OPTIWAVE 7400

Radar (FMCW) level transmitter for agitated and corrosive liquids

- Continuous, non-contact level measurement in harsh environments

- 24 GHz radar, Horn or Drop antennas

- Measuring range: 0…100 m / 328 ft

- -50…+200°C / -58…+392°F, up to +700°C / +1292°F in non-ex applications; -1…100 barg / -14.5…1450 psig (higher on request)

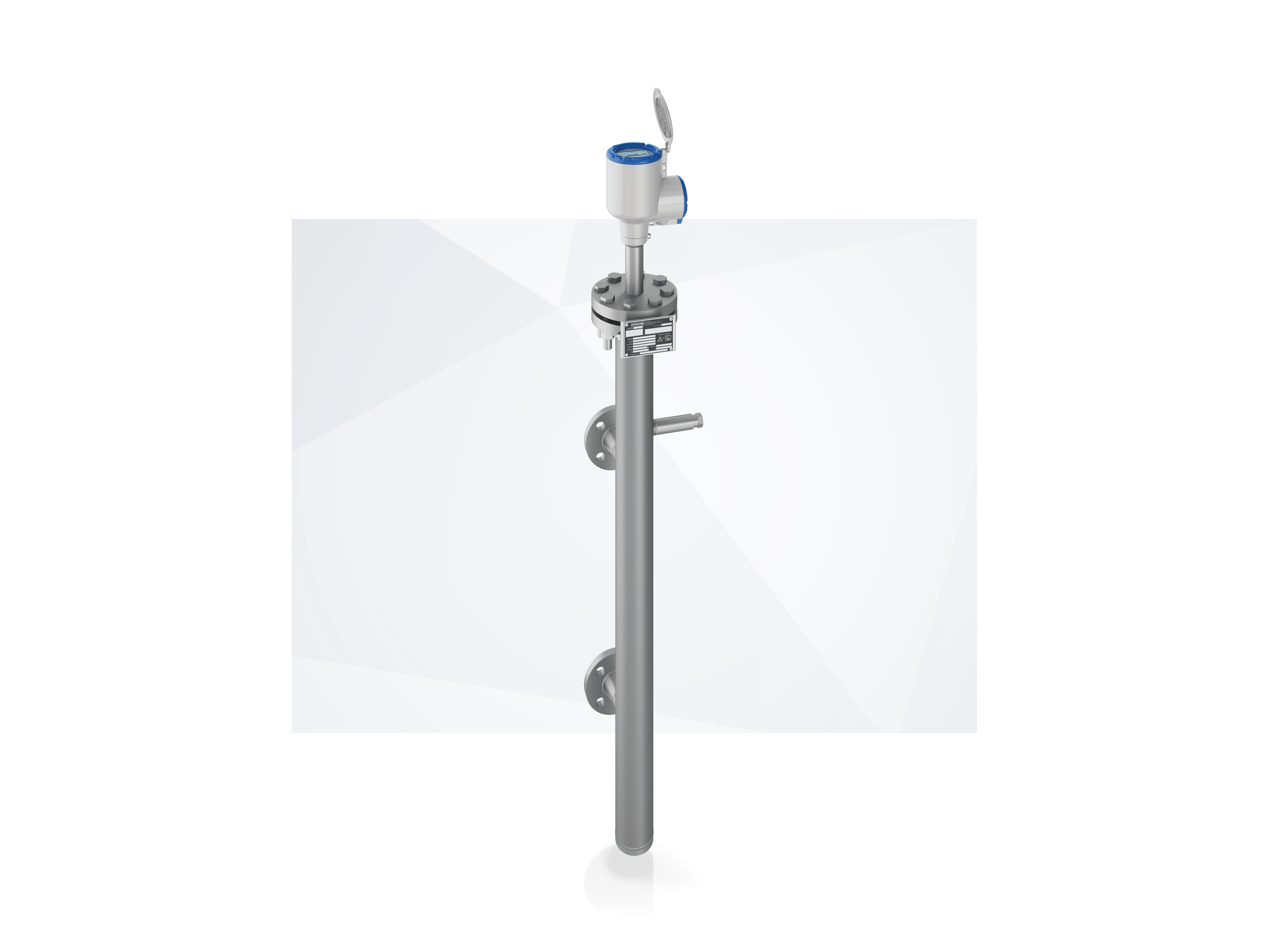

OPTIWAVE 7400 with DN80 / 3" PEEK Drop antenna

The OPTIWAVE 7400 is a 2-wire 24 GHz radar (FMCW) level transmitter for liquids in harsh environments like tanks with agitators containing corrosive media. It is particularly designed for continuous, non-contact level measurement under extreme conditions prevalent in the chemical, petrochemical, power, metal or oil and gas industry. The device features Metallic Horn antennas as well as PTFE and PEEK Drop antennas for measuring distances up to 100 m / 328 ft. The Drop antennas are perfectly suited for aggressive liquids in tanks. In applications with toxic and dangerous products, this radar device can be equipped with a METAGLAS® second sealing barrier.

