Juice production in sugar production

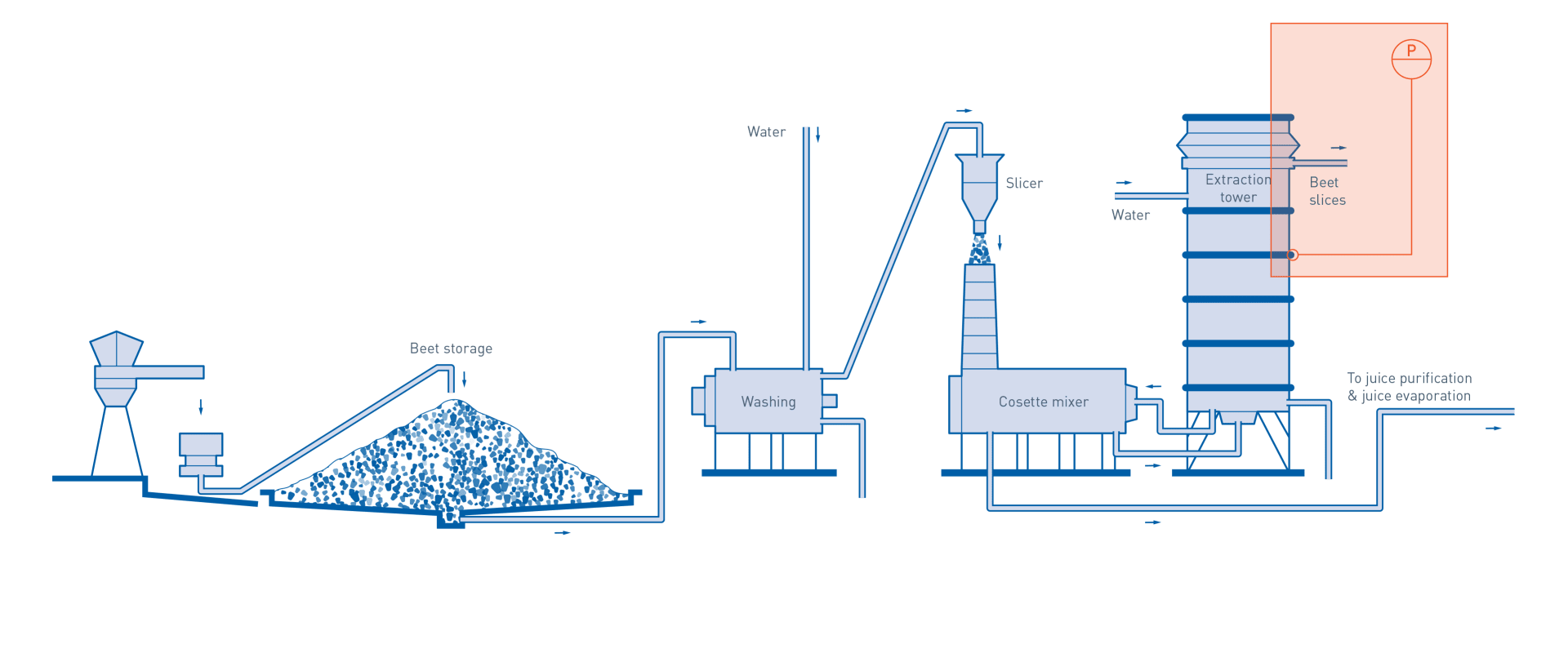

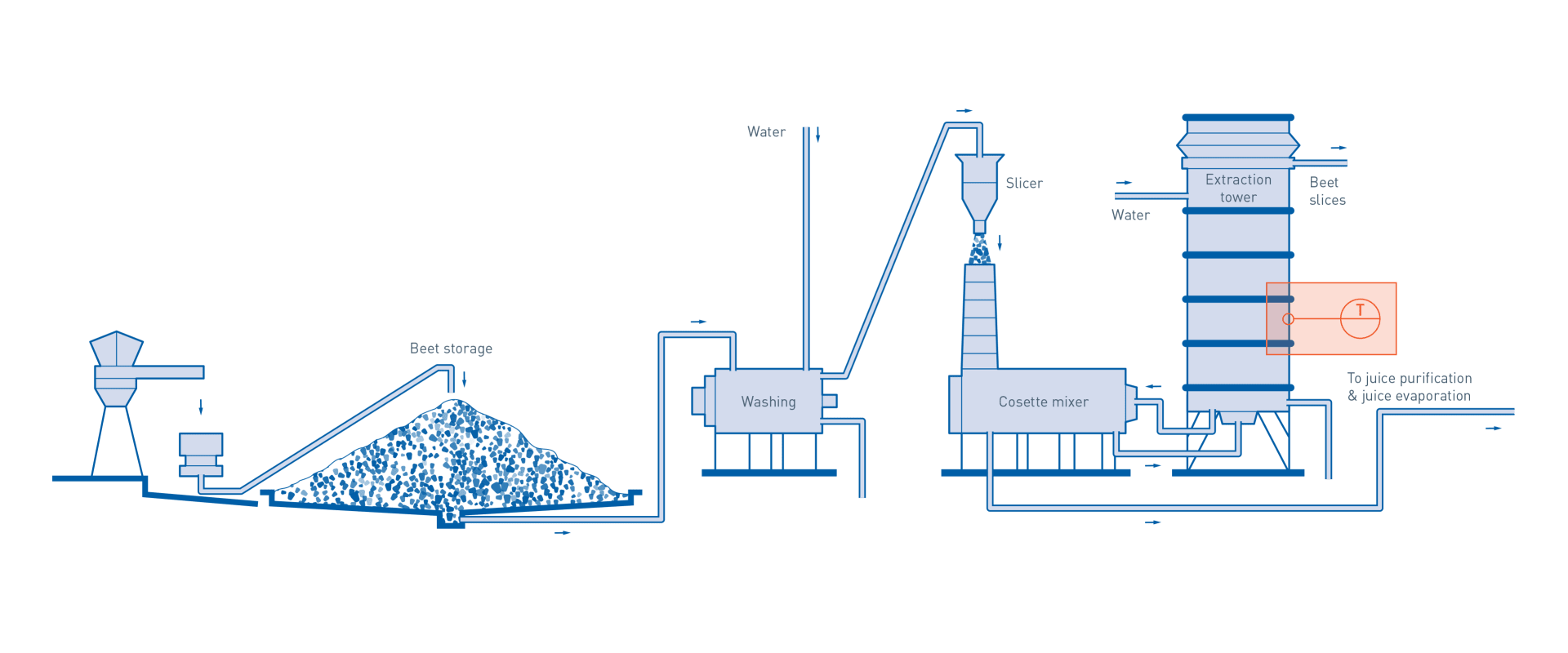

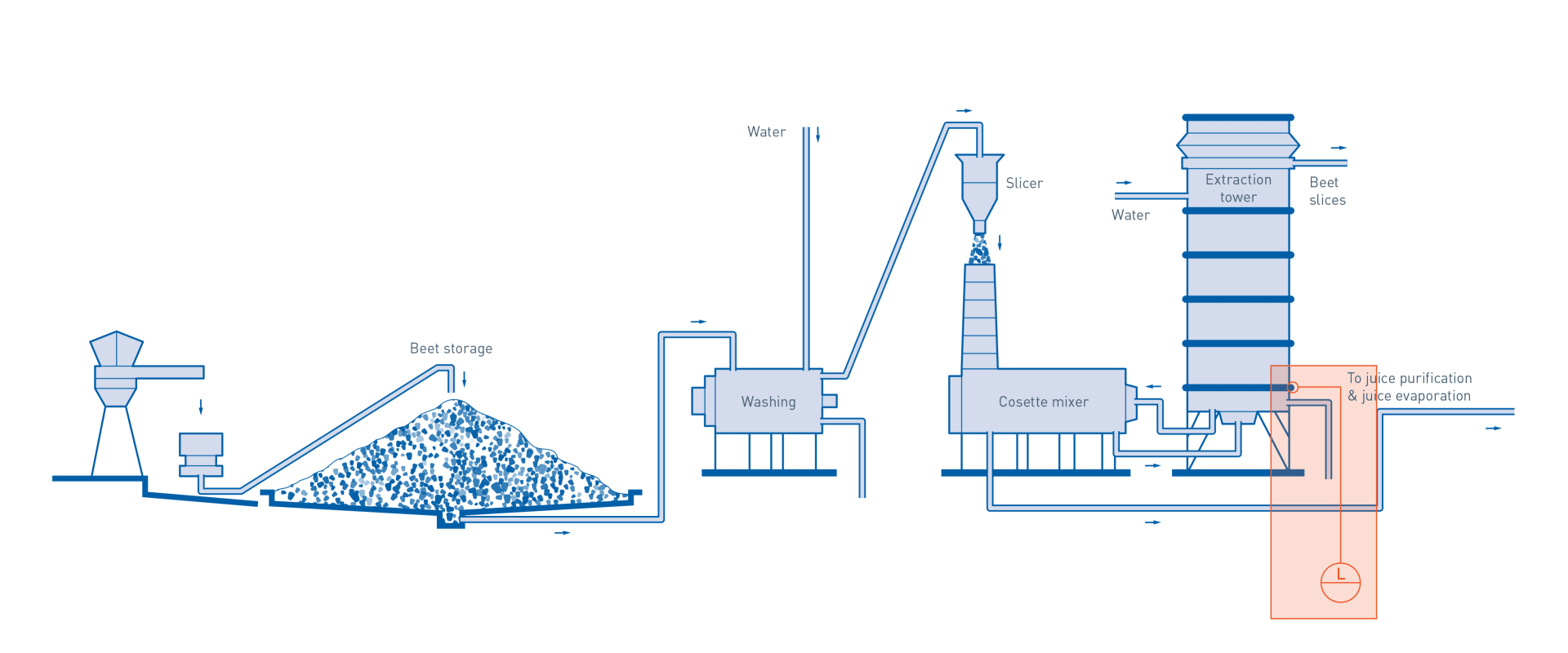

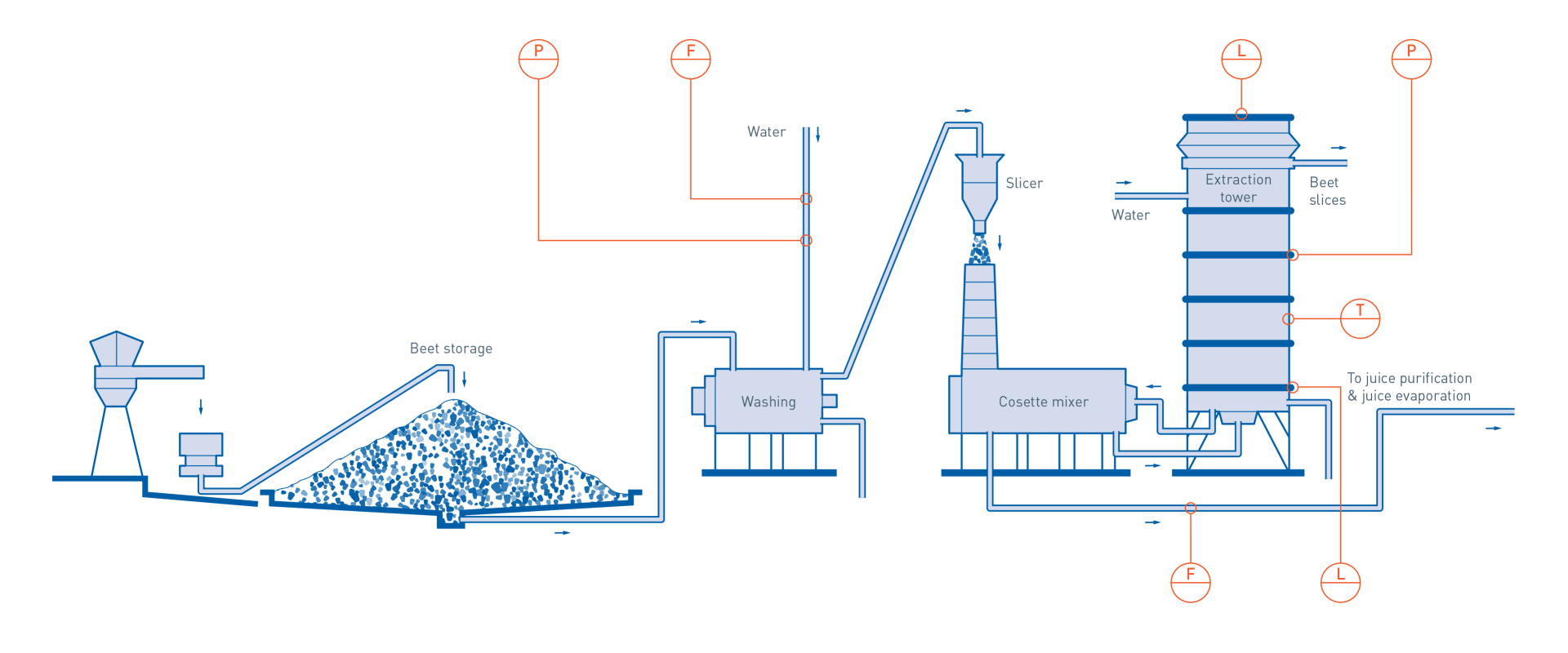

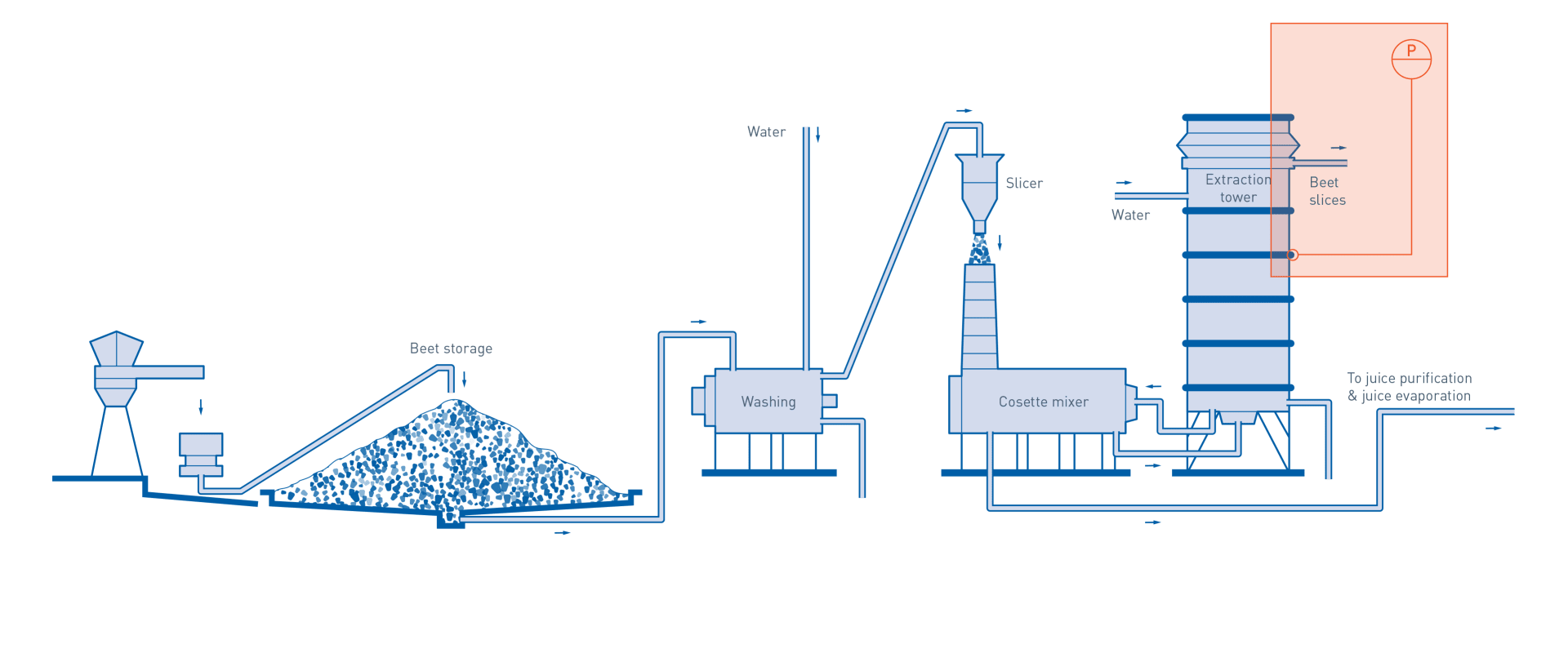

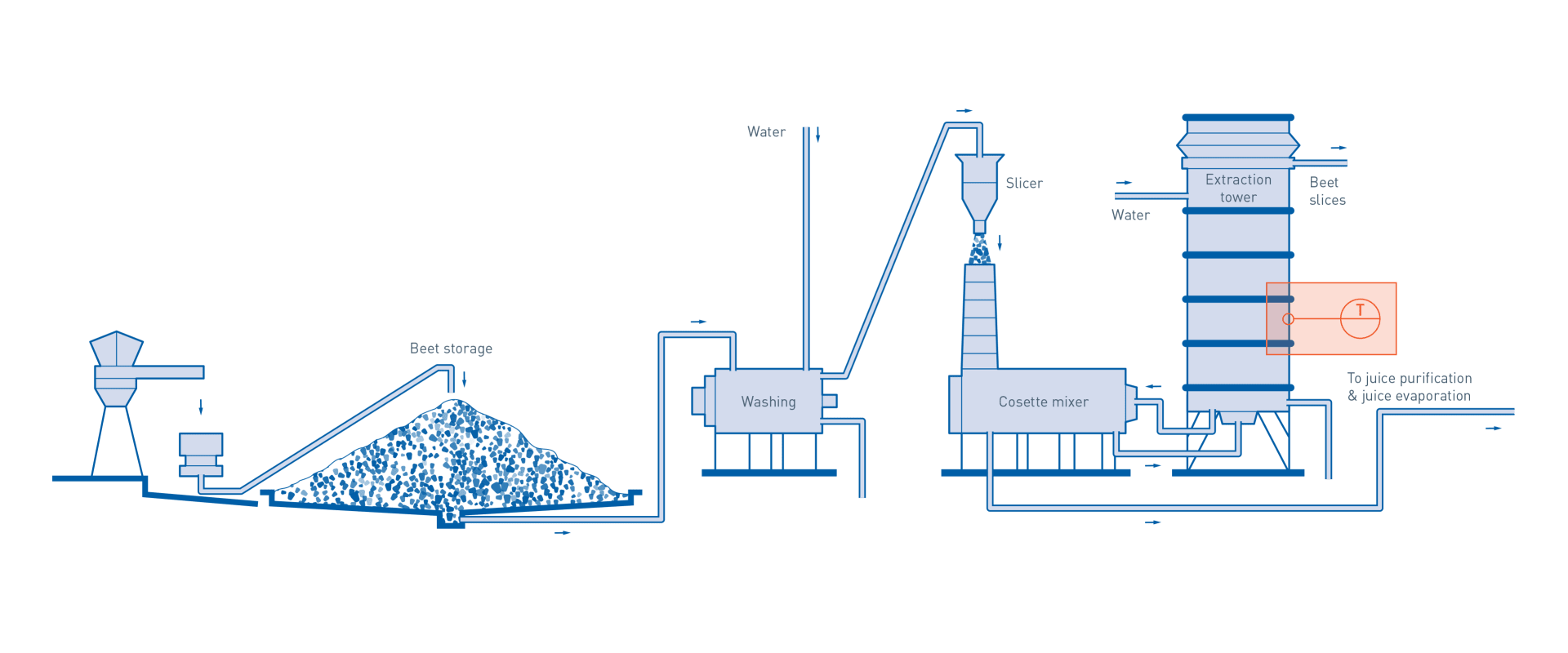

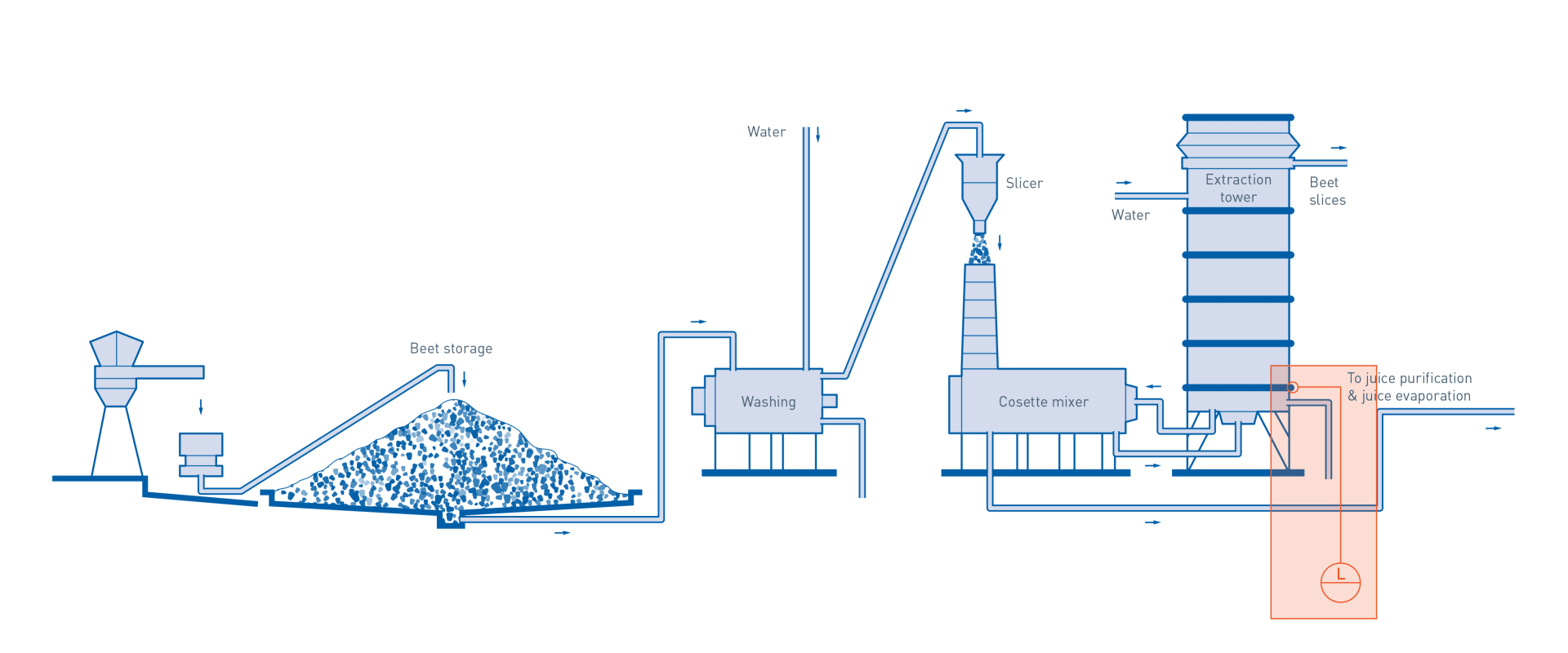

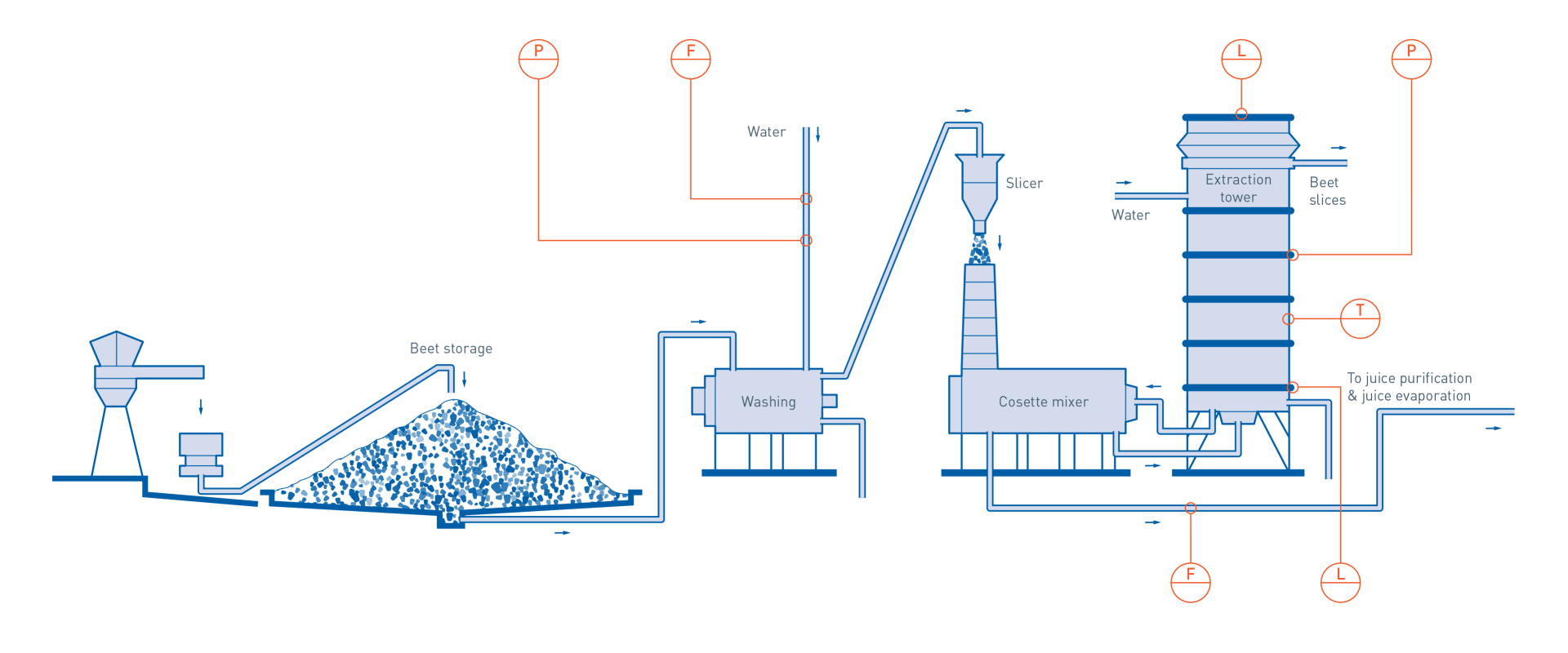

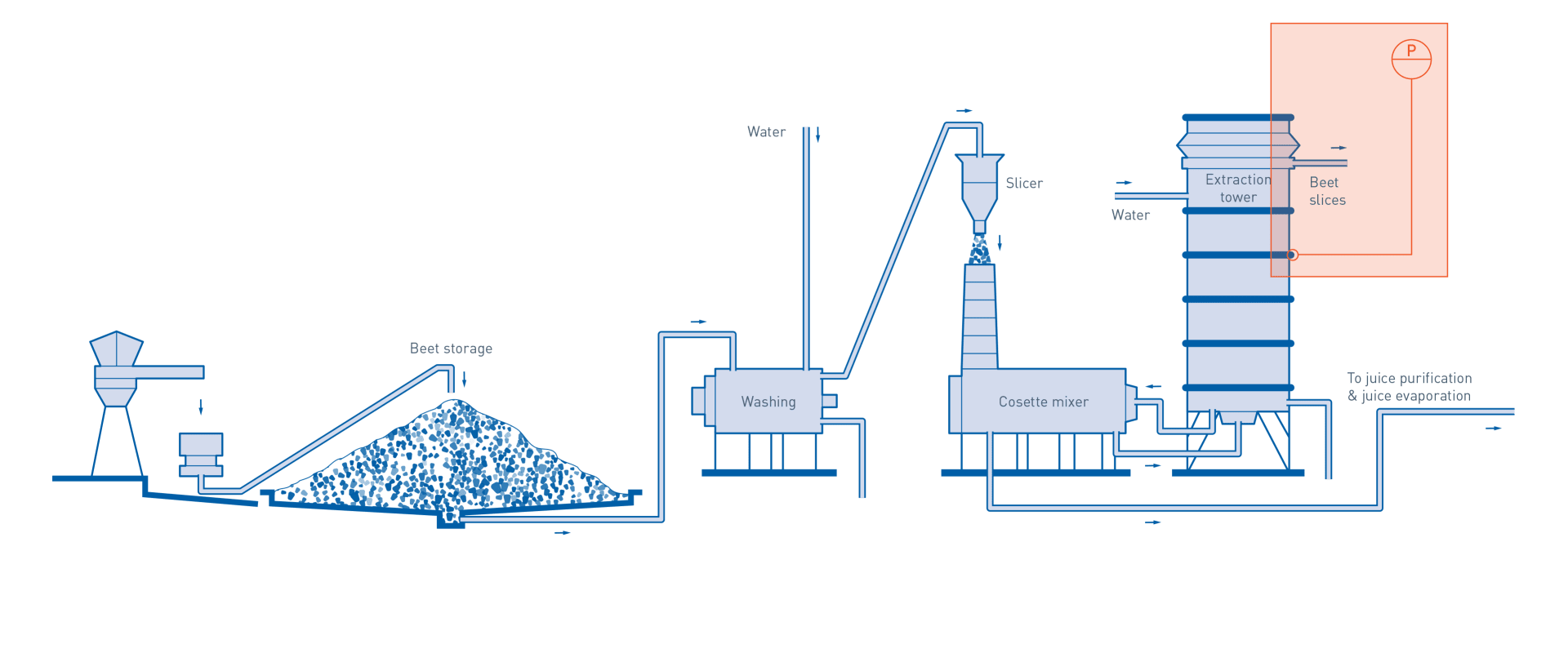

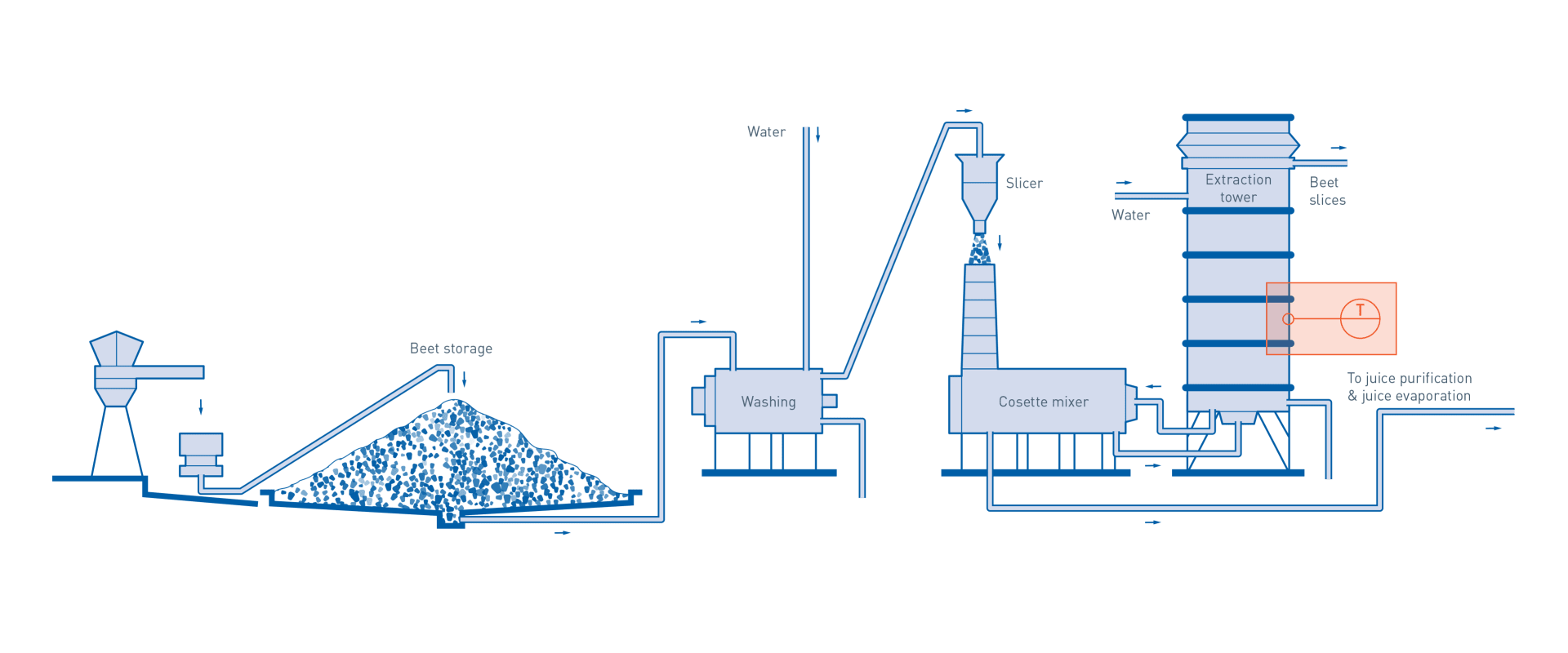

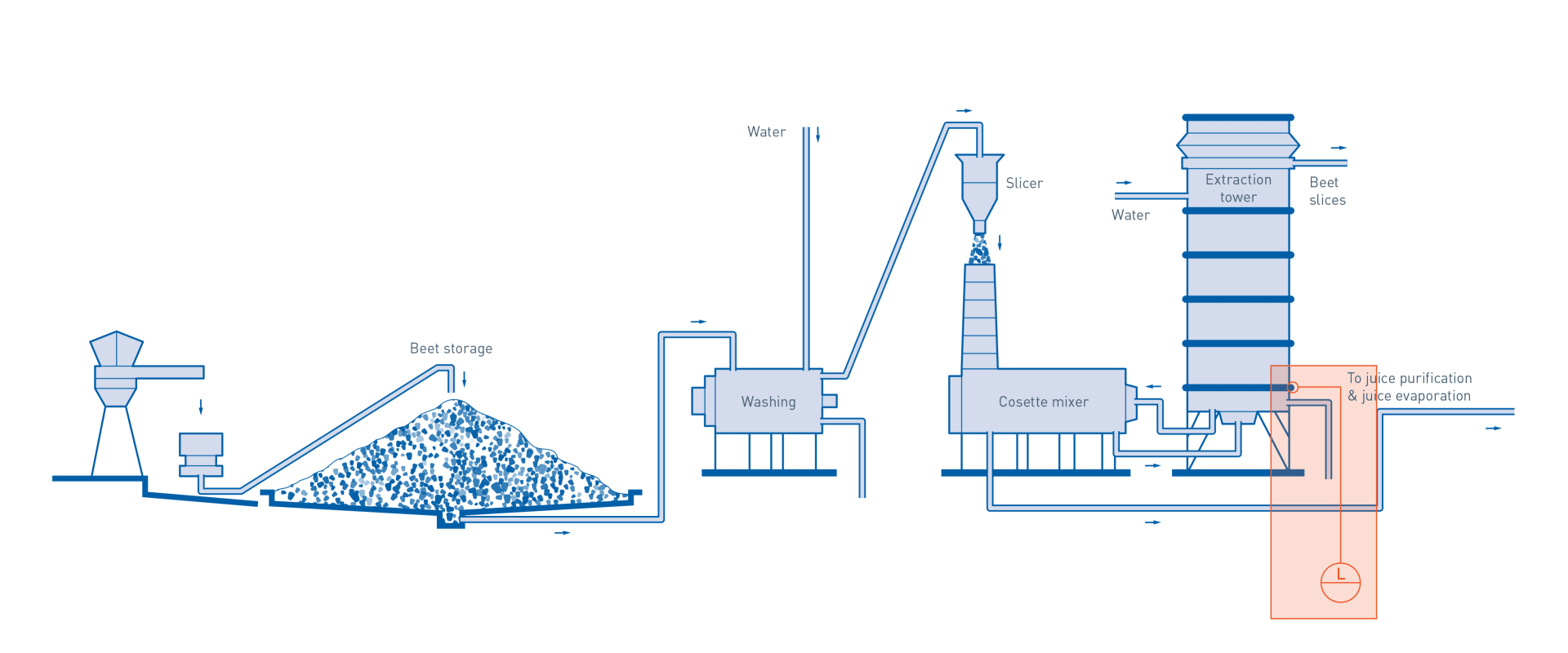

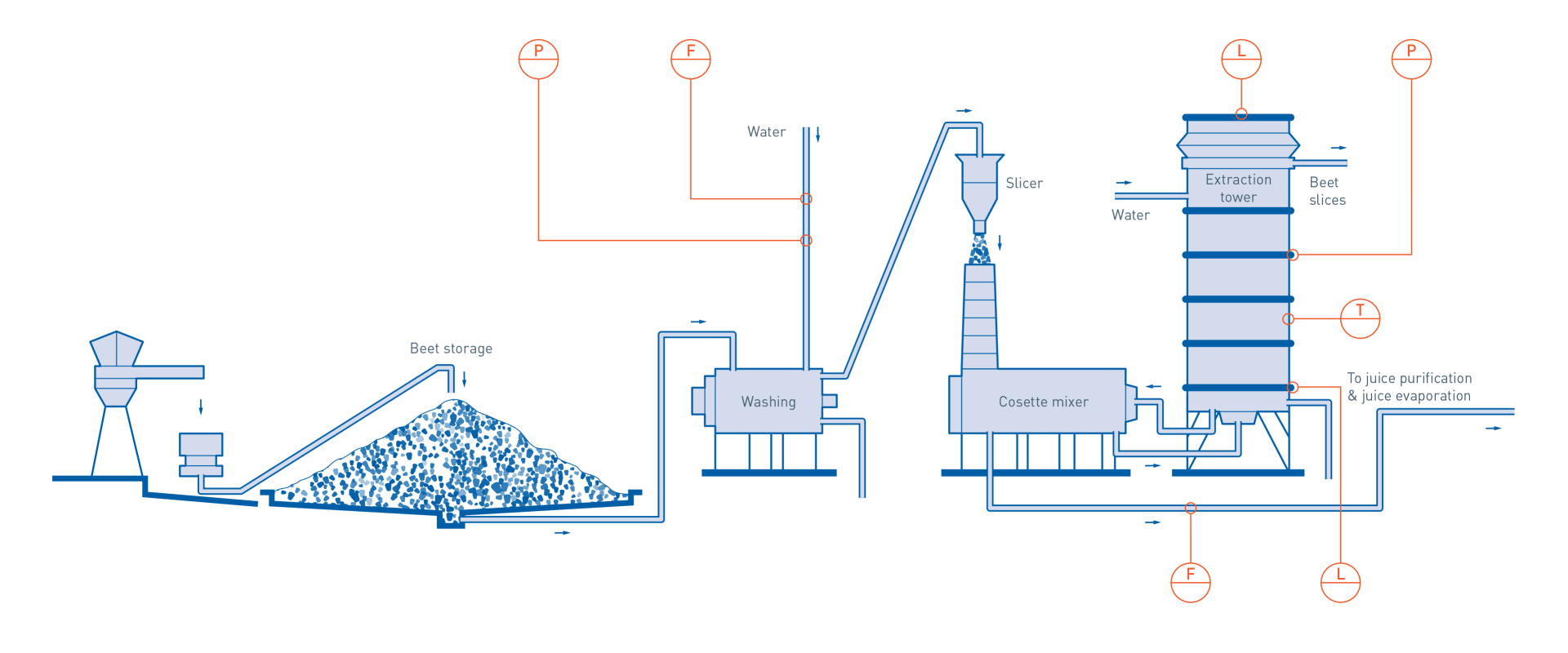

