Loading and fueling in the oil & gas industry

Monitoring of loading and fuelling

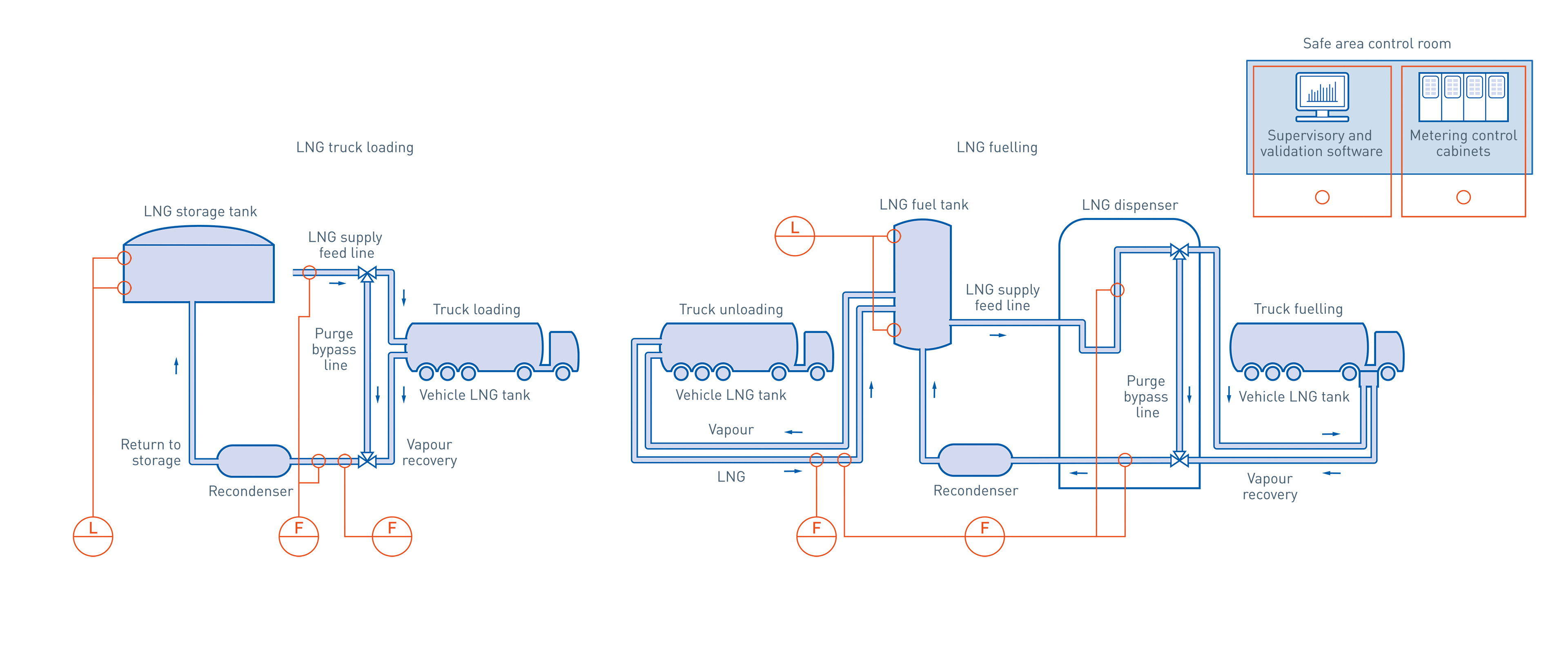

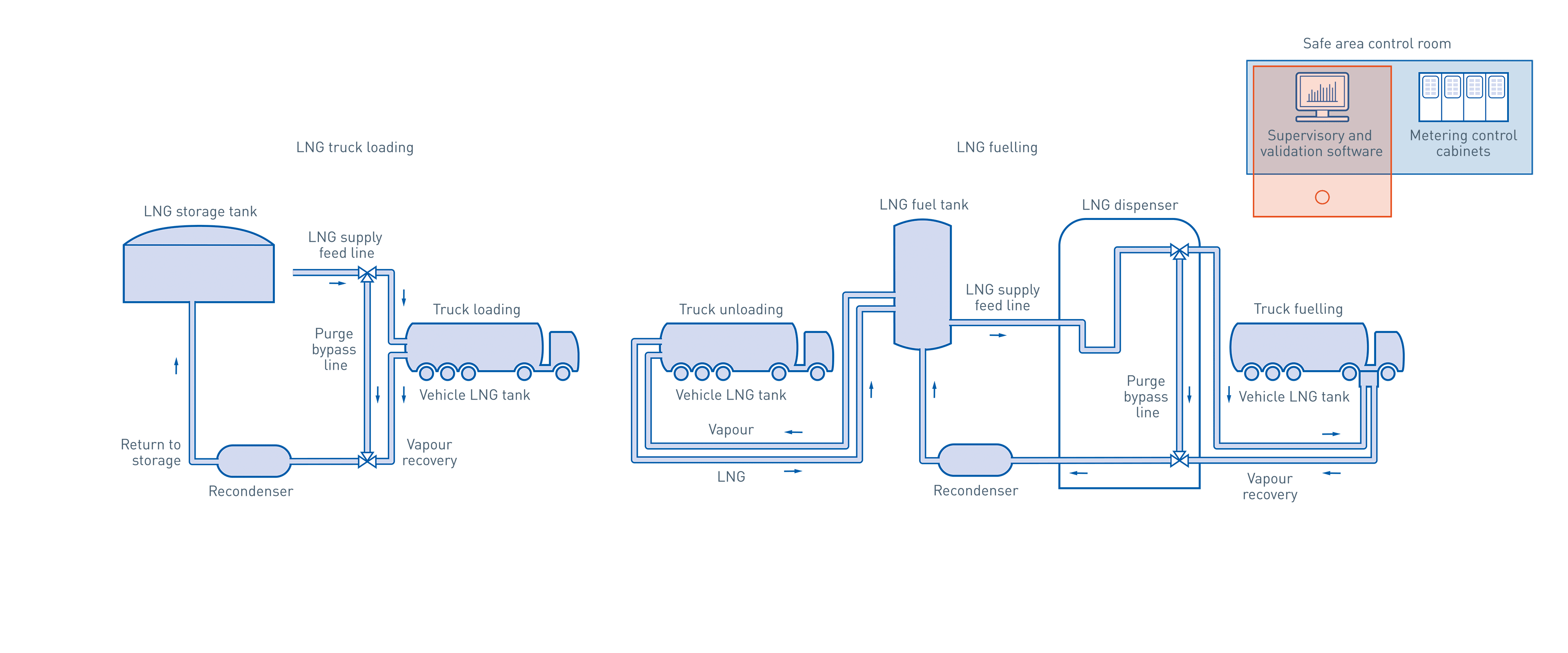

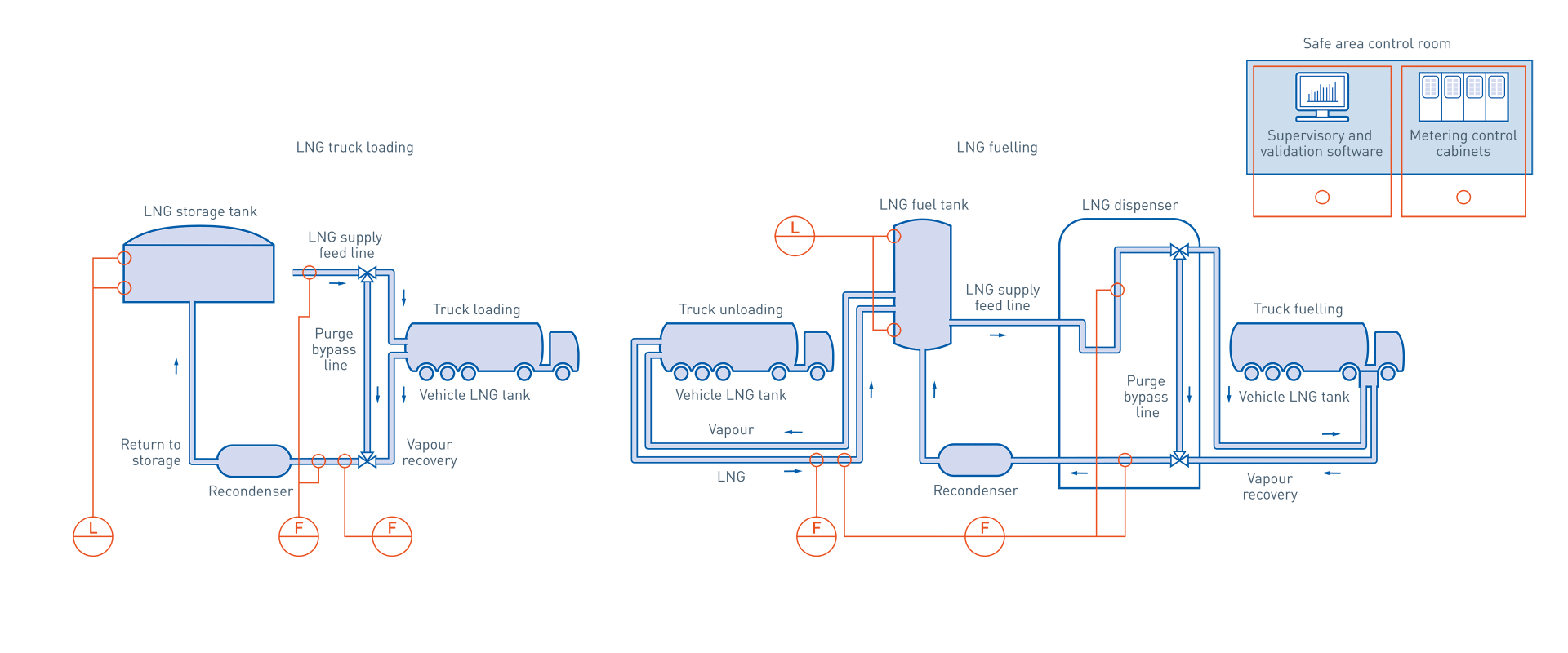

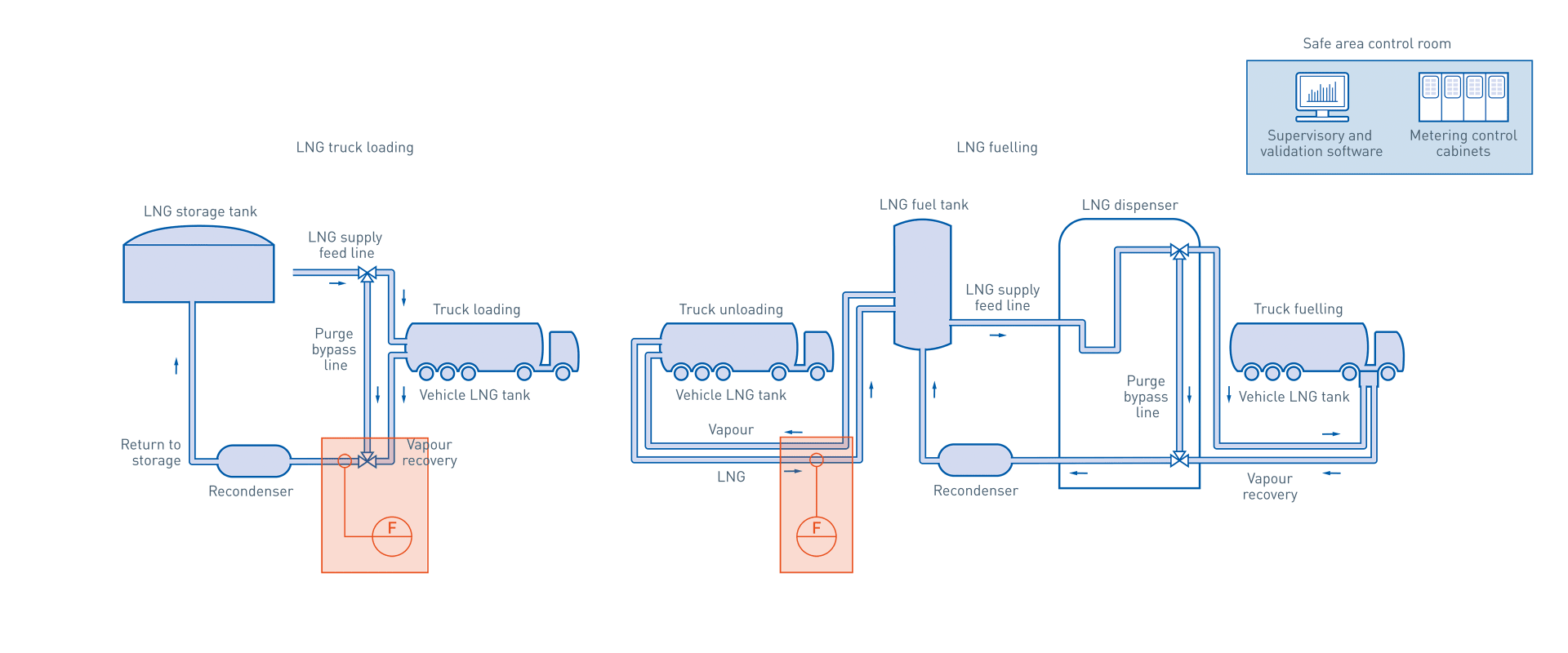

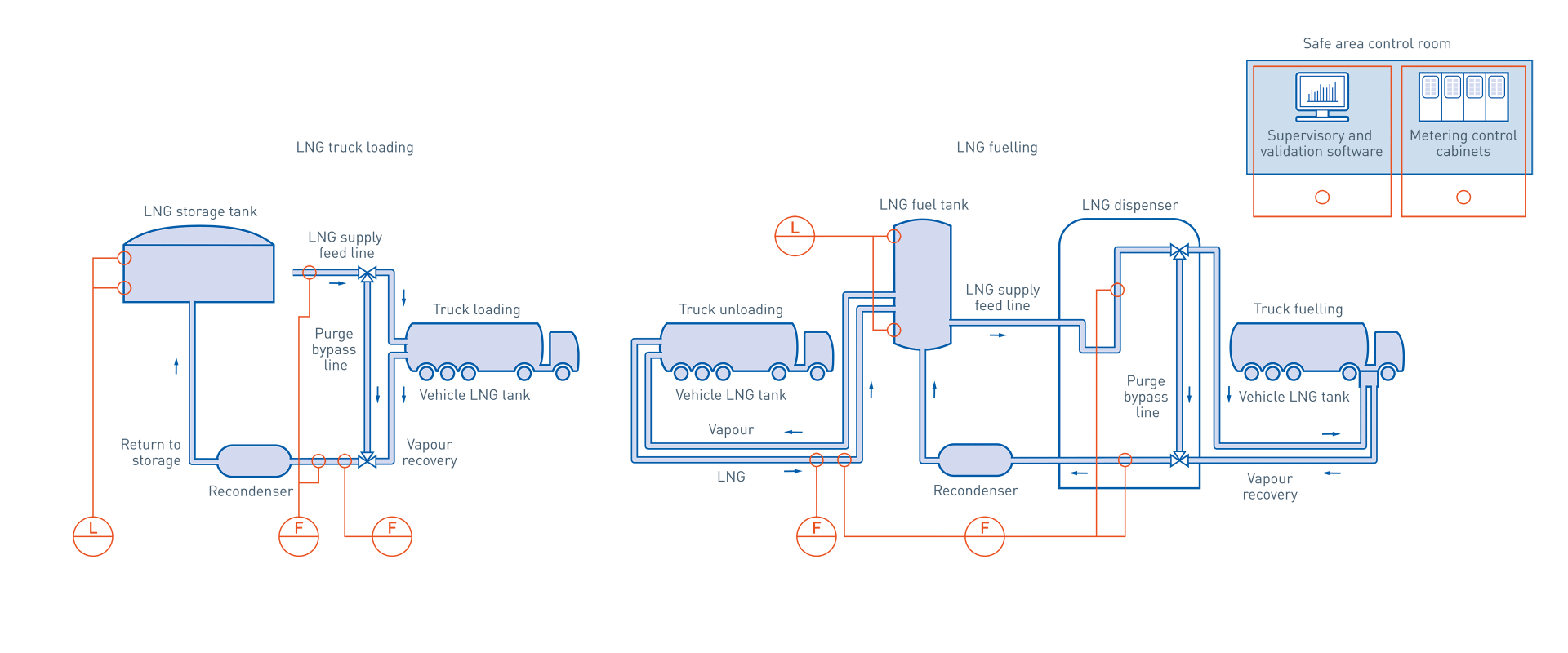

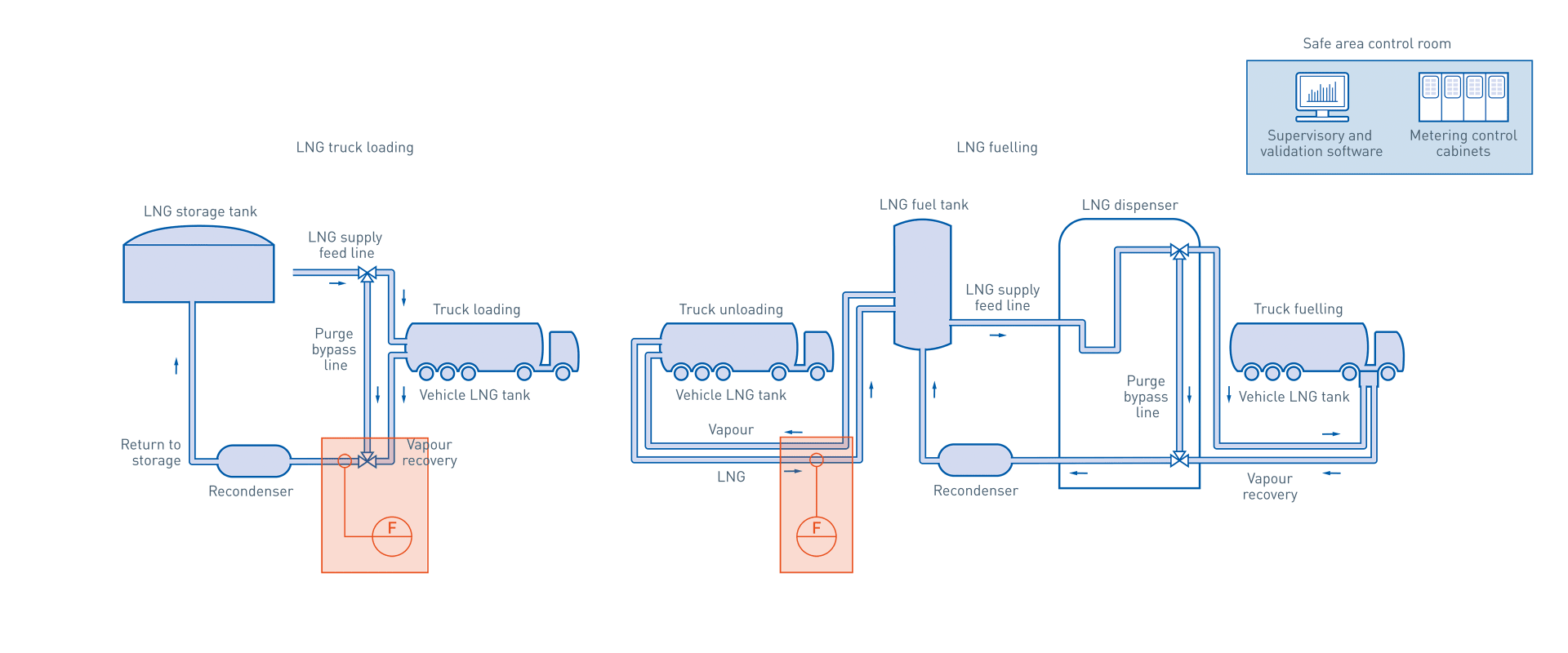

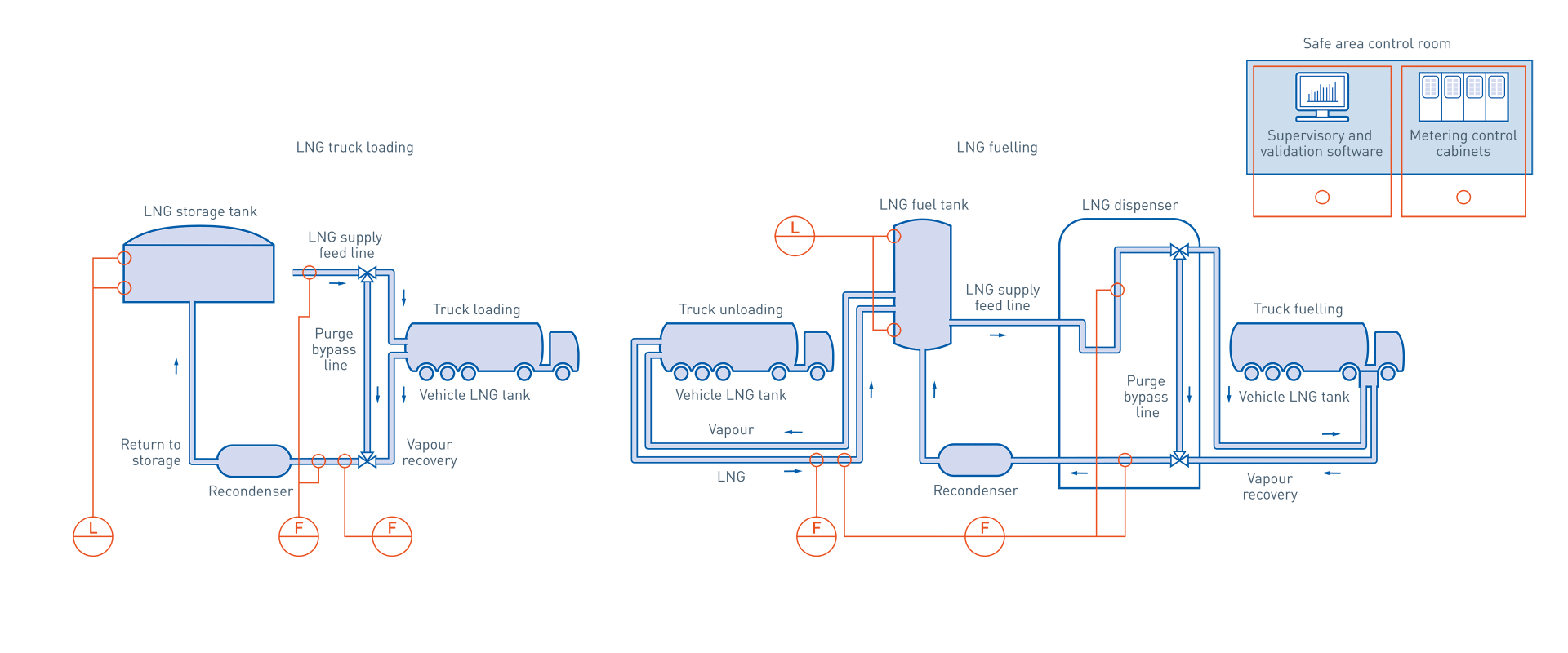

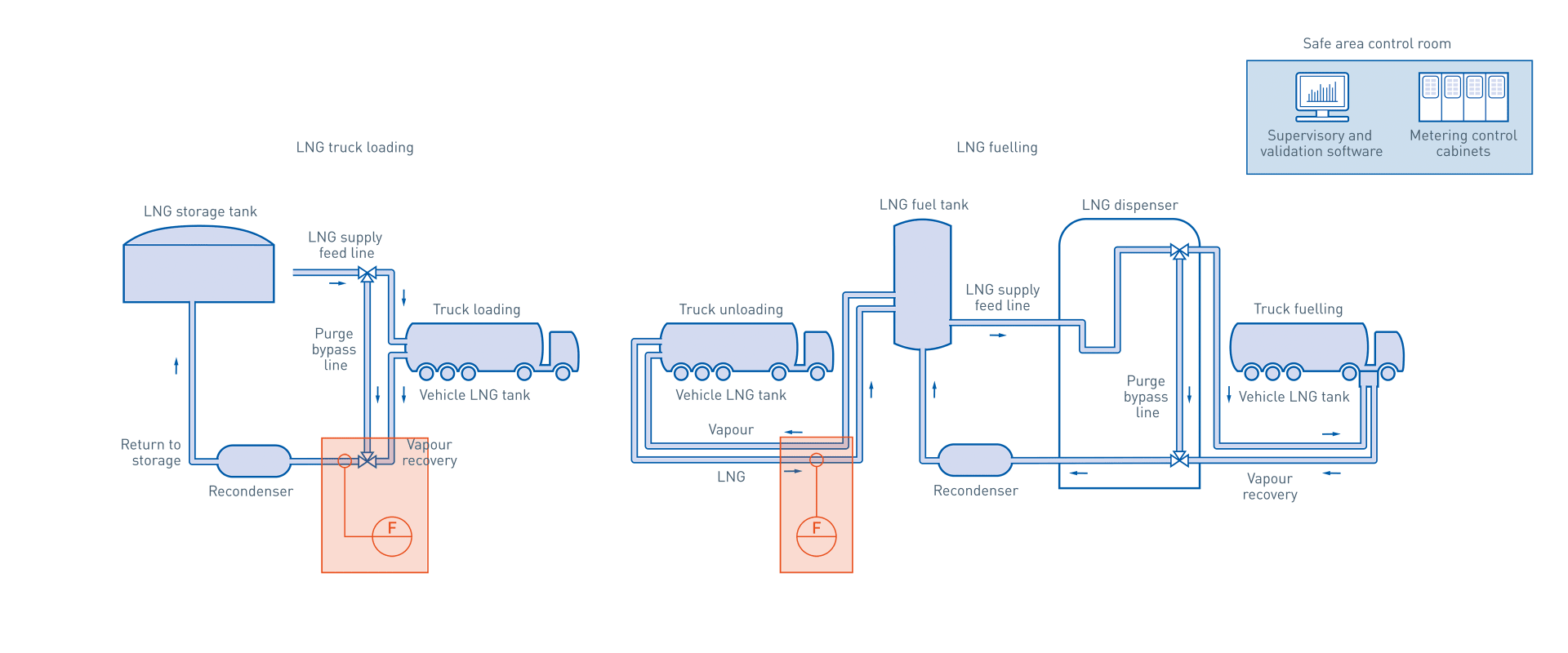

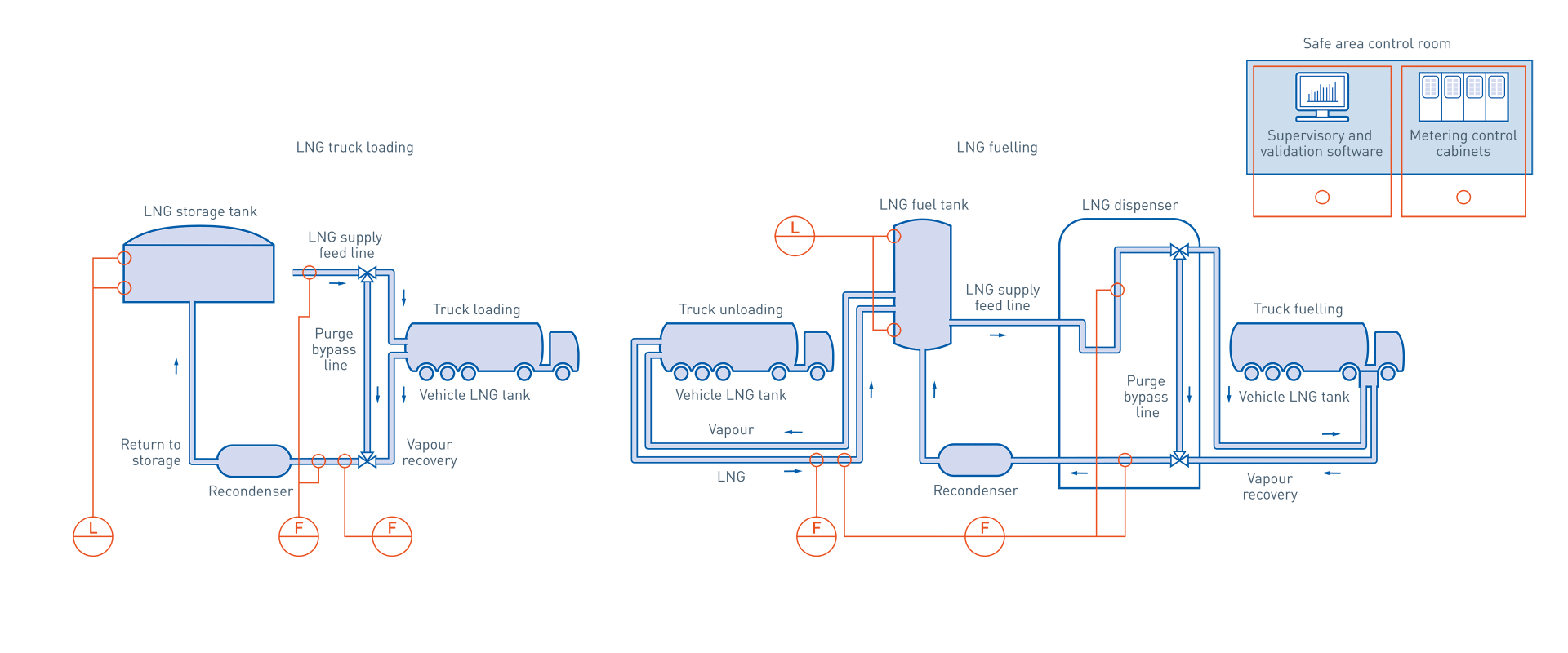

