WGS Wet gas measurement

Highly flexible and economical solution for well performance optimisation

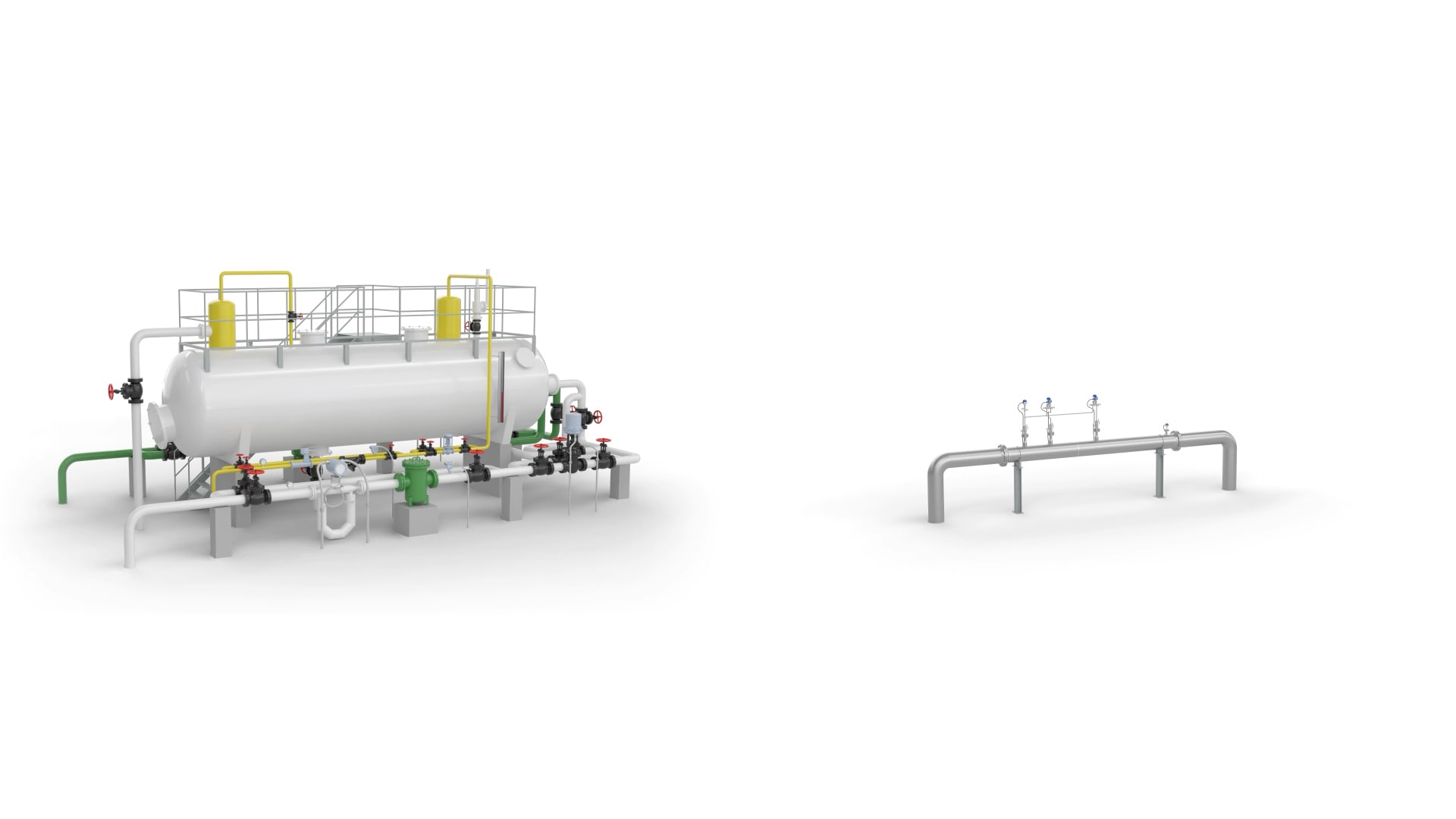

- Venturi based metering systems for wet gas (gas volume fraction 90...99%)