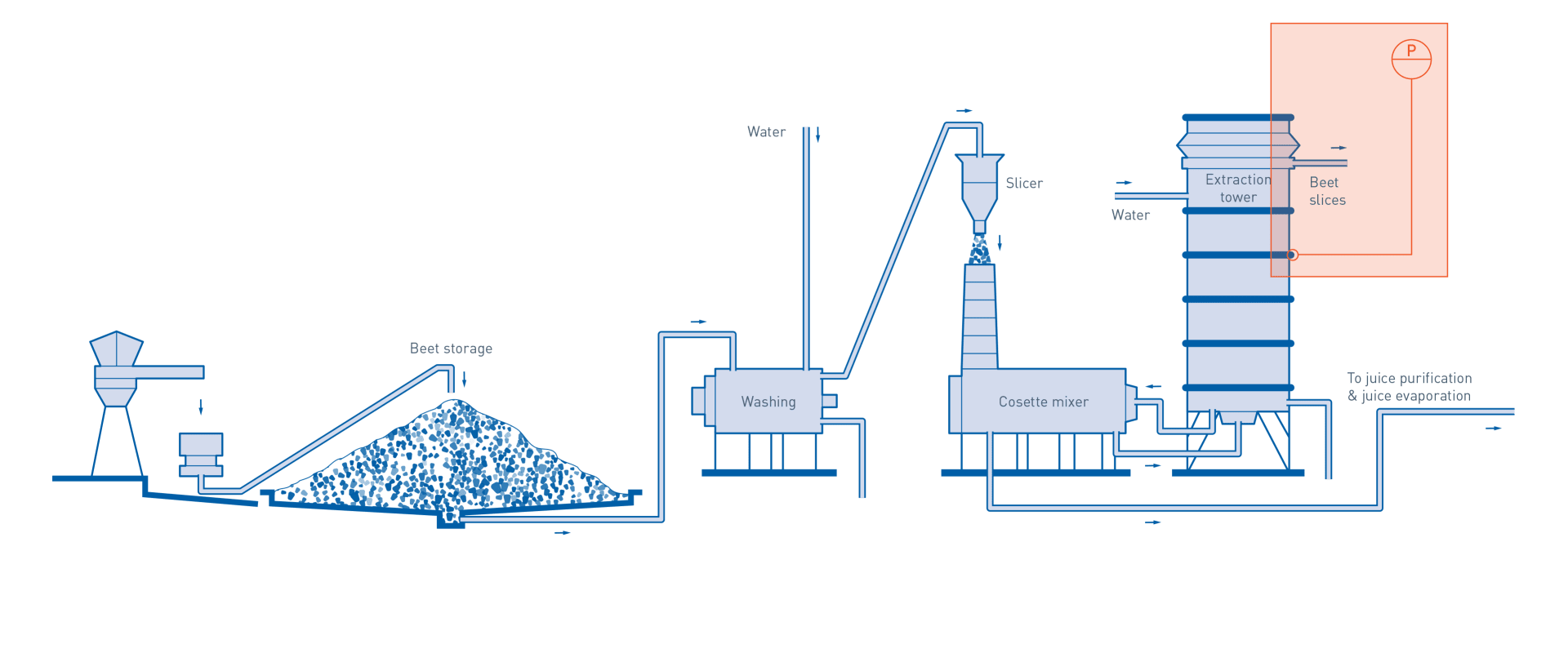

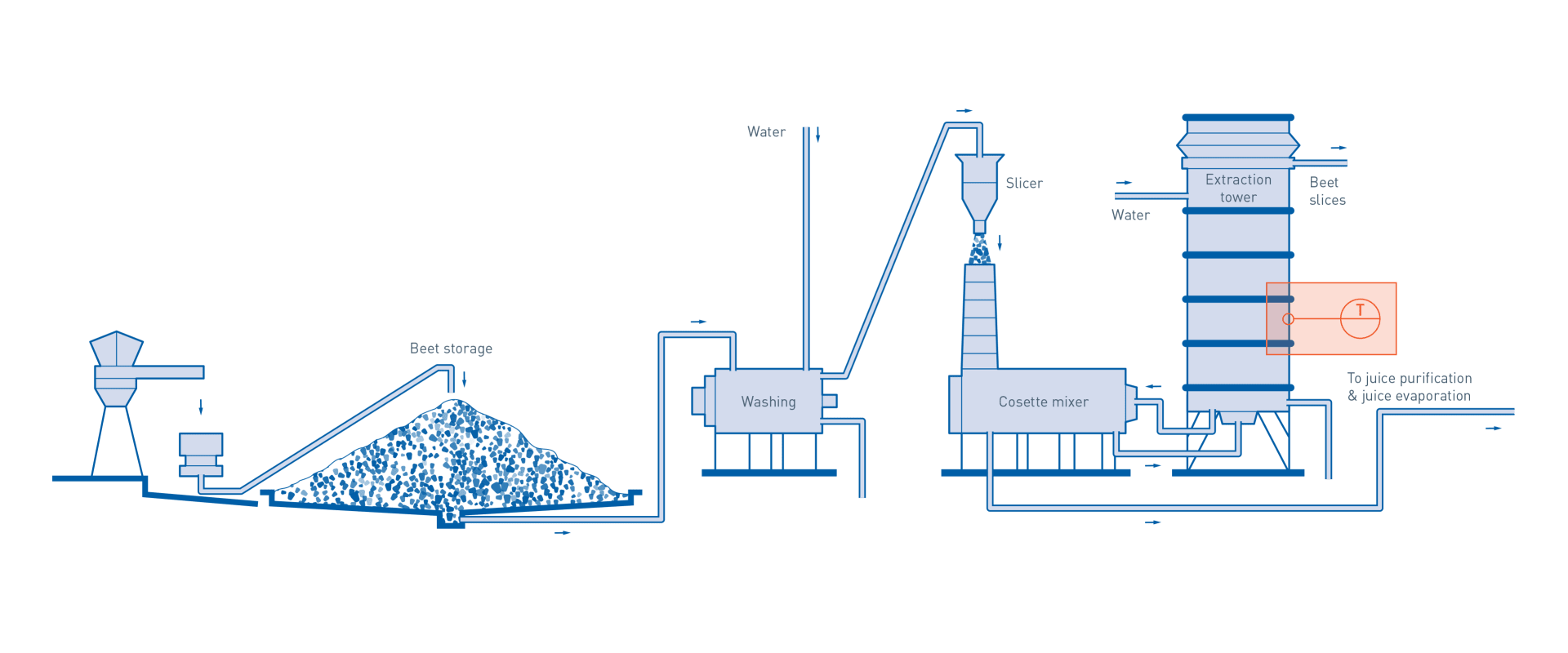

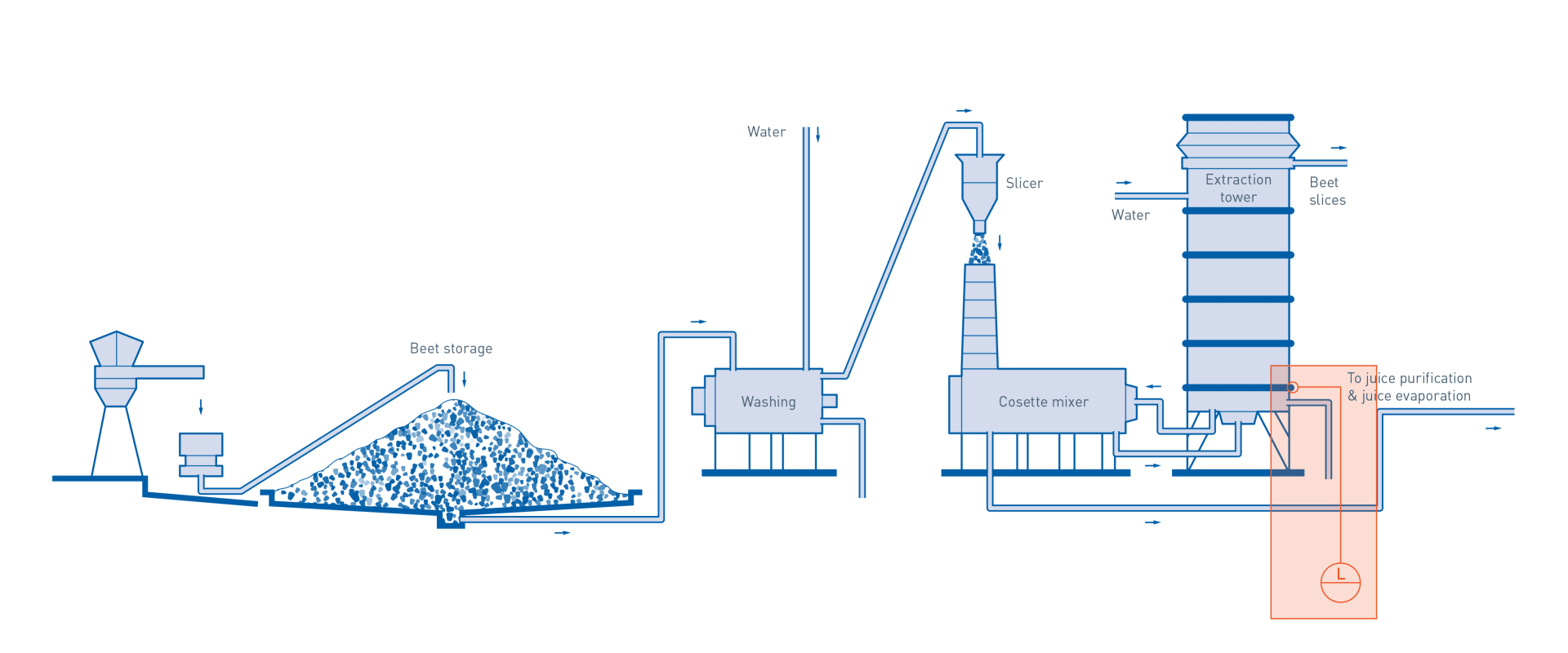

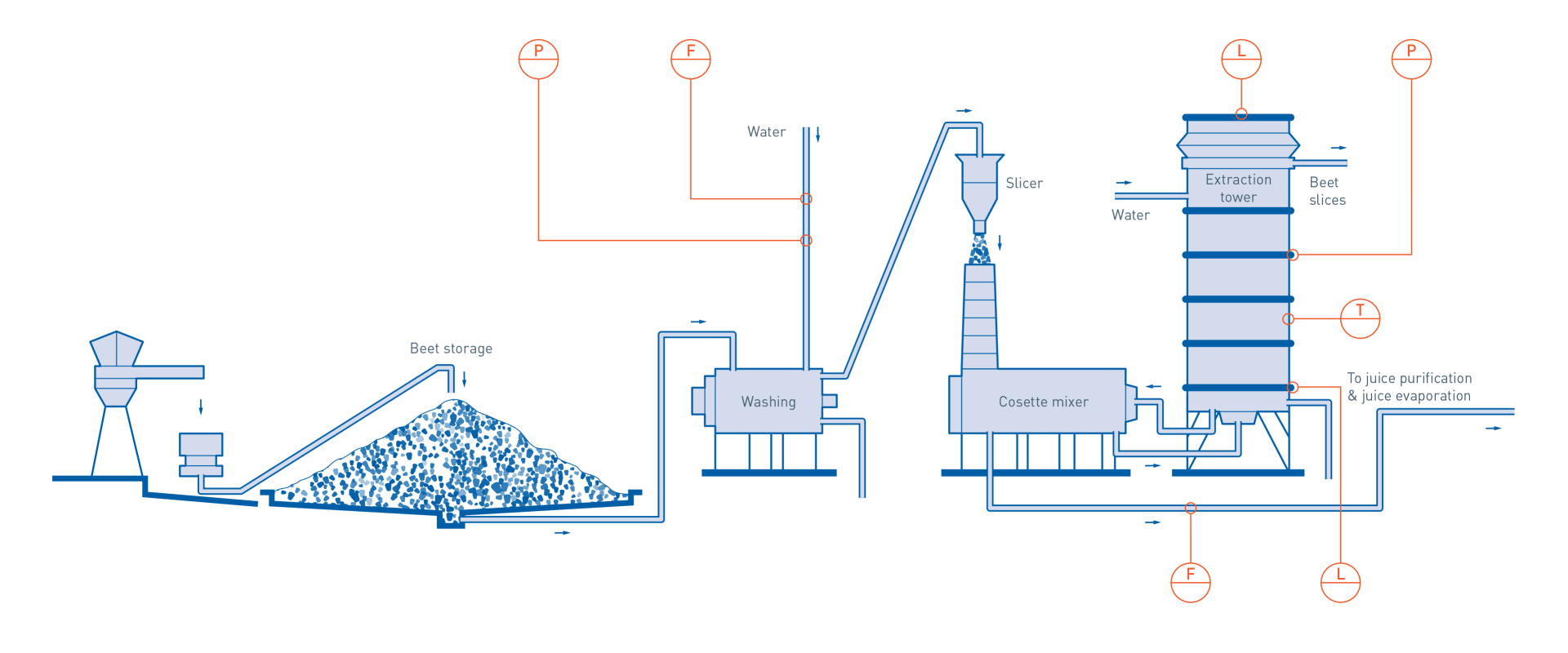

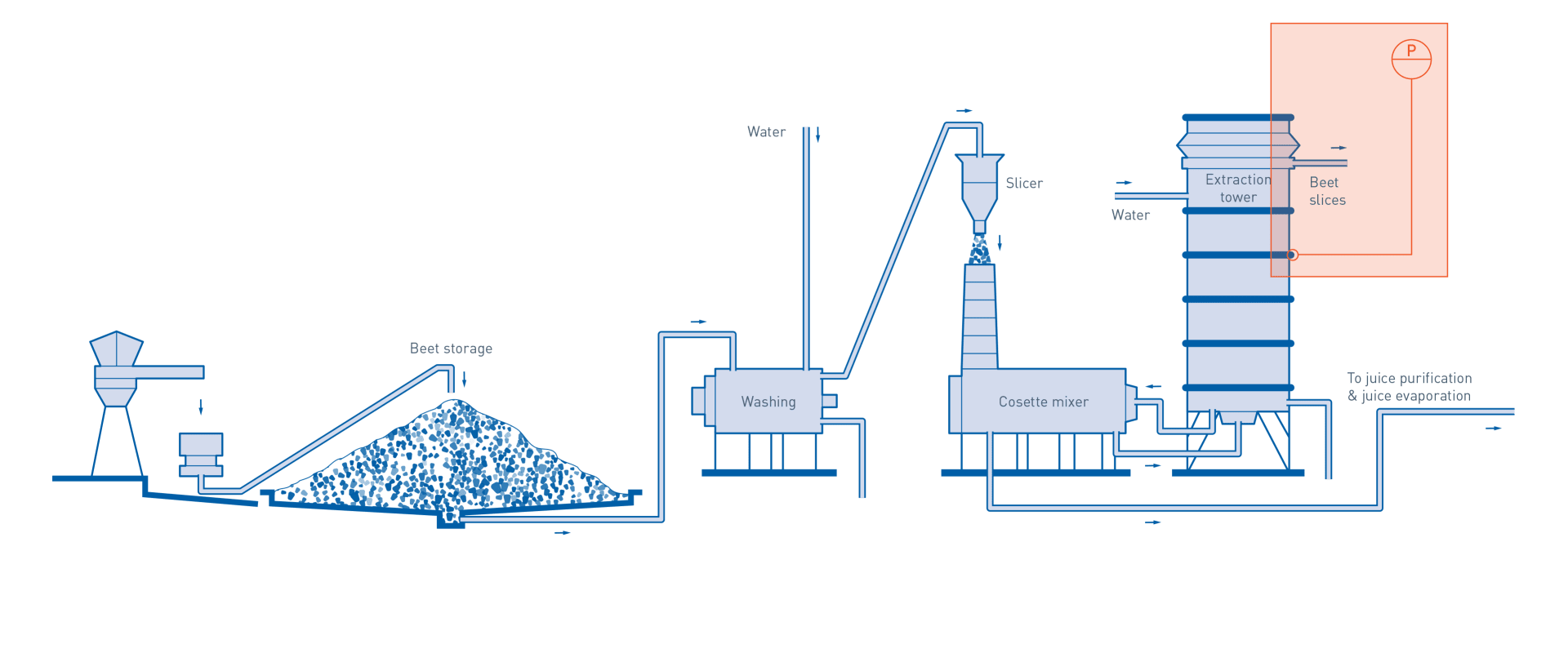

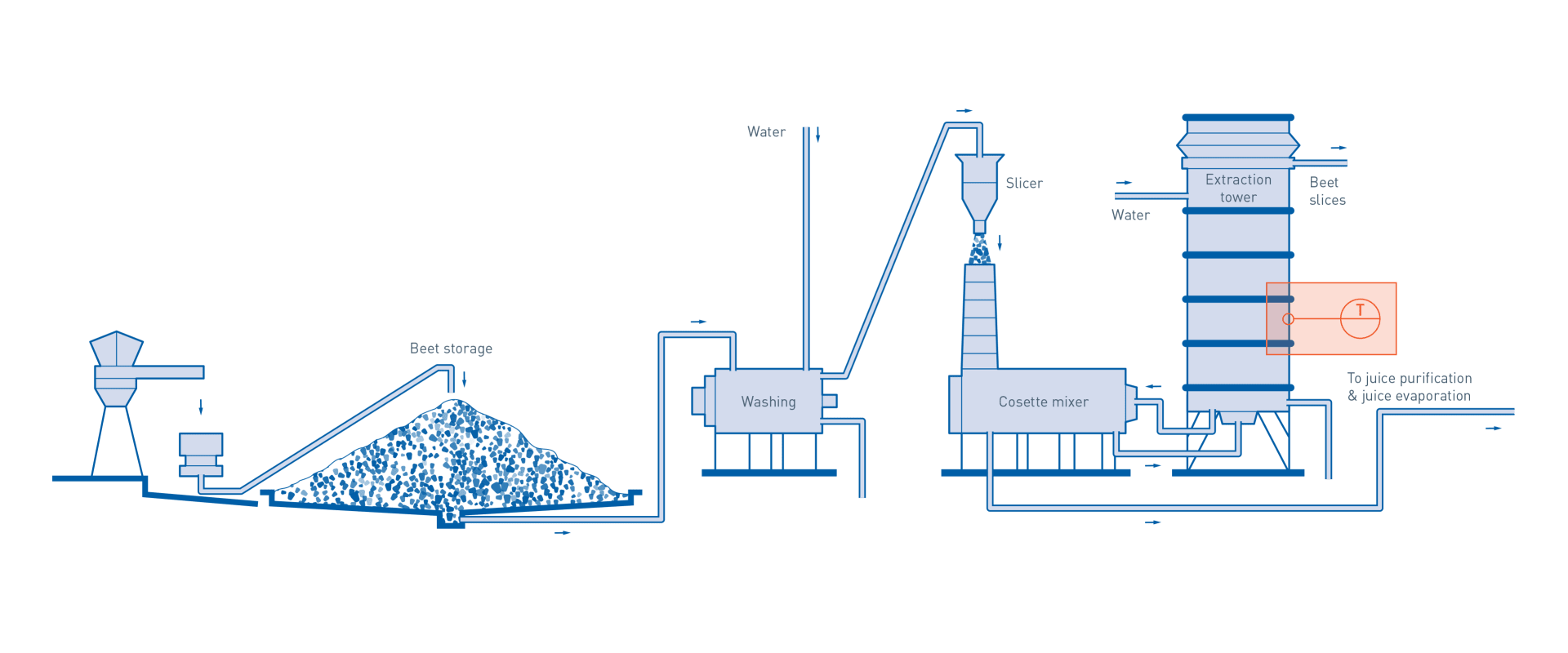

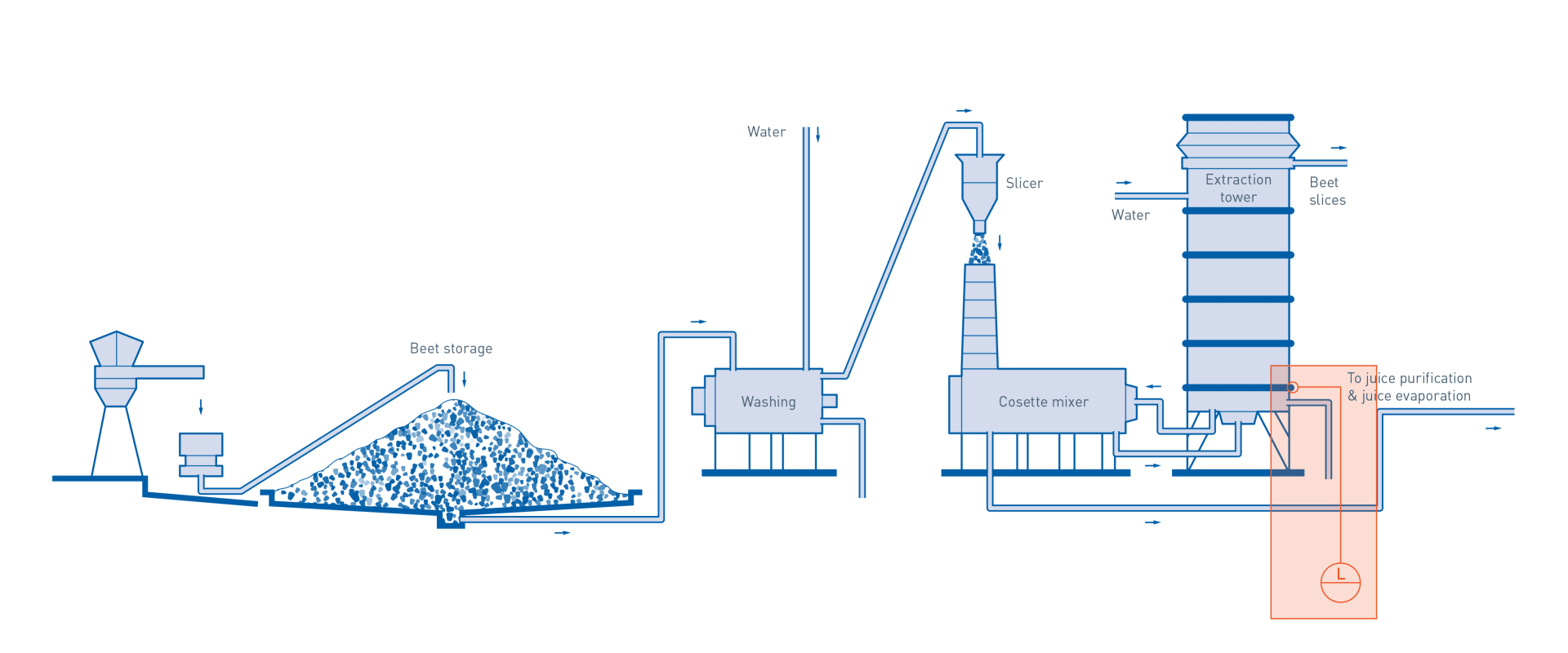

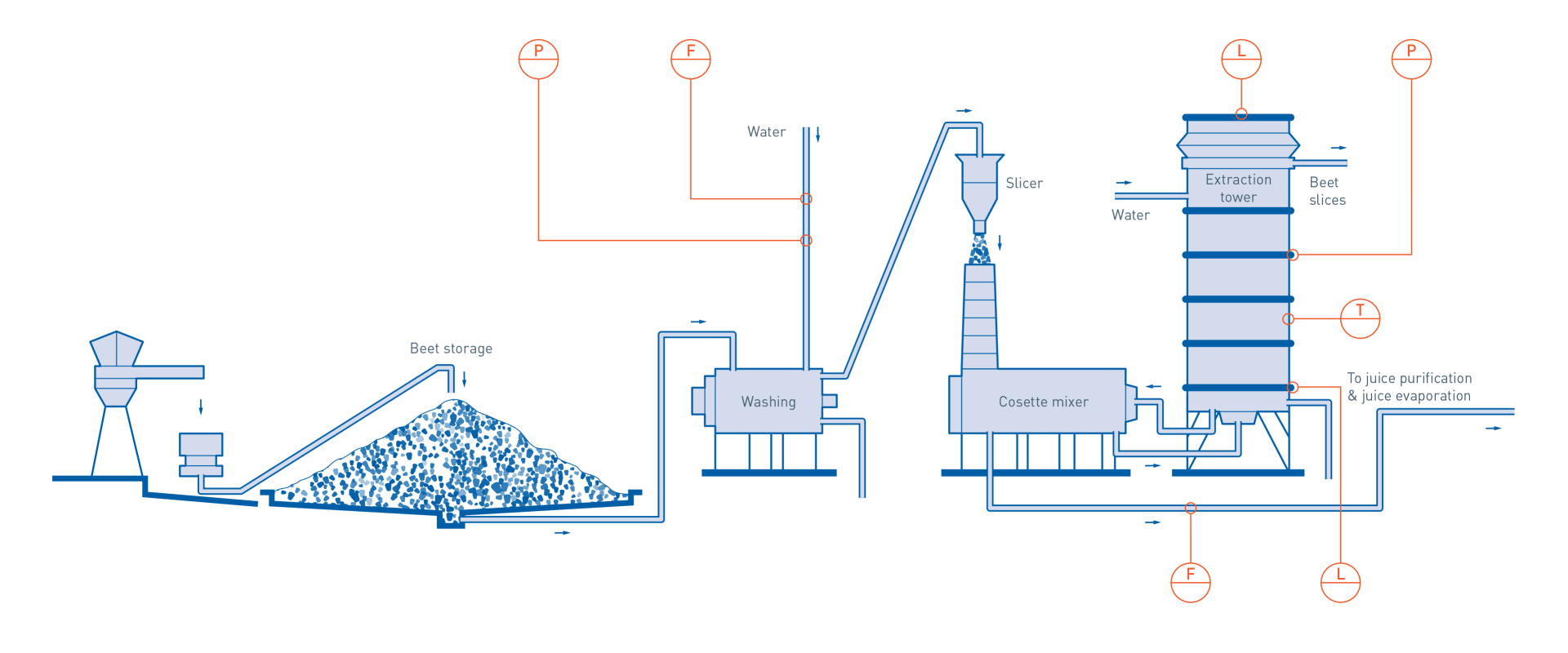

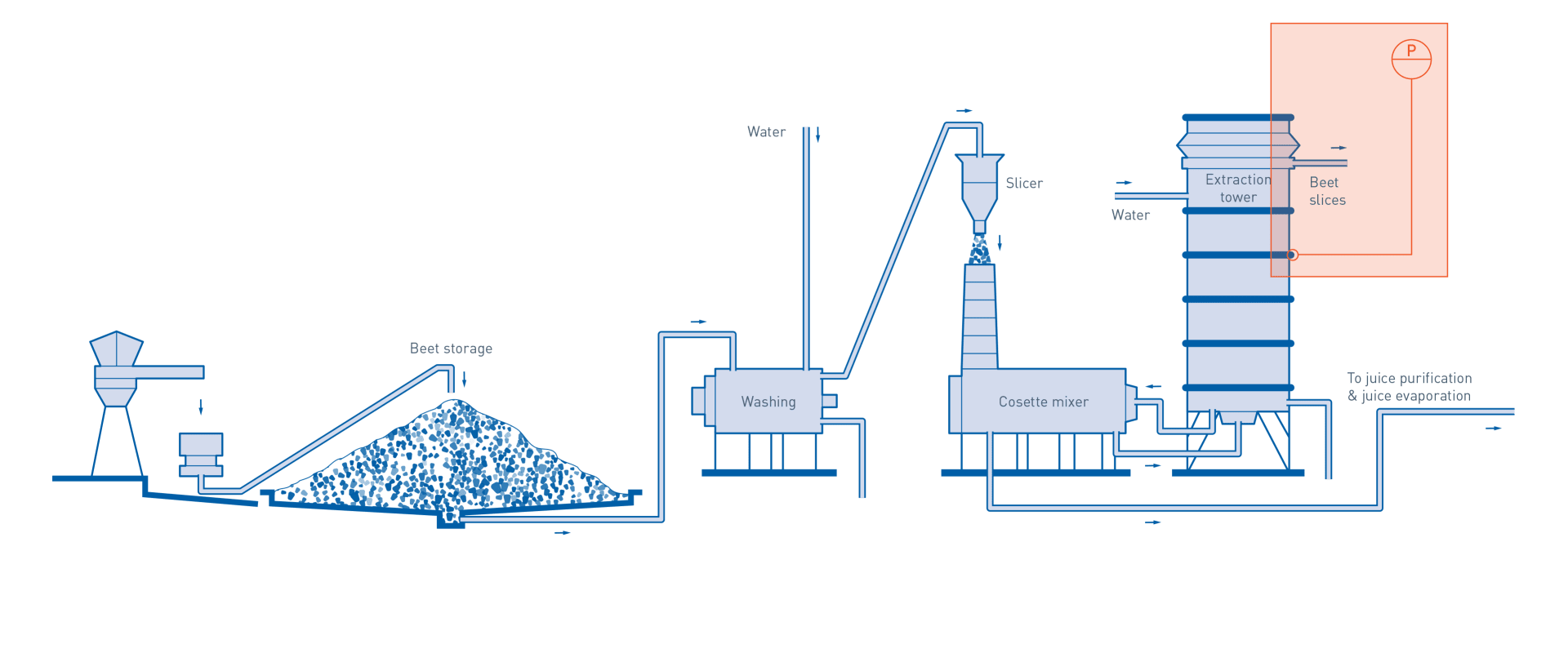

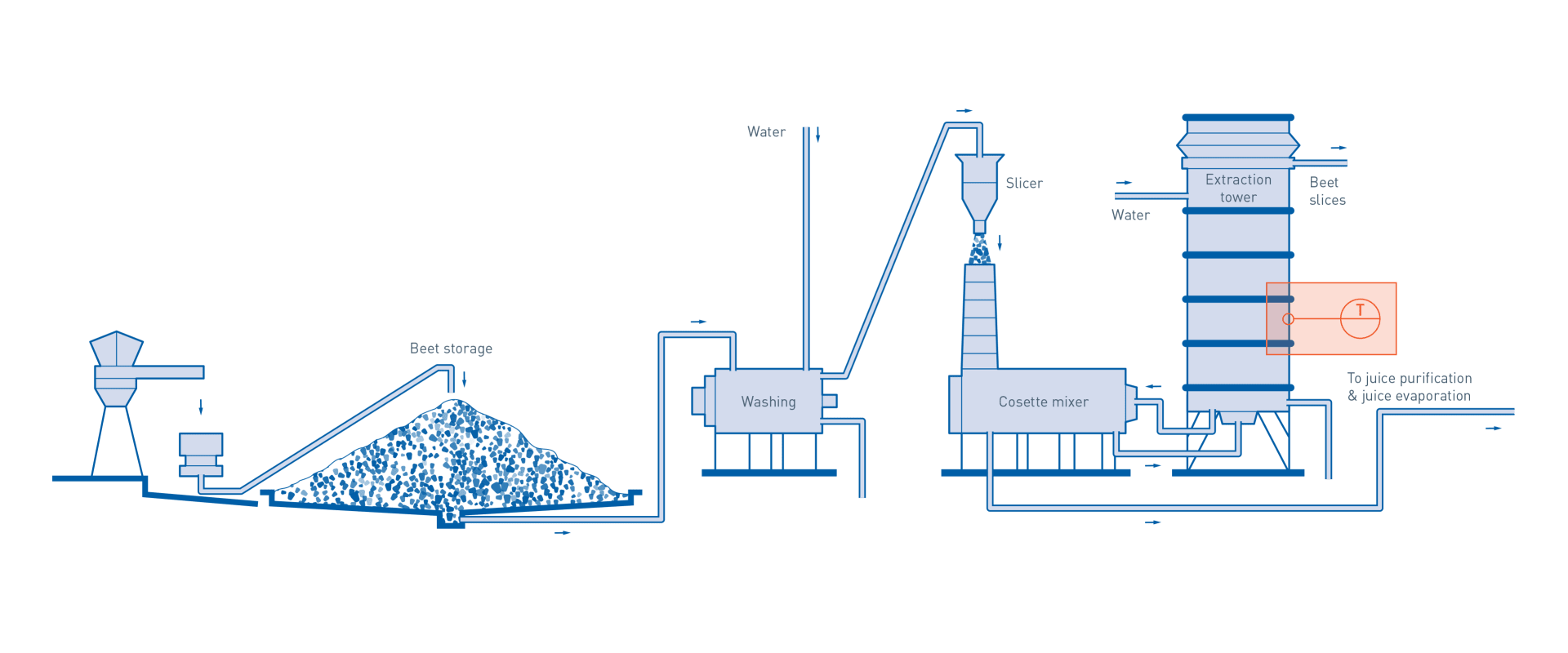

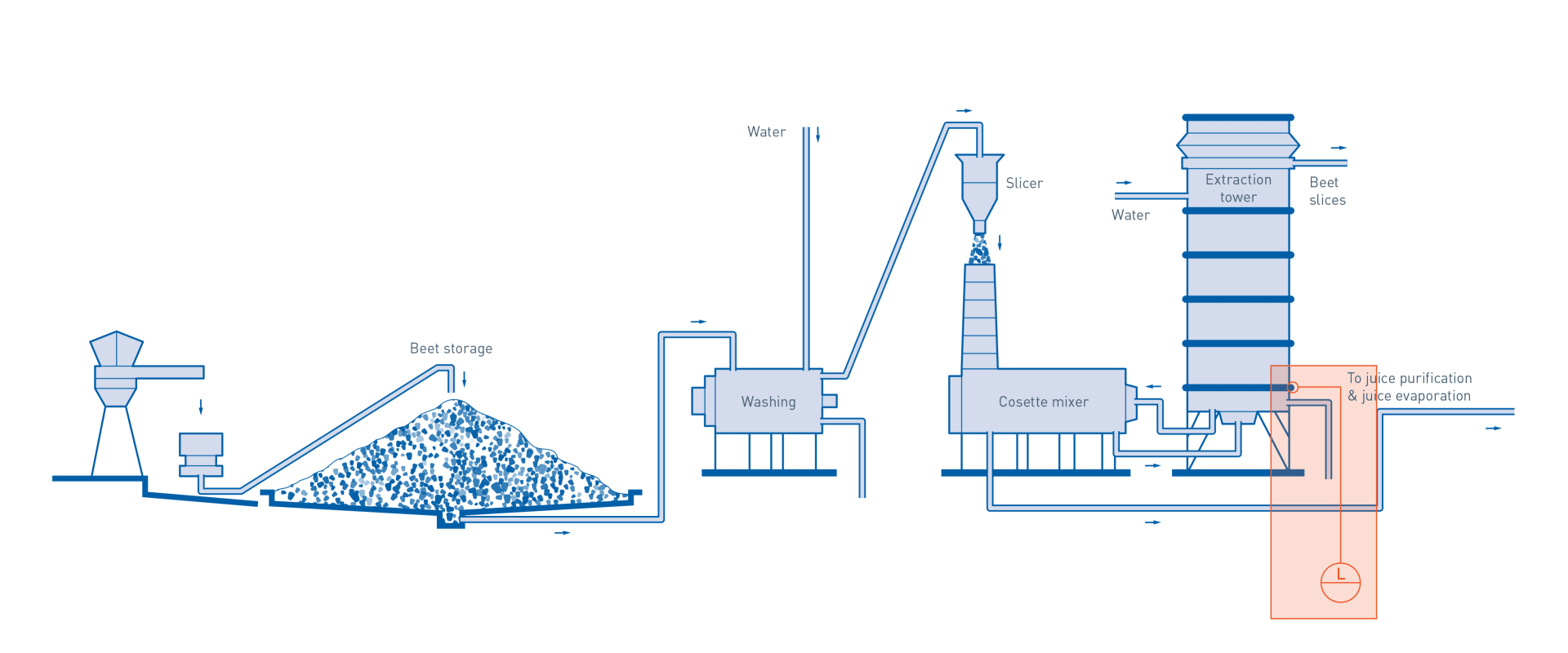

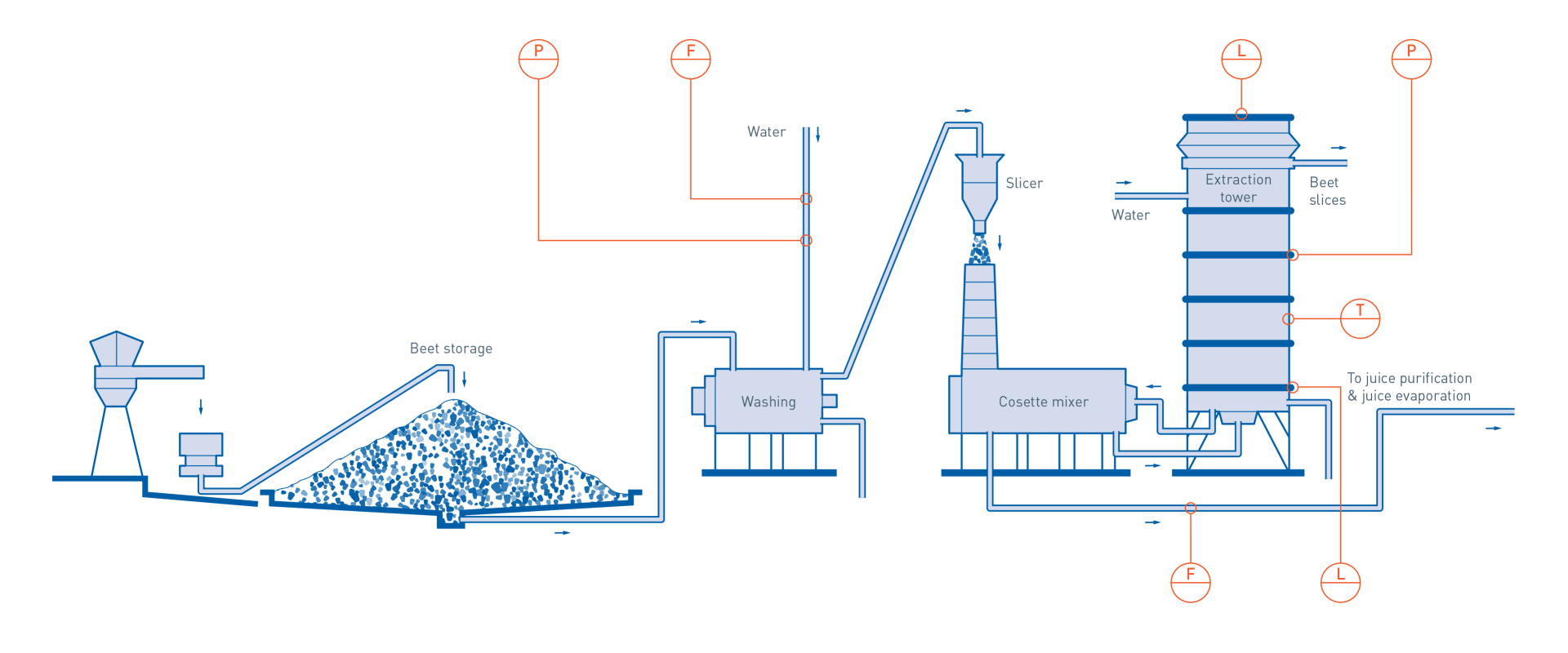