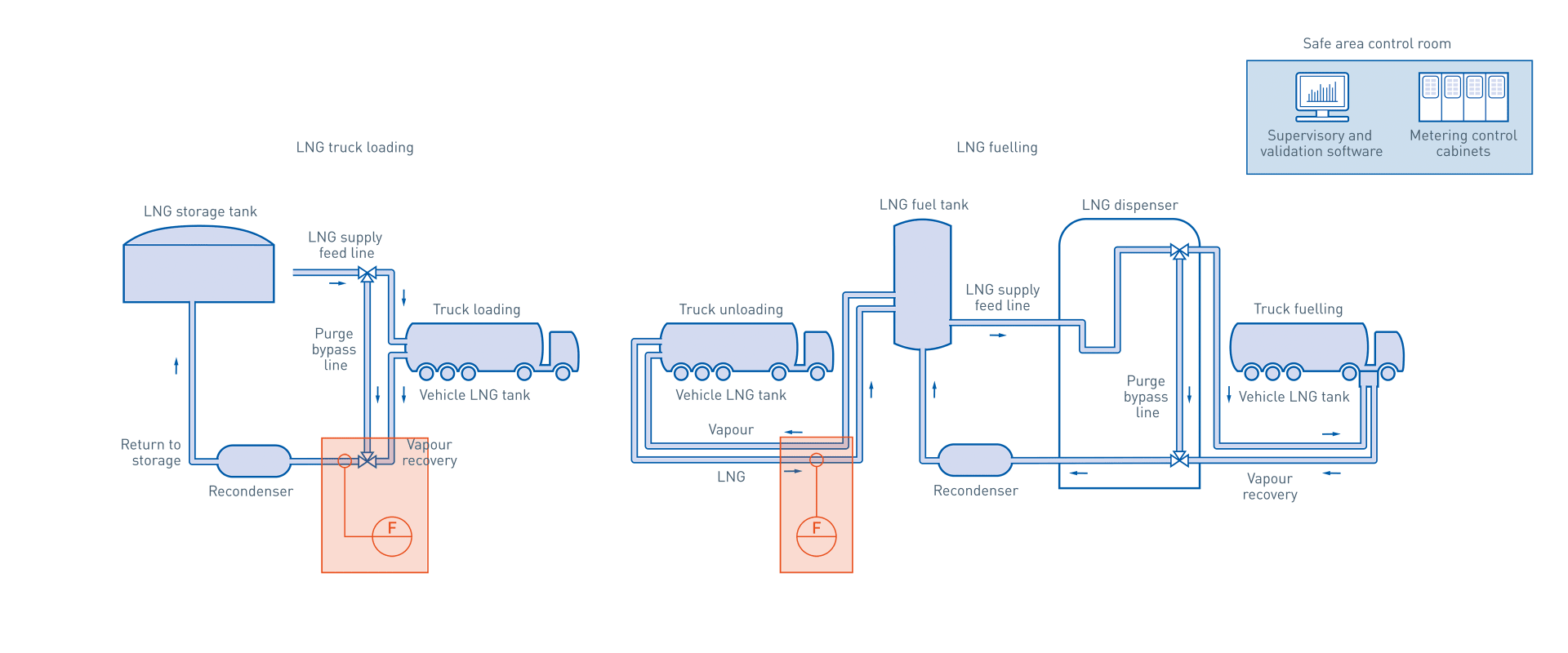

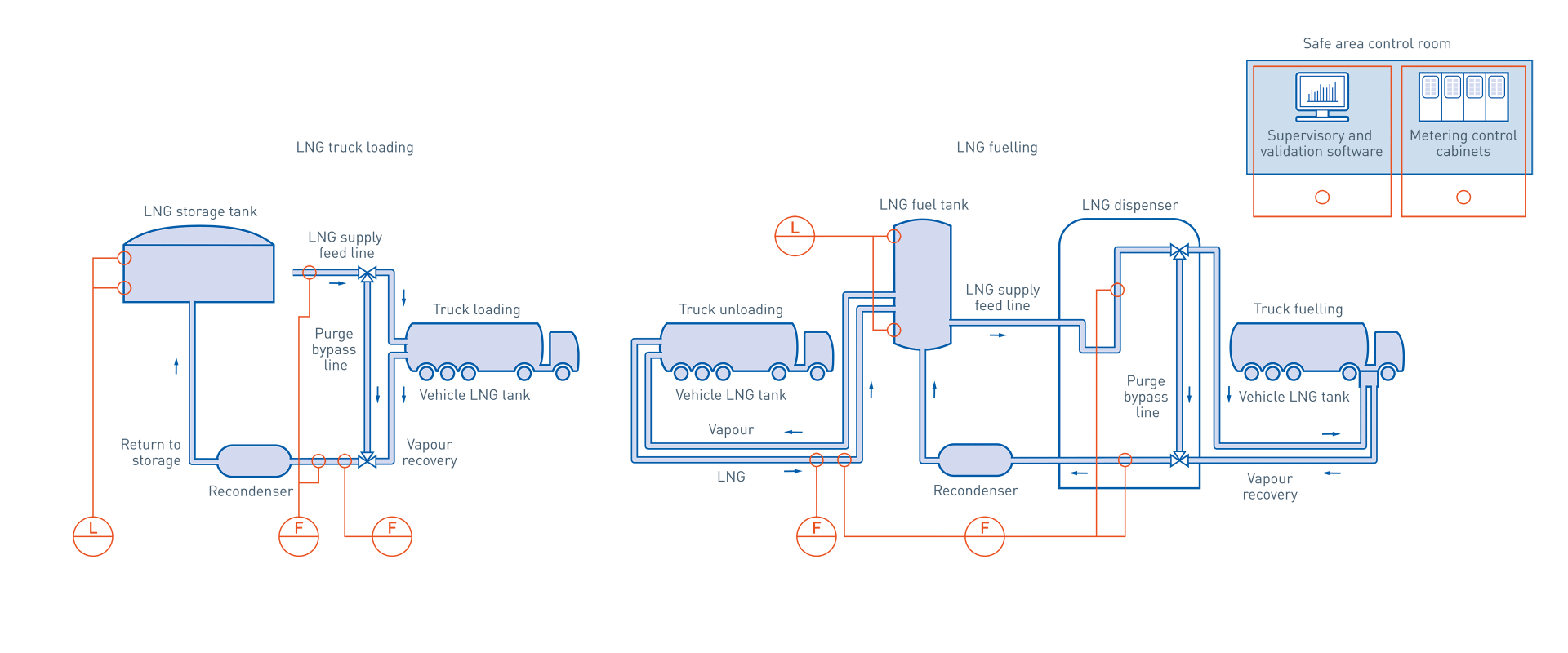

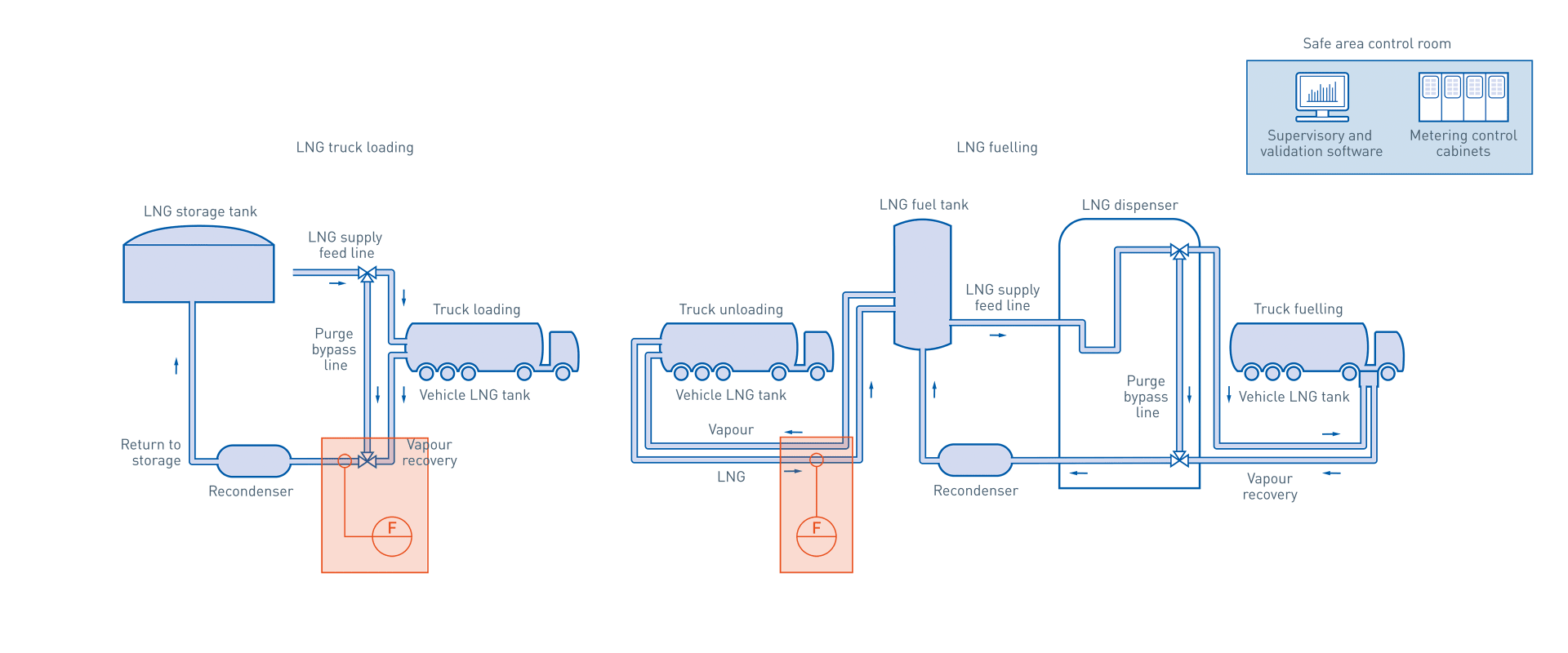

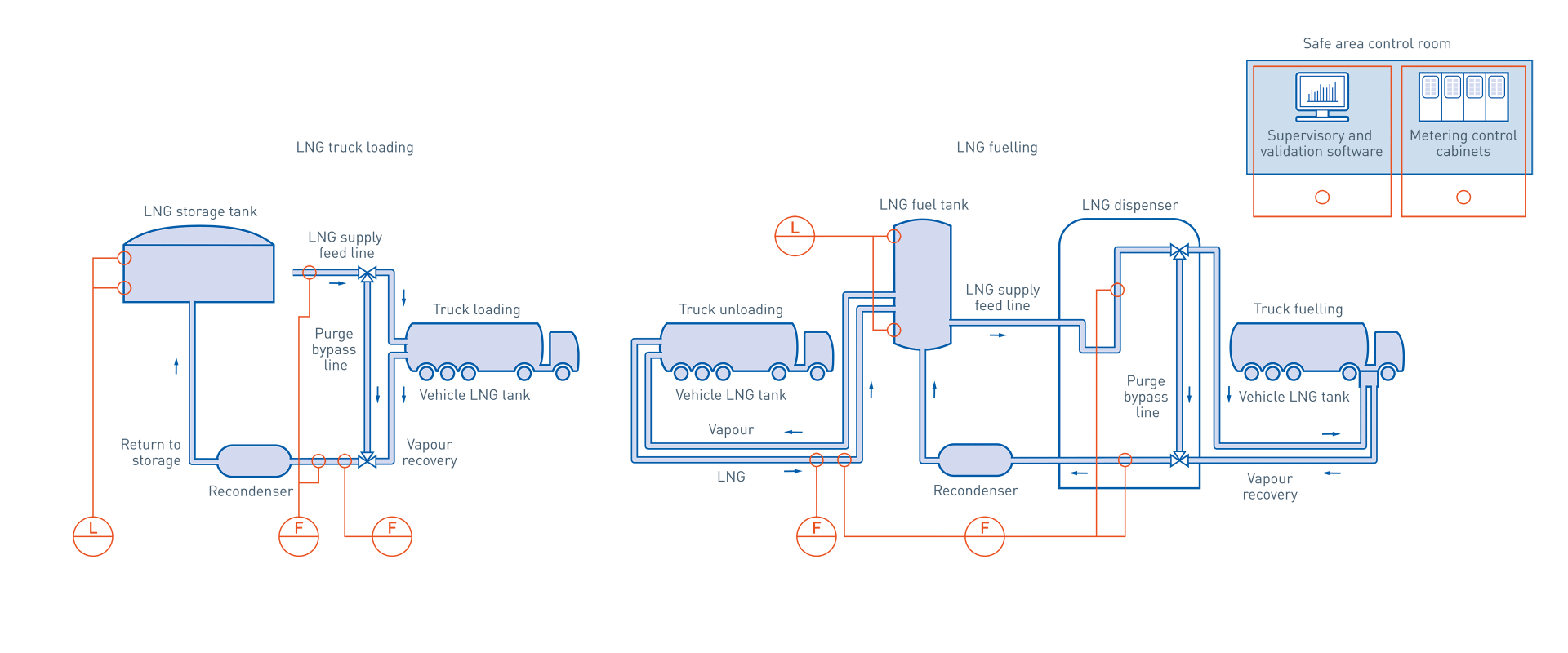

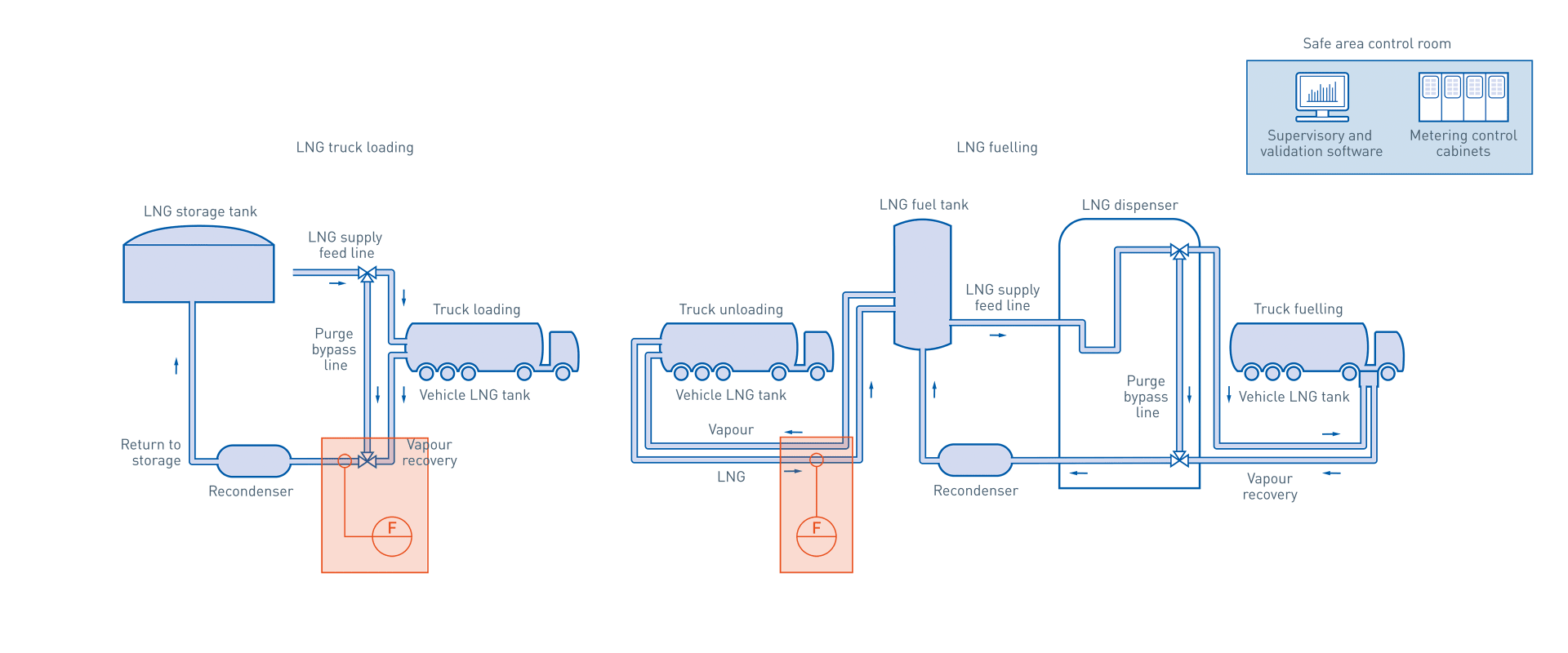

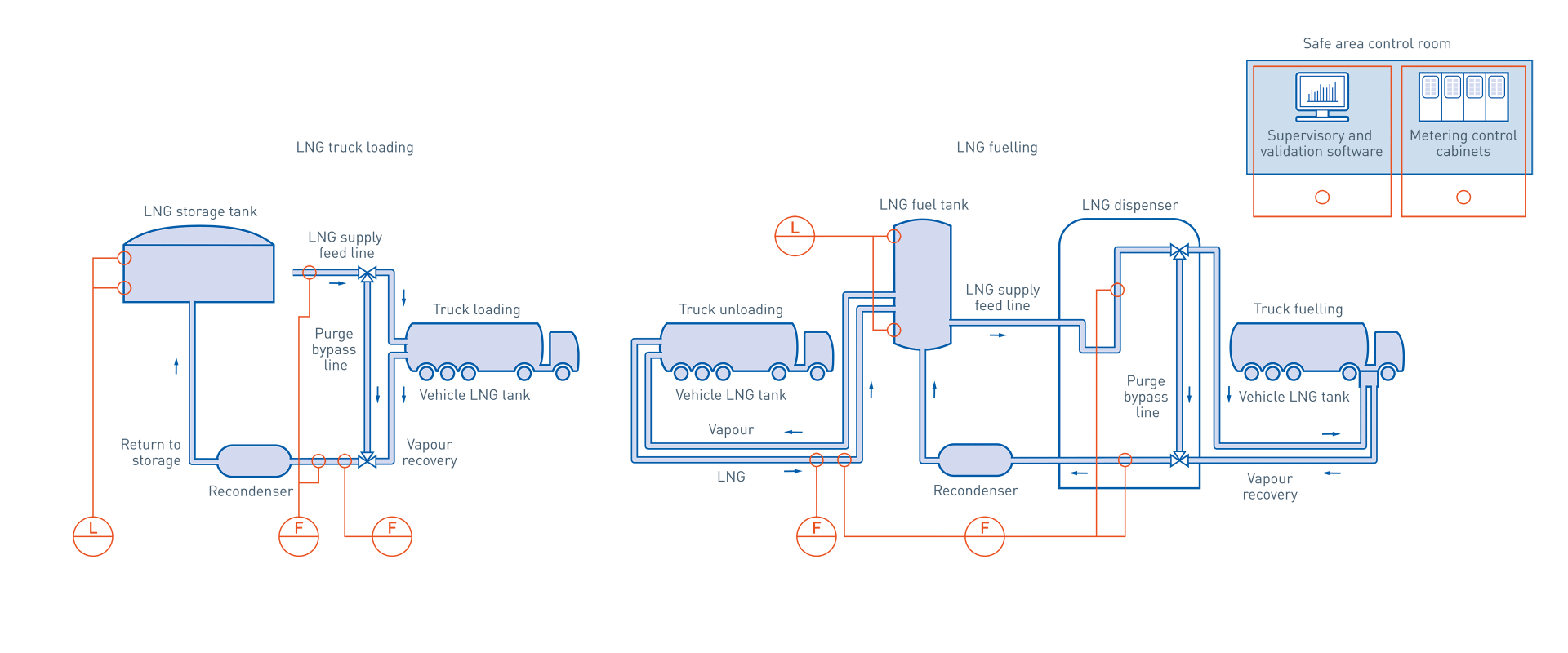

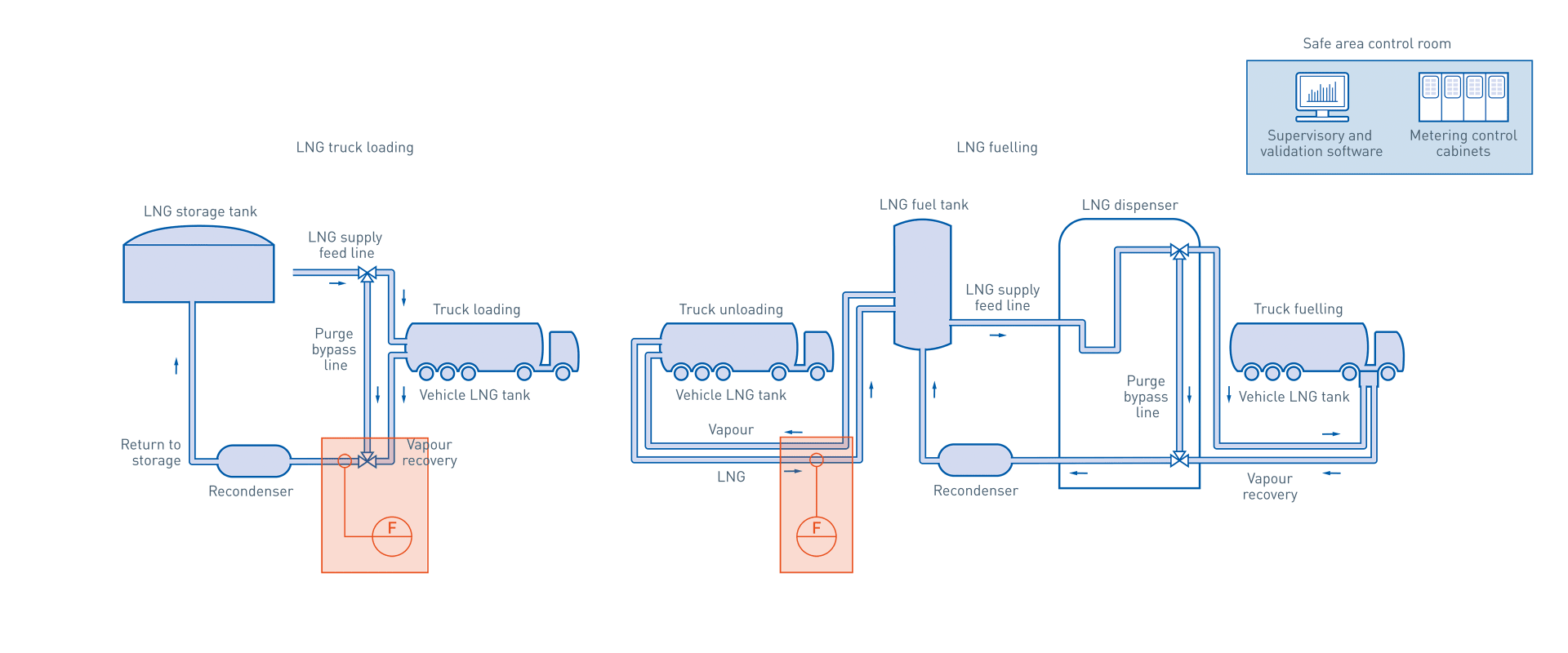

A recent development is ‘Small Scale LNG’, which involves the supply of smaller quantities of LNG delivered via a road tanker or a small ship, for distribution to special LNG fuel stations or loading facilities. The LNG is then sold as a fuel for trucks and for ships, which can reduce emissions in line with modern environmental policies. Also LNG bunkering ships are under development, which would refuel larger ships while they are in port loading or unloading their cargo.

During the loading of the tanker lorry or ship, the delivery of LNG is monitored by a custody transfer flow measurement installation, which also takes account of any LNG boil off gas returned to the storage tank after being re-liquefied in a condenser. At the LNG fuel station similar instrumentation and custody transfer flow measurement systems monitor the bulk delivered LNG, and also the smaller quantities dispensed to vehicles and other users of the LNG as a regular fuel.

KROHNE ultrasonic and Coriolis flowmeters, with the associated SUMMIT flow computer, have been successfully installed on several small scale LNG projects such as truck loading and LNG fuel dispensers. In Northern Europe, KROHNE has also recently supplied a road tanker mounted custody transfer approved delivery system, which includes a Coriolis flowmeter and flow computer, with a ticket printer to show the total delivery, all approved by the relevant local and fiscal authorities for sales of the LNG fuel.

