PipePatrol Batch Tracking

Solution for batch and interface tracking in multi-product pipelines

- Determination of the position of a batched product and identifying the mixing zone

- Predictions for arrival times and amounts of pure product available

- Safe operation and optimum capacity use of the pipeline

The determination of the position of a batched product and identifying the mixing zone, enables accurate predictions for arrival times and amounts of pure product available. In addition, separation of the interface from the actual product is easier, enabling planning for the most efficient yields.

This PipePatrol module tracks every batch and interface in multi-product pipelines, where several products such as gasoline, diesel and jet fuel are transported in sequence. It ensures safe operation as well as optimum capacity use of the pipeline. This enables the operator to minimise slop volume and increase the overall yields. For even better results PipePatrol Batch Tracking accepts input data from instruments along the pipeline, such as density meters or ultrasonic flowmeters, e.g. the KROHNE OPTISONIC 6300 clamp-on flowmeter.

Highlights

- Batch and interface tracking

- Estimated time of arrival calculation

- Interface calculation

- Slops/pure volume calculation

- Interface synchronization with other pipeline sensors enables improved predictions

Typical applications

- Oil pipelines from oil fields to refineries

- Multiproduct pipelines from refineries to tank farms

Related products

OPTIMASS 6400

Coriolis mass flowmeter for advanced process applications

- High accuracy (±0.05% flat), for cryogenic to HT media (-200…+400°C / -328…+752°F); maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- SIL 2/3; CT: OIML R117, R137, MI-005, MI-002; API, AGA; hygienic certifications

- Flange: DN10…300 / ½…12", max. PN 160 / ASME Cl 1500

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

OPTIMASS 2400

Coriolis mass flowmeter for highest capacity bulk measurement

- For gases and liquids up to 4,600 t/h; maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- CT: OIML R117, MI-005, MI-002; API and AGA compliant

- Flange: DN100…400 / 4…16", max. PN160 / ASME Cl 1500

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

OPTISONIC 3400

Ultrasonic flowmeter for liquid process applications

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

ALTOSONIC 5

Ultrasonic flowmeter for custody transfer (CT) measurement in upstream and midstream applications

- Multipath inline meter for crudes, refined products, cryogenic media and chemicals

- CT: OIML R117, API compliant

- Flange: 4…24"; max. ASME Cl 600

- -200…+250°C / -328…+482°F

OPTIBAR PC 5060

Pressure transmitter for advanced process pressure and level applications

- Robust design, with corrosion and abrasion resistant ceramic diaphragm

- 25 mbar…100 bar / 0.73…1450 psi; max. +150°C / +302°F

- Various threads, flanges, hygienic and other connections

- 2-wire, 4…20 mA, HART®, FF, Profibus-PA, Bluetooth®

OPTITEMP TRA-TF56

Resistance (RTD) temperature assembly for higher flow velocities and pressures

- Flange connection

- ASME-style, barstock thermowell with tapered tip

- -40…+600°C / +1100°F

OPTITEMP TRA-TS53

Resistance (RTD) temperature assembly for higher flow velocities and pressures

- Thread connection

- ASME-style, barstock thermowell with reduced tip

- -40…+600°C / +1100°F

OPTITEMP TRA-W30

Resistance (RTD) cable sensor for surface temperature measurement in industrial applications

- Hose clamp connection

- PTFE insulated copper contact plate for fast response times

- -50…+200°C / -58…+390°F

OPTITEMP TRA-W80

Resistance (RTD) cable sensor for measurement of soil temperature

- To be inserted or buried in the ground

- Stainless steel sheath and tapered tip, IP68 rated

- -40…+115°C / +239°F

Related solutions

PipePatrol Leak Detection

Solution for pipeline leak detection and localisation

- E-RTTM (Extended Real Time Transient Model) based leak detection and localisation

- Highly accurate and extremely reliable leak information

- Meets API 1130, API 1175, AB 864, German TRFL standards and CSA Z662

- System is either independent, or can be integrated with existing systems

PipePatrol Theft Detection

Solution for product theft detection

- Fast and reliable identification and localisation of unauthorised or illegal product discharges

- Dedicated theft pattern recognition for product theft detection

- Initiation of alarms within minutes to stop theft in the act

PipePatrol Line Break Detection

Solution for pipeline rupture detection

- Efficient and instant detection of pipeline ruptures, especially for high consequence areas

- Pipeline rupture pattern recognition system for automatic emergency shutdown

- Reliable and fast acting response systems and procedures to minimise environmental effects and danger

PipePatrol Predictive Modeling

Solution for prediction of pipeline conditions

- Simulation tool to predict pipeline conditions from current operating and manually definable static data

- Forecast future events and states of pipelines

PipePatrol Tightness Monitoring

Solution for detection of small and gradual leaks

- Detection of gradual leaks using standard pressure and temperature instrumentation