- Well performance verification and well management

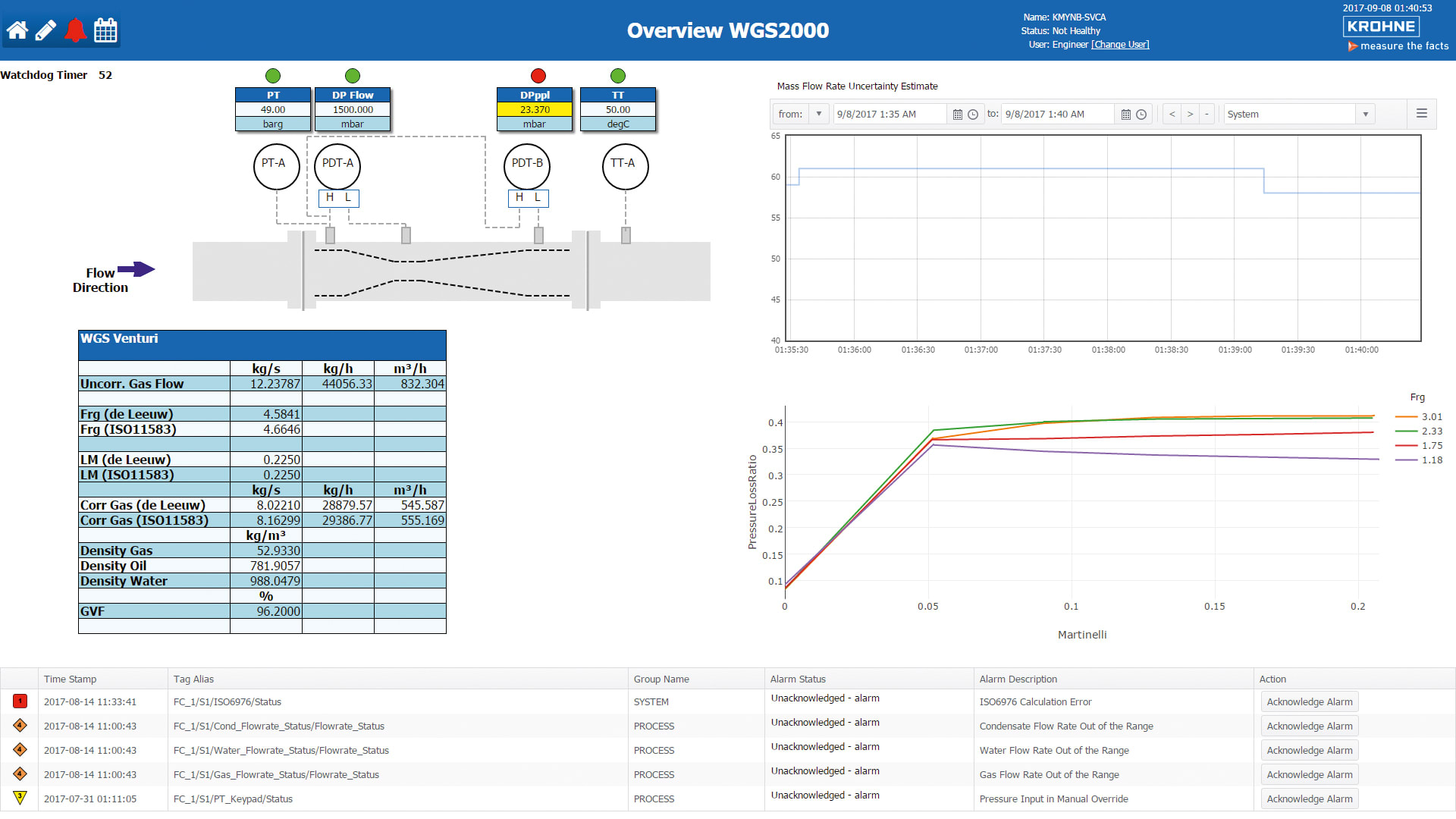

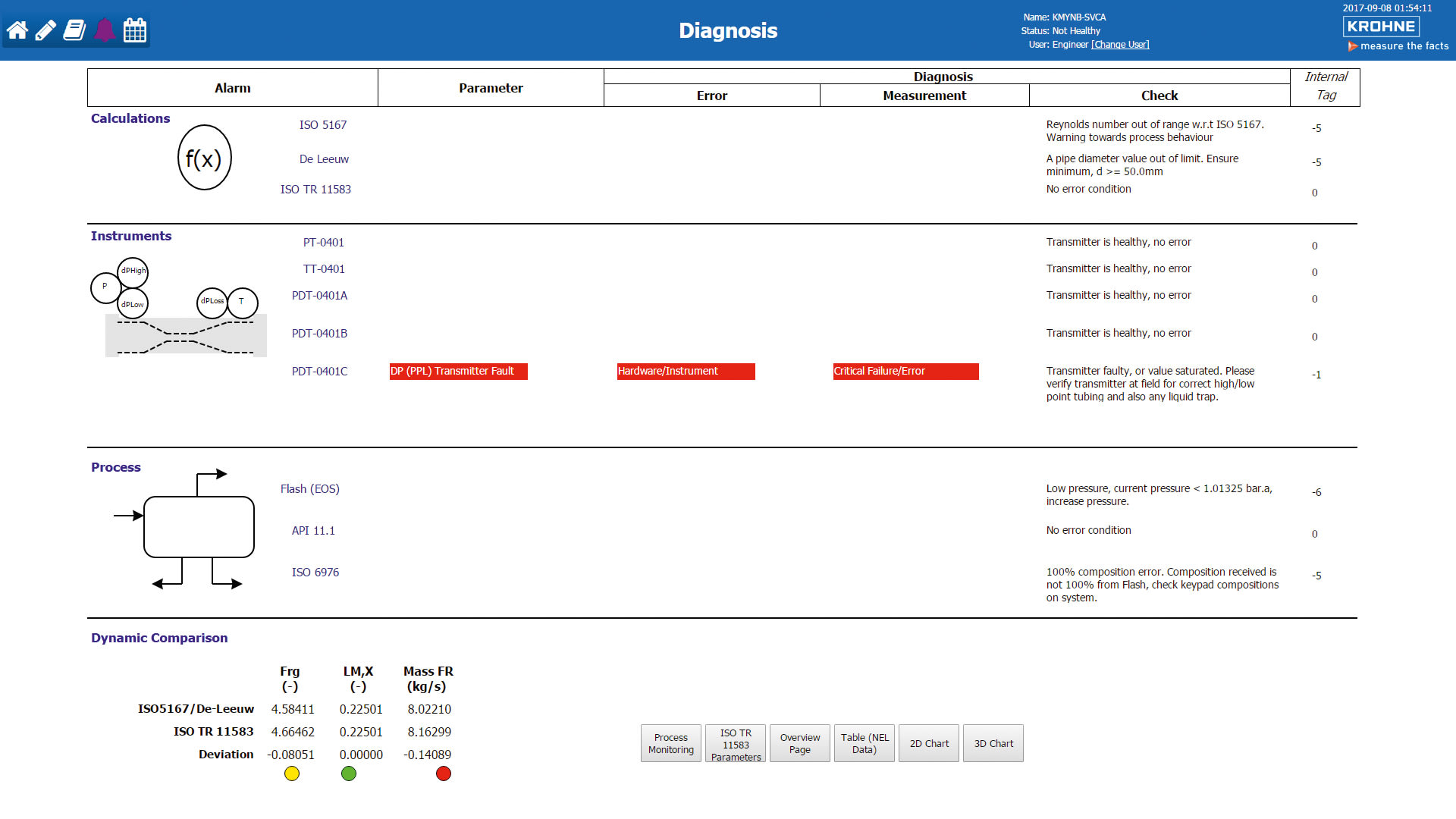