Process details

Loading and fueling in the oil & gas industry

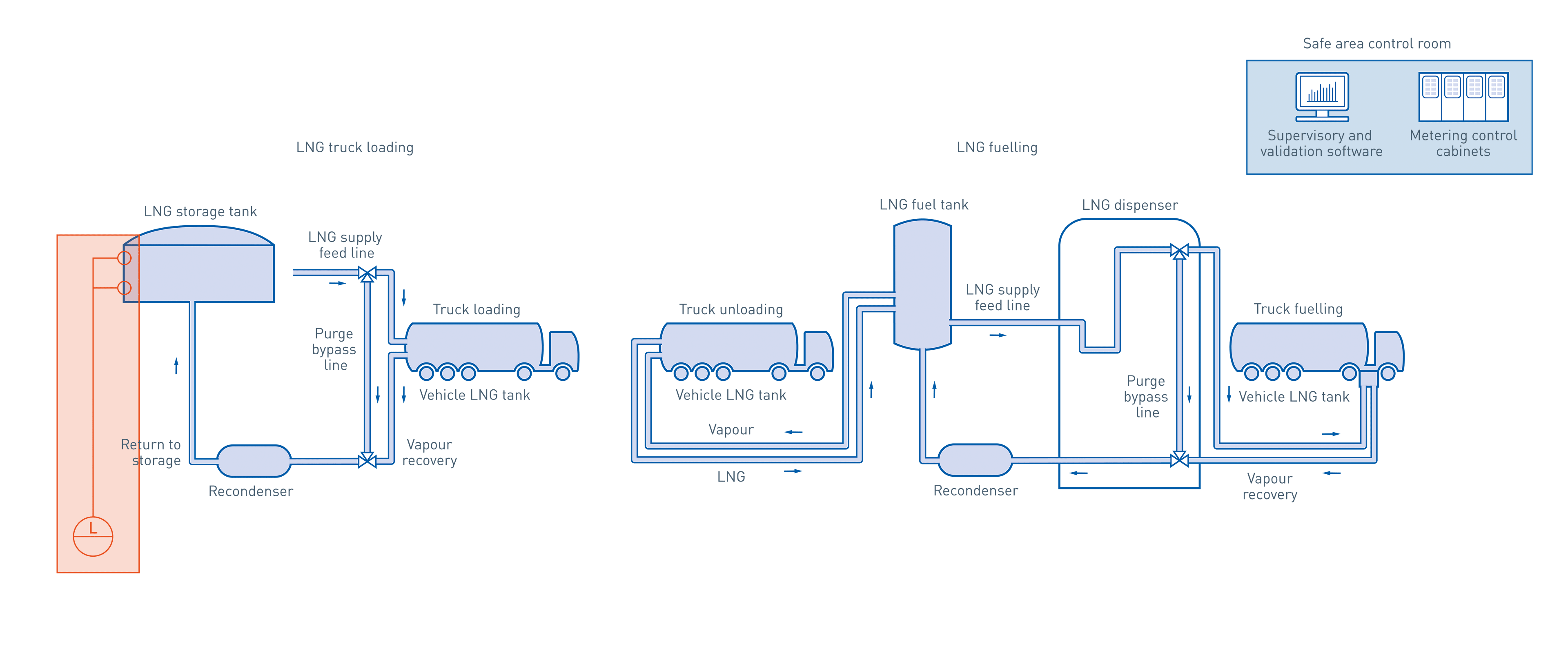

Requirements:

- Cryogenic temperatures (<-162°C)

- Risk of overfill or dry run

- Inventory measurement

Recommended products and solutions:

OPTISWITCH 5300

- Point level detection of liquids under extreme conditions

- Probe length: up to 3000 mm / 118 ft

- ≥0.47 g/cm3 / 0.017 lb/in3 (optional: ≥0.42 g/cm3 or 0.015 lb/in3)

- -196…+450°C / -321…+842°F; -1…160 barg / -14.5…2321 psig

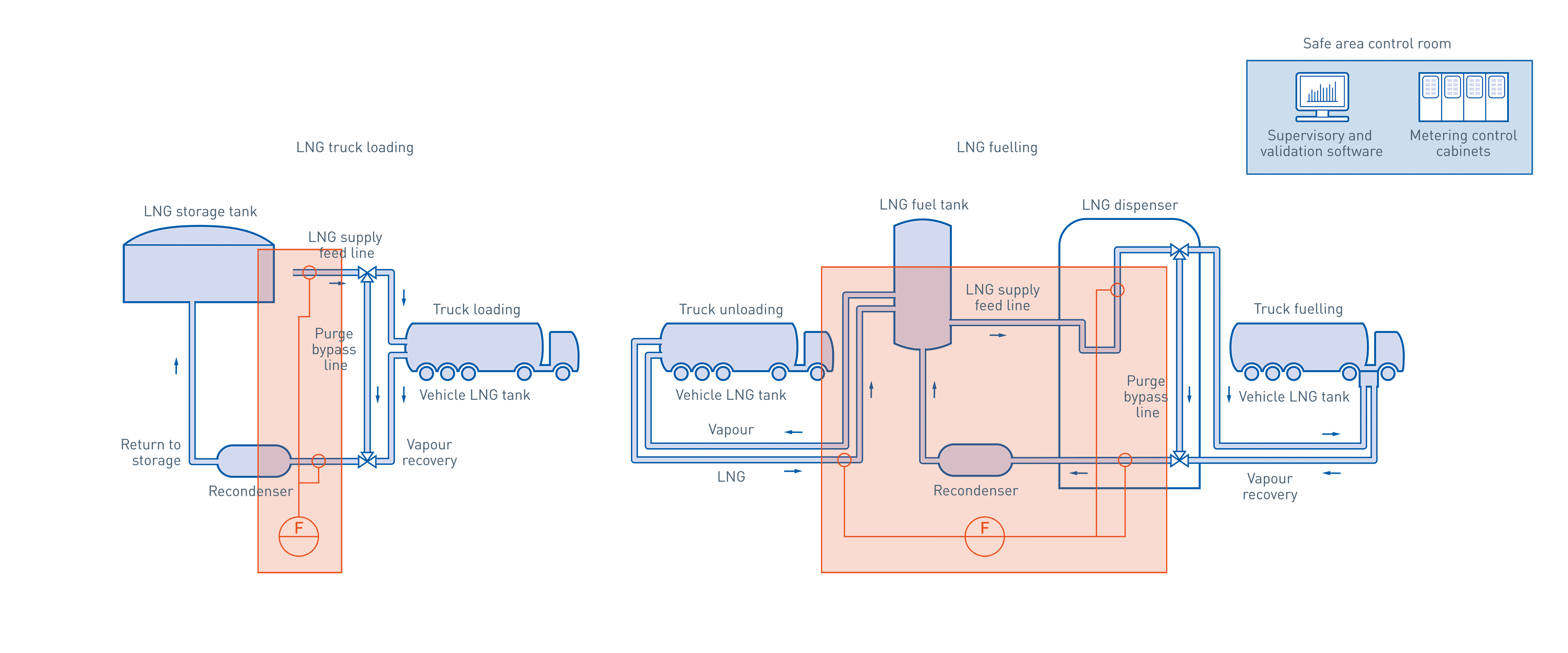

Requirements:

- Need for custody transfer certification

- Transparent programming and easy to operate

Recommended products and solutions:

SUMMIT 8800

- Cost effective solution due to modular hard- and software design

- Full colour graphical touch screen for maximum process transparency

- Easy operator access enabling time efficient maintenance

- Automatic Performance Monitoring extends recalibration interval

Requirements:

- Cryogenic temperatures (<162°C)

- Need for custody transfer certification

Recommended products and solutions:

OPTIMASS 6400

- High accuracy (±0.05% flat), for cryogenic to HT media (-200…+400°C / -328…+752°F); maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- SIL 2/3; CT: OIML R117, R137, MI-005, MI-002; API, AGA; hygienic certifications

- Flange: DN10…300 / ½…12", max. PN 160 / ASME Cl 1500

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

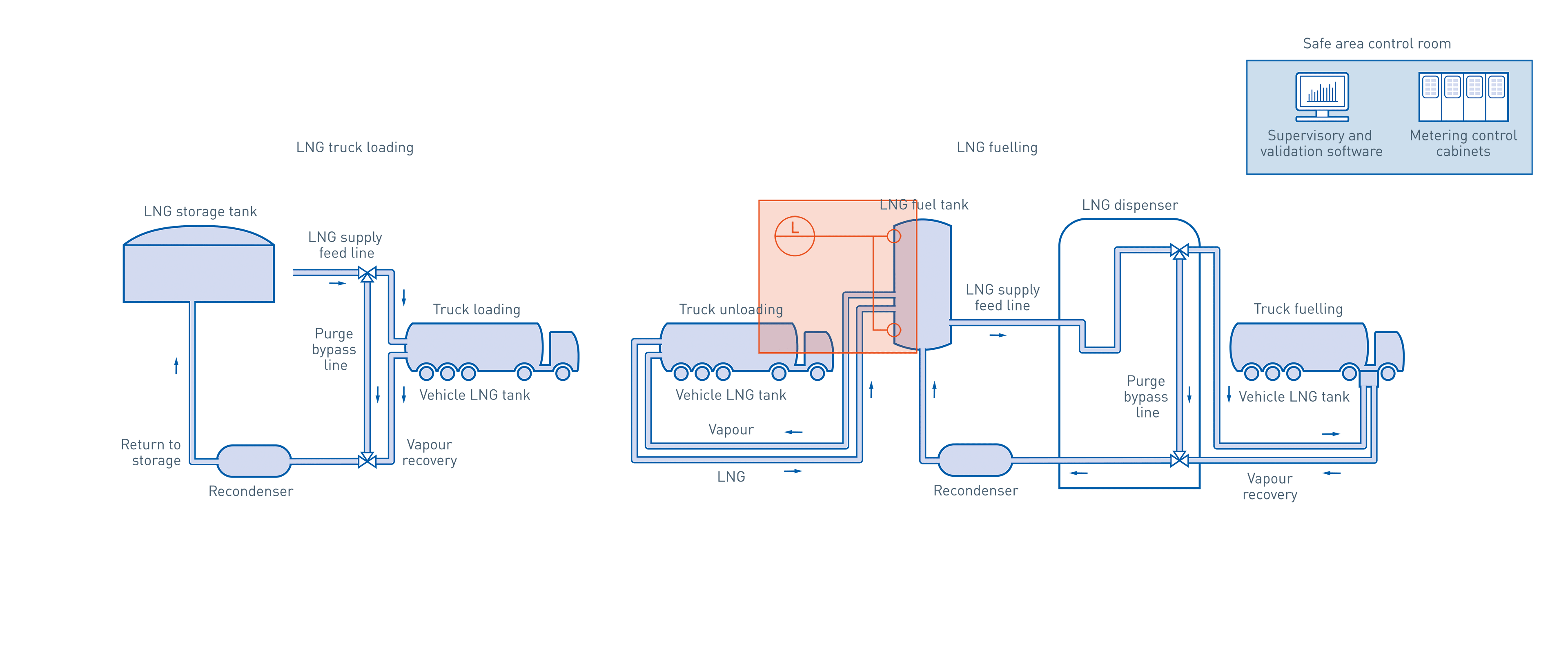

Requirements:

- Cryogenic temperatures (<162°C)

- Risk of overfill or dry run

- Inventory measurement

Recommended products and solutions:

OPTISWITCH 5300

- Point level detection of liquids under extreme conditions

- Probe length: up to 3000 mm / 118 ft

- ≥0.47 g/cm3 / 0.017 lb/in3 (optional: ≥0.42 g/cm3 or 0.015 lb/in3)

- -196…+450°C / -321…+842°F; -1…160 barg / -14.5…2321 psig

Requirements:

- Integration of flow computers, PLCs, supervisory computers and printers

- Installation of single flow computers up to fully redundant cabinet

- Complying with custody transfer requirements

Recommended products and solutions:

SUMMIT 8800

- Cost effective solution due to modular hard- and software design

- Full colour graphical touch screen for maximum process transparency

- Easy operator access enabling time efficient maintenance

- Automatic Performance Monitoring extends recalibration interval

Supervisory Control Cabinets

- Provides control of the metering system, including validation of field instrumentation

- Installed in a safe area, typically in a control room or dedicated building

- Supplied in combination with new metering systems, or for an upgrade to existing systems

Modular flow control and data transfer cabinets

- Cost effective, modular metering control solution

- Based on the SUMMIT 8800 flow computer

- Installed in a safe area, typically in a control room

Requirements:

- Visualisation and monitoring of critical processes

- Control of reporting, trends and alarm handling

- Statistical evaluation of measurement data

Recommended products and solutions:

SynEnergy Supervisory and visualisation software

- HMI/SCADA software for measurement solutions

- State of the art HTML5 secure web technology

- Optimisation of operation results due to predictive maintenance

- Easy integration into existing DCS and ERP networks

CalSys Analyser Management software

- Effective performance monitoring of quality measurement instruments (QMI)

- Automated analyser validation and statistical process control

- Complies with international standards and methods (ASTM D3764, ASTM D6299, OP 97-30425 etc.)

