Start-up & commissioning for pipeline management

Service support during the initiation of projects and implementation in the field

- Consultancy during the implementation of projects

- On-site commissioning services

- Assurance of smooth and continuous operation in the field

- Training of staff before system implementation

Implementing a pipeline project can be complex and expensive, and requires consistency and expertise throughout, from the initial kick-off meeting to the final commissioning. Professional consultancy input from an experienced partner is highly valuable. Based on over 30 years of experience in pipeline management and leak detection projects KROHNE offers design, start-up & commissioning services to guarantee smooth and continuous operation in the field. We take over responsibility for the whole project lifecycle: from planning through to final commissioning.

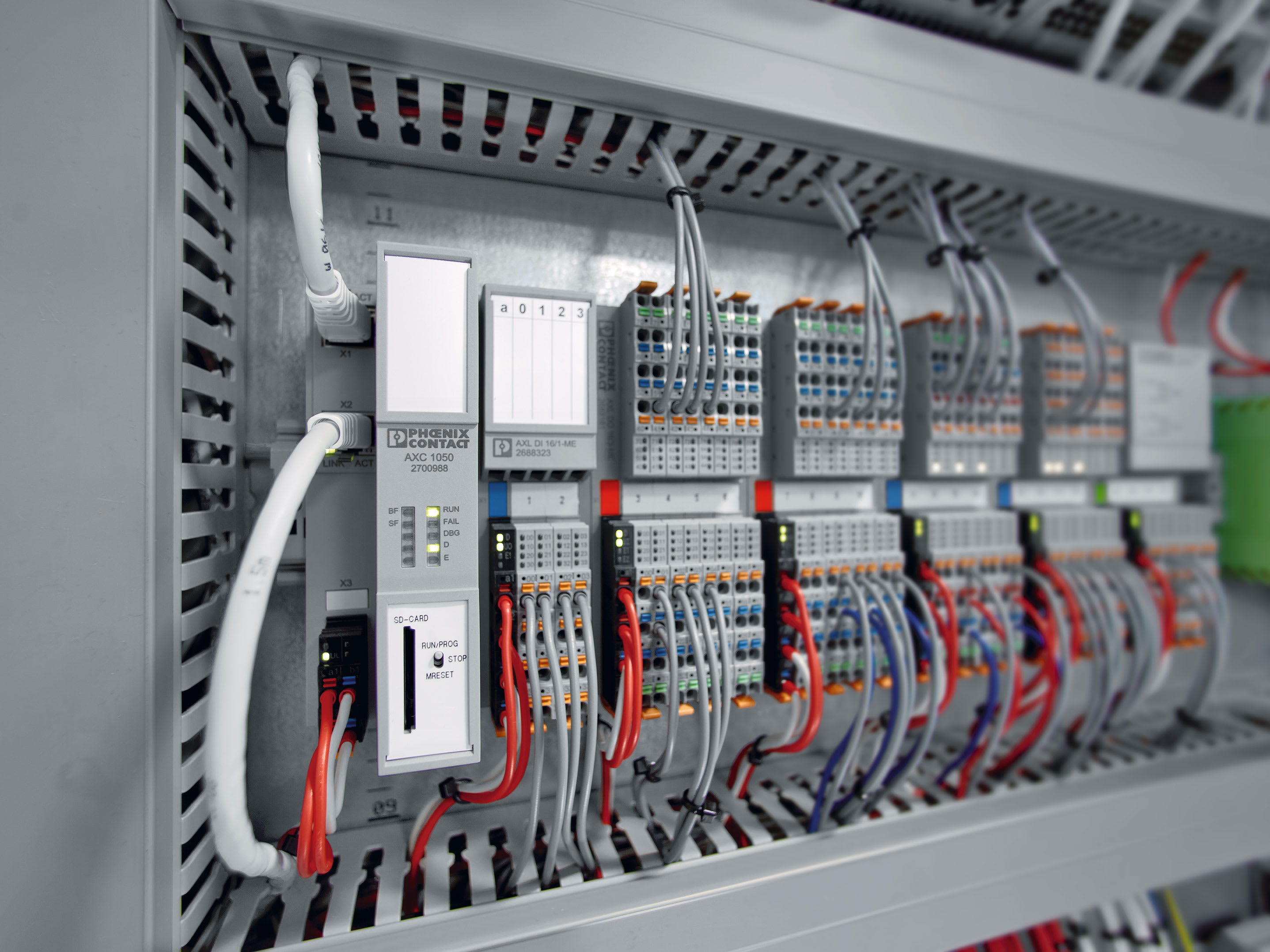

KROHNE offers a wide range of services to make a trouble-free implementation possible. Project management is performed according to ISO 9001 during all phases of the project including Factory Acceptance Tests (FAT), Integrated Factory Acceptance Tests (IFAT), Site Acceptance Tests (SAT) and Performance Acceptance Tests (PAT). Our expert engineers ensure that communication between all systems from the field to the control room are set up correctly and take care of the installation and wiring of the hardware equipment.

With the increasing complexity of pipeline systems, in-depth training and involvement of operations, engineering and maintenance personnel becomes a crucial factor in reliable and safe pipeline management. KROHNE offers a variety of formal training, from the basic introduction of leak detection principles to pre-familiarisation and configuration training. This enables operators to build their own team for pipeline management and enables them to proceed with any system changes independently.

Product highlights

- Project management (acc. To ISO 9001)

- Kick-off meetings

- Inspection of instrumentation and communication from the field to the control room

- FAT, IFAT, SAT, PAT

- Documentation from basic engineering to detailed design documents

- Installation and wiring of hardware equipment

- Operator, engineer and maintenance training and workshops

Typical applications

- Crude oil pipelines from oil fields to refineries

- Multiproduct pipelines from refineries to tank farms

- Subsea pipelines from FPSO units and platforms

- Non-continuously operated transport pipelines (e.g. for jet fuel)

- Water pipelines from desalination plants to cities

- Natural gas pipelines