- Smart diagnostics and system fault monitoring

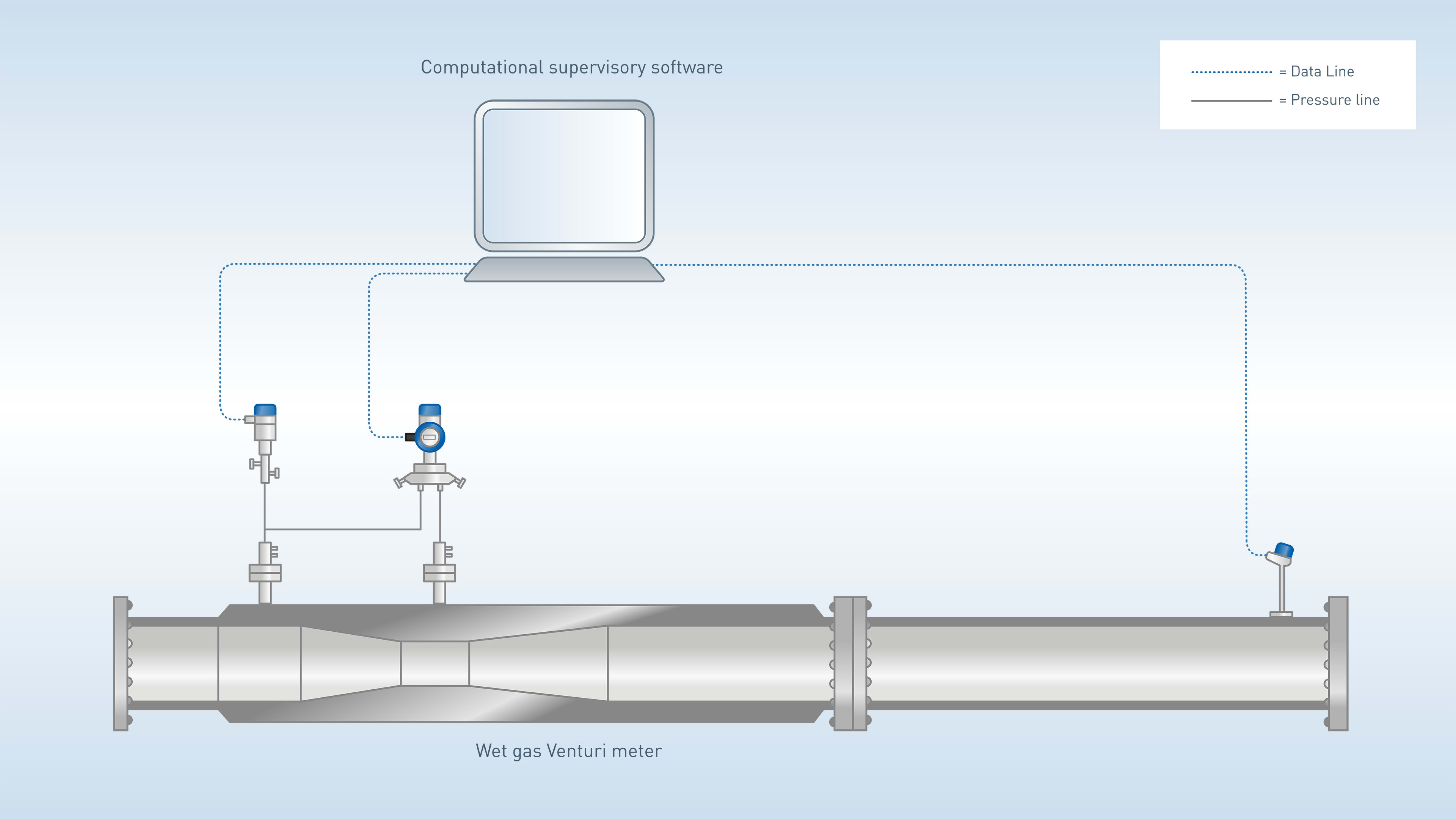

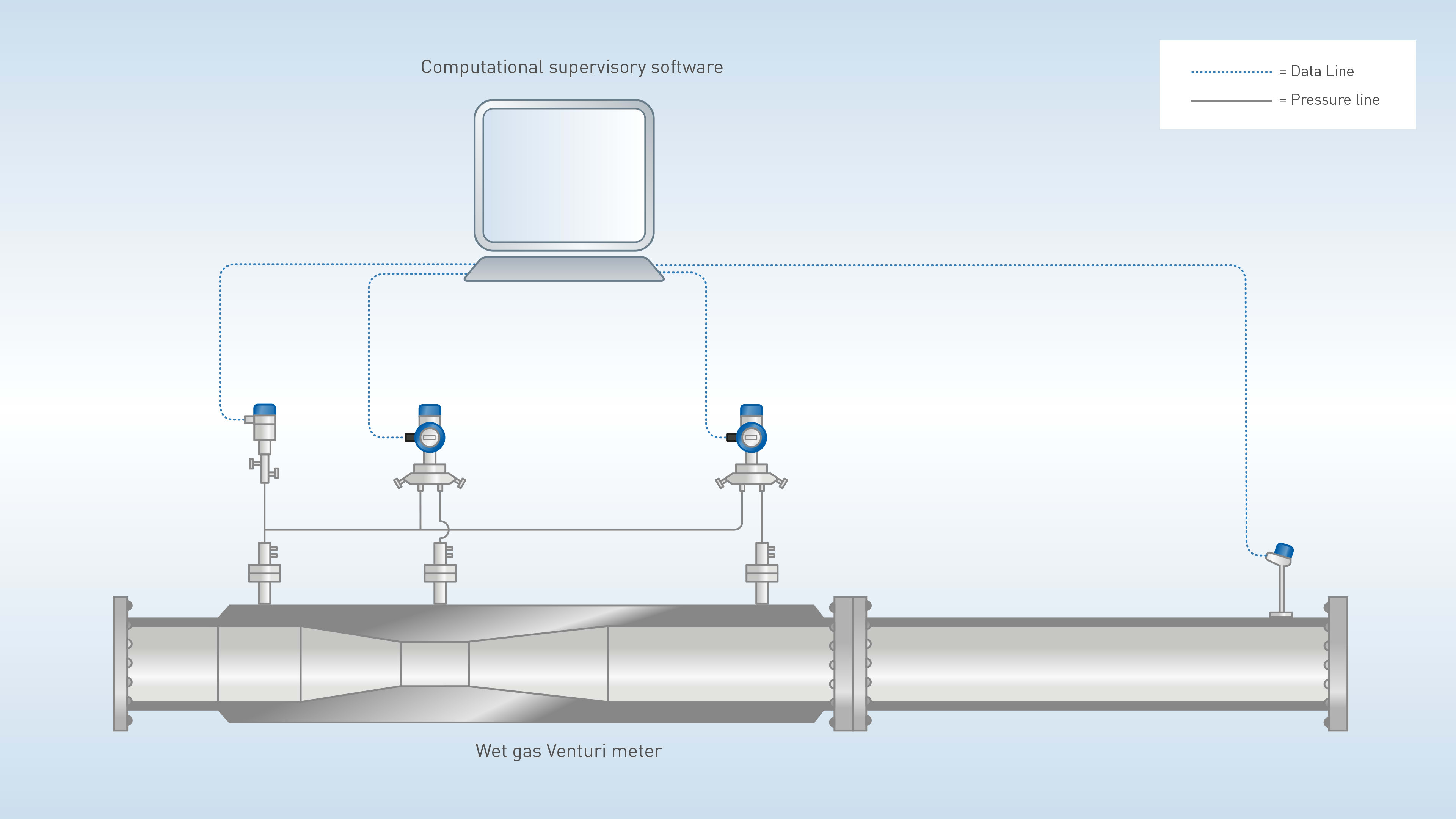

