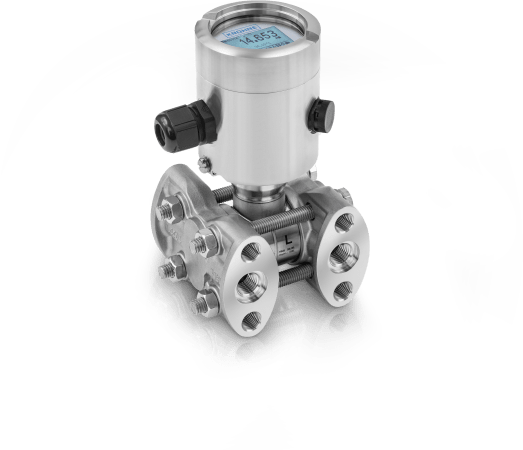

OPTIBAR DP 3050

Differential pressure transmitter for general flow, level and differential pressure applications

- The most compact design in its class

- Measuring ranges: 100 mbar…16 bar / 1.45…232 psi; Line pressure: up to 160 bar / 2320 psi

- Reference accuracy ± 0.1%

- 2-wire, 4…20 mA/HART®7

OPTIBAR DP 3050

The OPTIBAR DP 3050 is a differential pressure transmitter with integrated absolute pressure measurement. It is the ideal choice for general flow, level and differential pressure applications. The DP transmitter is currently the most compact pressure transmitter in the market – worldwide. This makes it particularly suitable for space-saving installation in applications with limited space, e.g. in mechanical and technical plant engineering. The compact DP transmitter features the proven-in-use DP transmitter technology of the OPTIBAR series, but comes without the high-end options of the more advanced OPTIBAR DP 7060. This way, the OPTIBAR DP 3050 is also one of the most cost-effective DP pressure transmitters in the market. For DP flow measurements it can be perfectly combined with KROHNE primary flow elements. Equipped with diaphragm seals, it is the right choice for hydrostatic level and general purpose DP measurements.

KROHNE is the only manufacturer of process instrumentation to carry out a total 3D linearisation of its differential pressure transmitters. For a robust and accurate differential pressure measurement, even under changing process conditions, each OPTIBAR DP 3050 differential pressure transmitter is linearised in all three dimensions during calibration: differential pressure, ambient temperature and static pressure are taken into account in combination. Since the full specified operating range is covered, an utmost stable and accurate measurement under all process conditions is guaranteed.

Product highlights

- Robust and space-saving stainless steel construction (316L / 1.4404)

- Total 3D linearisation for highest accuracy and stability under all process conditions

- Integrated static pressure measurement for additional process information

- Outstanding temperature stability even under harsh conditions

- Excellent repeatability and long-term stability

- Combined DP, SP and T measurements for maximum process reliability

- Suitable for OPTIBAR DSD diaphragm seal assembly

- Can be combined with many primary elements of the OPTIBAR OS and OPTIBAR PT series for flow measurement

- Optional display and adjustment module with intuitive user concept

- Internal push buttons for quick parameter set up

- Ex ia approvals for gas and dust atmosphere

Typical applications

General

- Differential pressure measurement of gases, vapours and liquids

- Pressure monitoring of filters and pumps with overload protection of up to 160 bar / 2321 psi

- Level measurement of liquids in open and pressurised vessels

- Flow measurement of gases, vapours and liquids

- Applications with tight installation spaces

- For various industrial use cases:

- General process technology

- Environmental technology

- Water and wastewater

- Iron, steel and metal

- Plant construction and engineering

- Hydraulic and pneumatic systems as well as other OEM machinery

Related products

Links

OPTIBAR portfolio

Related website

Explore our OPTIBAR product portfolio of process instruments for pressure and differential pressure applications.

Download Center

Pressure instruments

Download Center

- Technical datasheets and handbooks

- Flyers and brochures

- Certificates and approvals

- Software and driver