- Increased availability of gas chromatographs and critical process analysers

Loading and fueling in the oil & gas industry

Requirements:

- Cryogenic temperatures (<-162°C)

- Risk of overfill or dry run

- Inventory measurement

Recommended products and solutions:

OPTISWITCH 5300

- Point level detection of liquids under extreme conditions

- Probe length: up to 3000 mm / 118 ft

- ≥0.47 g/cm3 / 0.017 lb/in3 (optional: ≥0.42 g/cm3 or 0.015 lb/in3)

- -196…+450°C / -321…+842°F; -1…160 barg / -14.5…2321 psig

Requirements:

- Need for custody transfer certification

- Transparent programming and easy to operate

Recommended products and solutions:

SUMMIT 8800

- Cost effective solution due to modular hard- and software design

- Full colour graphical touch screen for maximum process transparency

- Easy operator access enabling time efficient maintenance

- Automatic Performance Monitoring extends recalibration interval

Requirements:

- Cryogenic temperatures (<162°C)

- Need for custody transfer certification

Recommended products and solutions:

OPTIMASS 6400

- High accuracy (±0.05% flat), for cryogenic to HT media (-200…+400°C / -328…+752°F); maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- SIL 2/3; CT: OIML R117, R137, MI-005, MI-002; API, AGA; hygienic certifications

- Flange: DN10…300 / ½…12", max. PN 160 / ASME Cl 1500

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

Requirements:

- Cryogenic temperatures (<162°C)

- Risk of overfill or dry run

- Inventory measurement

Recommended products and solutions:

OPTISWITCH 5300

- Point level detection of liquids under extreme conditions

- Probe length: up to 3000 mm / 118 ft

- ≥0.47 g/cm3 / 0.017 lb/in3 (optional: ≥0.42 g/cm3 or 0.015 lb/in3)

- -196…+450°C / -321…+842°F; -1…160 barg / -14.5…2321 psig

Requirements:

- Integration of flow computers, PLCs, supervisory computers and printers

- Installation of single flow computers up to fully redundant cabinet

- Complying with custody transfer requirements

Recommended products and solutions:

SUMMIT 8800

- Cost effective solution due to modular hard- and software design

- Full colour graphical touch screen for maximum process transparency

- Easy operator access enabling time efficient maintenance

- Automatic Performance Monitoring extends recalibration interval

Supervisory Control Cabinets

- Provides control of the metering system, including validation of field instrumentation

- Installed in a safe area, typically in a control room or dedicated building

- Supplied in combination with new metering systems, or for an upgrade to existing systems

Modular flow control and data transfer cabinets

- Cost effective, modular metering control solution

- Based on the SUMMIT 8800 flow computer

- Installed in a safe area, typically in a control room

Requirements:

- Visualisation and monitoring of critical processes

- Control of reporting, trends and alarm handling

- Statistical evaluation of measurement data

Recommended products and solutions:

SynEnergy Supervisory and visualisation software

- HMI/SCADA software for measurement solutions

- State of the art HTML5 secure web technology

- Optimisation of operation results due to predictive maintenance

- Easy integration into existing DCS and ERP networks

CalSys Analyser Management software

- Effective performance monitoring of quality measurement instruments (QMI)

- Automated analyser validation and statistical process control

- Complies with international standards and methods (ASTM D3764, ASTM D6299, OP 97-30425 etc.)

- Increased availability of gas chromatographs and critical process analysers

Requirements:

- Cryogenic temperatures (<-162°C)

- Risk of overfill or dry run

- Inventory measurement

Recommended products and solutions:

Loading and fueling in the oil & gas industry

Requirements:

- Cryogenic temperatures (<-162°C)

- Risk of overfill or dry run

- Inventory measurement

Recommended products and solutions:

OPTISWITCH 5300

- Point level detection of liquids under extreme conditions

- Probe length: up to 3000 mm / 118 ft

- ≥0.47 g/cm3 / 0.017 lb/in3 (optional: ≥0.42 g/cm3 or 0.015 lb/in3)

- -196…+450°C / -321…+842°F; -1…160 barg / -14.5…2321 psig

Requirements:

- Need for custody transfer certification

- Transparent programming and easy to operate

Recommended products and solutions:

SUMMIT 8800

- Cost effective solution due to modular hard- and software design

- Full colour graphical touch screen for maximum process transparency

- Easy operator access enabling time efficient maintenance

- Automatic Performance Monitoring extends recalibration interval

Requirements:

- Cryogenic temperatures (<162°C)

- Need for custody transfer certification

Recommended products and solutions:

OPTIMASS 6400

- High accuracy (±0.05% flat), for cryogenic to HT media (-200…+400°C / -328…+752°F); maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- SIL 2/3; CT: OIML R117, R137, MI-005, MI-002; API, AGA; hygienic certifications

- Flange: DN10…300 / ½…12", max. PN 160 / ASME Cl 1500

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

Requirements:

- Cryogenic temperatures (<162°C)

- Risk of overfill or dry run

- Inventory measurement

Recommended products and solutions:

OPTISWITCH 5300

- Point level detection of liquids under extreme conditions

- Probe length: up to 3000 mm / 118 ft

- ≥0.47 g/cm3 / 0.017 lb/in3 (optional: ≥0.42 g/cm3 or 0.015 lb/in3)

- -196…+450°C / -321…+842°F; -1…160 barg / -14.5…2321 psig

Requirements:

- Integration of flow computers, PLCs, supervisory computers and printers

- Installation of single flow computers up to fully redundant cabinet

- Complying with custody transfer requirements

Recommended products and solutions:

SUMMIT 8800

- Cost effective solution due to modular hard- and software design

- Full colour graphical touch screen for maximum process transparency

- Easy operator access enabling time efficient maintenance

- Automatic Performance Monitoring extends recalibration interval

Supervisory Control Cabinets

- Provides control of the metering system, including validation of field instrumentation

- Installed in a safe area, typically in a control room or dedicated building

- Supplied in combination with new metering systems, or for an upgrade to existing systems

Modular flow control and data transfer cabinets

- Cost effective, modular metering control solution

- Based on the SUMMIT 8800 flow computer

- Installed in a safe area, typically in a control room

Requirements:

- Visualisation and monitoring of critical processes

- Control of reporting, trends and alarm handling

- Statistical evaluation of measurement data

Recommended products and solutions:

SynEnergy Supervisory and visualisation software

- HMI/SCADA software for measurement solutions

- State of the art HTML5 secure web technology

- Optimisation of operation results due to predictive maintenance

- Easy integration into existing DCS and ERP networks

CalSys Analyser Management software

- Effective performance monitoring of quality measurement instruments (QMI)

- Automated analyser validation and statistical process control

- Complies with international standards and methods (ASTM D3764, ASTM D6299, OP 97-30425 etc.)

- Increased availability of gas chromatographs and critical process analysers

Requirements:

- Need for custody transfer certification

- Transparent programming and easy to operate

Recommended products and solutions:

Loading and fueling in the oil & gas industry

Requirements:

- Cryogenic temperatures (<-162°C)

- Risk of overfill or dry run

- Inventory measurement

Recommended products and solutions:

OPTISWITCH 5300

- Point level detection of liquids under extreme conditions

- Probe length: up to 3000 mm / 118 ft

- ≥0.47 g/cm3 / 0.017 lb/in3 (optional: ≥0.42 g/cm3 or 0.015 lb/in3)

- -196…+450°C / -321…+842°F; -1…160 barg / -14.5…2321 psig

Requirements:

- Need for custody transfer certification

- Transparent programming and easy to operate

Recommended products and solutions:

SUMMIT 8800

- Cost effective solution due to modular hard- and software design

- Full colour graphical touch screen for maximum process transparency

- Easy operator access enabling time efficient maintenance

- Automatic Performance Monitoring extends recalibration interval

Requirements:

- Cryogenic temperatures (<162°C)

- Need for custody transfer certification

Recommended products and solutions:

OPTIMASS 6400

- High accuracy (±0.05% flat), for cryogenic to HT media (-200…+400°C / -328…+752°F); maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- SIL 2/3; CT: OIML R117, R137, MI-005, MI-002; API, AGA; hygienic certifications

- Flange: DN10…300 / ½…12", max. PN 160 / ASME Cl 1500

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

Requirements:

- Cryogenic temperatures (<162°C)

- Risk of overfill or dry run

- Inventory measurement

Recommended products and solutions:

OPTISWITCH 5300

- Point level detection of liquids under extreme conditions

- Probe length: up to 3000 mm / 118 ft

- ≥0.47 g/cm3 / 0.017 lb/in3 (optional: ≥0.42 g/cm3 or 0.015 lb/in3)

- -196…+450°C / -321…+842°F; -1…160 barg / -14.5…2321 psig

Requirements:

- Integration of flow computers, PLCs, supervisory computers and printers

- Installation of single flow computers up to fully redundant cabinet

- Complying with custody transfer requirements

Recommended products and solutions:

SUMMIT 8800

- Cost effective solution due to modular hard- and software design

- Full colour graphical touch screen for maximum process transparency

- Easy operator access enabling time efficient maintenance

- Automatic Performance Monitoring extends recalibration interval

Supervisory Control Cabinets

- Provides control of the metering system, including validation of field instrumentation

- Installed in a safe area, typically in a control room or dedicated building

- Supplied in combination with new metering systems, or for an upgrade to existing systems

Modular flow control and data transfer cabinets

- Cost effective, modular metering control solution

- Based on the SUMMIT 8800 flow computer

- Installed in a safe area, typically in a control room

Requirements:

- Visualisation and monitoring of critical processes

- Control of reporting, trends and alarm handling

- Statistical evaluation of measurement data

Recommended products and solutions:

SynEnergy Supervisory and visualisation software

- HMI/SCADA software for measurement solutions

- State of the art HTML5 secure web technology

- Optimisation of operation results due to predictive maintenance

- Easy integration into existing DCS and ERP networks

CalSys Analyser Management software

- Effective performance monitoring of quality measurement instruments (QMI)

- Automated analyser validation and statistical process control

- Complies with international standards and methods (ASTM D3764, ASTM D6299, OP 97-30425 etc.)