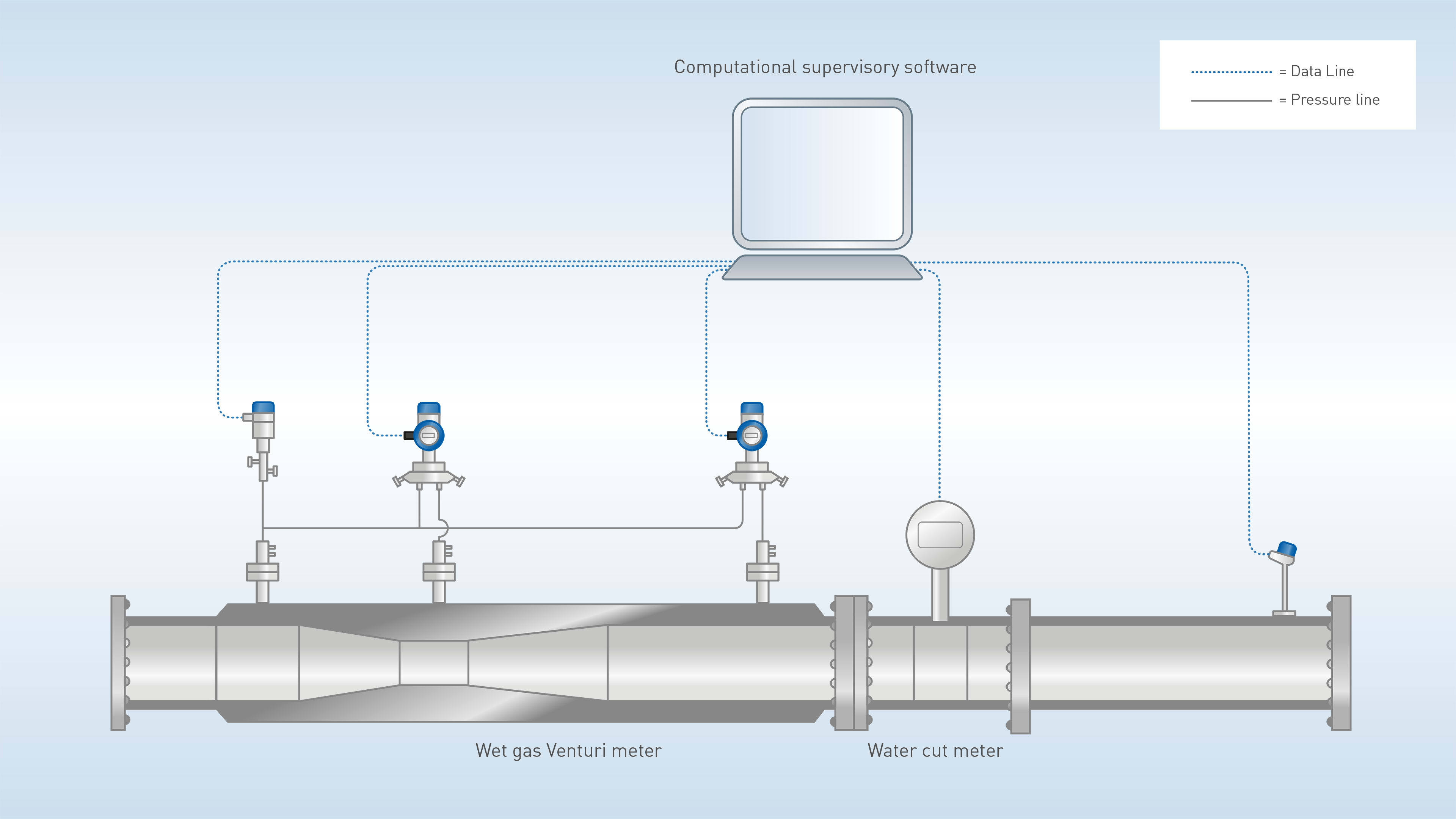

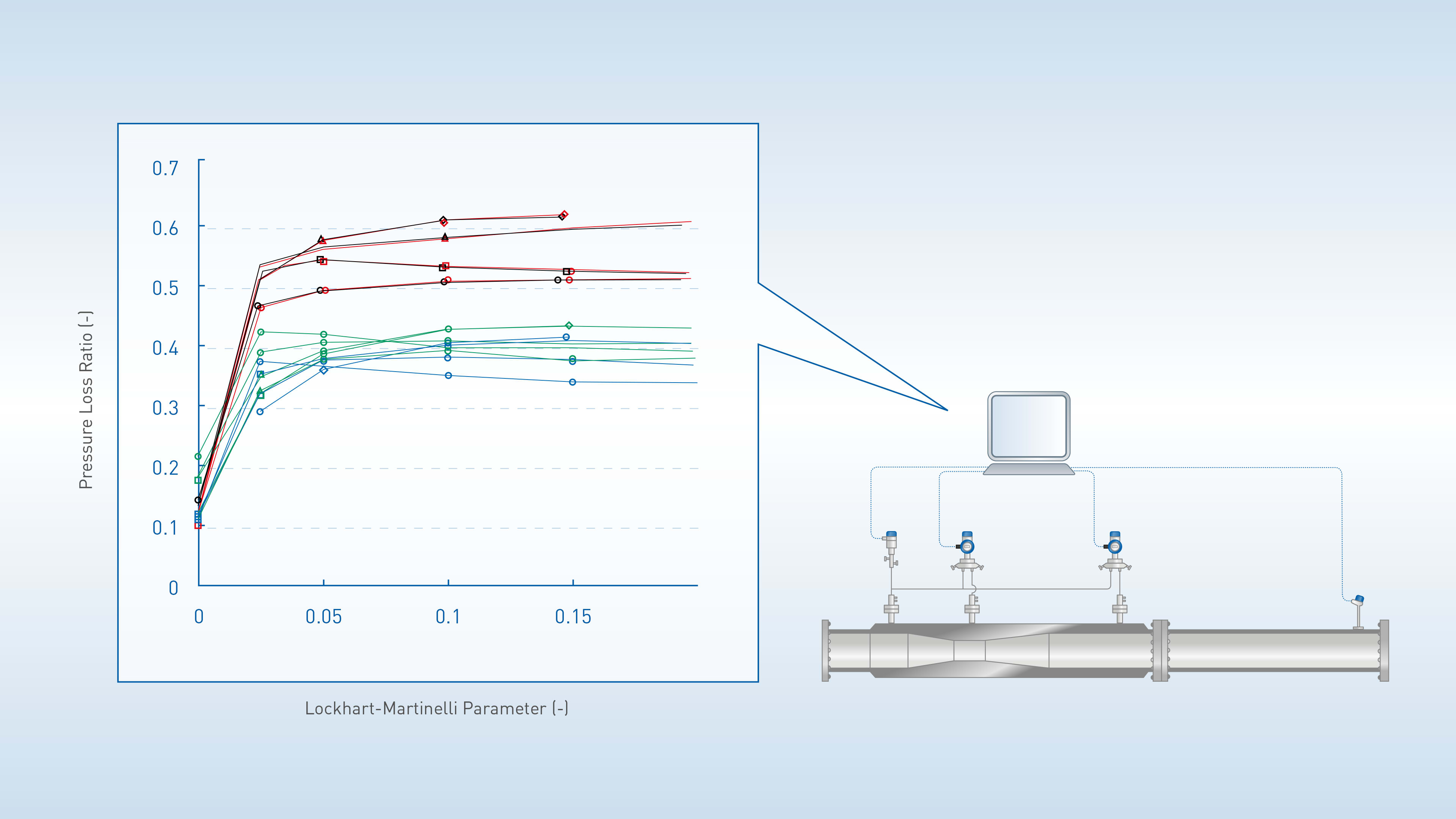

The KROHNE Venturi based wet gas solutions, WGS 1000 / 2000 / 3000, are designed to measure the flow of unprocessed gas directly from the well. Intermediate parameters at the point of measurement are calculated from known reservoir and well compositions and used to generate fraction and density tables for the operational range of the well or reservoir.

