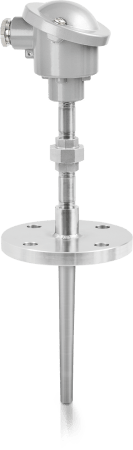

OPTITEMP TRA-TF56

Resistance (RTD) temperature assembly for higher flow velocities and pressures

- Flange connection

- ASME-style, barstock thermowell with tapered tip

- -40…+600°C / +1100°F

OPTITEMP TRA-TF56 – Standard version

The OPTITEMP TRA-TF56 is a flanged RTD sensor assembly with a tapered barstock thermowell. The temperature assembly for advanced requirements is used when the strength of welded multipart thermowells is not sufficient and a high mechanical stress resistance of the thermowell is required. It is therefore particularly suitable for temperature measurement in pipes, tanks or reactors at higher flow velocities and pressures (e.g. in the petrochemical or oil and gas industry). The RTD is designed to operate up to +600°C / +1100°F. The particular advantage of this sensor type is that its wetted parts can be coated (e.g. with PTFE), making it resistant to aggressive media.

The OPTITEMP TRA-TF56 features a modular design with a threaded neck tube that can be exchanged easily, even under operating conditions. This makes the temperature assembly very flexible. If it has been damaged from the outside, servicing can be carried out without process shut down. The resistance temperature device can be combined with most thermowells. It is available with ATEX and IECEx approvals.

Product highlights

- Temperature measurement of solids, liquids, gases and steam

- Modular design: Flexible union neck tube or threaded DIN neck tube for easy exchange under operating conditions

- Thermowell material: 1.4404 / 316L

- Chemically resistant PTFE or similar coating for all wetted parts available

- Temperature range: -40…+600°C /+1100°F

- Standard or customised lengths

- Different connection heads available (IP54…IP68)

- With optional temperature transmitter

- Available as intrinsically safe (Ex i) and flameproof (Ex d): ATEX, IECEx

Typical applications

- Applications with advanced requirements

- Temperature measurement of media requiring high mechanical stress resistance

- Suitable for applications where assemblies complying with ANSI standards are required

- Primarily used in the petrochemical industry, the oil and gas industry as well as in industries such as:

- Power generation

- Machinery and apparatus / OEM

- Iron and steel

- Pulp and paper

General information

| Measurement principle | Resistance (RTD) |

| Measured media | Gases, Liquids, Solids, Steam |

| Measuring point | Pipe |

| Measuring insert type | Replaceable spring loaded mineral isolated measuring insert OPTITEMP TR 100 |

| Measuring insert replaceable | Yes |

| RTD element type | 1 x Pt100, 2 x Pt100 |

| RTD configuration | 2-wire, 3-wire, 4-wire |

| Temperature sensor connection type option | Ceramic terminal block, Flying wires, Temperature transmitter |

| Assembly with thermowell | Yes |

| Temperature assembly design | ASME-style |

| Thermowell tip design | Tapered |

| Thermowell type | Barstock |

| Thermowell diameters | Ø22 mm / 0.87", Ø25 mm / 0.98" |

| Pressure ratings | EN (1092-1): PN40 ASME (B 16.5): Cl 300# |

Approvals/Standards

| Certificates/Approvals Ex | ATEX, IECEx |

Process connections

| Flange connections | EN (1092-1): DN25…50 ASME (B 16.5): 1…2" |

Links

Download Center

OPTITEMP

Download Center

- Technical datasheets and handbooks

- Flyers and brochures

- Certificates and approvals

- Software and driver