- Increased availability of gas chromatographs and critical process analysers

Requirements:

- Cryogenic temperatures (<162°C)

- Need for custody transfer certification

Recommended products and solutions:

Loading and fueling in the oil & gas industry

Requirements:

- Cryogenic temperatures (<-162°C)

- Risk of overfill or dry run

- Inventory measurement

Recommended products and solutions:

OPTISWITCH 5300

- Point level detection of liquids under extreme conditions

- Probe length: up to 3000 mm / 118 ft

- ≥0.47 g/cm3 / 0.017 lb/in3 (optional: ≥0.42 g/cm3 or 0.015 lb/in3)

- -196…+450°C / -321…+842°F; -1…160 barg / -14.5…2321 psig

Requirements:

- Need for custody transfer certification

- Transparent programming and easy to operate

Recommended products and solutions:

SUMMIT 8800

- Cost effective solution due to modular hard- and software design

- Full colour graphical touch screen for maximum process transparency

- Easy operator access enabling time efficient maintenance

- Automatic Performance Monitoring extends recalibration interval

Requirements:

- Cryogenic temperatures (<162°C)

- Need for custody transfer certification

Recommended products and solutions:

OPTIMASS 6400

- High accuracy (±0.05% flat), for cryogenic to HT media (-200…+400°C / -328…+752°F); maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- SIL 2/3; CT: OIML R117, R137, MI-005, MI-002; API, AGA; hygienic certifications

- Flange: DN10…300 / ½…12", max. PN 160 / ASME Cl 1500

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

Requirements:

- Cryogenic temperatures (<162°C)

- Risk of overfill or dry run

- Inventory measurement

Recommended products and solutions:

OPTISWITCH 5300

- Point level detection of liquids under extreme conditions

- Probe length: up to 3000 mm / 118 ft

- ≥0.47 g/cm3 / 0.017 lb/in3 (optional: ≥0.42 g/cm3 or 0.015 lb/in3)

- -196…+450°C / -321…+842°F; -1…160 barg / -14.5…2321 psig

Requirements:

- Integration of flow computers, PLCs, supervisory computers and printers

- Installation of single flow computers up to fully redundant cabinet

- Complying with custody transfer requirements

Recommended products and solutions:

SUMMIT 8800

- Cost effective solution due to modular hard- and software design

- Full colour graphical touch screen for maximum process transparency

- Easy operator access enabling time efficient maintenance

- Automatic Performance Monitoring extends recalibration interval

Supervisory Control Cabinets

- Provides control of the metering system, including validation of field instrumentation

- Installed in a safe area, typically in a control room or dedicated building

- Supplied in combination with new metering systems, or for an upgrade to existing systems

Modular flow control and data transfer cabinets

- Cost effective, modular metering control solution

- Based on the SUMMIT 8800 flow computer

- Installed in a safe area, typically in a control room

Requirements:

- Visualisation and monitoring of critical processes

- Control of reporting, trends and alarm handling

- Statistical evaluation of measurement data

Recommended products and solutions:

SynEnergy Supervisory and visualisation software

- HMI/SCADA software for measurement solutions

- State of the art HTML5 secure web technology

- Optimisation of operation results due to predictive maintenance

- Easy integration into existing DCS and ERP networks

CalSys Analyser Management software

- Effective performance monitoring of quality measurement instruments (QMI)

- Automated analyser validation and statistical process control

- Complies with international standards and methods (ASTM D3764, ASTM D6299, OP 97-30425 etc.)

- Increased availability of gas chromatographs and critical process analysers

Requirements:

- Cryogenic temperatures (<162°C)

- Risk of overfill or dry run

- Inventory measurement

Recommended products and solutions:

Loading and fueling in the oil & gas industry

Requirements:

- Cryogenic temperatures (<-162°C)

- Risk of overfill or dry run

- Inventory measurement

Recommended products and solutions:

OPTISWITCH 5300

- Point level detection of liquids under extreme conditions

- Probe length: up to 3000 mm / 118 ft

- ≥0.47 g/cm3 / 0.017 lb/in3 (optional: ≥0.42 g/cm3 or 0.015 lb/in3)

- -196…+450°C / -321…+842°F; -1…160 barg / -14.5…2321 psig

Requirements:

- Need for custody transfer certification

- Transparent programming and easy to operate

Recommended products and solutions:

SUMMIT 8800

- Cost effective solution due to modular hard- and software design

- Full colour graphical touch screen for maximum process transparency

- Easy operator access enabling time efficient maintenance

- Automatic Performance Monitoring extends recalibration interval

Requirements:

- Cryogenic temperatures (<162°C)

- Need for custody transfer certification

Recommended products and solutions:

OPTIMASS 6400

- High accuracy (±0.05% flat), for cryogenic to HT media (-200…+400°C / -328…+752°F); maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- SIL 2/3; CT: OIML R117, R137, MI-005, MI-002; API, AGA; hygienic certifications

- Flange: DN10…300 / ½…12", max. PN 160 / ASME Cl 1500

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

Requirements:

- Cryogenic temperatures (<162°C)

- Risk of overfill or dry run

- Inventory measurement

Recommended products and solutions:

OPTISWITCH 5300

- Point level detection of liquids under extreme conditions

- Probe length: up to 3000 mm / 118 ft

- ≥0.47 g/cm3 / 0.017 lb/in3 (optional: ≥0.42 g/cm3 or 0.015 lb/in3)

- -196…+450°C / -321…+842°F; -1…160 barg / -14.5…2321 psig

Requirements:

- Integration of flow computers, PLCs, supervisory computers and printers

- Installation of single flow computers up to fully redundant cabinet

- Complying with custody transfer requirements

Recommended products and solutions:

SUMMIT 8800

- Cost effective solution due to modular hard- and software design

- Full colour graphical touch screen for maximum process transparency

- Easy operator access enabling time efficient maintenance

- Automatic Performance Monitoring extends recalibration interval

Supervisory Control Cabinets

- Provides control of the metering system, including validation of field instrumentation

- Installed in a safe area, typically in a control room or dedicated building

- Supplied in combination with new metering systems, or for an upgrade to existing systems

Modular flow control and data transfer cabinets

- Cost effective, modular metering control solution

- Based on the SUMMIT 8800 flow computer

- Installed in a safe area, typically in a control room

Requirements:

- Visualisation and monitoring of critical processes

- Control of reporting, trends and alarm handling

- Statistical evaluation of measurement data

Recommended products and solutions:

SynEnergy Supervisory and visualisation software

- HMI/SCADA software for measurement solutions

- State of the art HTML5 secure web technology

- Optimisation of operation results due to predictive maintenance

- Easy integration into existing DCS and ERP networks

CalSys Analyser Management software

- Effective performance monitoring of quality measurement instruments (QMI)

- Automated analyser validation and statistical process control

- Complies with international standards and methods (ASTM D3764, ASTM D6299, OP 97-30425 etc.)

- Increased availability of gas chromatographs and critical process analysers

Requirements:

- Integration of flow computers, PLCs, supervisory computers and printers

- Installation of single flow computers up to fully redundant cabinet

- Complying with custody transfer requirements

Recommended products and solutions:

Loading and fueling in the oil & gas industry

Requirements:

- Cryogenic temperatures (<-162°C)

- Risk of overfill or dry run

- Inventory measurement

Recommended products and solutions:

OPTISWITCH 5300

- Point level detection of liquids under extreme conditions

- Probe length: up to 3000 mm / 118 ft

- ≥0.47 g/cm3 / 0.017 lb/in3 (optional: ≥0.42 g/cm3 or 0.015 lb/in3)

- -196…+450°C / -321…+842°F; -1…160 barg / -14.5…2321 psig

Requirements:

- Need for custody transfer certification

- Transparent programming and easy to operate

Recommended products and solutions:

SUMMIT 8800

- Cost effective solution due to modular hard- and software design

- Full colour graphical touch screen for maximum process transparency

- Easy operator access enabling time efficient maintenance

- Automatic Performance Monitoring extends recalibration interval

Requirements:

- Cryogenic temperatures (<162°C)

- Need for custody transfer certification

Recommended products and solutions:

OPTIMASS 6400

- High accuracy (±0.05% flat), for cryogenic to HT media (-200…+400°C / -328…+752°F); maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- SIL 2/3; CT: OIML R117, R137, MI-005, MI-002; API, AGA; hygienic certifications

- Flange: DN10…300 / ½…12", max. PN 160 / ASME Cl 1500

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

Requirements:

- Cryogenic temperatures (<162°C)

- Risk of overfill or dry run

- Inventory measurement

Recommended products and solutions:

OPTISWITCH 5300

- Point level detection of liquids under extreme conditions

- Probe length: up to 3000 mm / 118 ft

- ≥0.47 g/cm3 / 0.017 lb/in3 (optional: ≥0.42 g/cm3 or 0.015 lb/in3)

- -196…+450°C / -321…+842°F; -1…160 barg / -14.5…2321 psig

Requirements:

- Integration of flow computers, PLCs, supervisory computers and printers

- Installation of single flow computers up to fully redundant cabinet

- Complying with custody transfer requirements

Recommended products and solutions:

SUMMIT 8800

- Cost effective solution due to modular hard- and software design

- Full colour graphical touch screen for maximum process transparency

- Easy operator access enabling time efficient maintenance

- Automatic Performance Monitoring extends recalibration interval

Supervisory Control Cabinets

- Provides control of the metering system, including validation of field instrumentation

- Installed in a safe area, typically in a control room or dedicated building

- Supplied in combination with new metering systems, or for an upgrade to existing systems

Modular flow control and data transfer cabinets

- Cost effective, modular metering control solution

- Based on the SUMMIT 8800 flow computer

- Installed in a safe area, typically in a control room

Requirements:

- Visualisation and monitoring of critical processes

- Control of reporting, trends and alarm handling

- Statistical evaluation of measurement data

Recommended products and solutions:

SynEnergy Supervisory and visualisation software

- HMI/SCADA software for measurement solutions

- State of the art HTML5 secure web technology

- Optimisation of operation results due to predictive maintenance

- Easy integration into existing DCS and ERP networks

CalSys Analyser Management software

- Effective performance monitoring of quality measurement instruments (QMI)

- Automated analyser validation and statistical process control

- Complies with international standards and methods (ASTM D3764, ASTM D6299, OP 97-30425 etc.)

- Increased availability of gas chromatographs and critical process analysers

Requirements:

- Visualisation and monitoring of critical processes

- Control of reporting, trends and alarm handling

- Statistical evaluation of measurement data

Recommended products and solutions:

SynEnergy Supervisory and visualisation software

Solution for continuous process monitoring and reporting

CalSys Analyser Management software

Solution for analyser management and data acquisition (AMADAS)