The OPTIWAVE 7400 provides accurate readings even in processes with fast changing levels. It has approvals for hazardous areas and can be used in process conditions of up to +200°C / +392°F and 100 barg / 1450 psig. There is also a dedicated version available for non-ex applications with molten salt or other high temperature liquids up to +700°C / +1292°F. The radar level transmitter comes with a quick coupling system, allowing the converter to be removed under process conditions and upgrade obsolete radars in high-end applications, e.g. to obtain extended device features. The OPTIWAVE 7400 features extensive device diagnostics (acc. to NE 107) as well as HART®7 communication.

Product highlights

- 2-wire, loop-powered, with HART®7

- Distance piece for non-ex applications with molten salt or other high temperature liquids of up to +700°C / +1292°F

- PTFE or PEEK Drop antennas:

- Insensitive to condensation

- Small beam angle (4° with DN150 / 6″ PTFE antenna)

- Ellipsoidal shape and smooth surface to minimise scaling

- PTFE flange plate protection for corrosive media

- New DN100 / 4" Drop antenna for distances up to 80 m / 262.5 ft

- 316L Metallic Horn antennas with optional purging system

- Heating / cooling systems to prevent crystallisation or build-up in Metallic Horn antennas

- ±2 mm / ±0.08″ accuracy

- METAGLAS® second sealing barrier for toxic and dangerous liquids

- Antenna extensions to suit any nozzle length

- Empty tank spectrum function eliminates false reflections caused by tank internals

- Large choice of flange and thread connections

- Quick Coupling system permits removal of the converter under process conditions and 360° rotation for easy reading of display

- Converter compatible with all OPTIWAVE 7300 C flange connections

- Large, backlit LCD screen with 4-button keypad for operation with bar magnet; no need to open the housing cover

- PACTware™, HART® DD and DTM provided free of charge with full functionality

- Extensive device diagnostics acc. to NAMUR NE 107

- SIL 2/3 certified for safety-related applications

- 3-year warranty

Typical applications

General

- Level measurement in/on process tanks, reactors (max. 100 m / 328 ft) and open air applications (floating roofs etc.)

- Agitated liquids in tanks

- Processes with fast changing levels (≤60 m/min / 196.85 ft/min)

- High accuracy applications

- Non-Ex applications up to +700°C / +1292°F (e.g. molten salt in solar plants)

Chemical industry

- Alcohols, e.g. methanol, ethanol

- Solvents, acids, bases

- Additives

- Butadiene

- Ethylene, propylene

- Molten sulphur

Petrochemical industry, oil and gas industry

- Liquefied gases

- Hydrocarbons and fuels

- Benzene

- Hydraulic oils

- Condensates

Power industry

- Molten salt at Concentrated Solar Power plants (CSP)

Iron, steel and metal industry

- Molten steel batching

Product variants

OPTIWAVE 7400 with BM26A-5000

Radar (FMCW) level transmitter with bypass chamber

- All-in-one solution with FMCW radar and bypass chamber

- Large choice of bypass chamber materials e.g. 316L, 304L, alloy C276, alloy 625

- Level measurement up to 5.5 m / 18 ft (other dimensions on request)

- Ideal for difficult process conditions, e.g. turbulence, foam

Accessories for this product

General information

| Measurement principle | Radar |

| Level measurement type | Continuous measurement |

| Measured media | Liquids, Pastes, Slurries |

| Contact to measured medium | No |

| Interface measurement | No |

| Measuring range (liquids) | 0…100 m/ 0…328 ft |

| Process pressure | -1…100 barg/ -14.5…1450 psig |

| Pressure ratings | EN (1092-1): PN100 ASME (B 16.5): Cl 1500# JIS (B 2220): 10k |

| Process temperature | -50…200°C/ -58…+390°F Special version (on request): Up to +700°C/+1292°F |

| Ambient temperature | -40…+80°C/ -40…+176°F |

| Wetted parts | Austenitic stainless steel (1.4404/316L), Polyetheretherketone (PEEK), Polytetrafluoroethylene (PTFE) |

| Gaskets | Ethylene propylene diene monomer (EPDM), Fluoroelastomer rubber (FKM/FPM), Kalrez® 6375 |

| Accuracy (liquids) | ±2 mm/ ±0.08 in |

Approvals/Standards

| Certificates/Approvals Ex | ATEX, cQPSus, EAC Ex, IECEx, NEPSI |

| Certificates/Approvals Safety | SIL 2/3 |

| Certificates/Approvals Marine | DNV |

| Certificates/Approvals Others | CRN / ASME B31.3, NACE, WHG |

| Ingress protection | IP66/68, NEMA4X/6P |

| NAMUR compliance | NE 107, NE 21, NE 43, NE 53 |

Communication

| Digital outputs | FOUNDATION™ fieldbus, HART®, Profibus-PA |

| Analogue outputs | 4…20 mA |

Process connections

| Flange connections | EN (1092-1): DN40…200 ASME (B 16.5): 1½…8″ JIS (B 2220): 40…200A |

| Thread connections | Male: G1½ 1½ NPT |

Links

Download Center

OPTIWAVE 7400

Download Center

- Technical datasheets and handbooks

- Flyers and brochures

- Certificates and approvals

- Software and driver