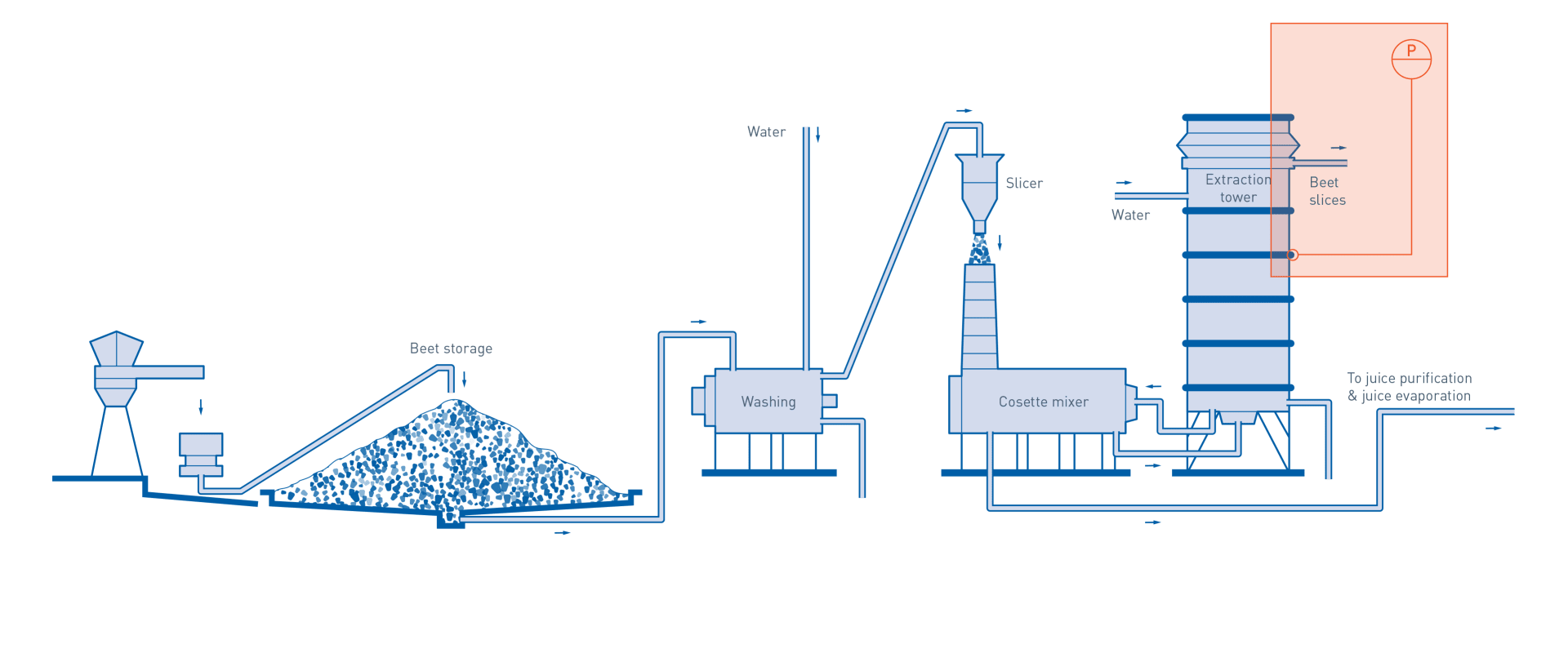

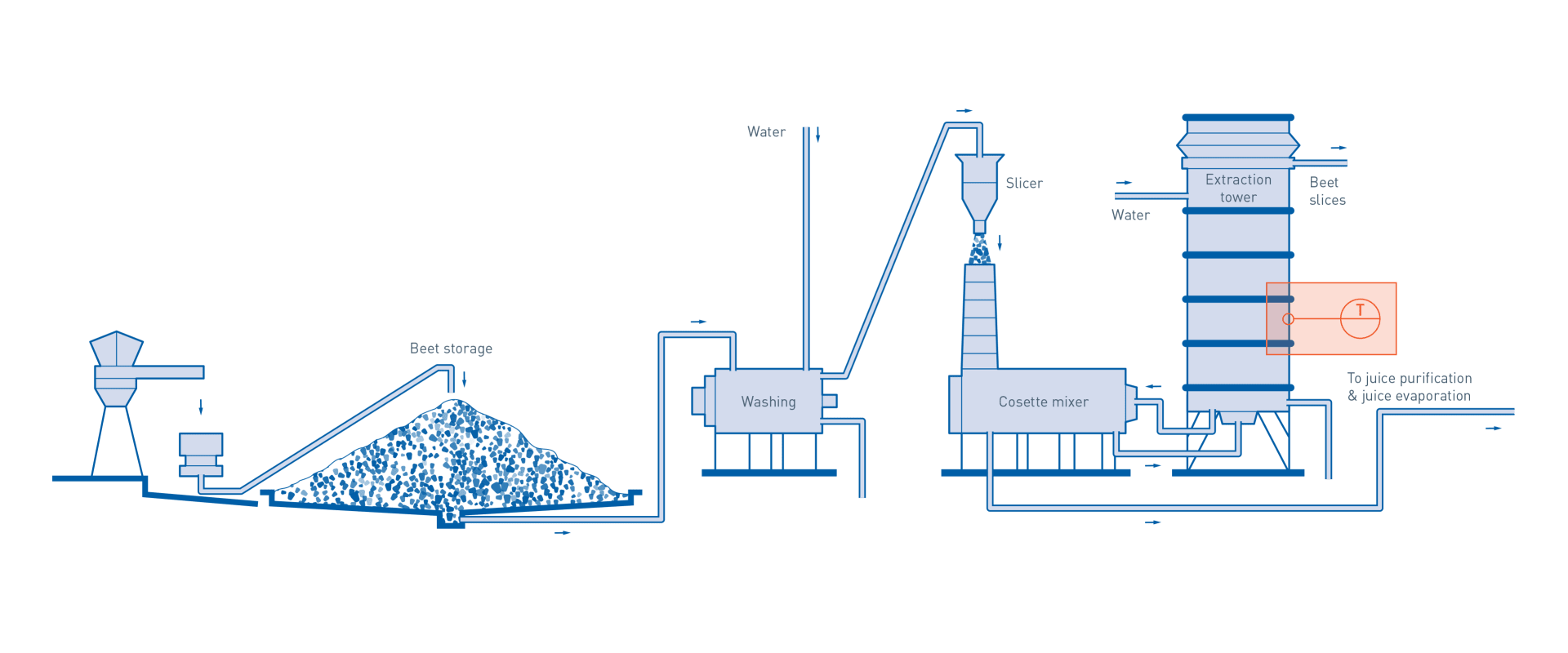

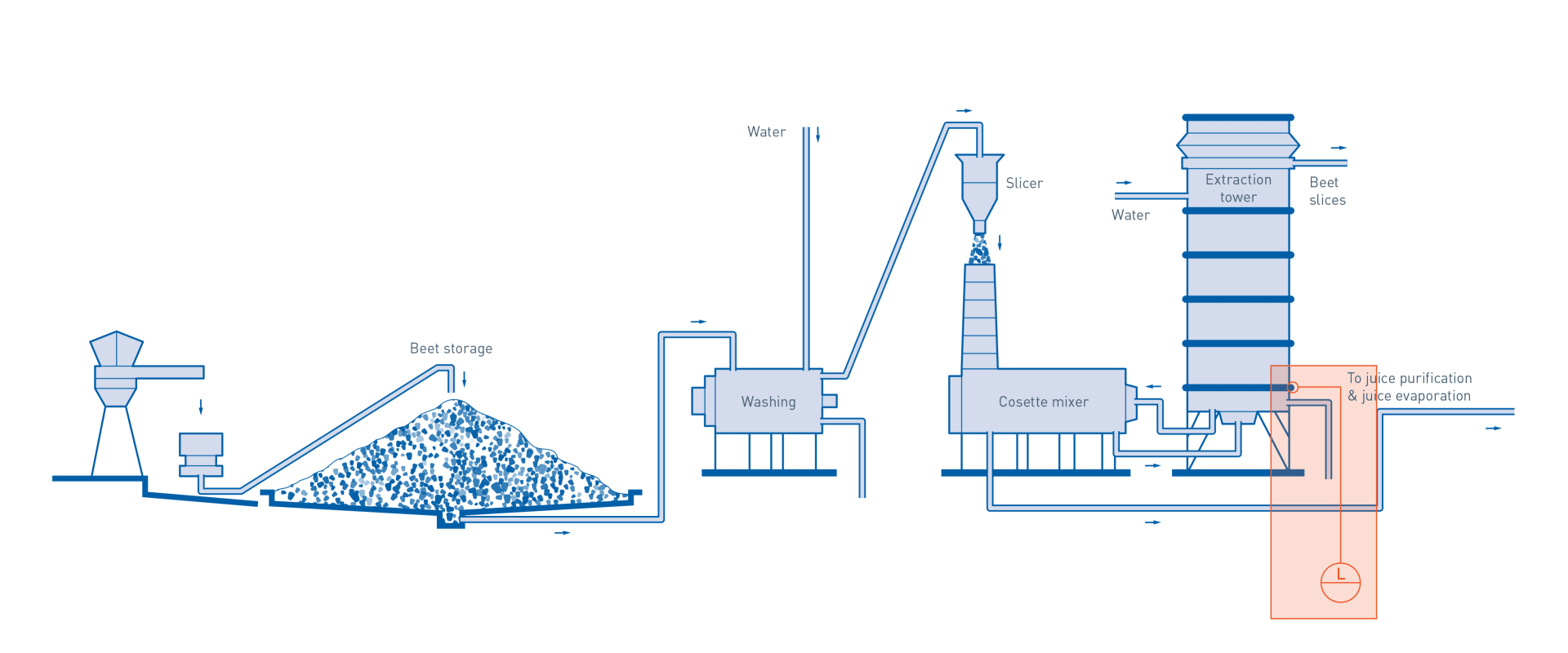

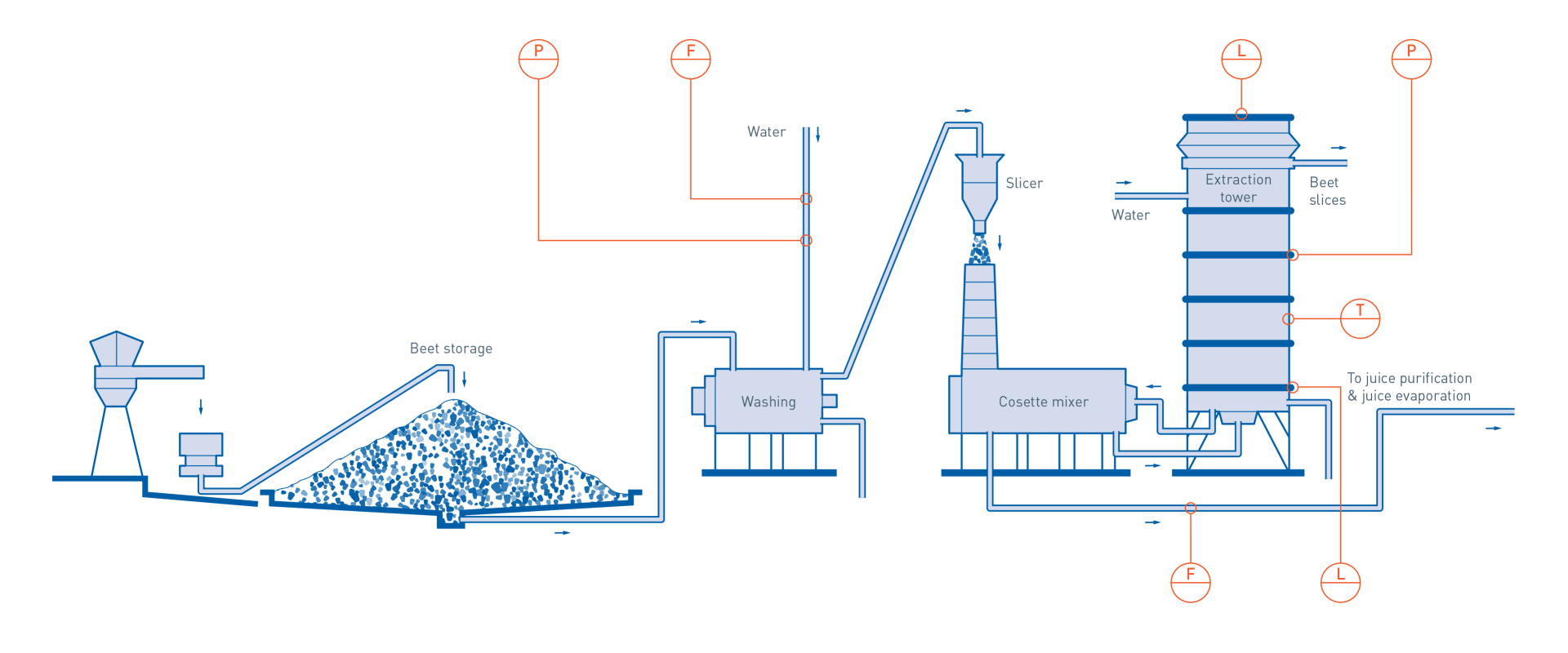

Handling of raw sugar beets

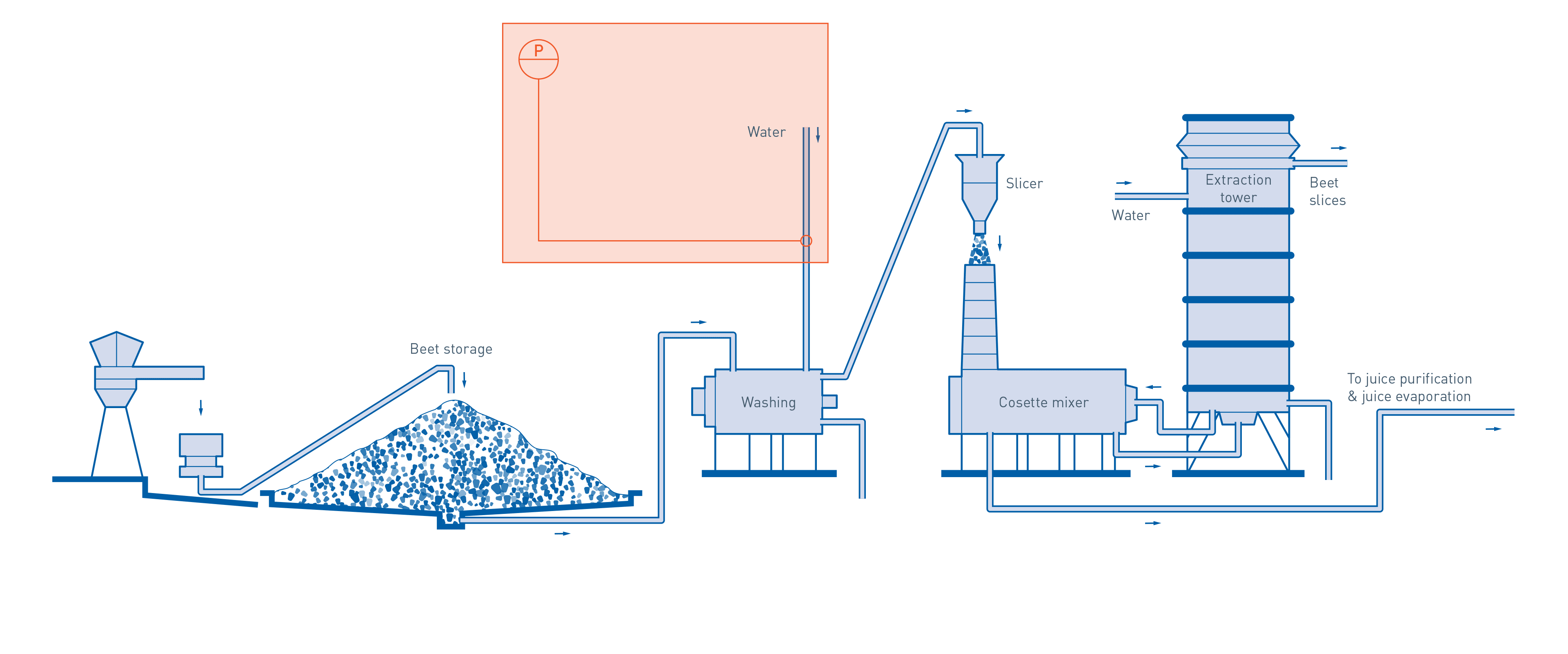

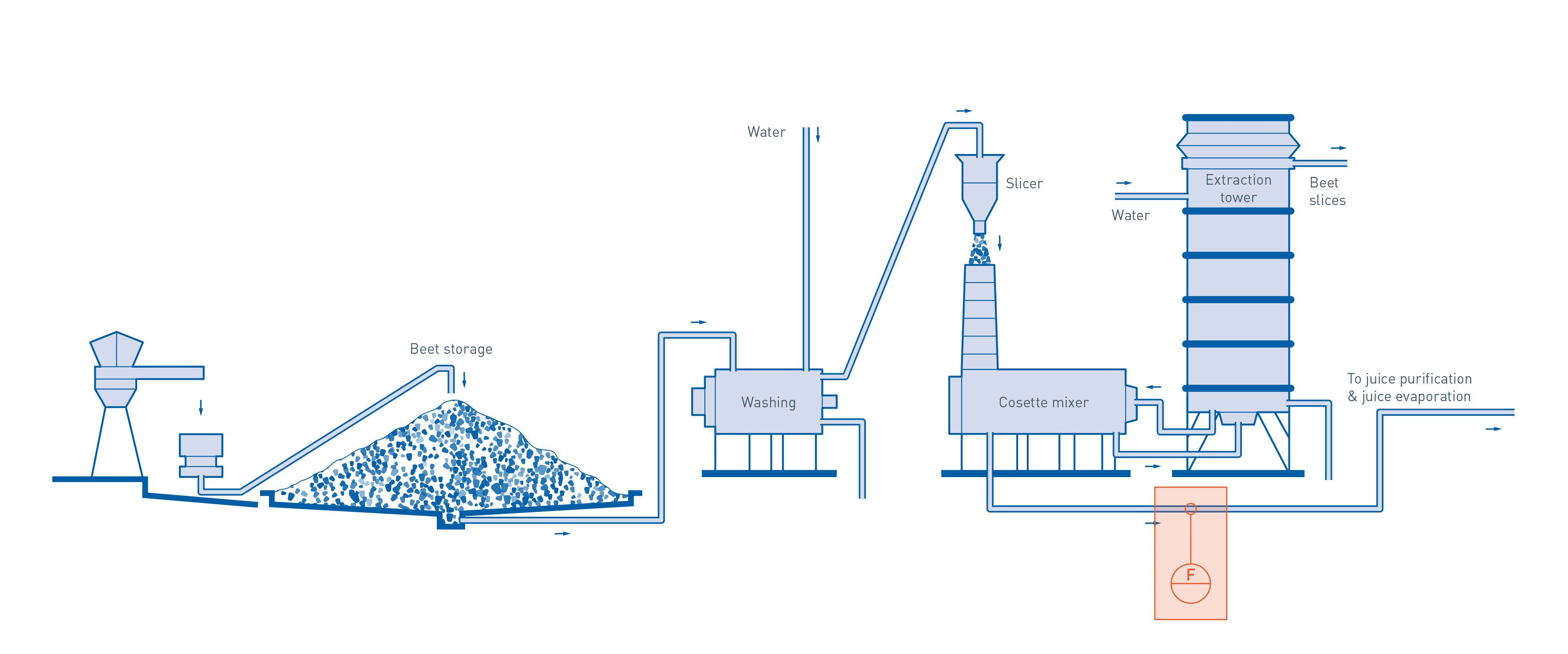

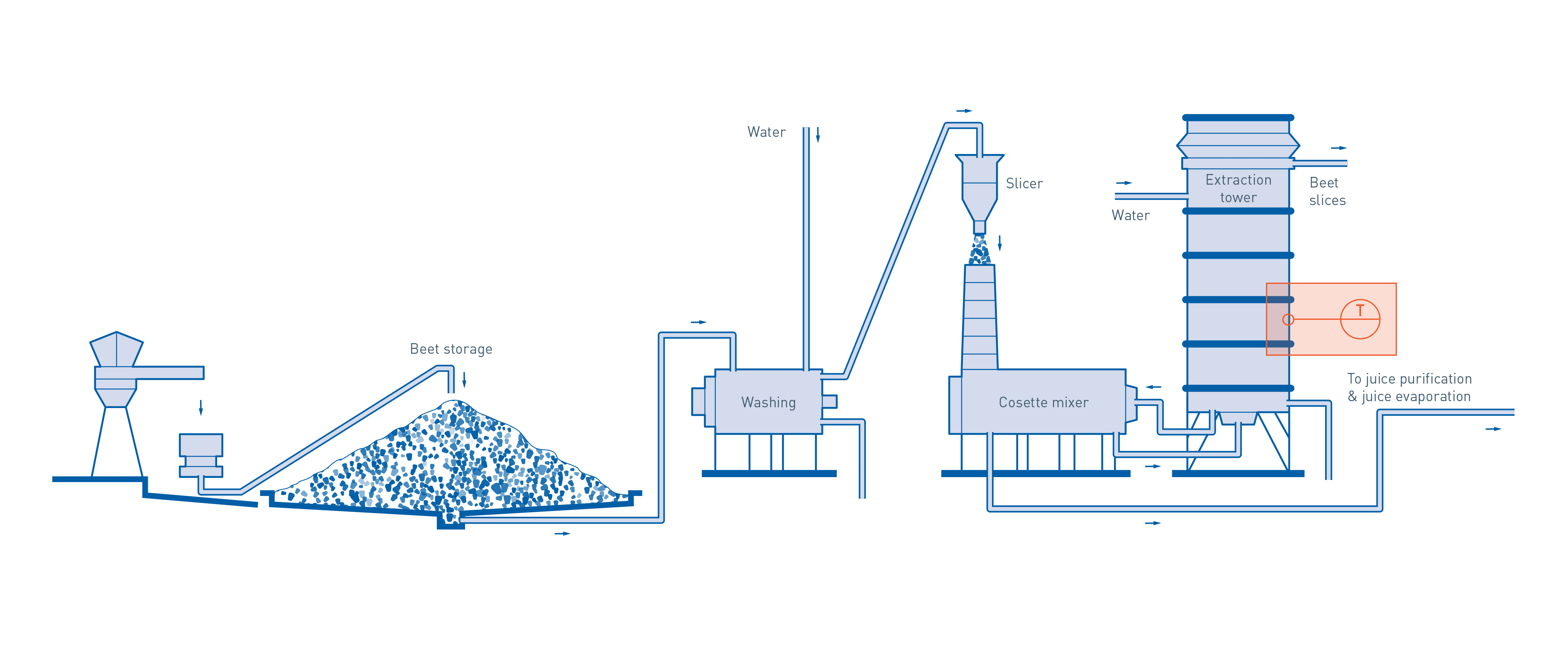

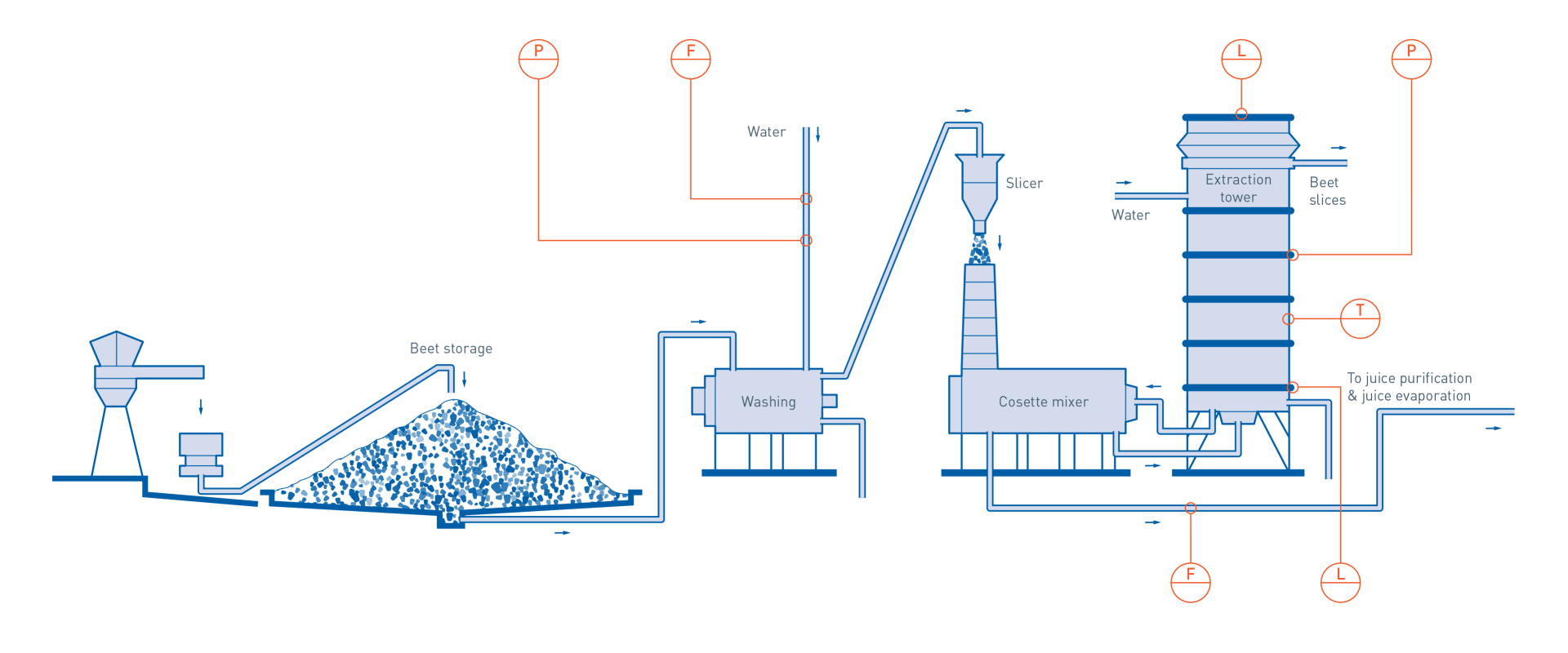

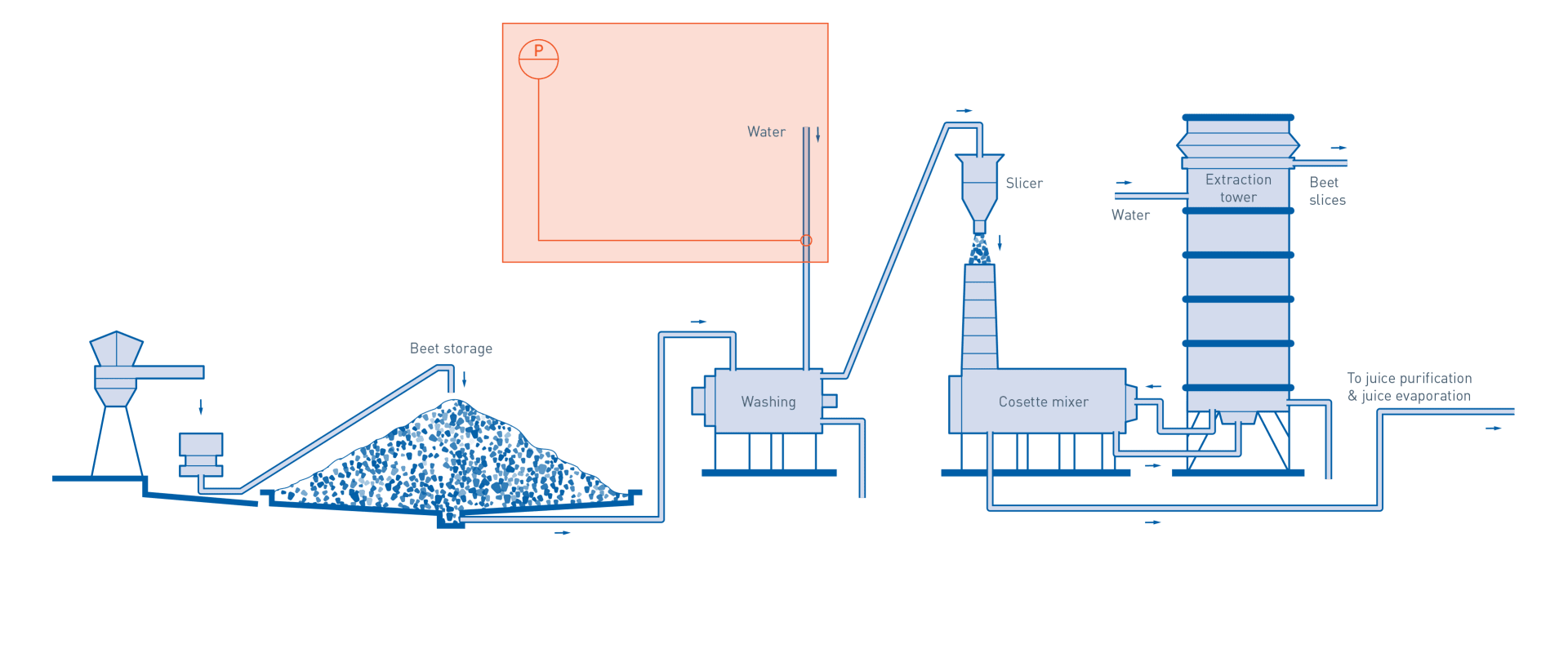

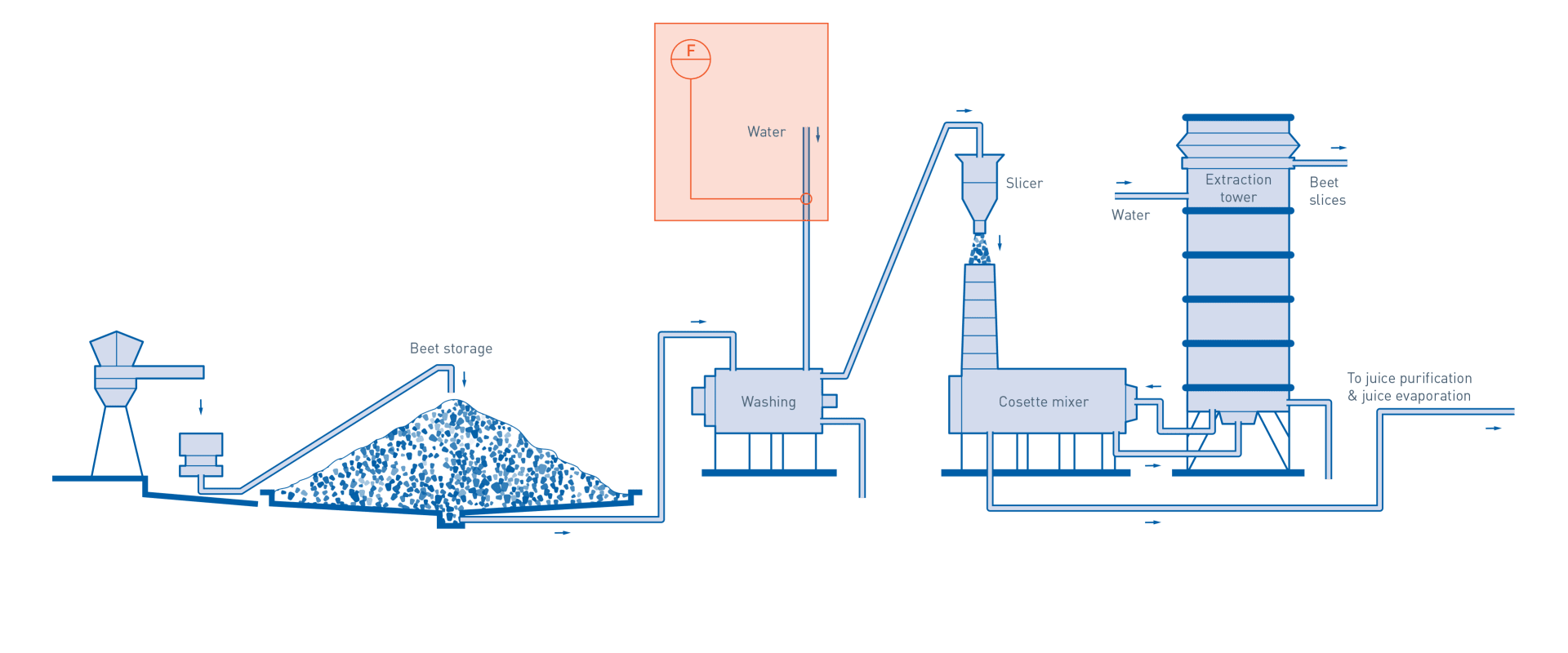

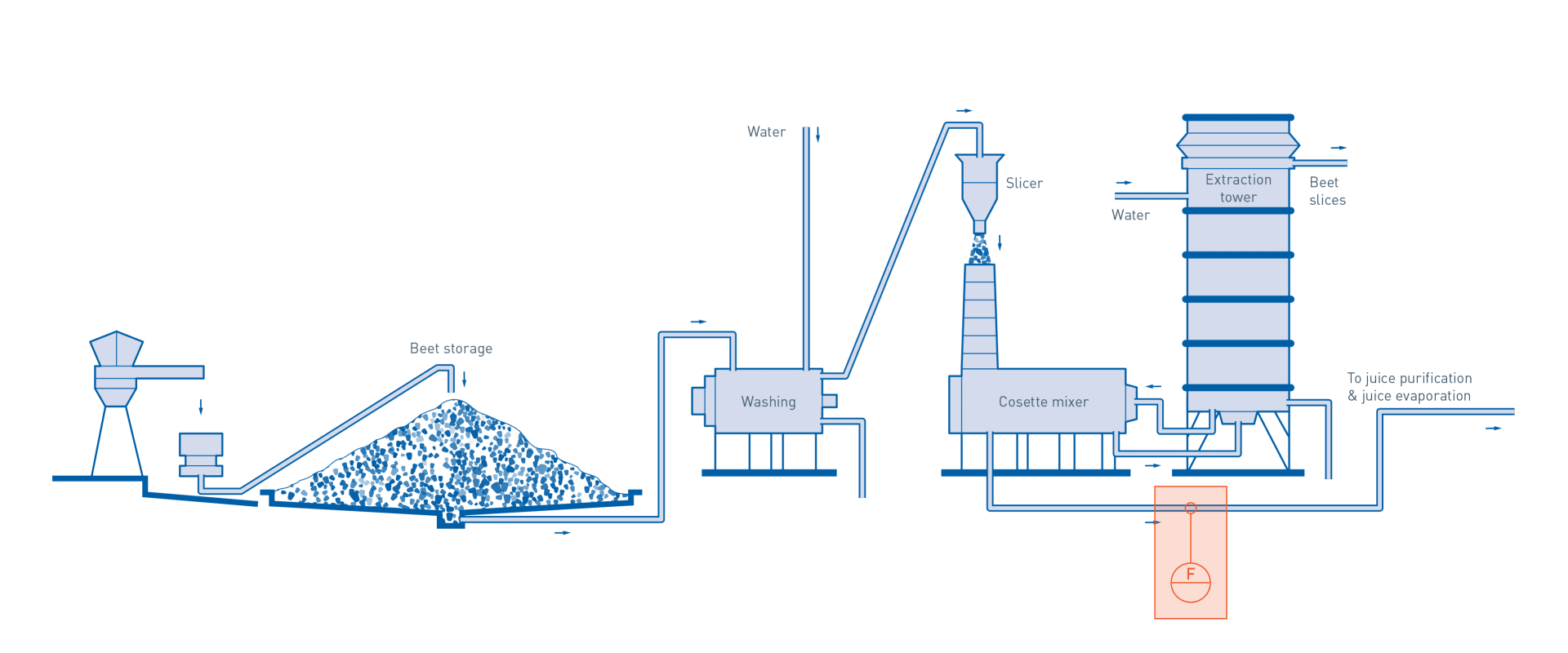

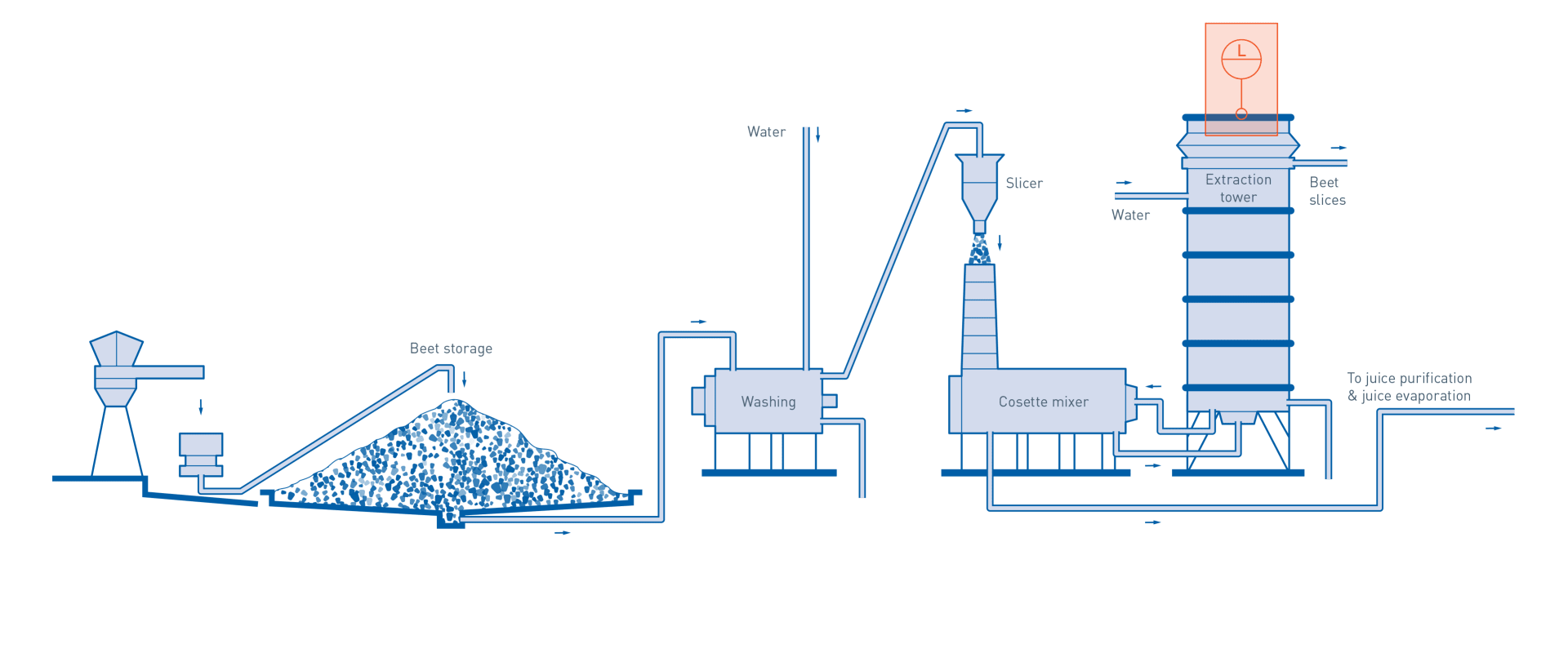

