Geothermal steam measurement systems

Venturi flow metering solutions with PLR compensation for steam applications

- Stable measurement of sub-saturated geothermal steam

- Continuous real-time flow measurement with steam quality indication

- Seamless integration with new or existing systems

- Low maintenance requirements

A reliable measurement of both steam quantity and quality is a major challenge for all geothermal power plants. As the steam is close to saturation or even wet, small deviations in the operating conditions or unrecognized process disturbances could cause condensation or liquid carry-over. Any incorrect measurement affects the plant control and jeopardize the lifetime of the turbine-blades.

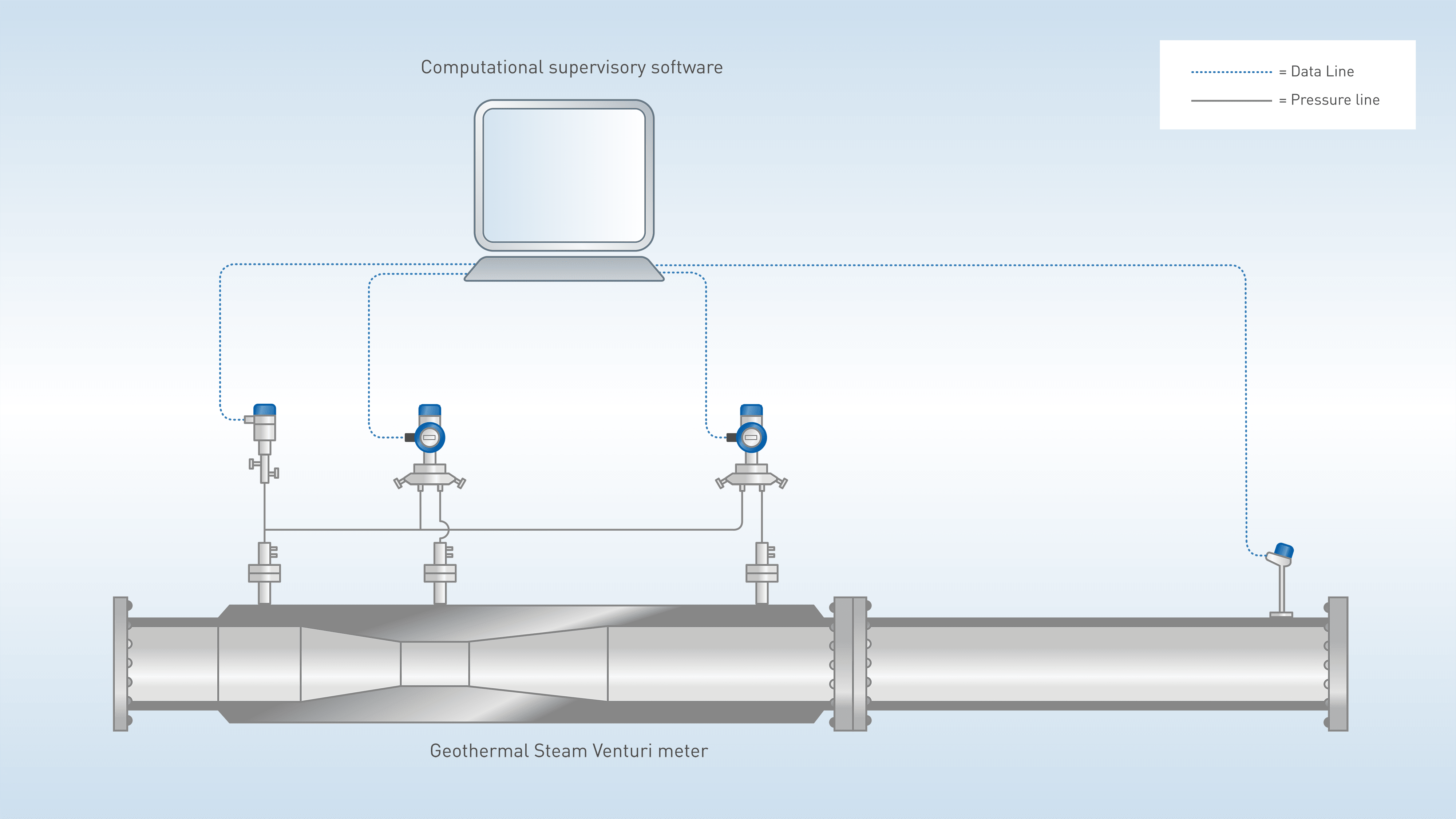

The KROHNE geothermal steam measurement system is an evolution of the WGS-series Venturi-based wetgas systems, field proven in the Oil & Gas Industry. The system consists of a 6D extended Venturi tube with heated annular chambers, and a Virtual Flow Computer (VFC) for liquid over-reading correlation and monitoring of the Pressure Loss Ratio (PLR) which indicates a shift in the liquid content.

The system fully complies with International Standards and combines a field proven Venturi flowmeter design with a virtual flow computer by KROHNE to accurately measure both the steam flowrate and condition. The system enables close monitoring and alarming of possible liquid carry-over without the need for additional on-line steam quality analysers.

