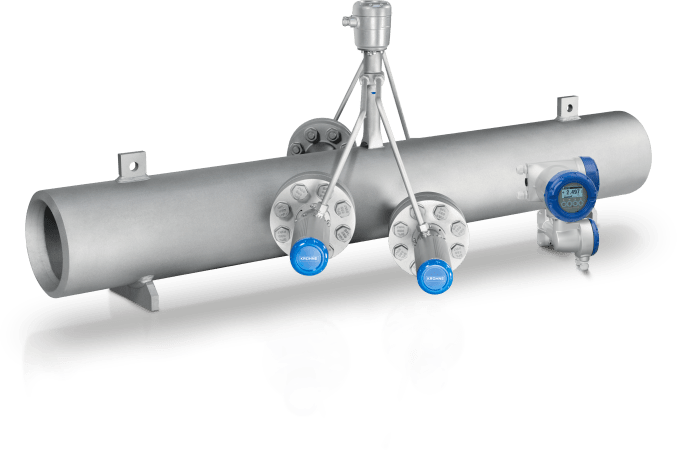

OPTISONIC 8300

Ultrasonic flowmeter for superheated steam and high temperature gases

- 2-path meter with optional mass flow and enthalpy calculation

- For steam billing, boiler or power plant monitoring (up to +620°C / +1148°F)

- DN100…1000 / 4…40"; max. PN250 / ASME Cl 2500

- Large turndown ratio (60:1)

OPTISONIC 8300 F

The OPTISONIC 8300 is a 2-path ultrasonic flowmeter for flow measurement of superheated steam and high temperature gases up to +620°C/ +1148°F and max. 200 bar / 2900 psi. It delivers high performance over a wide flow range (up to DN1000 / 40", turndown ratio: 60:1). This makes the flowmeter the ideal solution for boiler and power plant monitoring or as steam billing device. With temperature and pressure sensors connected to the meter, its integrated flow computer can also calculate steam mass flow or enthalpy.

The OPTISONIC 8300 was designed to avoid costly downtime of steam pipes. It features a full bore flow sensor without moving parts or obstructions to prevent pressure drop. It can uphold its high measuring accuracy (<±1% of measured value) without maintenance or subsequent calibration for up to 20 years. There is no need to remove the meter, valves and a bypass are thus not required. If verification of the measuring accuracy is necessary, it can be provided using the flowmeter diagnostics. The OPTISONIC 8300 comes with digital communication options.

Product highlights

- Bi-directional flow measurement over a wide dynamic range

- Integrated flow computer option: Mass flow and enthalpy calculation according to IAPWS-IF97

- Current inputs for external pressure and temperature sensors

- Suitable for energy balancing

- High accuracy: <±1% error of measured value (>DN150)

- Higher temperature and pressure ranges on request

- Extensive online diagnostics and functions for proper meter operation and verification

- Can be certified for custody transfer measurements (only in certain countries applicable)

- Full bore design: No moving parts, no wear, no pressure loss

- No periodical maintenance or recalibration needed

- Ex d certified stainless steel (316 L) connection box

- ATEX, IECEx, QPS and NEPSI approvals

- Hazardous area process temperatures up to +600°C / +1112°F

- Zone 0 approval for measurement of explosive gas mixtures

Typical applications

General

- Measurement of superheated steam and high temperature gases

- Custody transfer measurement of steam (only in certain countries applicable)

- Energy balancing

Conventional power industry

- Turbine performance measurement

- Boiler performance measurement

Chemical and other process industries

- Allocation of used steam in chemical or petrochemical processes

Applications

Related products

OPTISONIC 8000

Ultrasonic flow sensor for combination with GFC 300 signal converter

- Full bore design: pipe cross-section without restrictions

- Connection sizes: DN100…1000 / 4…40"

- Tube material: Carbon steel or alloy steel

Download Center

OPTISONIC 8300

Download Center

- Technical datasheets and handbooks

- Flyers and brochures

- Certificates and approvals

- Software and driver