The WGS wet gas measurement systems are capable of determining flowrates of dynamically changing well streams with a high accuracy of ±1...3%. Compared to a test separator, the WGS system is space-saving, can be implemented much quicker and requires low maintenance. The WGS 1000 / 2000 / 3000 comes with three different variants for basic to very demanding applications. Each wet gas system is based on a wet gas Venturi meter with computational supervisory software, providing continuous validation and smart diagnostic features. The whole project management from consultation to instrumentation, integration, service and support is provided by KROHNE.

Highlights

- Flexible, modifiable and modular system for a scalable solution

- Independent, fast and continuous update of well compositions and process conditions

- No radioactive source

- Low-maintenance reducing OPEX

- System designed according to ISO5167, ISO11583 and API guidelines

- Real-time well performance verification for a faster decision-making process

- Comprehensive calculation blocks resulting in a flexible solution

Typical applications

- Wet gas measurement

- Green and brown field performance monitoring

- FPSO/FSO/MOPU for integrated oil and gas production

- Redevelopment of mature oil fields with IOR/EOR implementation (gas-lifted wells, gas injector wells)

- Production (re)allocation and optimisation

- Well testing capability using shared testing line and manifold

- Flow assurance monitoring

Related products

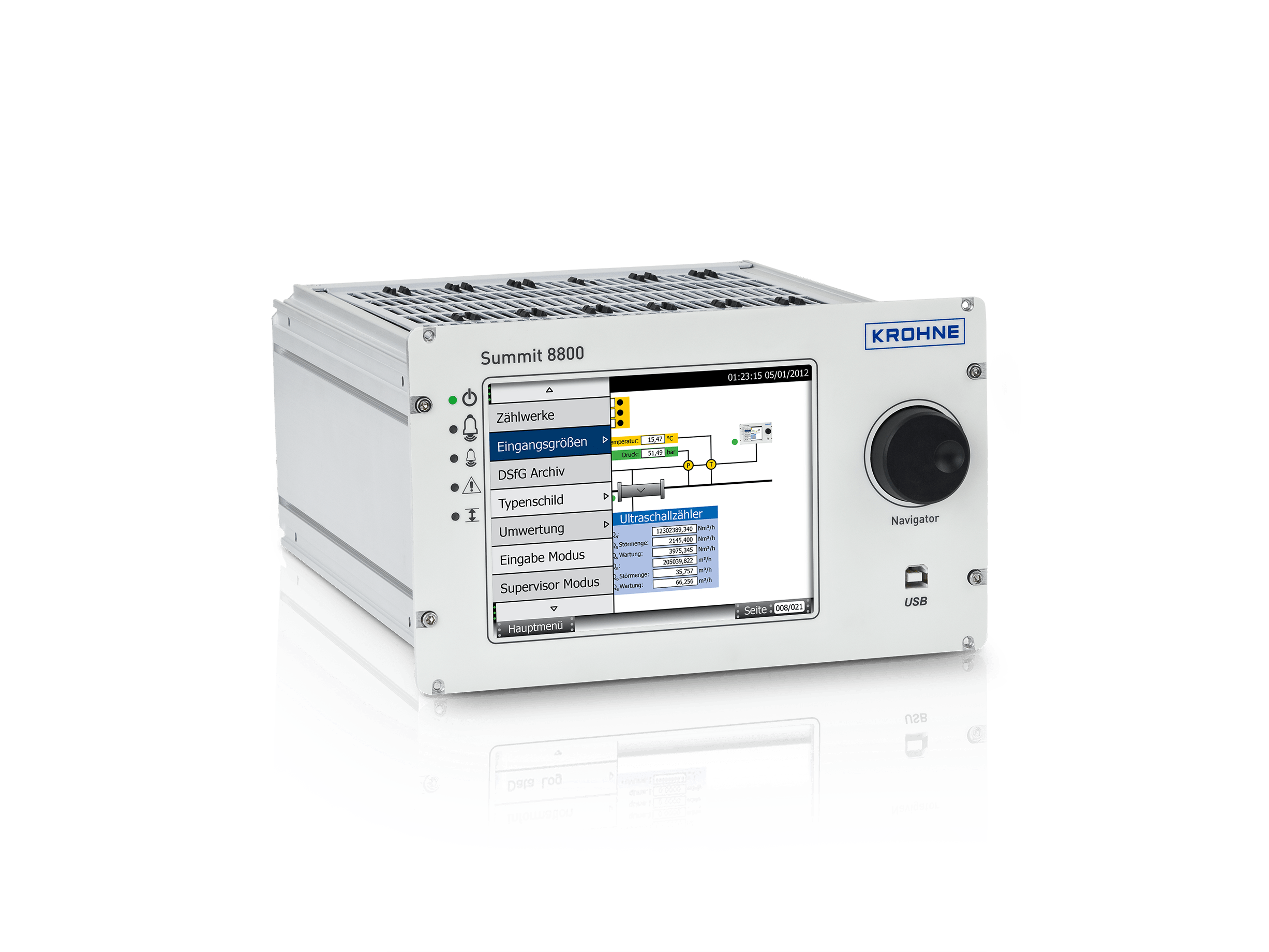

SUMMIT 8800

Flow computer for custody transfer (CT) measurement

- Cost effective solution due to modular hard- and software design

- Full colour graphical touch screen for maximum process transparency

- Easy operator access enabling time efficient maintenance

- Automatic Performance Monitoring extends recalibration interval

OPTIBAR DP 7060

Differential pressure transmitter for flow, level, differential pressure, density and interface measurements

- High performance DP transmitter with integrated line pressure measurement

- Measuring range: 30 mbar…16bar / 0.44…232 psi; Line pressure: up to 400 bar / 5800 psi

- Reference accuracy of ±0.065%

- 2-wire, 4…20 mA/HART®, FF, Profibus-PA, Bluetooth®

OPTITEMP TRA-TF56

Resistance (RTD) temperature assembly for higher flow velocities and pressures

- Flange connection

- ASME-style, barstock thermowell with tapered tip

- -40…+600°C / +1100°F

OPTITEMP TCA-TF56

Thermocouple (TC) temperature assembly for higher flow velocities and pressures

- Flange connection

- ASME-style, barstock thermowell with tapered tip

- -40…+600°C / +1100°F

Related solutions

Supervisory Control Cabinets

Complete solution for process control

- Provides control of the metering system, including validation of field instrumentation

- Installed in a safe area, typically in a control room or dedicated building

