OPTIMASS 7400

Coriolis mass flowmeter for advanced process applications

- High accuracy (±0.1%), for viscous, aggressive or shear-sensitive media; maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- CT: OIML R117, MI-005; API; hygienic certifications

- Flange: DN10…100 / ½…4", max. PN100 / ASME Cl 600; others

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

OPTIMASS 7400 C – Compact version with flange

The OPTIMASS 7400 is a high-end Coriolis mass flowmeter for demanding process and custody transfer (CT) applications. It is the ideal solution when it comes to high accuracy measurement of gases and shear-sensitive or viscous liquids, slurries, very aggressive media or media with a low flow velocity. The meter features Entrained Gas Management (EGMTM) for liquid applications and thus maintains operation even with entrained gas of up to 100%.

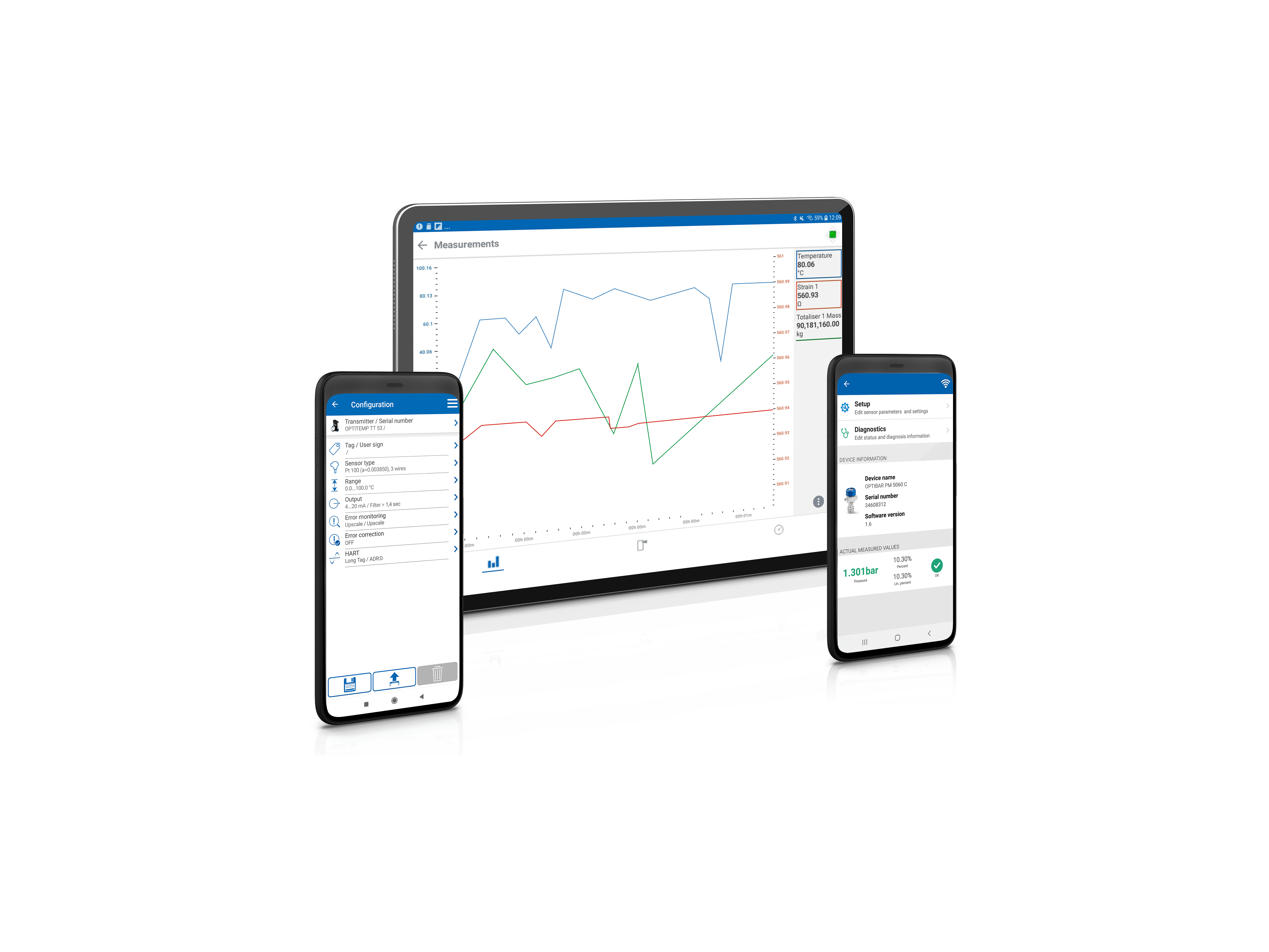

The OPTIMASS 7400 is the only single straight tube mass flowmeter for use when custody transfer is required in the highest OIML accuracy class of 0.3. Together with the OPTIMASS 7010, it is also the only Coriolis meter with a single straight tube to be available in four sensor materials (titanium, stainless steel, Hastelloy® C, tantalum). Due to its sensor design, there is virtually no pressure loss and the flowmeter is self-draining and easy to clean, which makes it also the perfect choice for hygienic applications. The Coriolis device can also be used in hazardous areas. Like with all other KROHNE mass flowmeters there are no installation