- Continuous and automatic reporting according to regulatory requirements

- Avoid negative effects on normal pipeline operation

PipePatrol Stress Monitoring

Solution for monitoring of pipeline lifetime stress

- Evaluation and documentation of lifetime stress

- Assessment of the remaining pipeline service life

- Monitoring of pressure measurements at sensor points

PipePatrol Pump Monitoring

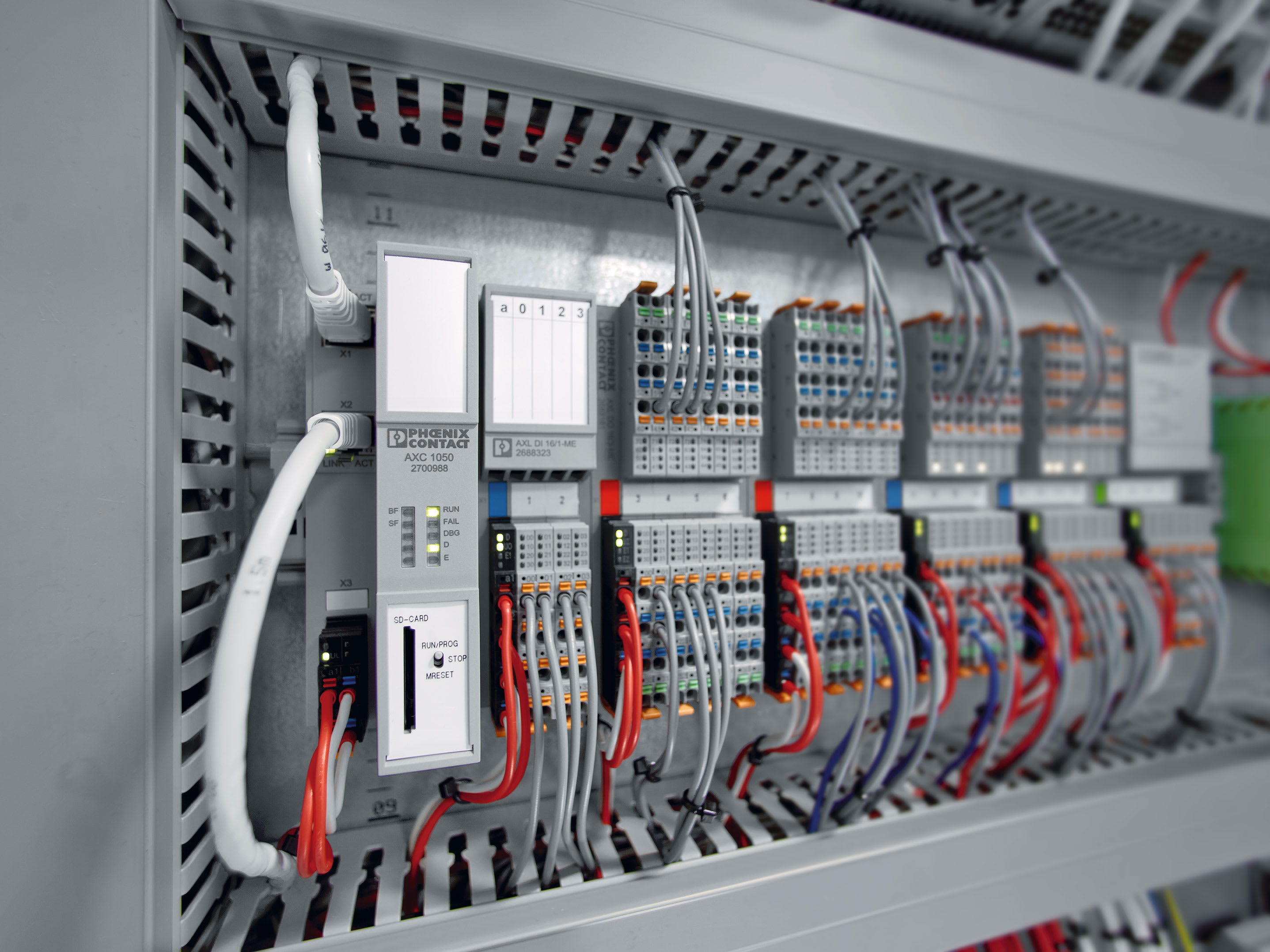

Control cabinet solution for monitoring of pumps and motors

- Monitoring of the essential mechanical, electrical, and hydrodynamic measurement values

- Reduction of the operational energy consumption through demand-oriented system management

PipePatrol Cyber Security

Cyber security solution for pipeline management

- Complementing solutions for pipeline monitoring and protection

- Protection against cyber risks

- Secure communication, fulfilling the latest standards

PipePatrol Data acquisition

Data transmission solution for pipelines

- Reliable systems for data acquisition and transmission and components for data encryption

- Particularly safe communication, fulfilling the latest safety standards

Related services

Consultancy & engineering for pipeline management

From operation and design of pipelines, through to certification

- Design of safe and reliable pipeline systems

- Consultancy during the whole project lifecycle by experienced pipeline management experts

- Support in the selection of the right technology and instrumentation

- Support of certification according to legal requirements

Start-up & commissioning for pipeline management

Service support during the initiation of projects and implementation in the field

- Consultancy during the implementation of projects

- On-site commissioning services

- Assurance of smooth and continuous operation in the field

- Training of staff before system implementation

System calibration & validation for pipeline management

Optimisation to operating conditions and achieving full performance

- Calibration of pipeline protection and monitoring systems

- Adjustments according to the application requirements to increase sensitivity and enable the accurate identification of pipeline incidents

- System validation according to effectiveness and certification

Operation & maintenance for pipeline management

Support for the protection and efficient operation of pipelines

- Identification of irregular behaviour in pipeline operation on site or via remote access

- Swift response to leak or theft events enabled by emergency support systems

- Inspection and maintenance to increase system life cycle

Training for pipeline management

Seminars and workshops on pipeline protection and monitoring systems

- In-depth training of operational, engineering and maintenance personnel

- From web-based eLearning to extensive on-site workshops

- Customised to suit the specific requirements of the operator and the application

Links

Pipeline Management Solutions

Related website

Find more information about KROHNE Pipeline Management Solutions and our partners on this dedicated website.