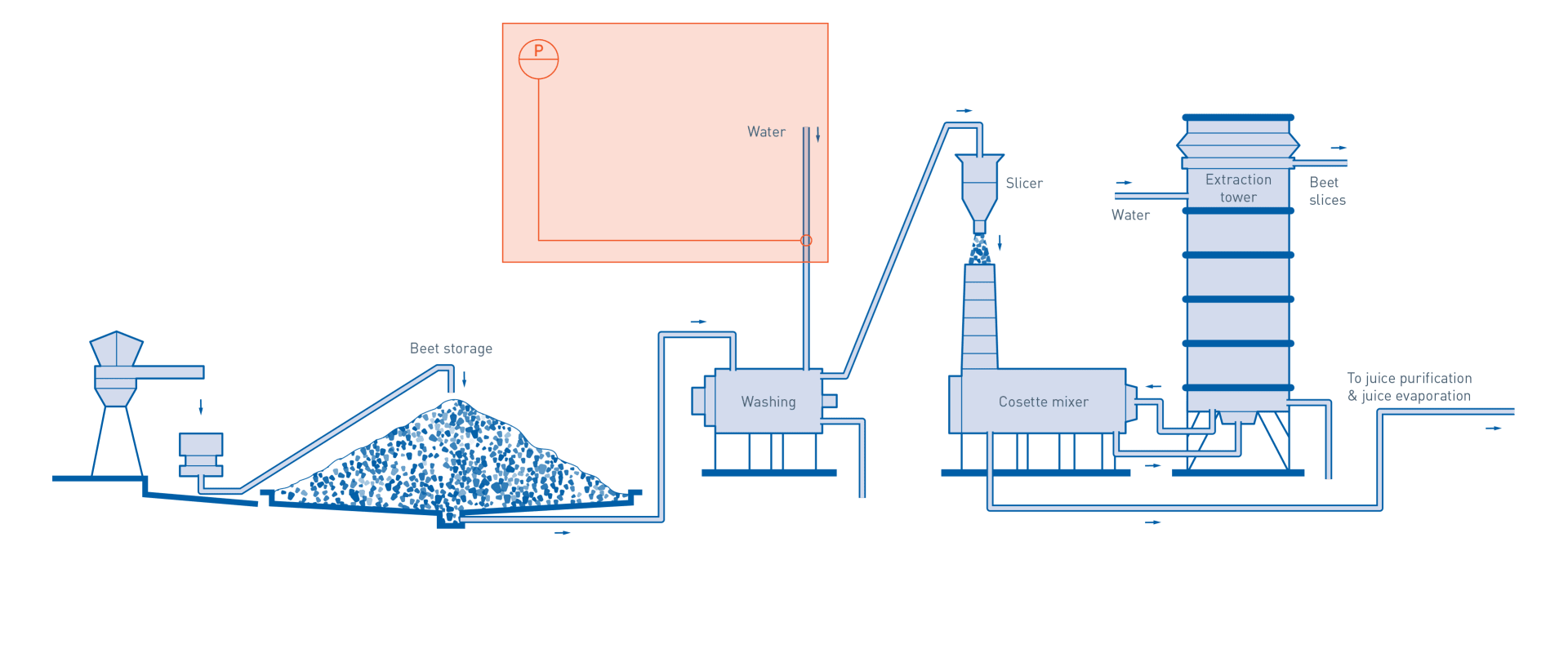

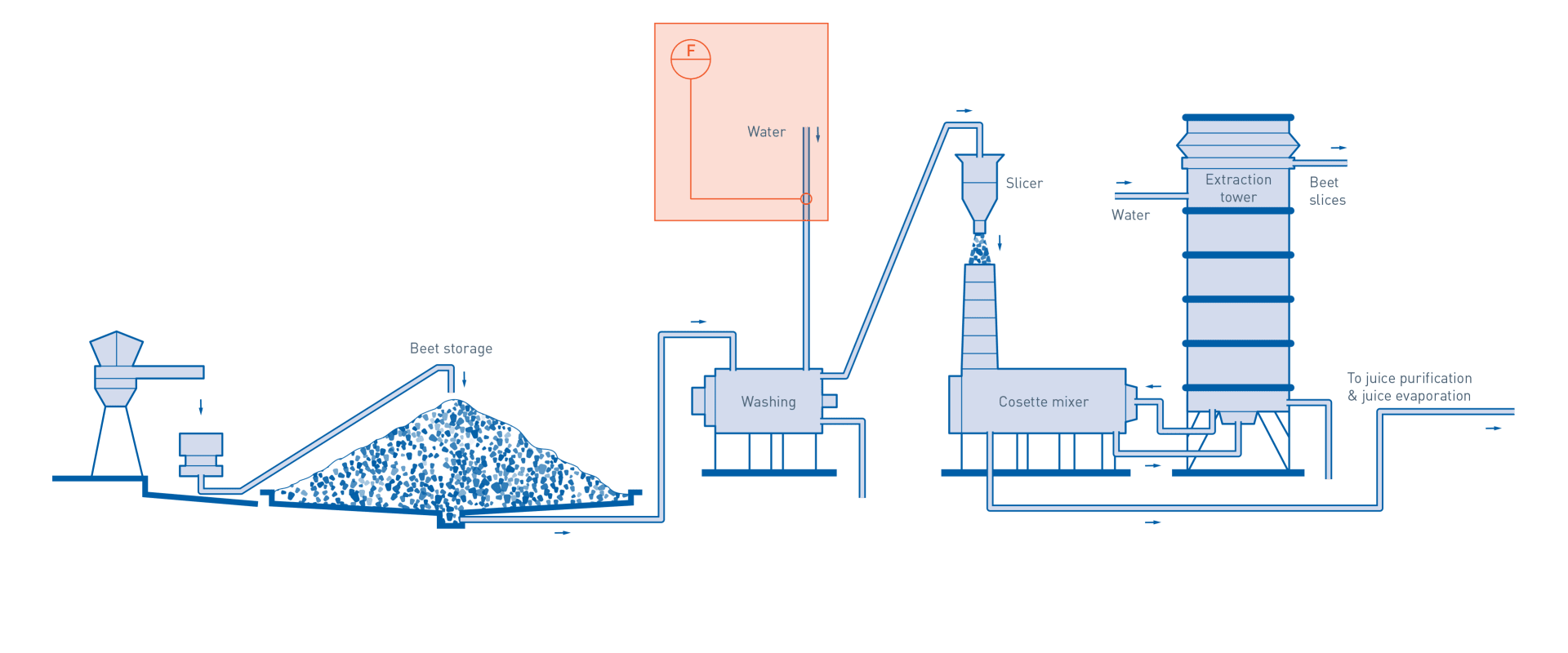

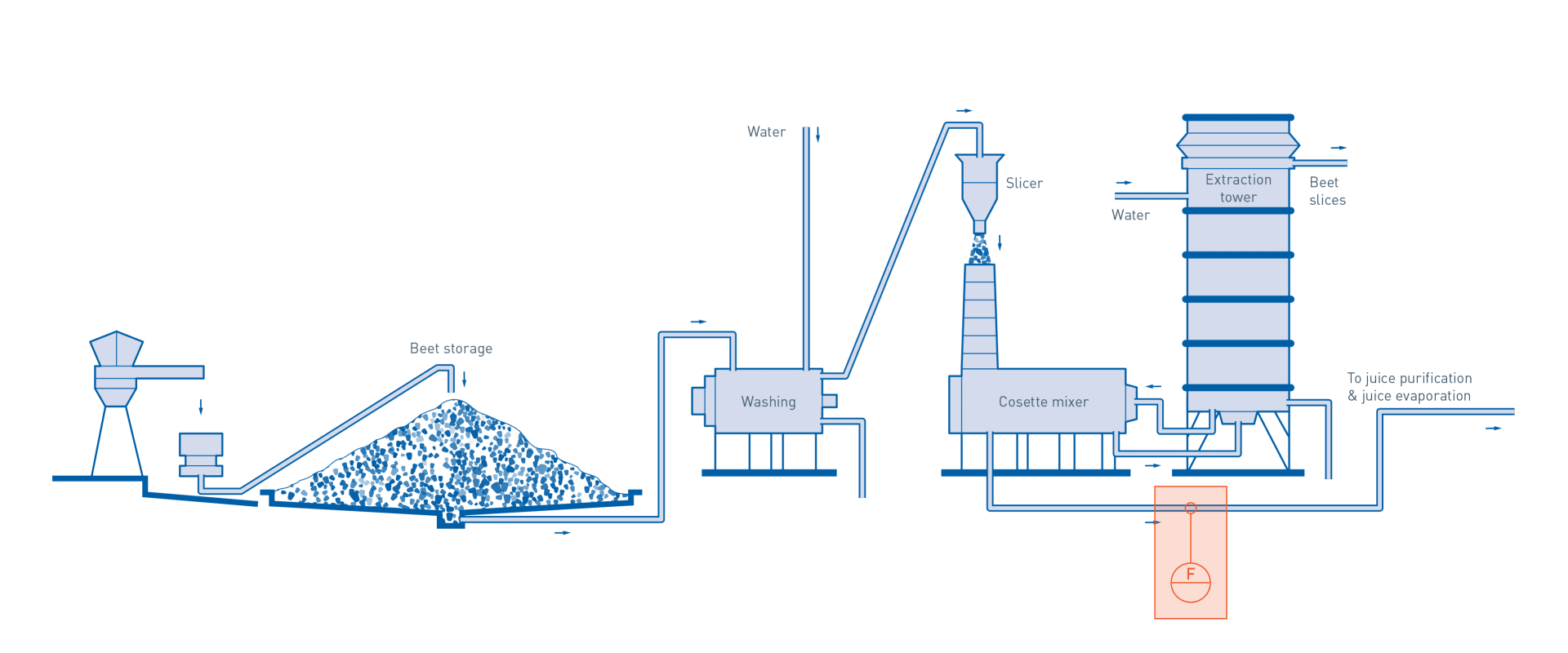

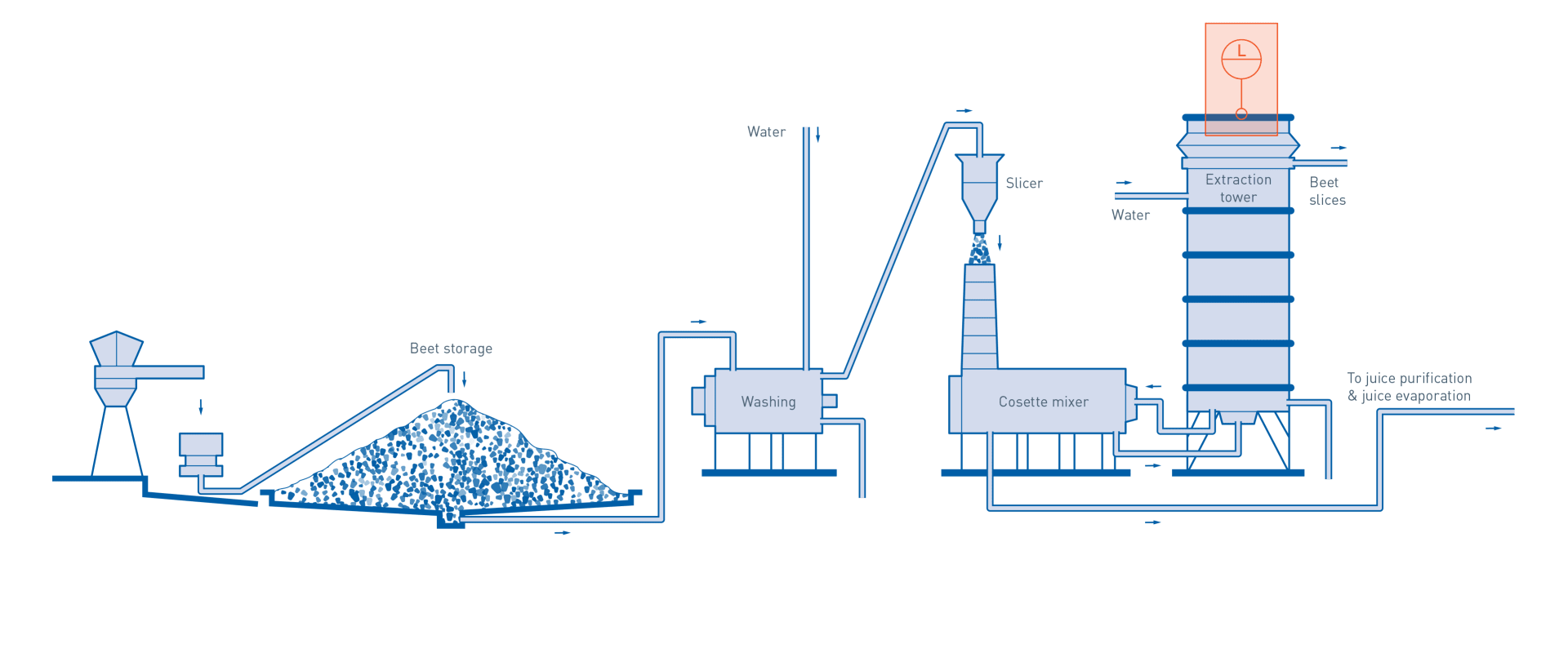

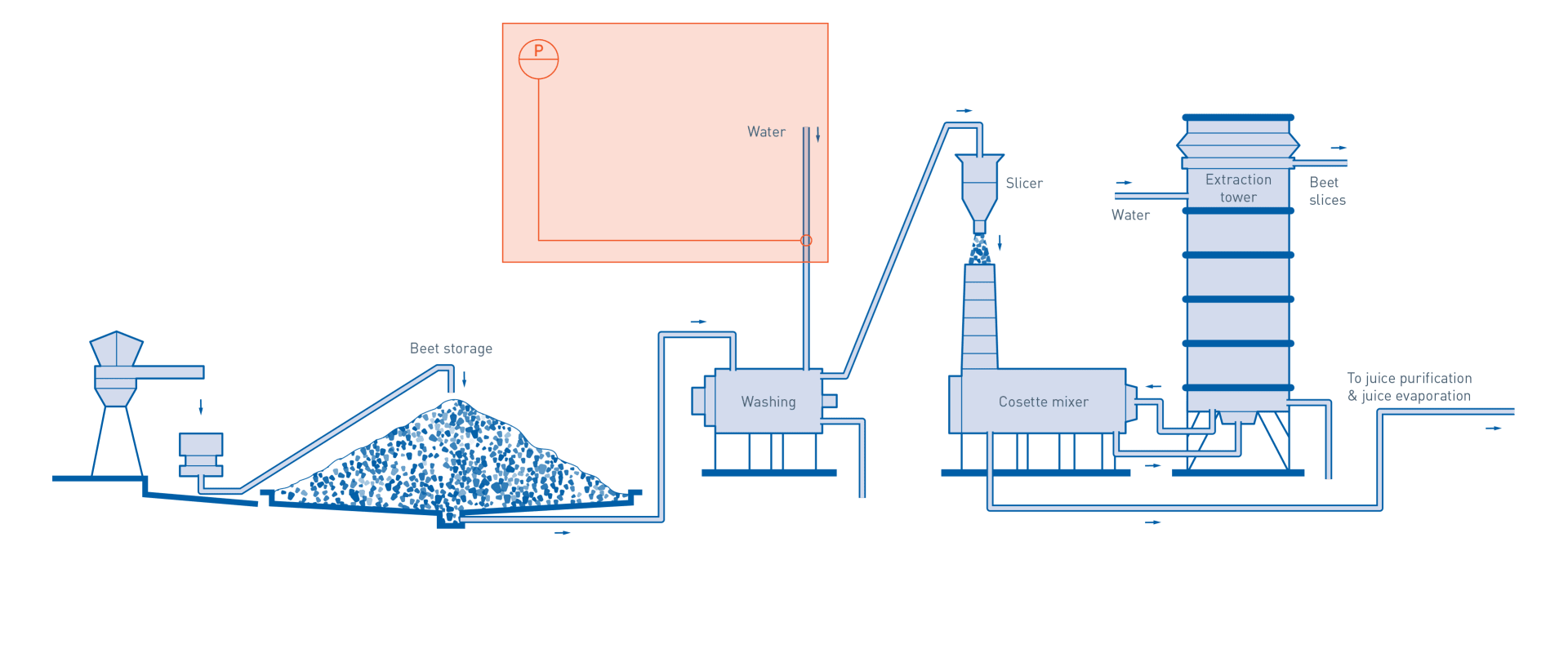

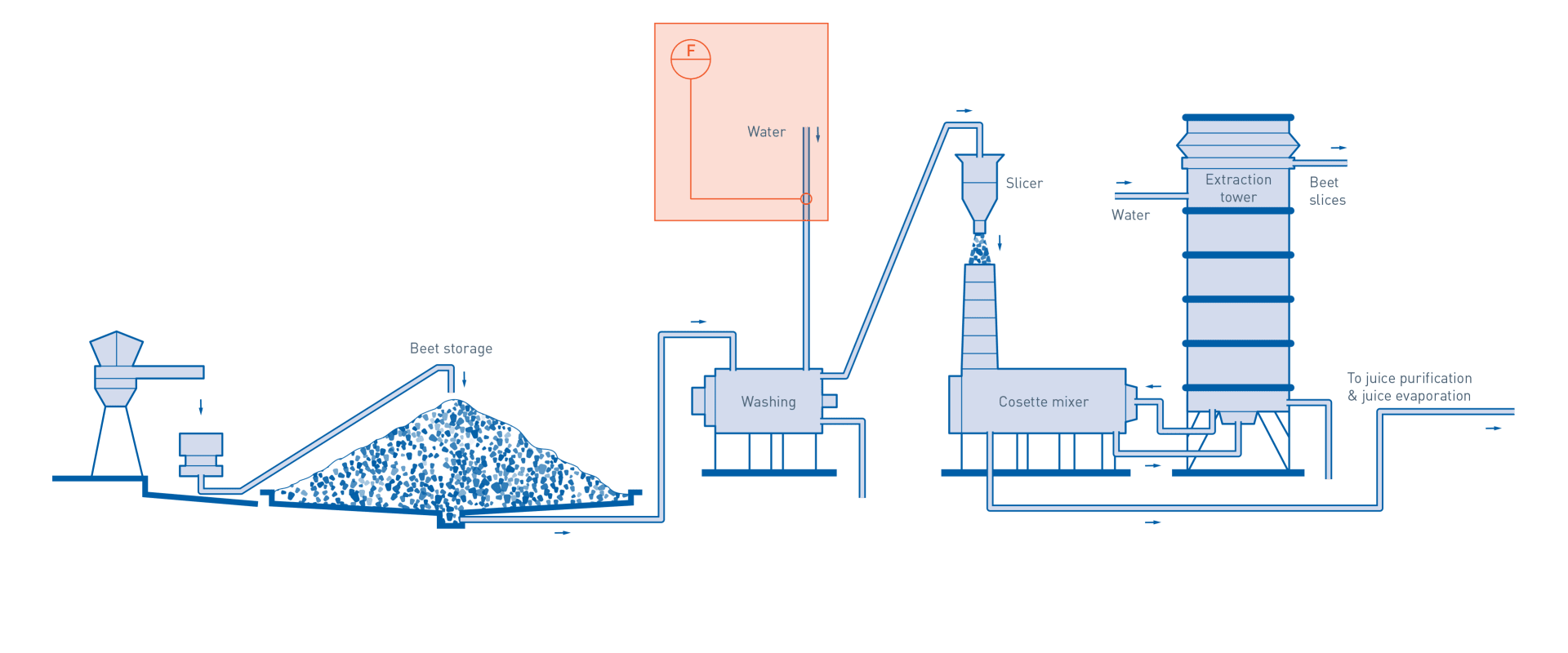

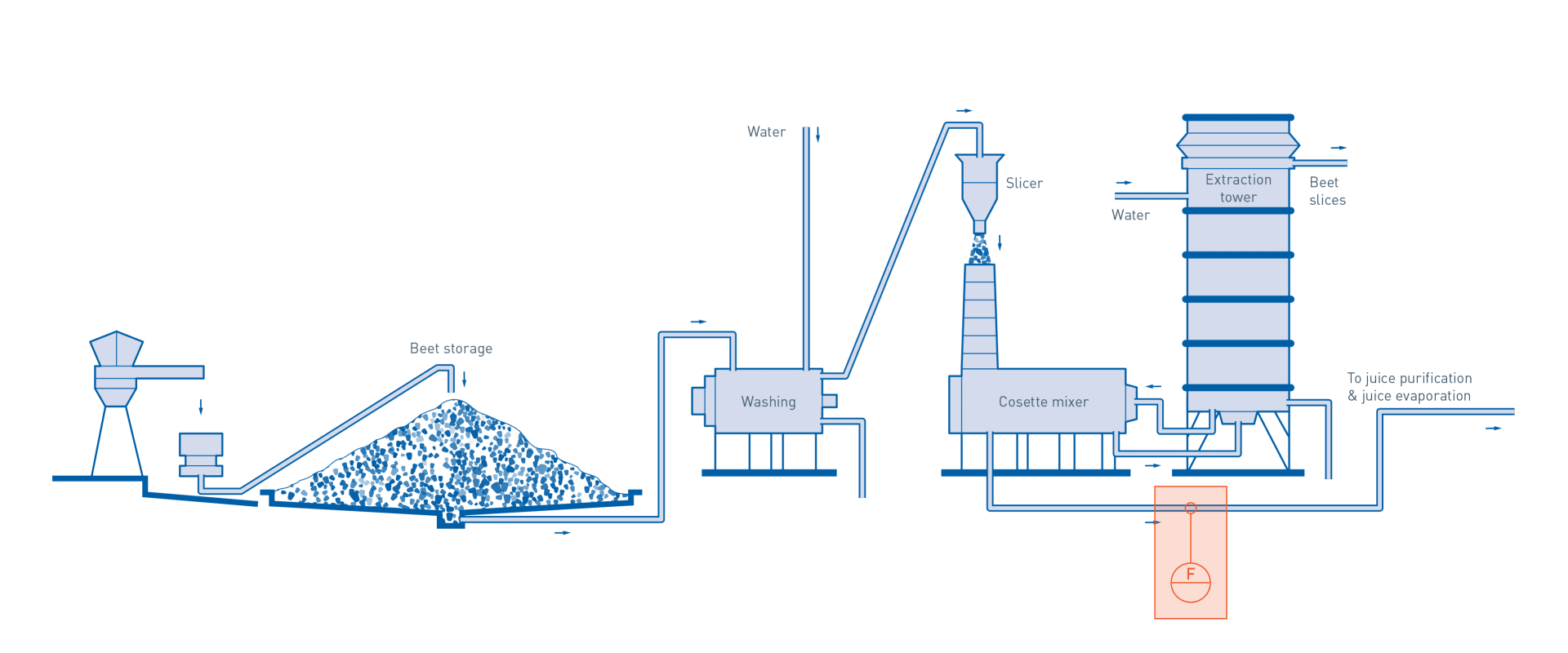

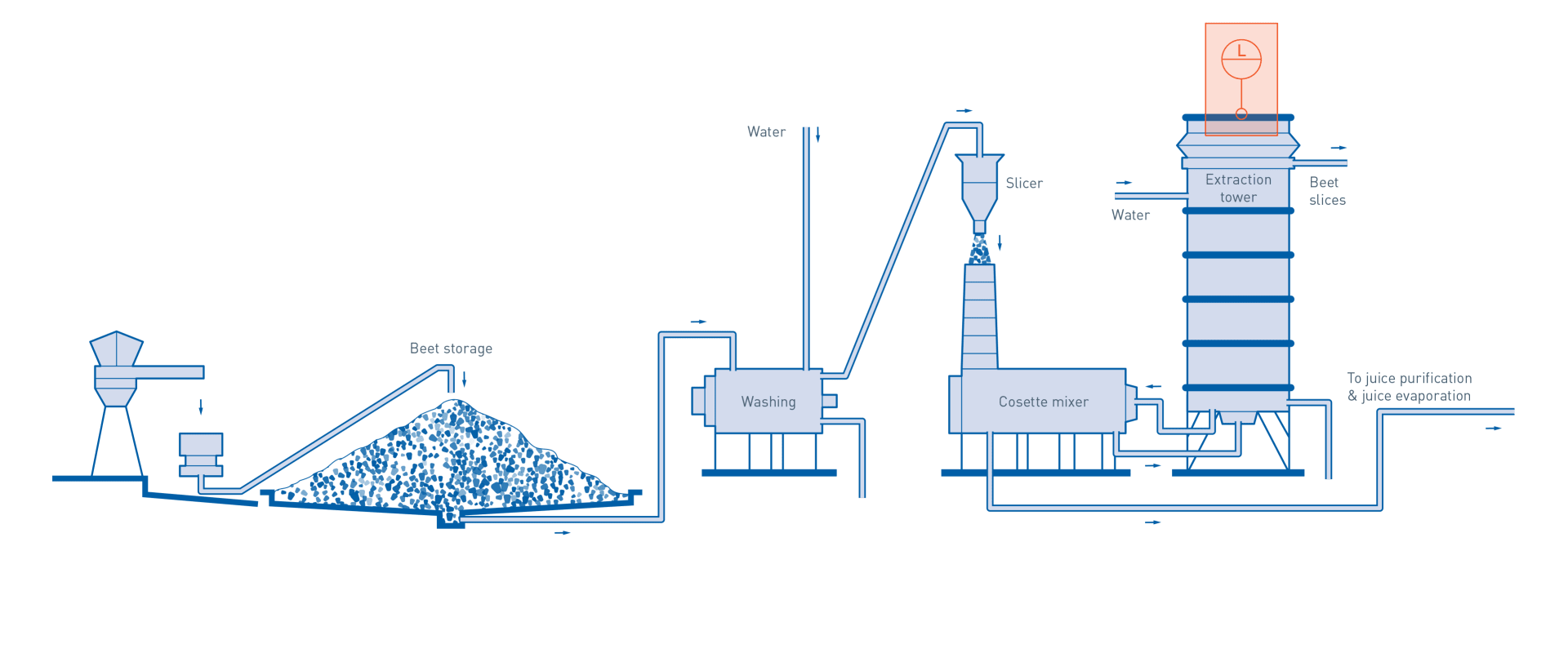

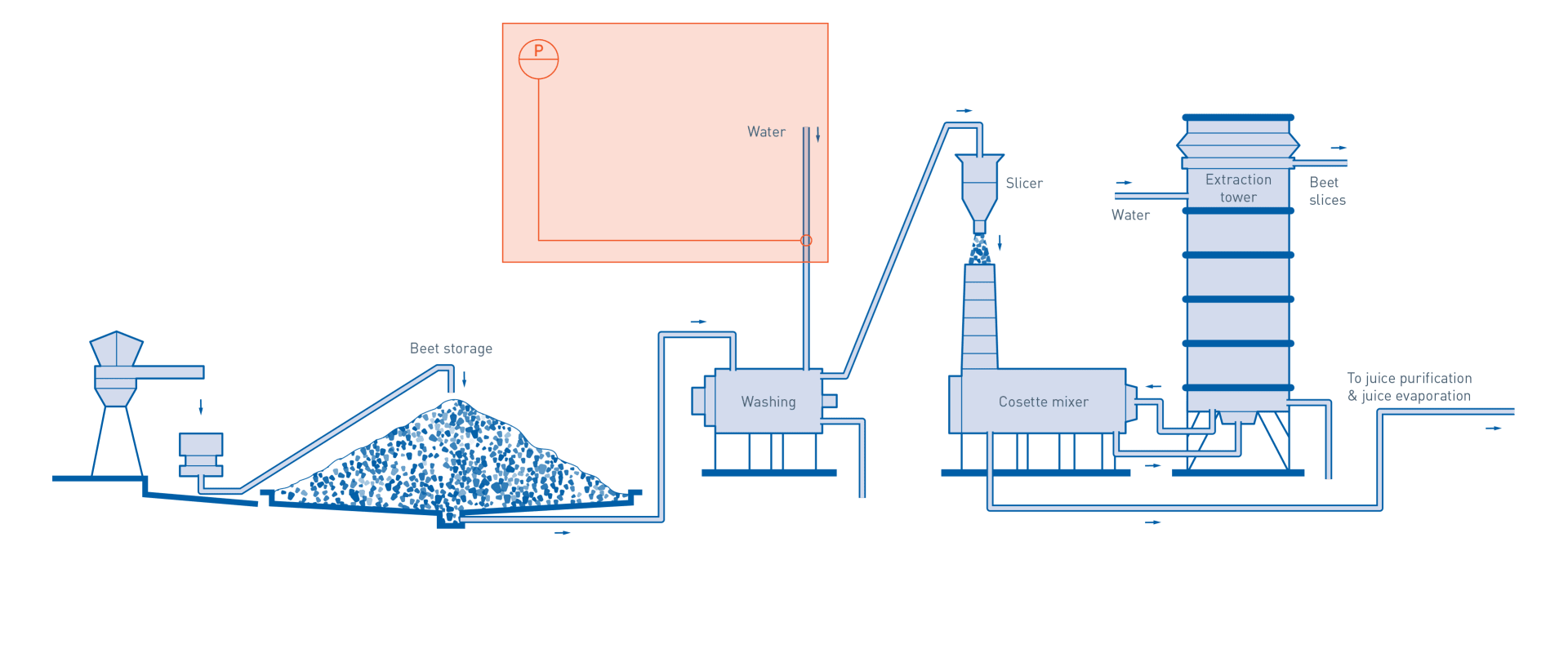

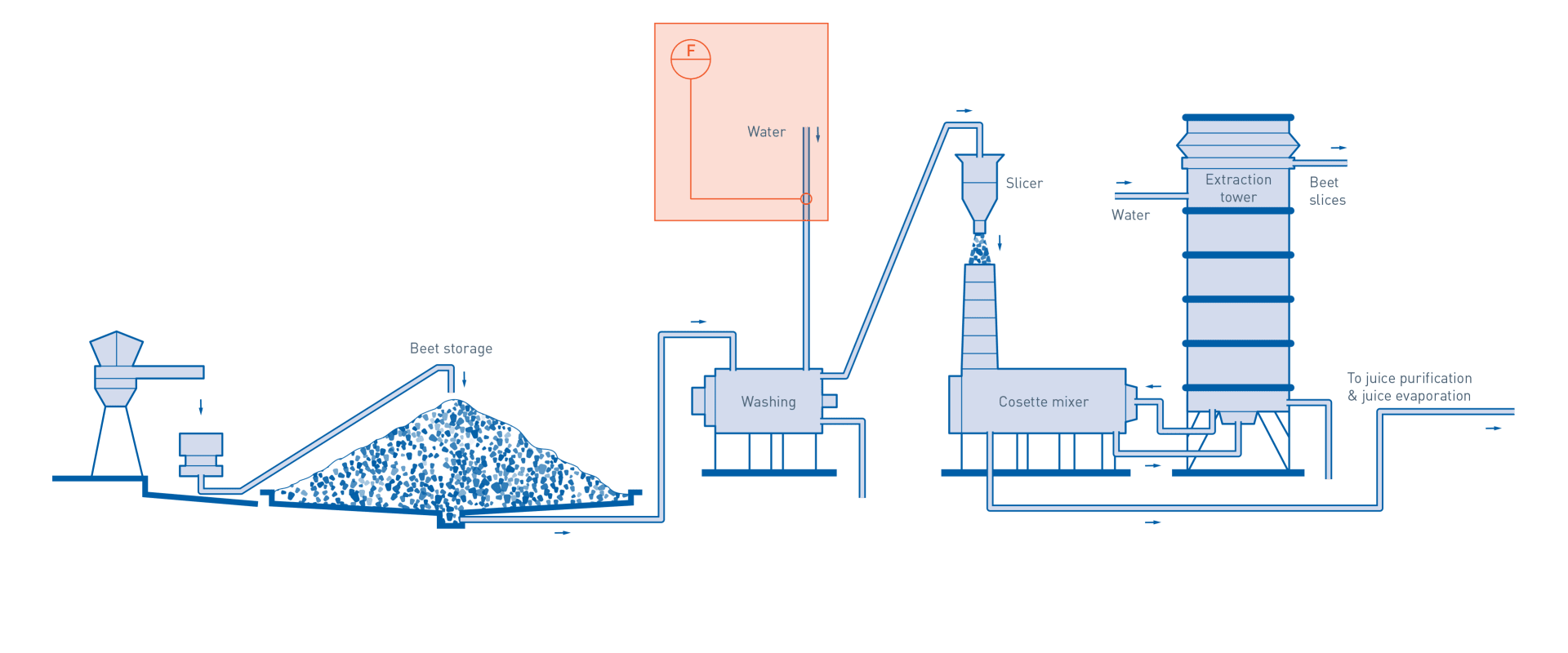

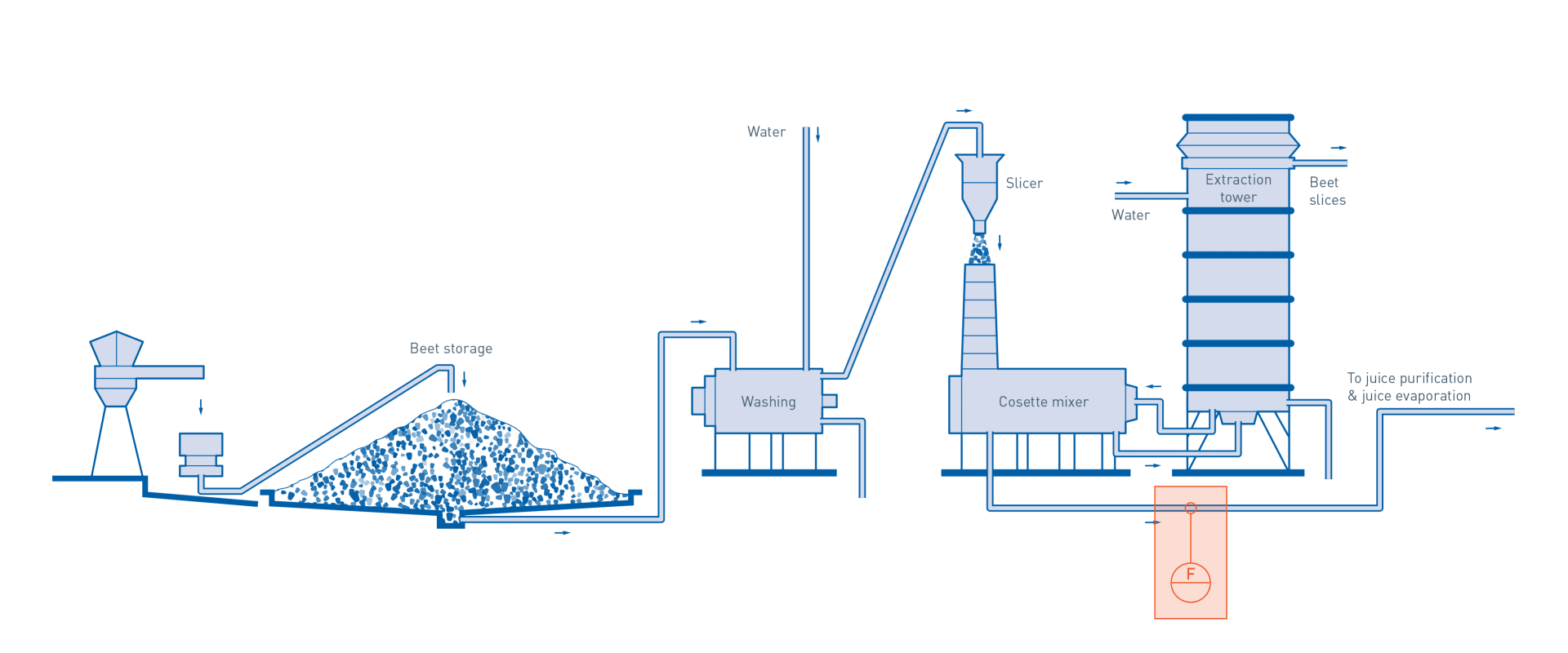

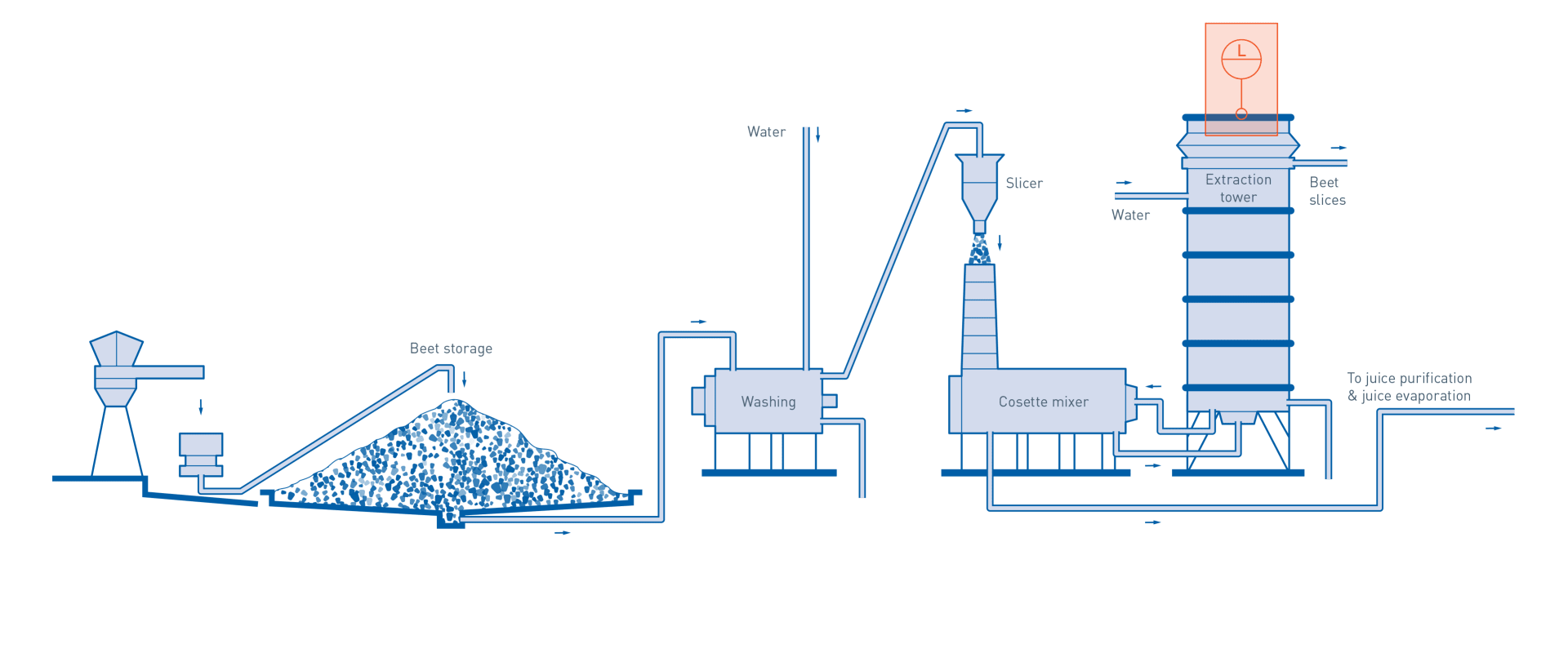