restrictions as the flowmeter is not affected by crosstalk/line vibrations and can thus be installed in series or in parallel. The Coriolis mass flowmeter also provides enhanced diagnostics (NE 107) and comes with various digital communication options. Via the OPTICHECK Flow Mobile app all device settings can be managed on-site via a secure Bluetooth® connection. In this way, a variety of commissioning tasks, e.g. zero calibration or configuration of diagnostics, can be done wirelessly.

Product highlights

- Single straight tube design

- Entrained Gas Management (EGMTM): maintains operation with air or gas entrainments in the medium

- Device commissioning, verification, diagnostics and monitoring via a secure wireless Bluetooth® connection (<20 m / 65.6 ft)

- Fast and completely digital signal processing

- High accuracy mass, density and volume flow measurement (±0.1% of MV)

- Highest OIML accuracy class of 0.3 for custody transfer (CT)

- Extensive sensor and process diagnostics (incl. NE 107)

- Integrated temperature measurement

- Available in four sensor materials: titanium, stainless steel, Hastelloy® or tantalum

- With sensor size DN80 / 3" in titanium or Hastelloy® it is the largest single straight tube meter on the market

- Optional PED approved secondary pressure containment up to 100 barg / 1450 psig

- Many options (heat tracing, purge port etc.)

- No crosstalk: resistant to installation and process effects

- Various approvals and certifications (hygienic, custody transfer, marine, hazardous areas etc.)