- Supplied in combination with new metering systems, or for an upgrade to existing systems

Modular flow control and data transfer cabinets

Basic flow control solution

- Cost effective, modular metering control solution

- Based on the SUMMIT 8800 flow computer

- Installed in a safe area, typically in a control room

Flow computing

Flow computer solution for the visualisation of measurements

- Graphical representation of all measurements

- Fully pre-configured and tested according to customer requirements

- Different liquid and gas streams measured and displayed on a single flow computer

Metering houses and shelters

Turnkey housing solution for the installation of electronic systems and cabinets on-site

- A safe area for the installation of electronic equipment and cabinets

- Integrated HVAC system where required

- Local operator supervisory work station can be included

SynEnergy Supervisory and visualisation software

Solution for continuous process monitoring and reporting

- HMI/SCADA software for measurement solutions

- State of the art HTML5 secure web technology

- Optimisation of operation results due to predictive maintenance

- Easy integration into existing DCS and ERP networks

Related services

Consultancy & engineering for wet gas and wellhead flow measurement

Selection and design of the optimal single phase or multiphase solution

- Consultancy regarding the most suitable measurement solution

- Cost effective engineering concepts tailored to the application and installation

- Detailed design of mechanical set-up, instrumentation, E&I and software

- System architecture tailored to the project requirements

Start-up & commissioning for wet gas and wellhead flow measurement

Global on-site commissioning services for on- and offshore multiphase and wet gas systems

- Start-up of equipment, and assistance in performing wellhead and wet gas measurements

- Assurance of smooth and continuous operation in the field

- Training for operators, engineering and maintenance personnel

System calibration & validation for wet gas and wellhead flow measurement

Achieving full performance in the field with reliable measurements

- Optimisation of the system according to application requirements

- Remote technical assistance by KROHNE experts

- Test plans and comparison of results

- Intuitive input of fluid properties for wet gas measurement systems

- Field validation of measurement performance

Operation & maintenance for wet gas and wellhead flow measurement

Maintaining field operations at peak performance without compromise

- Support for operators in performing well production measurements

- Maintenance contracts and service level agreements

- Pre-defined service rates and response times

- 24/7 Customer support and emergency helpdesk

- Periodic health checks and software updates