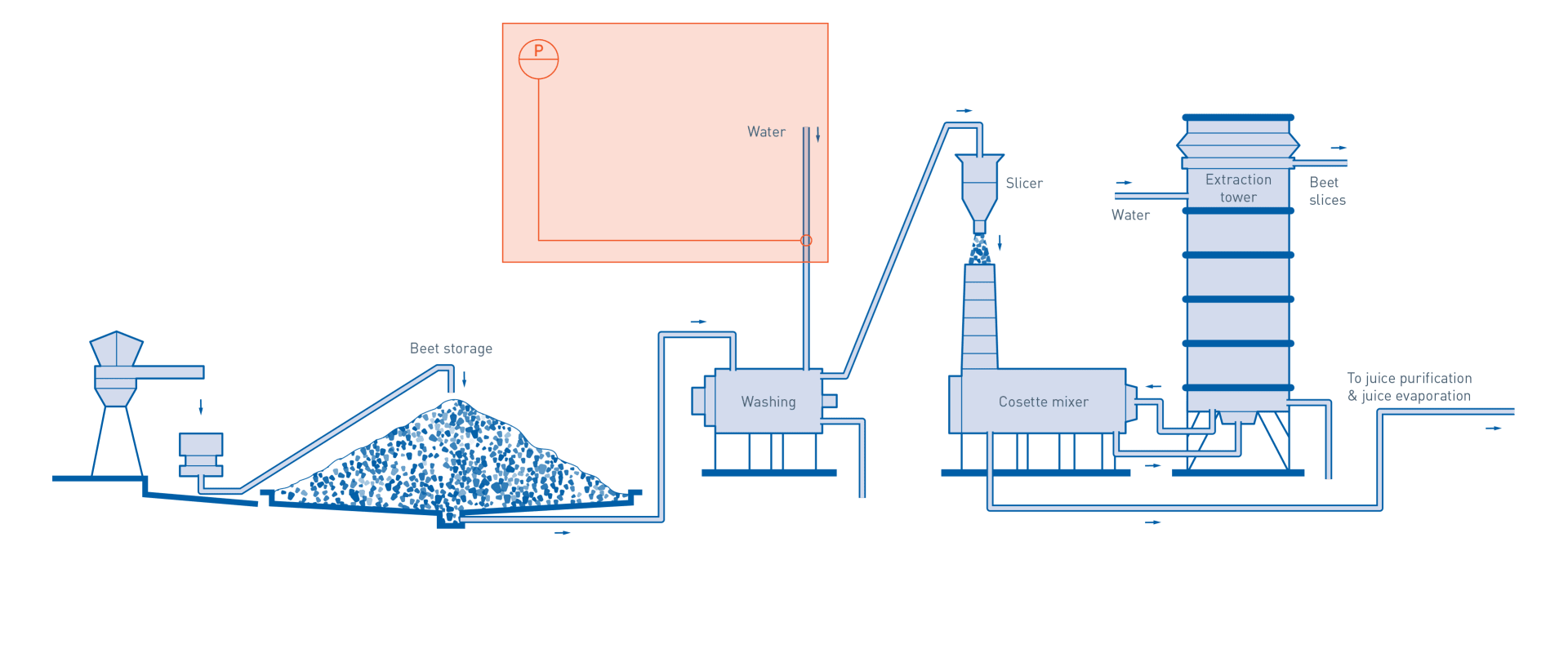

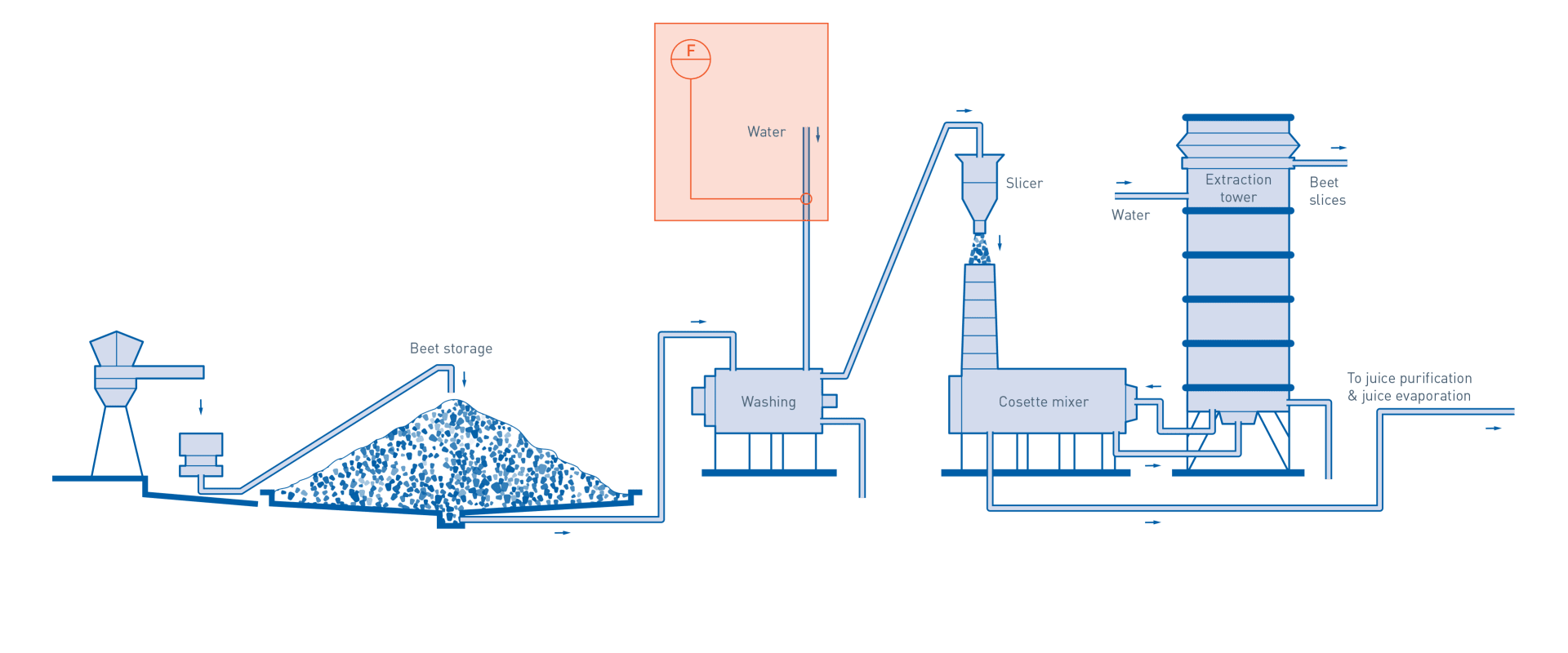

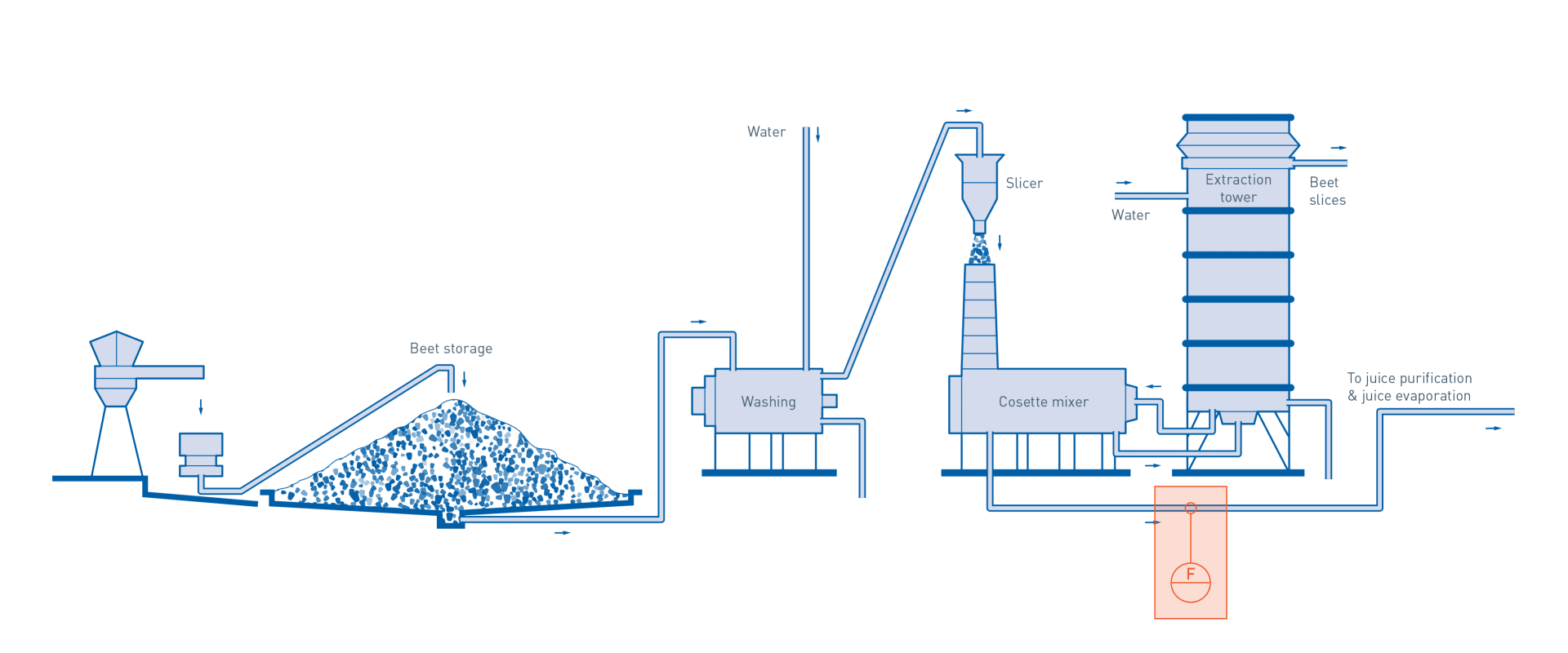

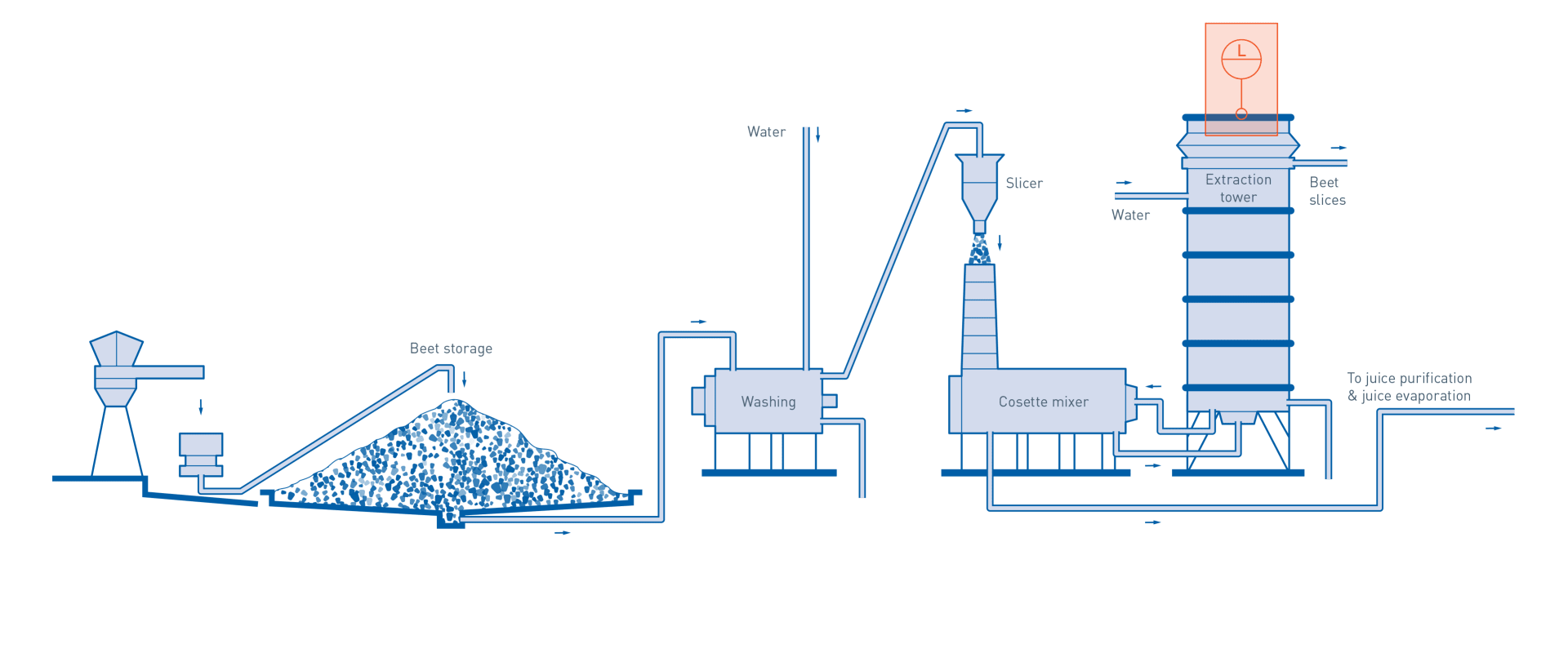

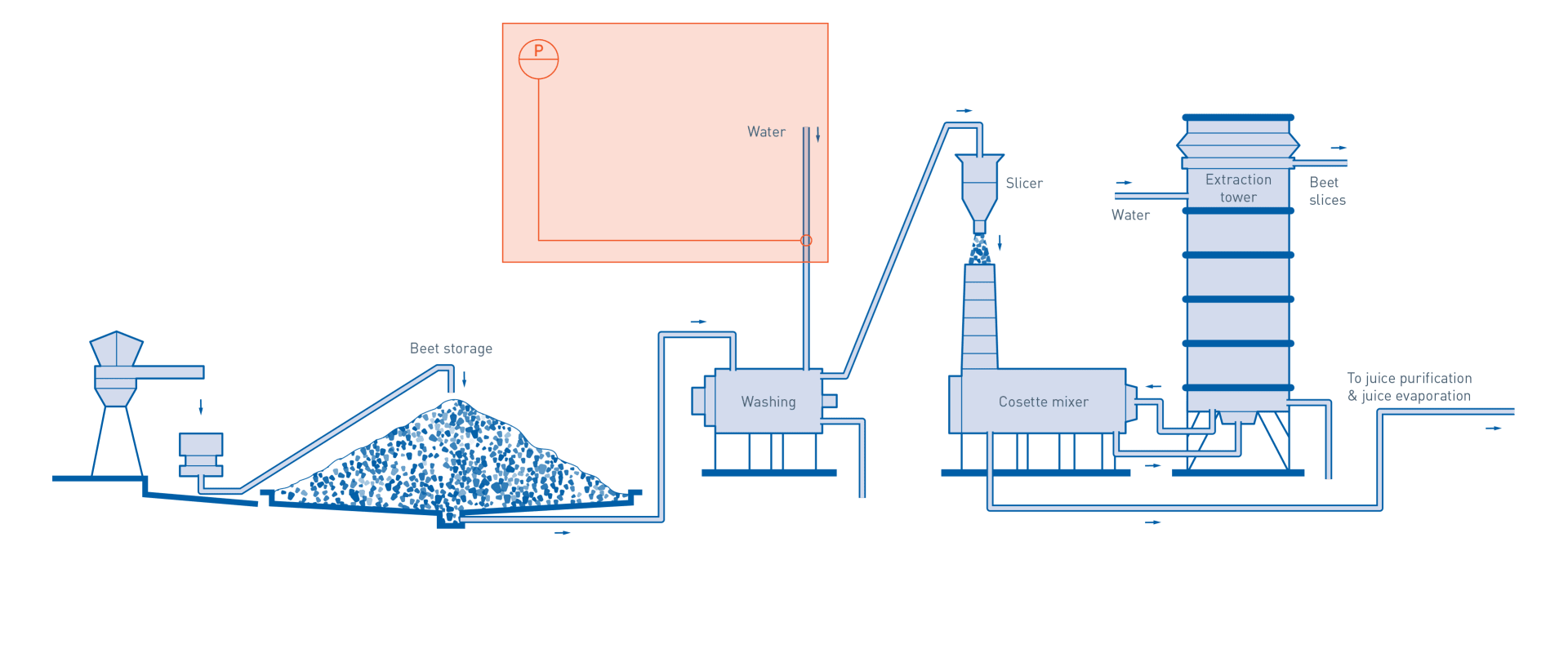

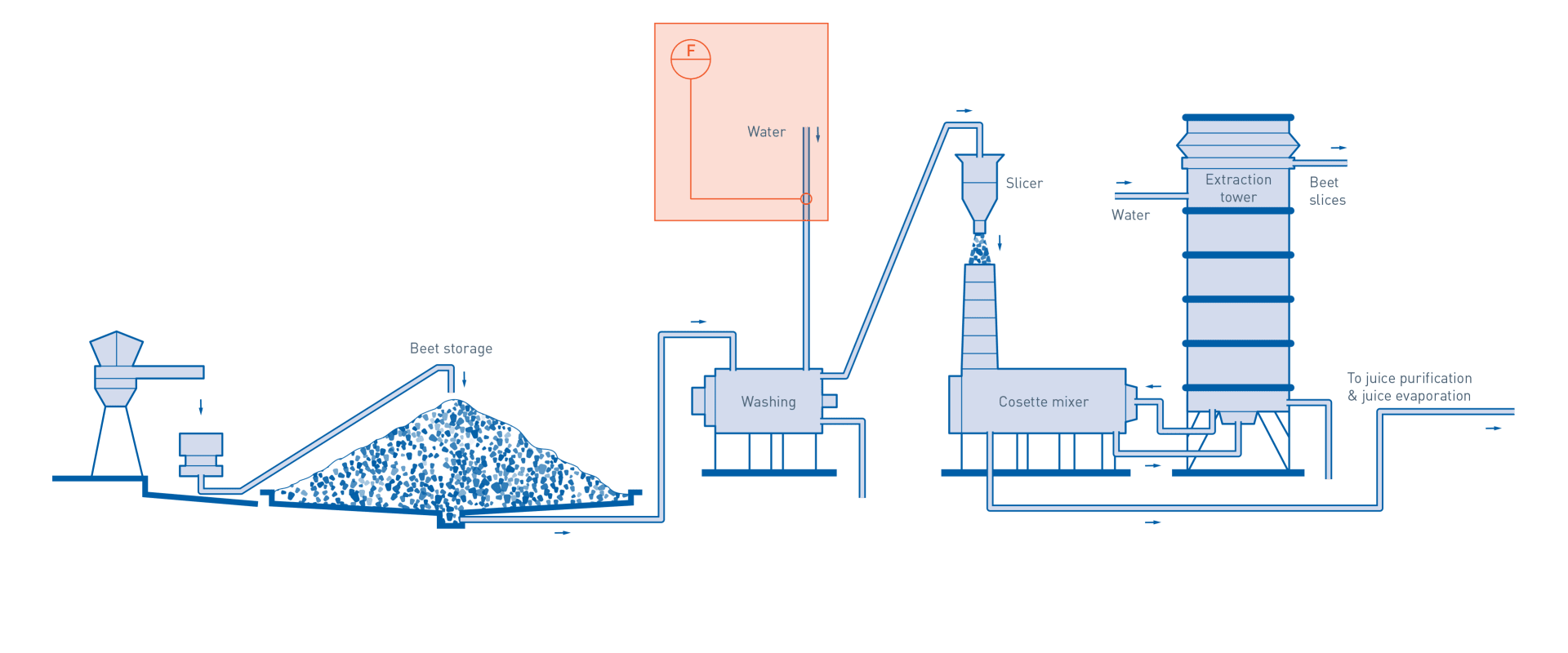

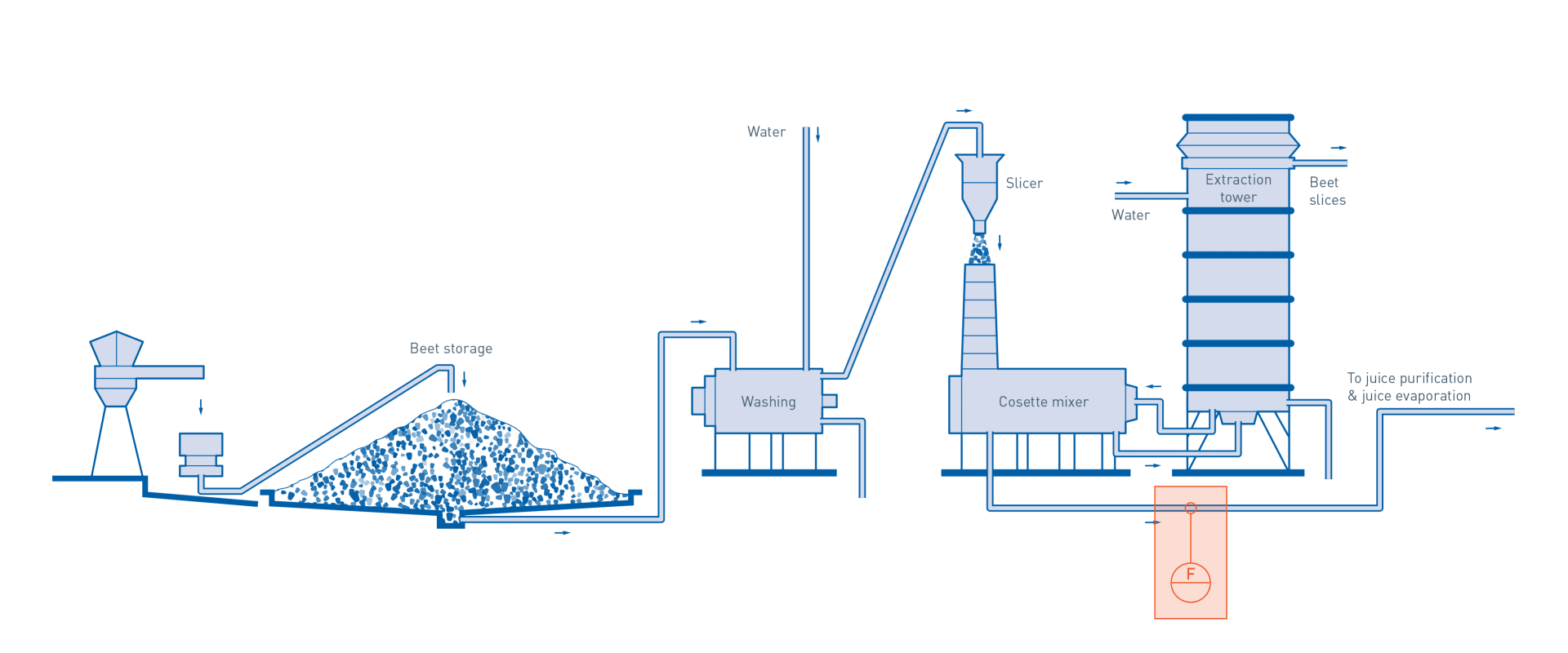

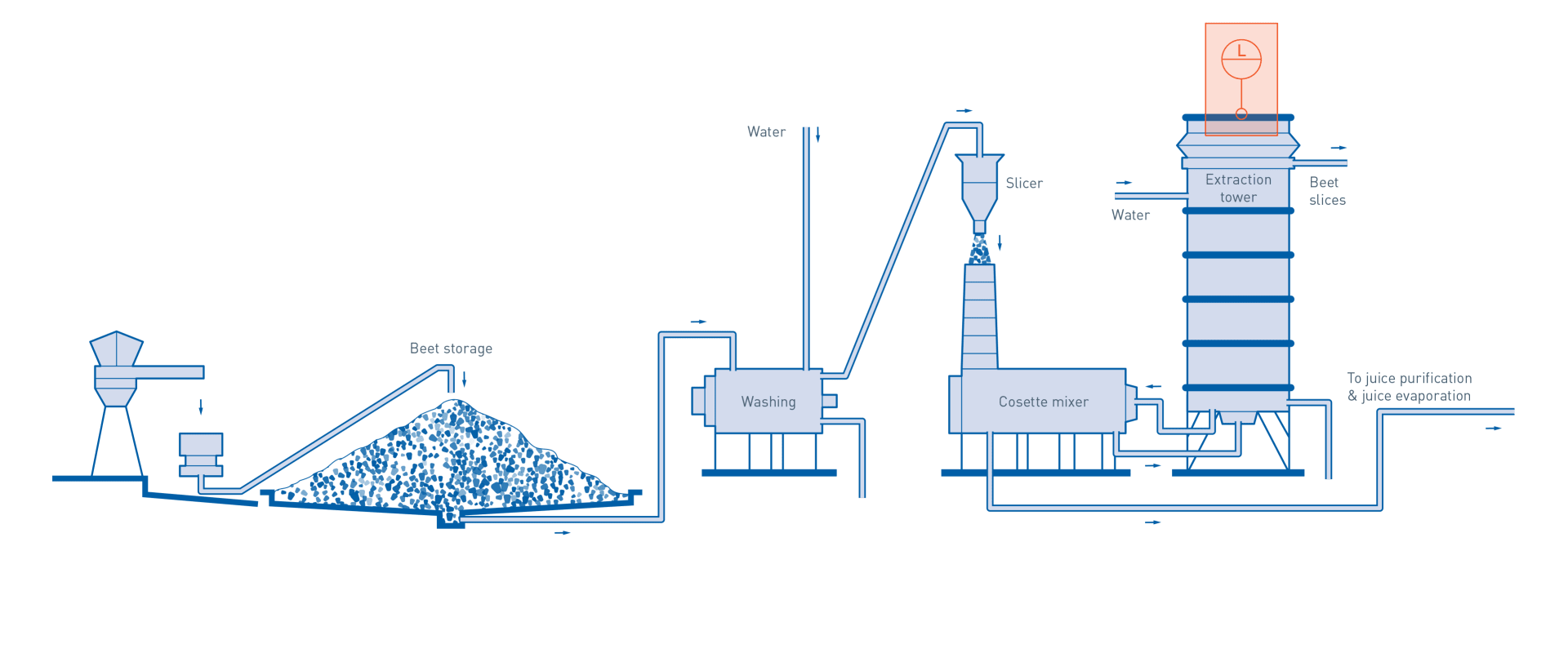

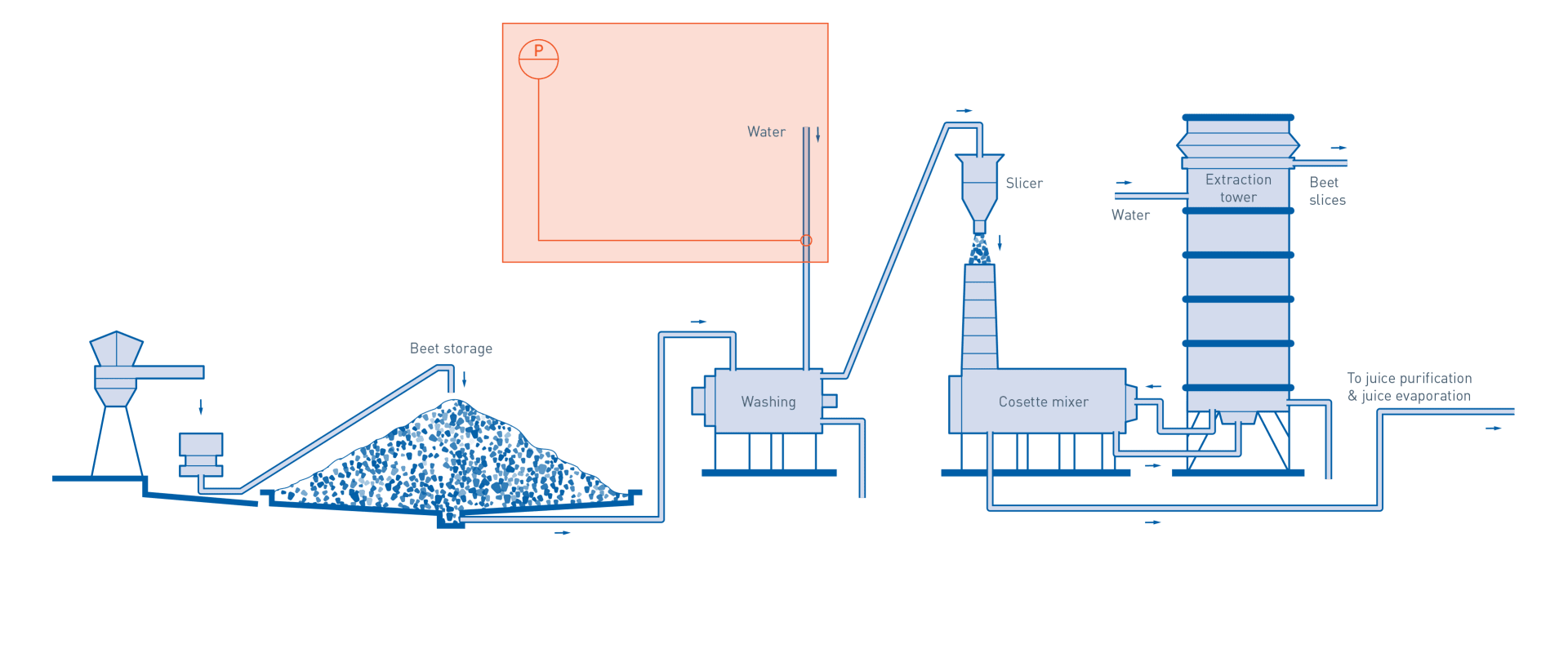

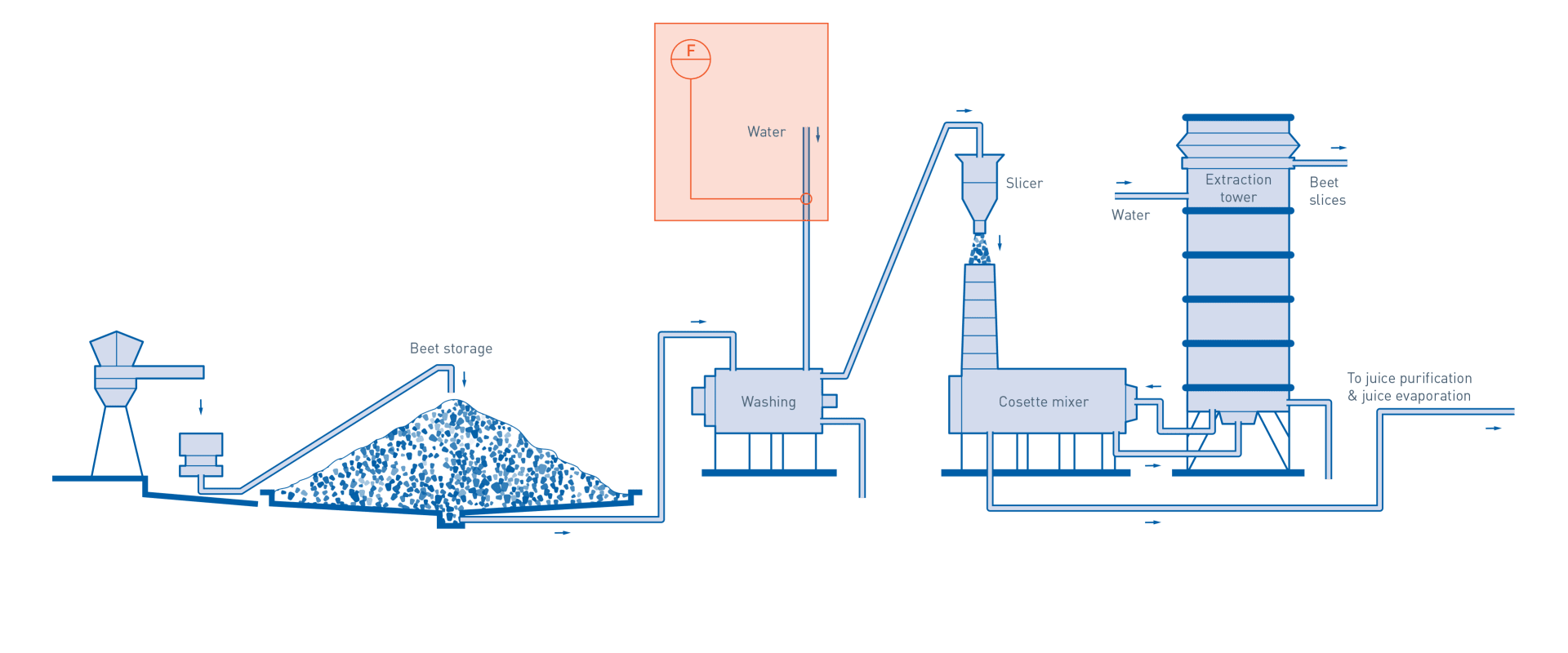

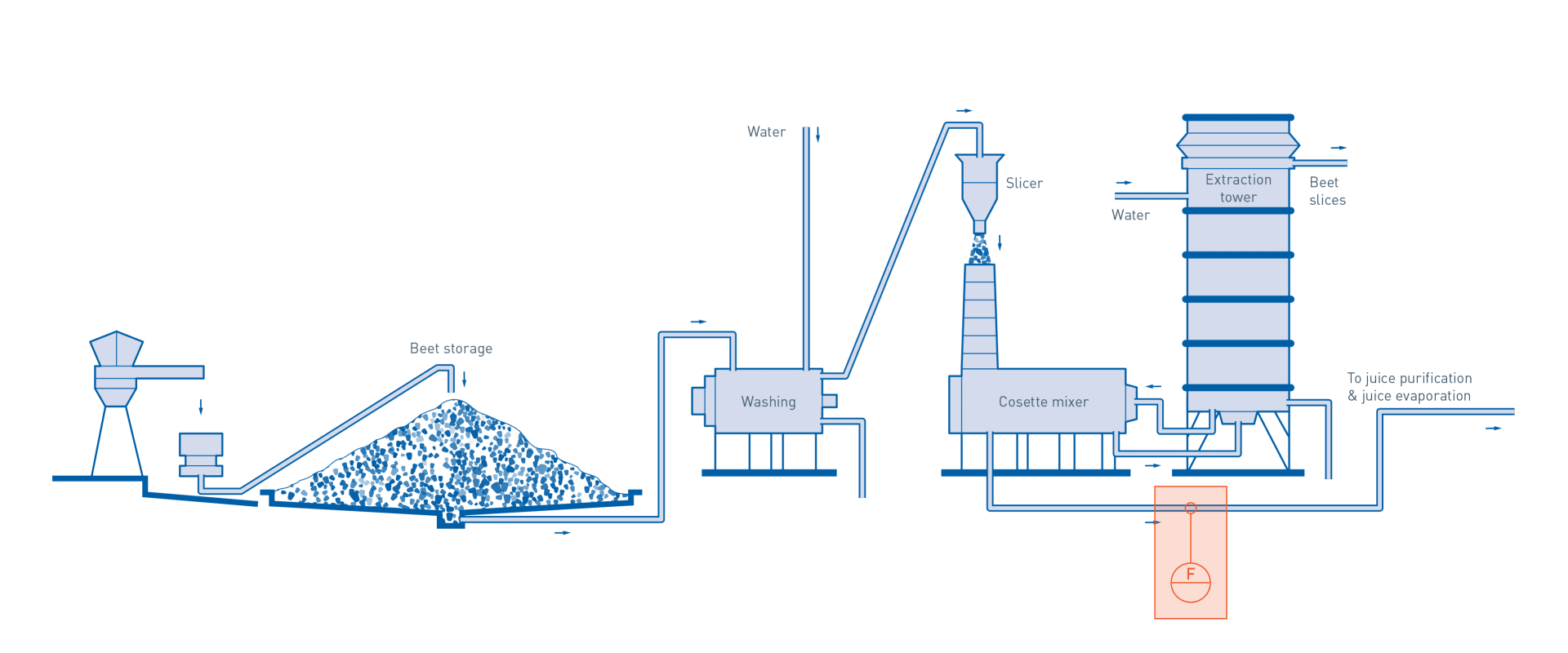

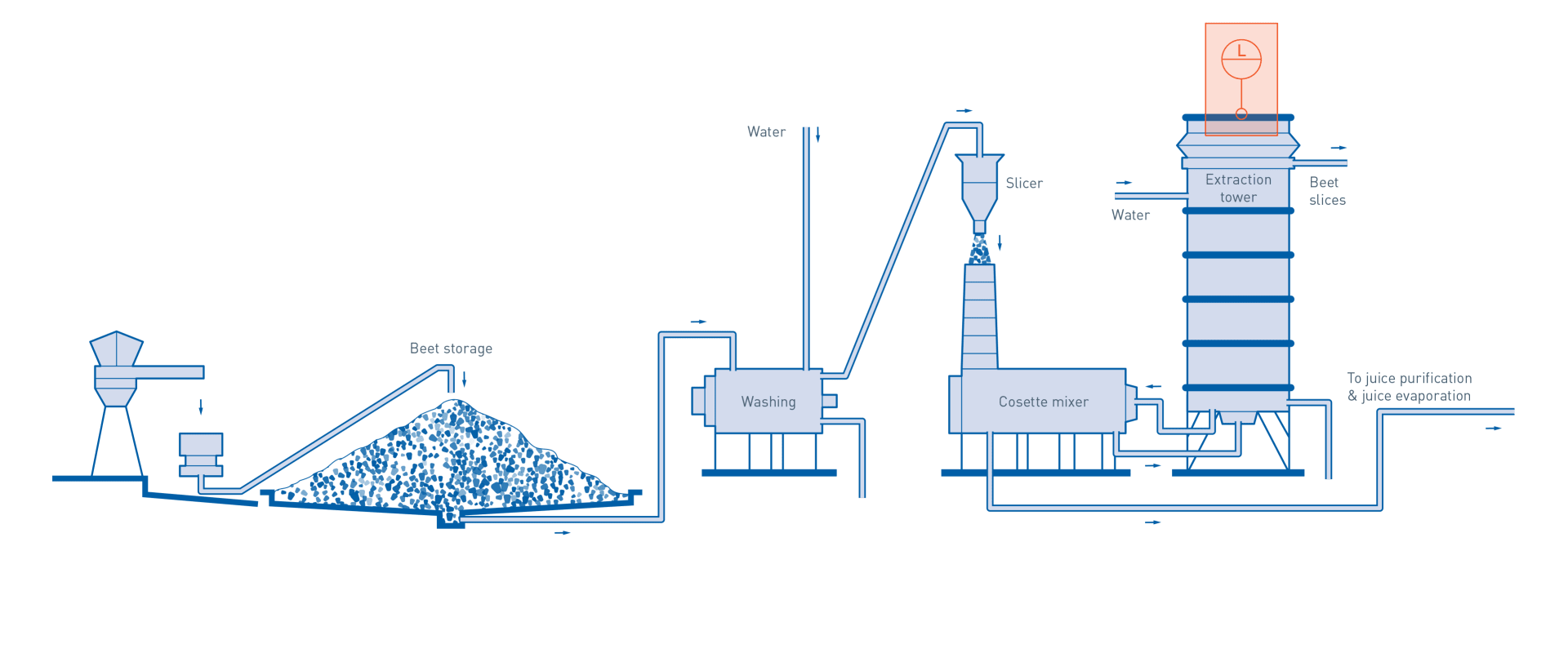

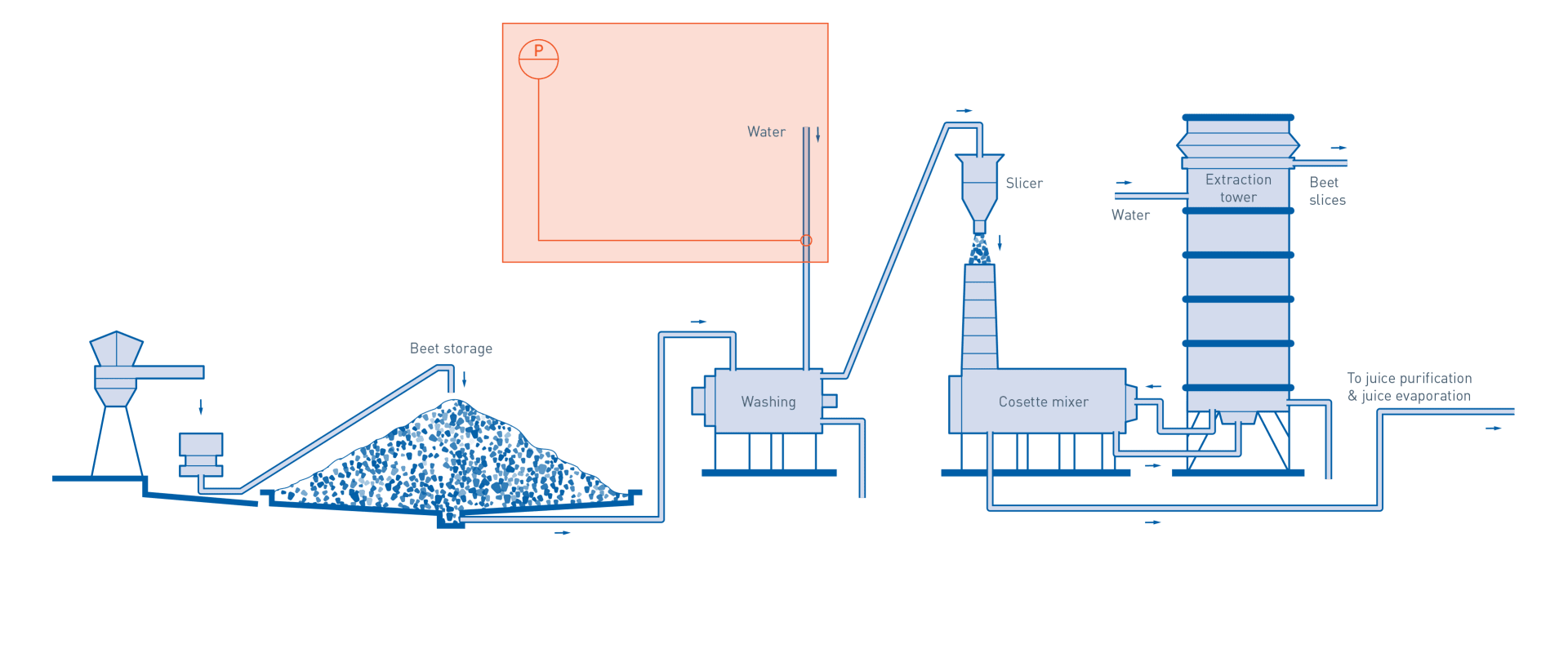