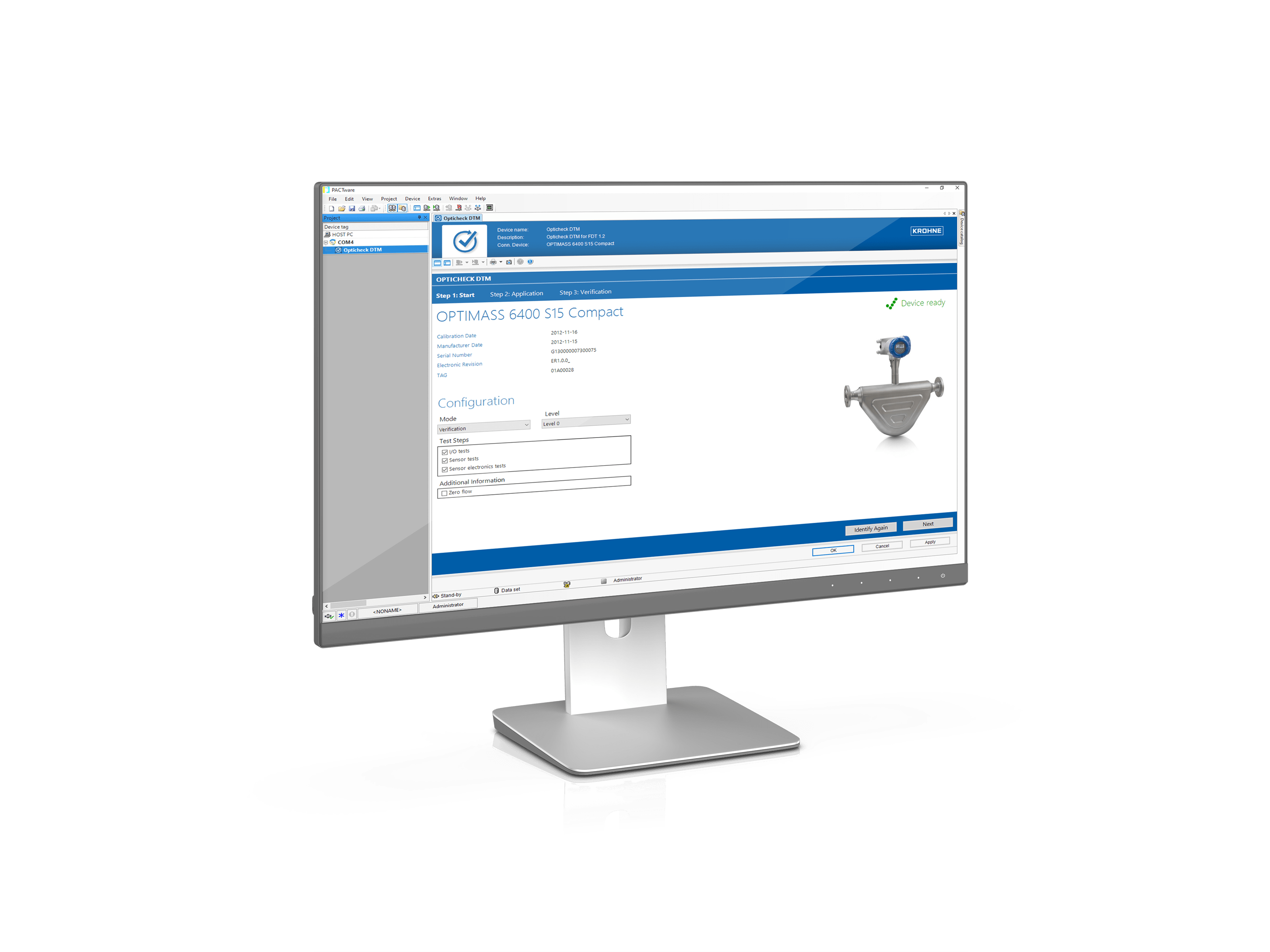

- On-site verification of flowmeter with OPTICHECK service tool

Typical applications

General

- Measurement of liquids, gases and gas entrained liquids

- Very aggressive, highly corrosive or shear-sensitive media

- Products requiring a low flow velocity

- Non-homogeneous mixtures

- Slurries or products with entrained solids

- Custody transfer (fiscal metering)

Chemical and other process industries

- Measurement of concentration, density

- Bulk loading

- Batching to reactors

- Acids, bases, phosgene and other chloride substances, sulphuric substances

Food and beverage industry

- Batching, dosing, filling

- Measurement of flow, density, specific gravity in brewing processes

- Dosing of hop extract

- Milk reception, dosing and separation processes in dairies

- Measurement of Brix, density and flow in fruit juices

- Oily and greasy products (e.g. creamy spinach mixtures etc.)

- Liquid chocolate, honey, marmalade, syrup, ice cream etc.

- CO2 injection

- Alcoholic beverages (whisky, wine, vodka etc.)

Pharmaceutical industry

- Batching, dosing, filling

- Solvent extraction

Oil and gas industry

- Metering skids, bulk and tanker loading, pipeline transfer, in-line density measurement

- Liquid hydrocarbons, liquefied gases (propane etc.)

Pulp and paper industry

- Paperstock, pulp

- Coating kitchens

Water and wastewater industry

- Flocculant dosing

- Sludge flow and density measurement

Product variants

OPTIMASS 7400

Food & Beverage version

Coriolis mass flowmeter for advanced food and beverage applications

- High accuracy mass flow and concentration measurement in advanced dosing and process control applications

- Single straight tube design for viscous and dense fluids (e.g. honey, cacao mass, ketchup, mayonnaise, minced meat, etc.)

- With Entrained Gas Management (EGM™) for applications with aerated products (e.g raw milk, spinach)

- FDA, EC1935/2004 conform; 3A, EHEDG certified

Accessories for this product

Applications

Related products

Links

Download Center

OPTIMASS 7000

Download Center

- Technical datasheets and handbooks

- Flyers and brochures

- Certificates and approvals

- Software and driver