Highlights

- Real-time measurement with steam wetness indication enables real-time process control

- Measurement range; GVF > 90% or Lockhart Martinelli X < 0.3

- Standard sizes available from 2 … 48” (50 … 1200 mm), larger sizes available on request

- Pressure rating available in accordance to relevant standards

- NACE MR 0175 compliant and suitable for NGC’s and TDS’s

- Minimal permanent pressure loss

- Continuous online monitoring of PLR enables immediate safety measures in case of process issues, and enables turbine safeguarding

- Allows accurate monitoring of the complete dehydration process (separator, demister, condensate traps)

- Provides trending, alarm management, reporting and integration with plant management and control systems

- Extended Diagnostics

Typical applications

- Steam cycle in geothermal power plants

- Continuous steam integrity monitoring

- Geothermal steam measurement system for steam flow and quality

- Geothermal steam measurement in turbine steam line

Related products

Related solutions

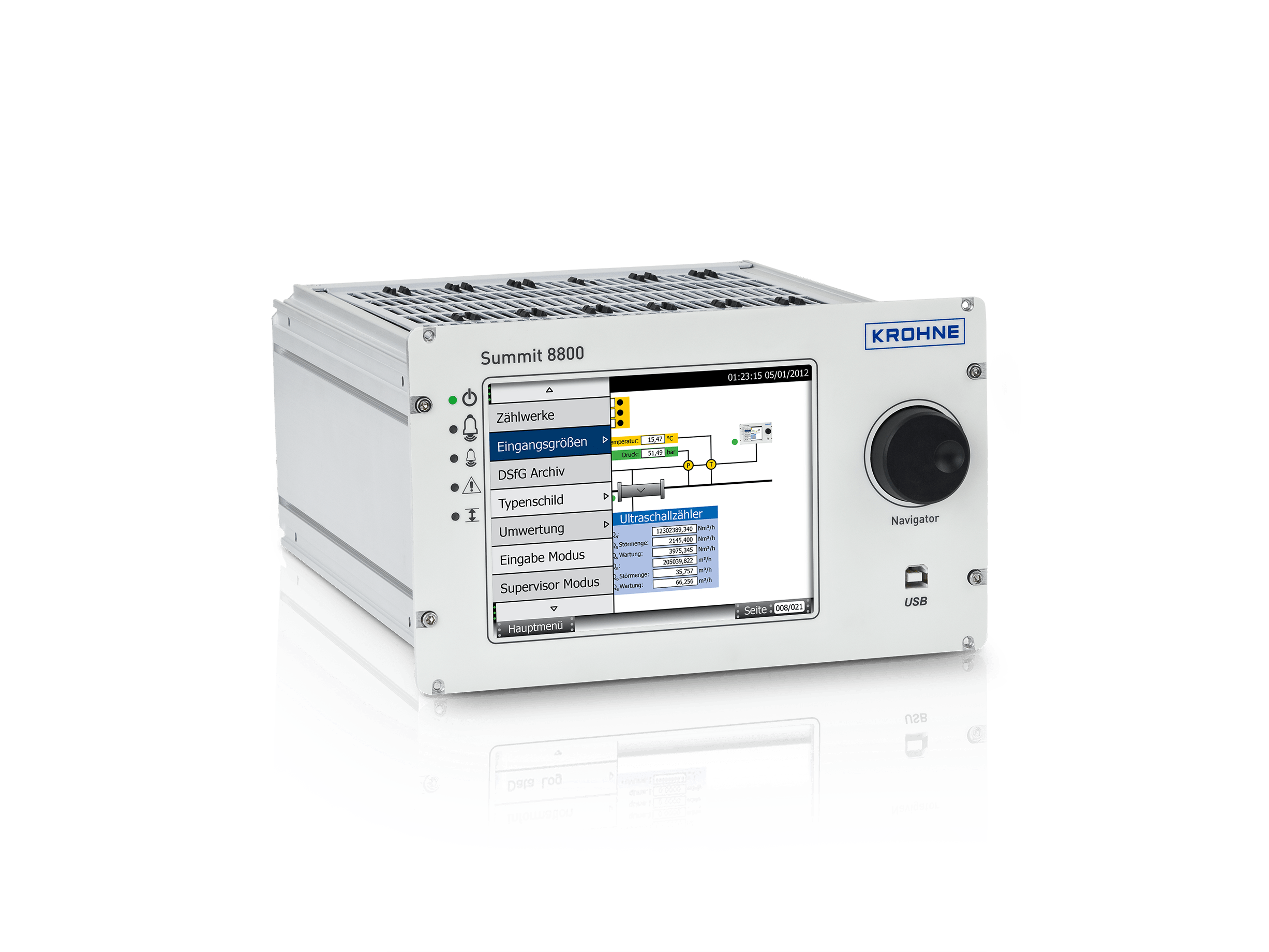

Supervisory Control Cabinets

Complete solution for process control

- Provides control of the metering system, including validation of field instrumentation

- Installed in a safe area, typically in a control room or dedicated building

- Supplied in combination with new metering systems, or for an upgrade to existing systems