PipePatrol Tightness Monitoring

Solution for detection of small and gradual leaks

- Detection of gradual leaks using standard pressure and temperature instrumentation

- Continuous and automatic reporting according to regulatory requirements

- Avoid negative effects on normal pipeline operation

Small or gradual leaks are often not covered by standard systems, as pressure and temperature changes along the pipeline can mask small losses. The detection solutions possible are normally time and cost intensive.

PipePatrol Tightness Monitoring is a method for the detection of gradual leaks using standard pressure and temperature instrumentation. This solution completely fulfils the requirements of TRFL 2017 and VdTÜV Bulletin 1051. It automatically creates a report according to these regulations and has been validated by independent 3rd party authorities. PipePatrol Tightness Monitoring avoids the classical pressure tests where the pipeline has to be filled with water, as it works with the actual gas or liquid in the pipeline, avoiding any negative effects on normal pipeline operation.

Highlights

- Fulfils German requirement TRFL 2017 and VdTÜV Bulletin 1051

- Export of data for further analysis tools

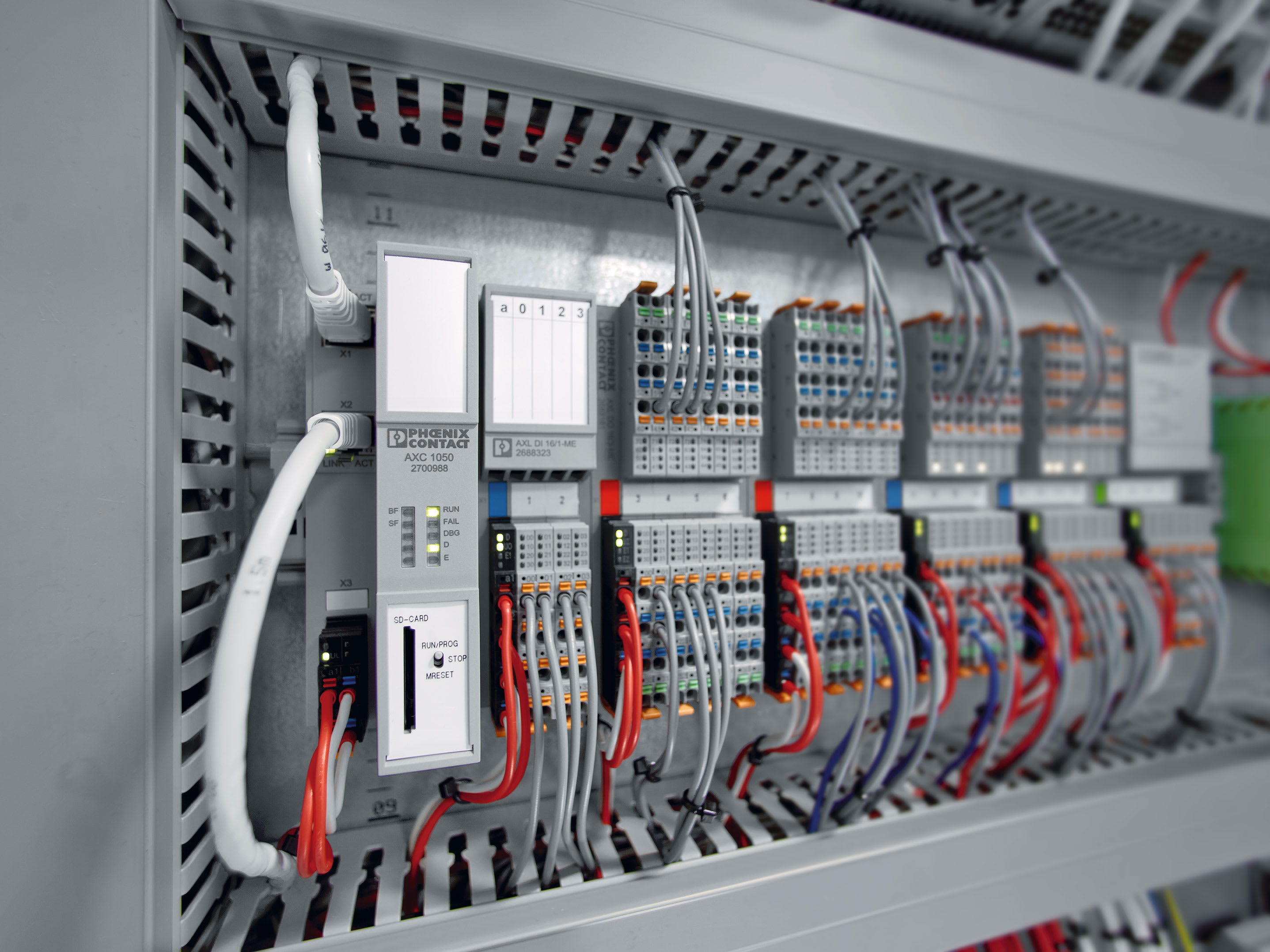

- Easy retro-fit through variable interface (OPC-Server)

- Approved by independent 3rd party authority

Typical applications

- Crude oil pipelines from oil fields to refineries

- Multiproduct pipelines from refineries to tank farms

- Subsea pipelines from FPSO units and platforms

- Non-continuously operated transport pipelines (e.g. for jet fuel)

Applications

Related products

Related solutions

Related services

Links

Pipeline Management Solutions

Related website

Find more information about KROHNE Pipeline Management Solutions and our partners on this dedicated website.