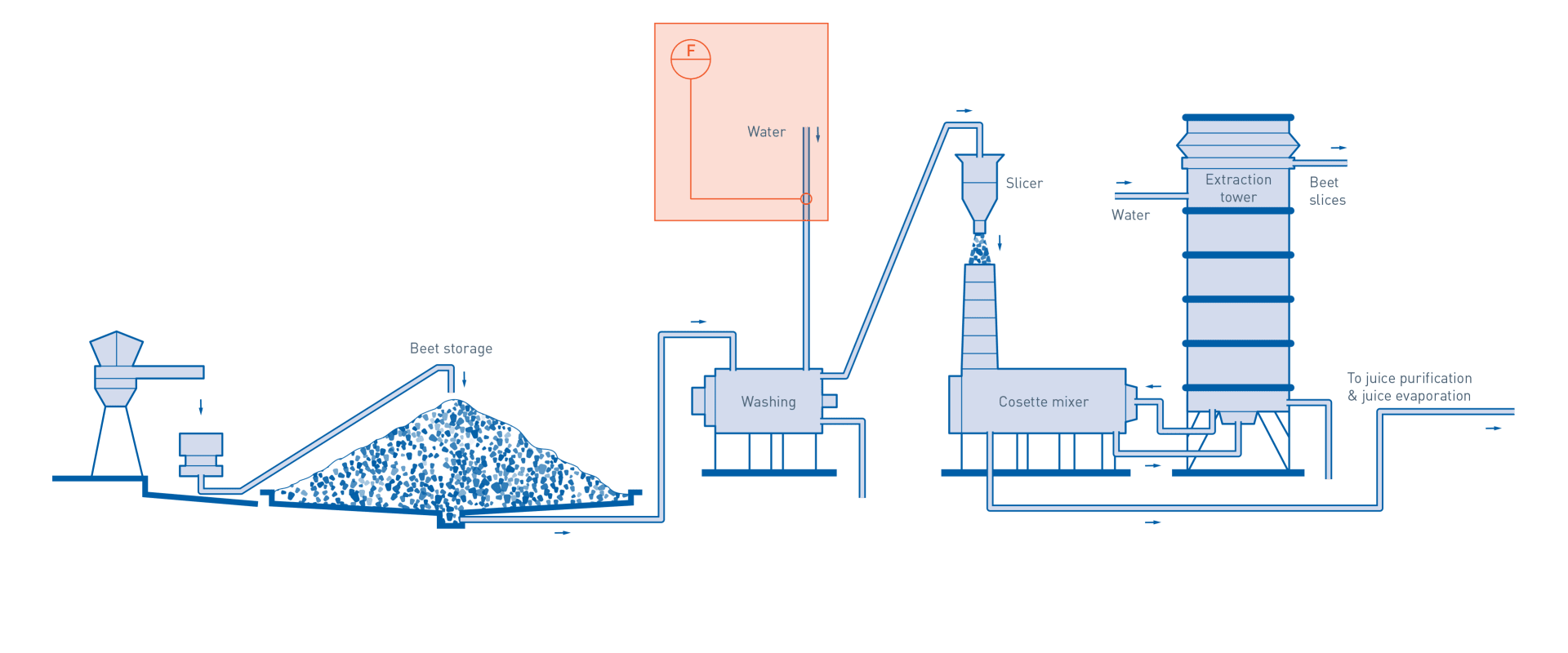

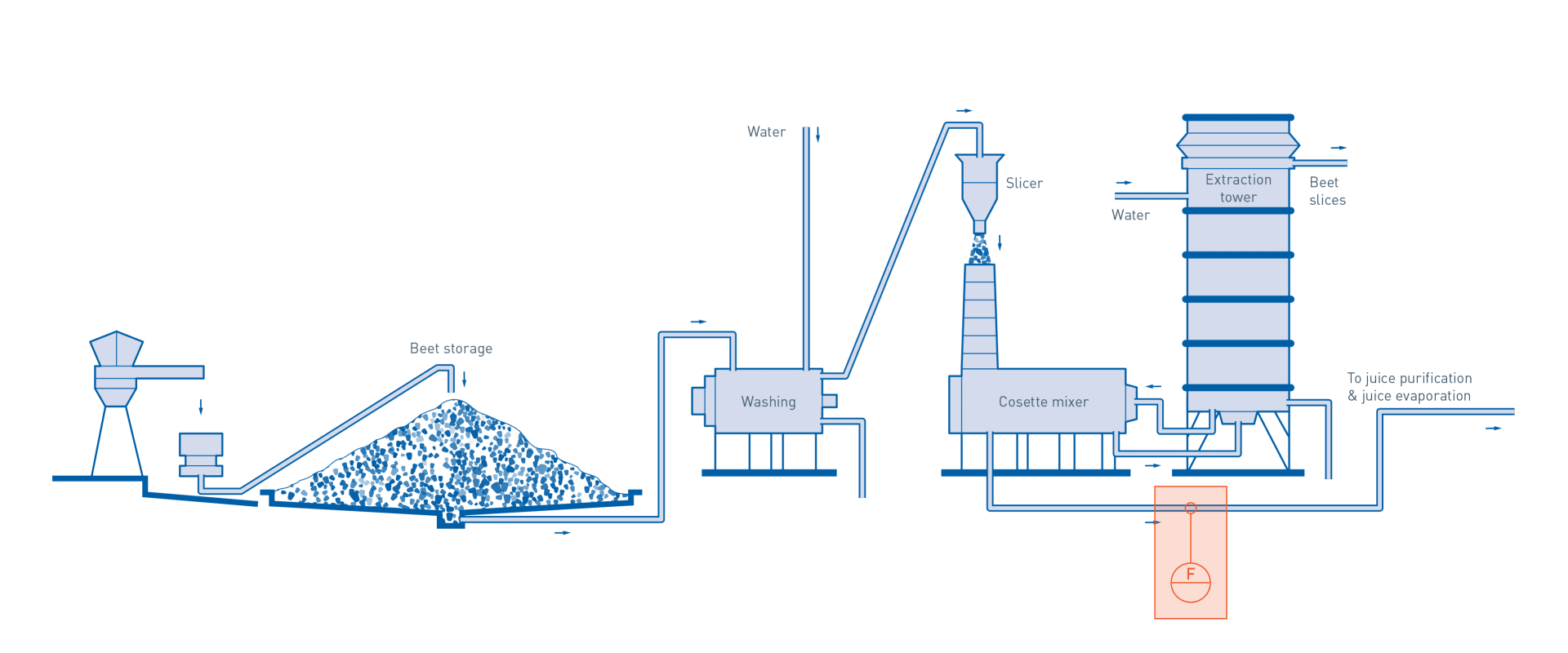

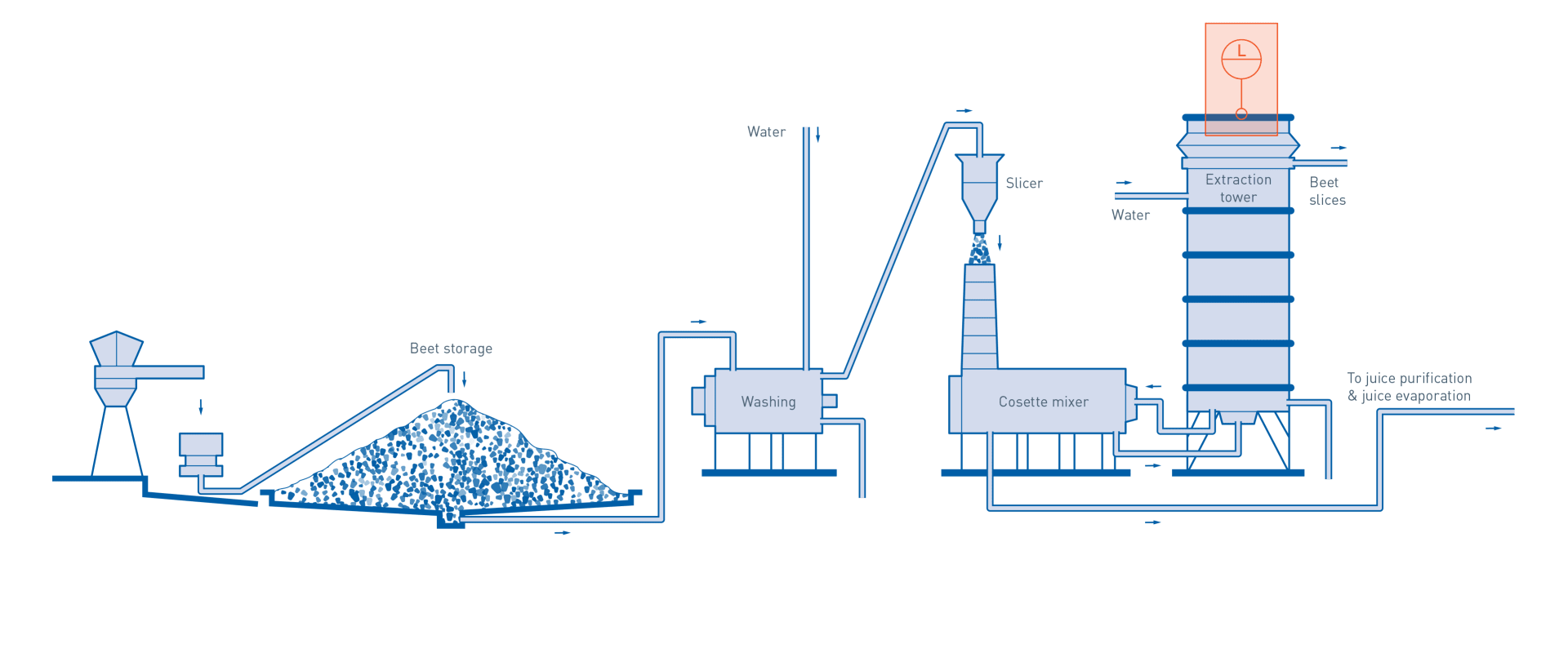

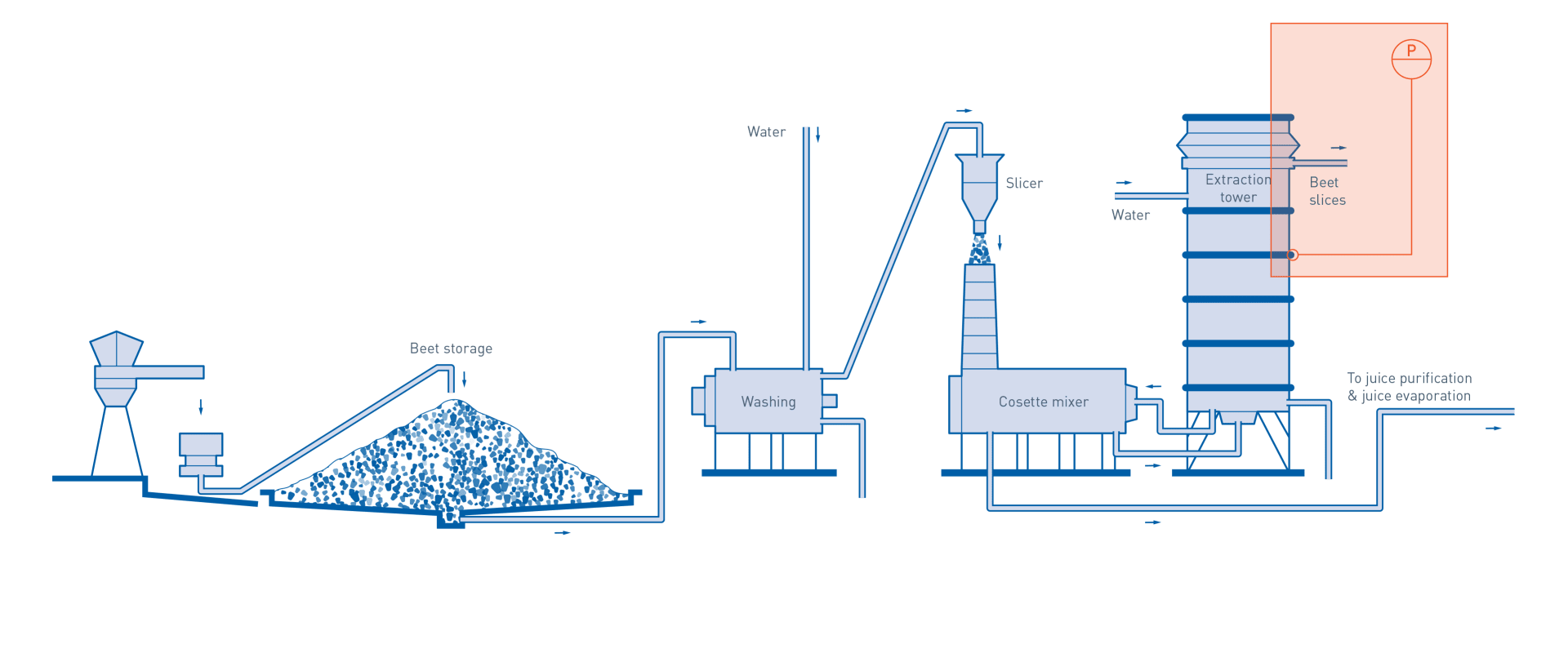

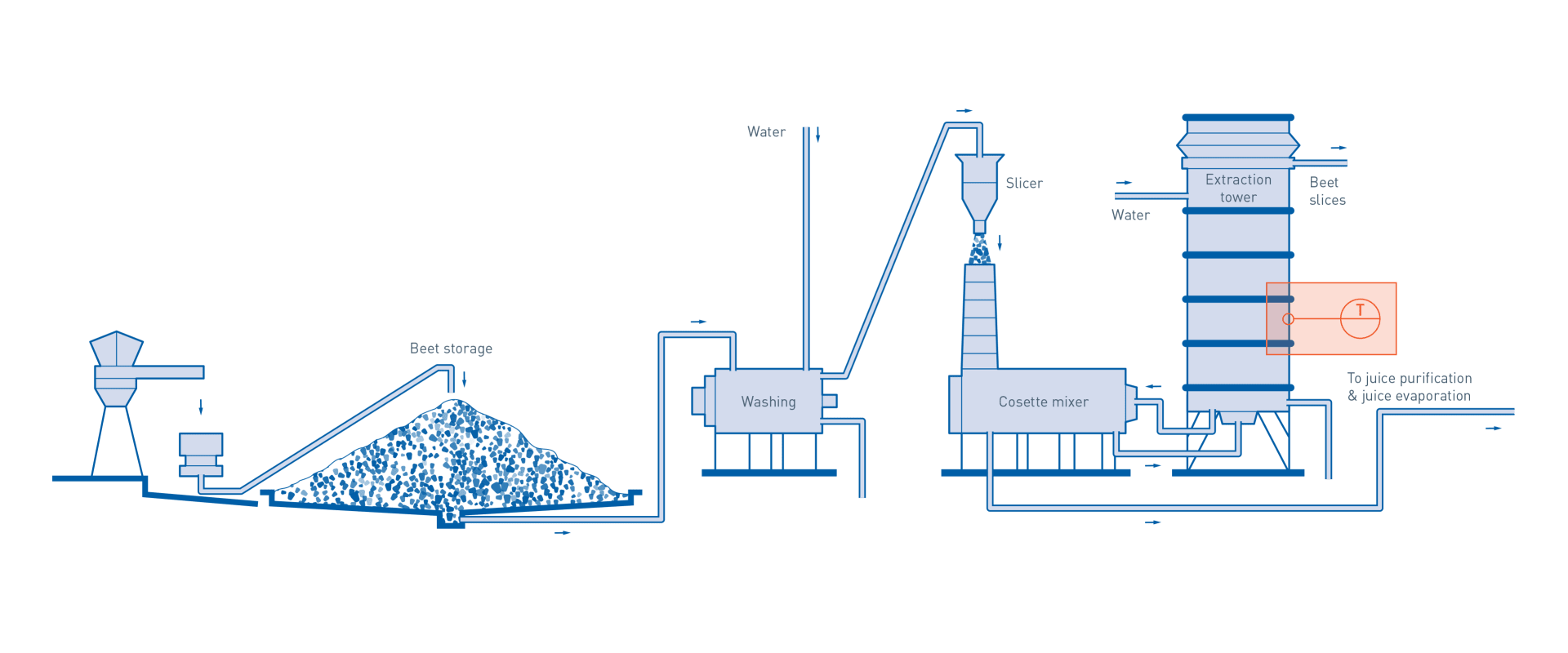

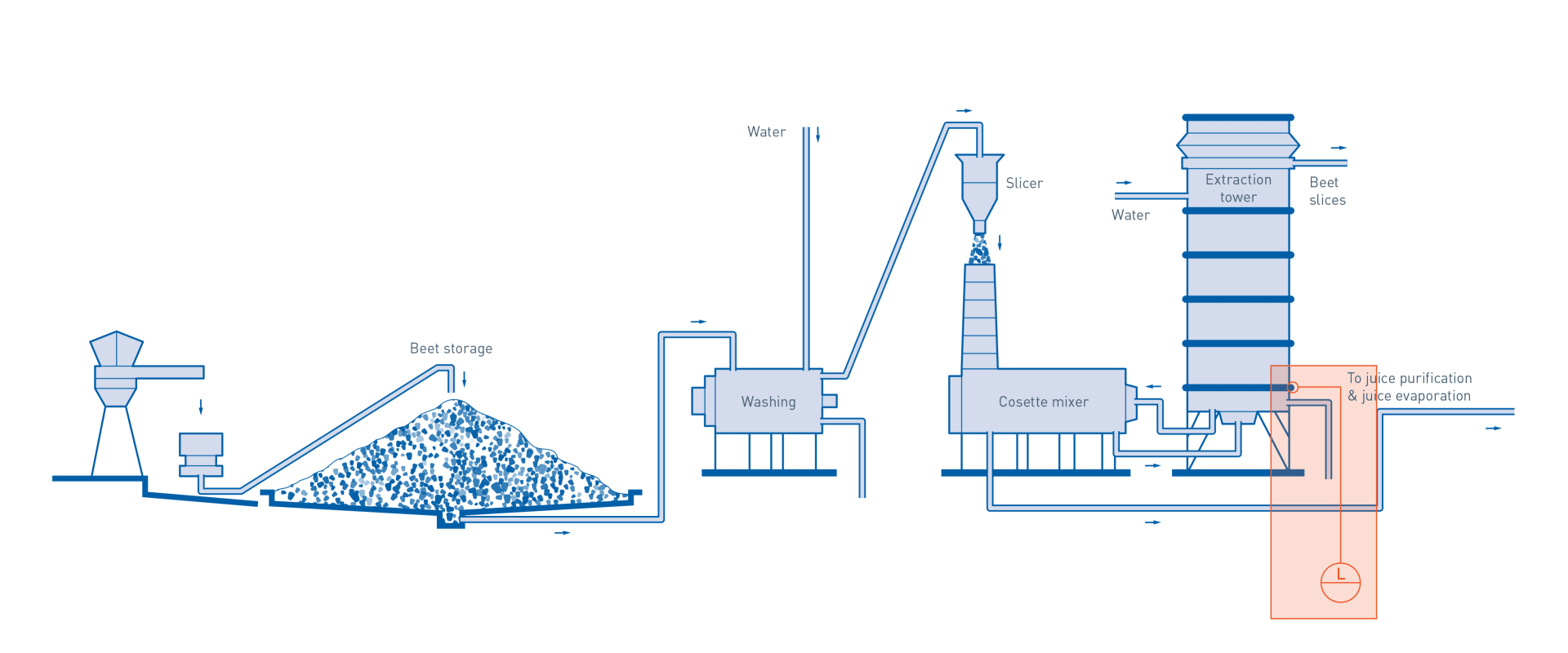

In juice production the raw sugar beet arrives at the mill yards, often delivered by the farmer direct. Quantities are monitored using a weighbridge, and the beet is mechanically unloaded, and stored in large open bays. After further washing, the beet are cut into v-shaped strips known as ‘cosettes’ in the slicer. The sugar extraction starts in the cossette scalder, where the strips are heated in water, and are then sent to an extraction tower. Water at 70°C is poured through the tower to extract the sugar and produce ‘raw juice’, which is sent on to the purification stages to extract the sugar. Further liquid is extracted from the cossettes by means of screw presses and these are then dried by hot air. Usually they are formed into pellets and sold for use in livestock feed and pet food.

The flow and temperature of the circulating liquids are monitored by the obstructionless OPTIFLUX electromagnetic flowmeters, and OPTITEMP probes and temperature transmitters. OPTIBAR pressure transmitters are used to monitor pressure in the water lines and the cossette juice extraction tower. Non-contact OPTIWAVE radar level transmitters can also measure the level of the mixture in the extraction tower.

Process details

Juice production in the food & beverage industry

Requirements:

- Process control

Recommended products and solutions:

OPTIBAR PC 5060

- Robust design, with corrosion and abrasion resistant ceramic diaphragm

- 25 mbar…100 bar / 0.73…1450 psi; max. +150°C / +302°F

- Various threads, flanges, hygienic and other connections

- 2-wire, 4…20 mA, HART®, FF, Profibus-PA, Bluetooth®

Requirements:

- Process control

Recommended products and solutions:

OPTIFLUX 1050

- Cost-effective flow measurement of liquids (≥5 μS/cm) up to +120°C / +248°F

- Extra isolation of electronics for use in high humidity areas

- Wafer-style design: DN10…150 / ⅜…6", max. PN40 / ASME Cl 300

- 4…20 mA, pulse, frequency, status, HART®, Modbus

Requirements:

- Handling of high solid content

Recommended products and solutions:

OPTIFLUX 4100

- Chemically resistant, for liquids (>5 μS/cm) with solid content (≤10%)

- Up to +180°C / +356°F

- Flange: DN2.5…1200 / ⅒…48", max. PN40 / ASME Cl 300

- 4…20 mA, pulse, frequency, status, HART®

Requirements:

- Handling of dirty and volatile environment

Recommended products and solutions:

OPTIWAVE 3500

- Continuous, non-contact level measurement in small and narrow vessels, small storage tanks and agitated tanks

- 80 GHz radar, flush-mounted Lens antenna

- Measuring range: 0…50 m / 164 ft

- -40…+150°C / +302°F; -1…25 barg / -14.5…362 psig

Requirements:

- Process control

Recommended products and solutions:

OPTIBAR PC 5060

- Robust design, with corrosion and abrasion resistant ceramic diaphragm

- 25 mbar…100 bar / 0.73…1450 psi; max. +150°C / +302°F

- Various threads, flanges, hygienic and other connections

- 2-wire, 4…20 mA, HART®, FF, Profibus-PA, Bluetooth®

Requirements:

- Process control

Recommended products and solutions:

OPTITEMP TRA-H61

- G½ thread with VARIVENT®, DIN 11851, SMS 1145 and other hygienic adapters

- Stainless steel thermowell with reduced tip (FDA, EC1935/2004 conform; optional IP69)

- -50…+200°C / -58…+390°F

OPTITEMP TRA-H65

- Welded clamp connection

- Stainless steel thermowell with reduced tip (3A certified, FDA, EC1935/2004 conform; optional IP69)

- -50…+200°C / -58…+390°F

OPTITEMP TRA-C61

- Hygienic G½ thread with VARIVENT®, DIN 11851, SMS 1145 and other hygienic adapters

- Built-in transmitter and stainless steel sheath (FDA, EC1935/2004 conform, optional IP69)

- -50…+200°C / -58…+392°F

OPTITEMP TRA-C65

- Welded clamp connection

- Built-in transmitter and stainless steel sheath (3A certified, FDA-, EC1935/2004 conform; optional IP69)

- -50…+200°C / -58…+392°F

Requirements:

- Process control

Recommended products and solutions:

OPTISWITCH 6500

- Point level detection of liquids, liquid-liquid interface and solids

- Minimal insertion length: 12 mm / 0.47"

- -20…+200°C / -4…+392°F; -1…16 barg / -14.5…580 psig

Juice production in the food & beverage industry

Requirements:

- Process control

Recommended products and solutions:

OPTIBAR PC 5060

- Robust design, with corrosion and abrasion resistant ceramic diaphragm

- 25 mbar…100 bar / 0.73…1450 psi; max. +150°C / +302°F

- Various threads, flanges, hygienic and other connections

- 2-wire, 4…20 mA, HART®, FF, Profibus-PA, Bluetooth®

Requirements:

- Process control

Recommended products and solutions:

OPTIFLUX 1050

- Cost-effective flow measurement of liquids (≥5 μS/cm) up to +120°C / +248°F

- Extra isolation of electronics for use in high humidity areas

- Wafer-style design: DN10…150 / ⅜…6", max. PN40 / ASME Cl 300

- 4…20 mA, pulse, frequency, status, HART®, Modbus

Requirements:

- Handling of high solid content

Recommended products and solutions:

OPTIFLUX 4100

- Chemically resistant, for liquids (>5 μS/cm) with solid content (≤10%)

- Up to +180°C / +356°F

- Flange: DN2.5…1200 / ⅒…48", max. PN40 / ASME Cl 300

- 4…20 mA, pulse, frequency, status, HART®

Requirements:

- Handling of dirty and volatile environment

Recommended products and solutions:

OPTIWAVE 3500

- Continuous, non-contact level measurement in small and narrow vessels, small storage tanks and agitated tanks

- 80 GHz radar, flush-mounted Lens antenna

- Measuring range: 0…50 m / 164 ft

- -40…+150°C / +302°F; -1…25 barg / -14.5…362 psig

Requirements:

- Process control

Recommended products and solutions:

OPTIBAR PC 5060

- Robust design, with corrosion and abrasion resistant ceramic diaphragm

- 25 mbar…100 bar / 0.73…1450 psi; max. +150°C / +302°F

- Various threads, flanges, hygienic and other connections

- 2-wire, 4…20 mA, HART®, FF, Profibus-PA, Bluetooth®

Requirements:

- Process control

Recommended products and solutions:

OPTITEMP TRA-H61

- G½ thread with VARIVENT®, DIN 11851, SMS 1145 and other hygienic adapters

- Stainless steel thermowell with reduced tip (FDA, EC1935/2004 conform; optional IP69)

- -50…+200°C / -58…+390°F

OPTITEMP TRA-H65

- Welded clamp connection

- Stainless steel thermowell with reduced tip (3A certified, FDA, EC1935/2004 conform; optional IP69)

- -50…+200°C / -58…+390°F

OPTITEMP TRA-C61

- Hygienic G½ thread with VARIVENT®, DIN 11851, SMS 1145 and other hygienic adapters

- Built-in transmitter and stainless steel sheath (FDA, EC1935/2004 conform, optional IP69)

- -50…+200°C / -58…+392°F

OPTITEMP TRA-C65

- Welded clamp connection

- Built-in transmitter and stainless steel sheath (3A certified, FDA-, EC1935/2004 conform; optional IP69)

- -50…+200°C / -58…+392°F

Requirements:

- Process control

Recommended products and solutions:

OPTISWITCH 6500

- Point level detection of liquids, liquid-liquid interface and solids

- Minimal insertion length: 12 mm / 0.47"

- -20…+200°C / -4…+392°F; -1…16 barg / -14.5…580 psig

Requirements:

- Process control

Recommended products and solutions:

OPTIBAR PC 5060

Pressure transmitter for advanced process pressure and level applications

Juice production in the food & beverage industry

Requirements:

- Process control

Recommended products and solutions:

OPTIBAR PC 5060

- Robust design, with corrosion and abrasion resistant ceramic diaphragm

- 25 mbar…100 bar / 0.73…1450 psi; max. +150°C / +302°F

- Various threads, flanges, hygienic and other connections

- 2-wire, 4…20 mA, HART®, FF, Profibus-PA, Bluetooth®

Requirements:

- Process control

Recommended products and solutions:

OPTIFLUX 1050

- Cost-effective flow measurement of liquids (≥5 μS/cm) up to +120°C / +248°F

- Extra isolation of electronics for use in high humidity areas

- Wafer-style design: DN10…150 / ⅜…6", max. PN40 / ASME Cl 300

- 4…20 mA, pulse, frequency, status, HART®, Modbus

Requirements:

- Handling of high solid content

Recommended products and solutions:

OPTIFLUX 4100

- Chemically resistant, for liquids (>5 μS/cm) with solid content (≤10%)

- Up to +180°C / +356°F

- Flange: DN2.5…1200 / ⅒…48", max. PN40 / ASME Cl 300

- 4…20 mA, pulse, frequency, status, HART®

Requirements:

- Handling of dirty and volatile environment

Recommended products and solutions:

OPTIWAVE 3500

- Continuous, non-contact level measurement in small and narrow vessels, small storage tanks and agitated tanks

- 80 GHz radar, flush-mounted Lens antenna

- Measuring range: 0…50 m / 164 ft

- -40…+150°C / +302°F; -1…25 barg / -14.5…362 psig

Requirements:

- Process control

Recommended products and solutions:

OPTIBAR PC 5060

- Robust design, with corrosion and abrasion resistant ceramic diaphragm

- 25 mbar…100 bar / 0.73…1450 psi; max. +150°C / +302°F

- Various threads, flanges, hygienic and other connections

- 2-wire, 4…20 mA, HART®, FF, Profibus-PA, Bluetooth®

Requirements:

- Process control

Recommended products and solutions:

OPTITEMP TRA-H61

- G½ thread with VARIVENT®, DIN 11851, SMS 1145 and other hygienic adapters

- Stainless steel thermowell with reduced tip (FDA, EC1935/2004 conform; optional IP69)

- -50…+200°C / -58…+390°F

OPTITEMP TRA-H65

- Welded clamp connection

- Stainless steel thermowell with reduced tip (3A certified, FDA, EC1935/2004 conform; optional IP69)

- -50…+200°C / -58…+390°F

OPTITEMP TRA-C61

- Hygienic G½ thread with VARIVENT®, DIN 11851, SMS 1145 and other hygienic adapters

- Built-in transmitter and stainless steel sheath (FDA, EC1935/2004 conform, optional IP69)

- -50…+200°C / -58…+392°F

OPTITEMP TRA-C65

- Welded clamp connection

- Built-in transmitter and stainless steel sheath (3A certified, FDA-, EC1935/2004 conform; optional IP69)

- -50…+200°C / -58…+392°F

Requirements:

- Process control

Recommended products and solutions:

OPTISWITCH 6500

- Point level detection of liquids, liquid-liquid interface and solids

- Minimal insertion length: 12 mm / 0.47"

- -20…+200°C / -4…+392°F; -1…16 barg / -14.5…580 psig

Requirements:

- Process control

Recommended products and solutions:

OPTIFLUX 1050

Electromagnetic flowmeter for basic applications with conductive liquids

Juice production in the food & beverage industry

Requirements:

- Process control

Recommended products and solutions:

OPTIBAR PC 5060

- Robust design, with corrosion and abrasion resistant ceramic diaphragm

- 25 mbar…100 bar / 0.73…1450 psi; max. +150°C / +302°F

- Various threads, flanges, hygienic and other connections

- 2-wire, 4…20 mA, HART®, FF, Profibus-PA, Bluetooth®

Requirements:

- Process control

Recommended products and solutions:

OPTIFLUX 1050

- Cost-effective flow measurement of liquids (≥5 μS/cm) up to +120°C / +248°F

- Extra isolation of electronics for use in high humidity areas

- Wafer-style design: DN10…150 / ⅜…6", max. PN40 / ASME Cl 300

- 4…20 mA, pulse, frequency, status, HART®, Modbus

Requirements:

- Handling of high solid content

Recommended products and solutions:

OPTIFLUX 4100

- Chemically resistant, for liquids (>5 μS/cm) with solid content (≤10%)

- Up to +180°C / +356°F

- Flange: DN2.5…1200 / ⅒…48", max. PN40 / ASME Cl 300

- 4…20 mA, pulse, frequency, status, HART®

Requirements:

- Handling of dirty and volatile environment

Recommended products and solutions:

OPTIWAVE 3500

- Continuous, non-contact level measurement in small and narrow vessels, small storage tanks and agitated tanks

- 80 GHz radar, flush-mounted Lens antenna

- Measuring range: 0…50 m / 164 ft

- -40…+150°C / +302°F; -1…25 barg / -14.5…362 psig

Requirements:

- Process control

Recommended products and solutions:

OPTIBAR PC 5060

- Robust design, with corrosion and abrasion resistant ceramic diaphragm

- 25 mbar…100 bar / 0.73…1450 psi; max. +150°C / +302°F

- Various threads, flanges, hygienic and other connections

- 2-wire, 4…20 mA, HART®, FF, Profibus-PA, Bluetooth®

Requirements:

- Process control

Recommended products and solutions:

OPTITEMP TRA-H61

- G½ thread with VARIVENT®, DIN 11851, SMS 1145 and other hygienic adapters

- Stainless steel thermowell with reduced tip (FDA, EC1935/2004 conform; optional IP69)

- -50…+200°C / -58…+390°F

OPTITEMP TRA-H65

- Welded clamp connection

- Stainless steel thermowell with reduced tip (3A certified, FDA, EC1935/2004 conform; optional IP69)

- -50…+200°C / -58…+390°F

OPTITEMP TRA-C61

- Hygienic G½ thread with VARIVENT®, DIN 11851, SMS 1145 and other hygienic adapters

- Built-in transmitter and stainless steel sheath (FDA, EC1935/2004 conform, optional IP69)

- -50…+200°C / -58…+392°F

OPTITEMP TRA-C65

- Welded clamp connection

- Built-in transmitter and stainless steel sheath (3A certified, FDA-, EC1935/2004 conform; optional IP69)

- -50…+200°C / -58…+392°F

Requirements:

- Process control

Recommended products and solutions:

OPTISWITCH 6500

- Point level detection of liquids, liquid-liquid interface and solids

- Minimal insertion length: 12 mm / 0.47"

- -20…+200°C / -4…+392°F; -1…16 barg / -14.5…580 psig

Requirements:

- Handling of high solid content

Recommended products and solutions:

OPTIFLUX 4100

Electromagnetic flowmeter for standard applications with abrasive and aggressive liquids

Juice production in the food & beverage industry

Requirements:

- Process control

Recommended products and solutions:

OPTIBAR PC 5060

- Robust design, with corrosion and abrasion resistant ceramic diaphragm

- 25 mbar…100 bar / 0.73…1450 psi; max. +150°C / +302°F

- Various threads, flanges, hygienic and other connections

- 2-wire, 4…20 mA, HART®, FF, Profibus-PA, Bluetooth®

Requirements:

- Process control

Recommended products and solutions:

OPTIFLUX 1050

- Cost-effective flow measurement of liquids (≥5 μS/cm) up to +120°C / +248°F

- Extra isolation of electronics for use in high humidity areas

- Wafer-style design: DN10…150 / ⅜…6", max. PN40 / ASME Cl 300

- 4…20 mA, pulse, frequency, status, HART®, Modbus

Requirements:

- Handling of high solid content

Recommended products and solutions:

OPTIFLUX 4100

- Chemically resistant, for liquids (>5 μS/cm) with solid content (≤10%)

- Up to +180°C / +356°F

- Flange: DN2.5…1200 / ⅒…48", max. PN40 / ASME Cl 300

- 4…20 mA, pulse, frequency, status, HART®

Requirements:

- Handling of dirty and volatile environment

Recommended products and solutions:

OPTIWAVE 3500

- Continuous, non-contact level measurement in small and narrow vessels, small storage tanks and agitated tanks

- 80 GHz radar, flush-mounted Lens antenna

- Measuring range: 0…50 m / 164 ft

- -40…+150°C / +302°F; -1…25 barg / -14.5…362 psig

Requirements:

- Process control

Recommended products and solutions:

OPTIBAR PC 5060

- Robust design, with corrosion and abrasion resistant ceramic diaphragm

- 25 mbar…100 bar / 0.73…1450 psi; max. +150°C / +302°F

- Various threads, flanges, hygienic and other connections

- 2-wire, 4…20 mA, HART®, FF, Profibus-PA, Bluetooth®

Requirements:

- Process control

Recommended products and solutions:

OPTITEMP TRA-H61

- G½ thread with VARIVENT®, DIN 11851, SMS 1145 and other hygienic adapters

- Stainless steel thermowell with reduced tip (FDA, EC1935/2004 conform; optional IP69)

- -50…+200°C / -58…+390°F

OPTITEMP TRA-H65

- Welded clamp connection

- Stainless steel thermowell with reduced tip (3A certified, FDA, EC1935/2004 conform; optional IP69)

- -50…+200°C / -58…+390°F

OPTITEMP TRA-C61

- Hygienic G½ thread with VARIVENT®, DIN 11851, SMS 1145 and other hygienic adapters

- Built-in transmitter and stainless steel sheath (FDA, EC1935/2004 conform, optional IP69)

- -50…+200°C / -58…+392°F

OPTITEMP TRA-C65

- Welded clamp connection

- Built-in transmitter and stainless steel sheath (3A certified, FDA-, EC1935/2004 conform; optional IP69)

- -50…+200°C / -58…+392°F

Requirements:

- Process control

Recommended products and solutions:

OPTISWITCH 6500

- Point level detection of liquids, liquid-liquid interface and solids

- Minimal insertion length: 12 mm / 0.47"

- -20…+200°C / -4…+392°F; -1…16 barg / -14.5…580 psig

Requirements:

- Handling of dirty and volatile environment

Recommended products and solutions:

OPTIWAVE 3500

Radar (FMCW) level transmitter for liquids with hygienic requirements

Juice production in the food & beverage industry

Requirements:

- Process control

Recommended products and solutions:

OPTIBAR PC 5060

- Robust design, with corrosion and abrasion resistant ceramic diaphragm

- 25 mbar…100 bar / 0.73…1450 psi; max. +150°C / +302°F

- Various threads, flanges, hygienic and other connections

- 2-wire, 4…20 mA, HART®, FF, Profibus-PA, Bluetooth®

Requirements:

- Process control

Recommended products and solutions:

OPTIFLUX 1050

- Cost-effective flow measurement of liquids (≥5 μS/cm) up to +120°C / +248°F

- Extra isolation of electronics for use in high humidity areas

- Wafer-style design: DN10…150 / ⅜…6", max. PN40 / ASME Cl 300

- 4…20 mA, pulse, frequency, status, HART®, Modbus

Requirements:

- Handling of high solid content

Recommended products and solutions:

OPTIFLUX 4100

- Chemically resistant, for liquids (>5 μS/cm) with solid content (≤10%)

- Up to +180°C / +356°F

- Flange: DN2.5…1200 / ⅒…48", max. PN40 / ASME Cl 300

- 4…20 mA, pulse, frequency, status, HART®

Requirements:

- Handling of dirty and volatile environment

Recommended products and solutions:

OPTIWAVE 3500

- Continuous, non-contact level measurement in small and narrow vessels, small storage tanks and agitated tanks

- 80 GHz radar, flush-mounted Lens antenna

- Measuring range: 0…50 m / 164 ft

- -40…+150°C / +302°F; -1…25 barg / -14.5…362 psig

Requirements:

- Process control

Recommended products and solutions:

OPTIBAR PC 5060

- Robust design, with corrosion and abrasion resistant ceramic diaphragm

- 25 mbar…100 bar / 0.73…1450 psi; max. +150°C / +302°F

- Various threads, flanges, hygienic and other connections

- 2-wire, 4…20 mA, HART®, FF, Profibus-PA, Bluetooth®

Requirements:

- Process control

Recommended products and solutions:

OPTITEMP TRA-H61

- G½ thread with VARIVENT®, DIN 11851, SMS 1145 and other hygienic adapters

- Stainless steel thermowell with reduced tip (FDA, EC1935/2004 conform; optional IP69)

- -50…+200°C / -58…+390°F

OPTITEMP TRA-H65

- Welded clamp connection

- Stainless steel thermowell with reduced tip (3A certified, FDA, EC1935/2004 conform; optional IP69)

- -50…+200°C / -58…+390°F

OPTITEMP TRA-C61

- Hygienic G½ thread with VARIVENT®, DIN 11851, SMS 1145 and other hygienic adapters

- Built-in transmitter and stainless steel sheath (FDA, EC1935/2004 conform, optional IP69)

- -50…+200°C / -58…+392°F

OPTITEMP TRA-C65

- Welded clamp connection

- Built-in transmitter and stainless steel sheath (3A certified, FDA-, EC1935/2004 conform; optional IP69)

- -50…+200°C / -58…+392°F

Requirements:

- Process control

Recommended products and solutions:

OPTISWITCH 6500

- Point level detection of liquids, liquid-liquid interface and solids

- Minimal insertion length: 12 mm / 0.47"

- -20…+200°C / -4…+392°F; -1…16 barg / -14.5…580 psig

Requirements:

- Process control

Recommended products and solutions:

OPTIBAR PC 5060

Pressure transmitter for advanced process pressure and level applications

Juice production in the food & beverage industry

Requirements:

- Process control

Recommended products and solutions:

OPTIBAR PC 5060

- Robust design, with corrosion and abrasion resistant ceramic diaphragm

- 25 mbar…100 bar / 0.73…1450 psi; max. +150°C / +302°F

- Various threads, flanges, hygienic and other connections

- 2-wire, 4…20 mA, HART®, FF, Profibus-PA, Bluetooth®

Requirements:

- Process control

Recommended products and solutions:

OPTIFLUX 1050

- Cost-effective flow measurement of liquids (≥5 μS/cm) up to +120°C / +248°F

- Extra isolation of electronics for use in high humidity areas

- Wafer-style design: DN10…150 / ⅜…6", max. PN40 / ASME Cl 300

- 4…20 mA, pulse, frequency, status, HART®, Modbus

Requirements:

- Handling of high solid content

Recommended products and solutions:

OPTIFLUX 4100

- Chemically resistant, for liquids (>5 μS/cm) with solid content (≤10%)

- Up to +180°C / +356°F

- Flange: DN2.5…1200 / ⅒…48", max. PN40 / ASME Cl 300

- 4…20 mA, pulse, frequency, status, HART®

Requirements:

- Handling of dirty and volatile environment

Recommended products and solutions:

OPTIWAVE 3500

- Continuous, non-contact level measurement in small and narrow vessels, small storage tanks and agitated tanks

- 80 GHz radar, flush-mounted Lens antenna

- Measuring range: 0…50 m / 164 ft

- -40…+150°C / +302°F; -1…25 barg / -14.5…362 psig

Requirements:

- Process control

Recommended products and solutions:

OPTIBAR PC 5060

- Robust design, with corrosion and abrasion resistant ceramic diaphragm

- 25 mbar…100 bar / 0.73…1450 psi; max. +150°C / +302°F

- Various threads, flanges, hygienic and other connections

- 2-wire, 4…20 mA, HART®, FF, Profibus-PA, Bluetooth®

Requirements:

- Process control

Recommended products and solutions:

OPTITEMP TRA-H61

- G½ thread with VARIVENT®, DIN 11851, SMS 1145 and other hygienic adapters

- Stainless steel thermowell with reduced tip (FDA, EC1935/2004 conform; optional IP69)

- -50…+200°C / -58…+390°F

OPTITEMP TRA-H65

- Welded clamp connection

- Stainless steel thermowell with reduced tip (3A certified, FDA, EC1935/2004 conform; optional IP69)

- -50…+200°C / -58…+390°F

OPTITEMP TRA-C61

- Hygienic G½ thread with VARIVENT®, DIN 11851, SMS 1145 and other hygienic adapters

- Built-in transmitter and stainless steel sheath (FDA, EC1935/2004 conform, optional IP69)

- -50…+200°C / -58…+392°F

OPTITEMP TRA-C65

- Welded clamp connection

- Built-in transmitter and stainless steel sheath (3A certified, FDA-, EC1935/2004 conform; optional IP69)

- -50…+200°C / -58…+392°F

Requirements:

- Process control

Recommended products and solutions:

OPTISWITCH 6500

- Point level detection of liquids, liquid-liquid interface and solids

- Minimal insertion length: 12 mm / 0.47"

- -20…+200°C / -4…+392°F; -1…16 barg / -14.5…580 psig

Requirements:

- Process control

Recommended products and solutions:

OPTITEMP TRA-H61

Resistance (RTD) temperature assembly for hygienic applications

OPTITEMP TRA-H65

Resistance (RTD) temperature assembly for hygienic applications

Juice production in the food & beverage industry

Requirements:

- Process control

Recommended products and solutions:

OPTIBAR PC 5060

- Robust design, with corrosion and abrasion resistant ceramic diaphragm

- 25 mbar…100 bar / 0.73…1450 psi; max. +150°C / +302°F

- Various threads, flanges, hygienic and other connections

- 2-wire, 4…20 mA, HART®, FF, Profibus-PA, Bluetooth®

Requirements:

- Process control

Recommended products and solutions:

OPTIFLUX 1050

- Cost-effective flow measurement of liquids (≥5 μS/cm) up to +120°C / +248°F

- Extra isolation of electronics for use in high humidity areas

- Wafer-style design: DN10…150 / ⅜…6", max. PN40 / ASME Cl 300

- 4…20 mA, pulse, frequency, status, HART®, Modbus

Requirements:

- Handling of high solid content

Recommended products and solutions:

OPTIFLUX 4100

- Chemically resistant, for liquids (>5 μS/cm) with solid content (≤10%)

- Up to +180°C / +356°F

- Flange: DN2.5…1200 / ⅒…48", max. PN40 / ASME Cl 300

- 4…20 mA, pulse, frequency, status, HART®

Requirements:

- Handling of dirty and volatile environment

Recommended products and solutions:

OPTIWAVE 3500

- Continuous, non-contact level measurement in small and narrow vessels, small storage tanks and agitated tanks

- 80 GHz radar, flush-mounted Lens antenna

- Measuring range: 0…50 m / 164 ft

- -40…+150°C / +302°F; -1…25 barg / -14.5…362 psig

Requirements:

- Process control

Recommended products and solutions:

OPTIBAR PC 5060

- Robust design, with corrosion and abrasion resistant ceramic diaphragm

- 25 mbar…100 bar / 0.73…1450 psi; max. +150°C / +302°F

- Various threads, flanges, hygienic and other connections

- 2-wire, 4…20 mA, HART®, FF, Profibus-PA, Bluetooth®

Requirements:

- Process control

Recommended products and solutions:

OPTITEMP TRA-H61

- G½ thread with VARIVENT®, DIN 11851, SMS 1145 and other hygienic adapters

- Stainless steel thermowell with reduced tip (FDA, EC1935/2004 conform; optional IP69)

- -50…+200°C / -58…+390°F

OPTITEMP TRA-H65

- Welded clamp connection

- Stainless steel thermowell with reduced tip (3A certified, FDA, EC1935/2004 conform; optional IP69)

- -50…+200°C / -58…+390°F

OPTITEMP TRA-C61

- Hygienic G½ thread with VARIVENT®, DIN 11851, SMS 1145 and other hygienic adapters

- Built-in transmitter and stainless steel sheath (FDA, EC1935/2004 conform, optional IP69)

- -50…+200°C / -58…+392°F

OPTITEMP TRA-C65

- Welded clamp connection

- Built-in transmitter and stainless steel sheath (3A certified, FDA-, EC1935/2004 conform; optional IP69)

- -50…+200°C / -58…+392°F

Requirements:

- Process control

Recommended products and solutions:

OPTISWITCH 6500

- Point level detection of liquids, liquid-liquid interface and solids

- Minimal insertion length: 12 mm / 0.47"

- -20…+200°C / -4…+392°F; -1…16 barg / -14.5…580 psig

Requirements:

- Process control