two measurement principles in one device

- Measuring range: 0.3…5.5 / 1…18 ft (longer on request)

- Density: 0.5…3 kg/l / 31…187 lb/ft3

- -50…+300°C / -58…+570°F; -1…100 barg / -14.5…1450 psig

Requirements:

- Cryogenic temperatures (<-162°C)

- Accurate measurement for process control

Recommended products and solutions:

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt