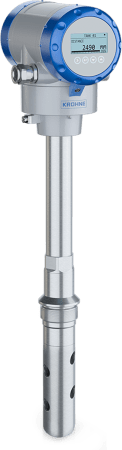

OPTIFLEX 7200

Guided radar (TDR) level transmitter for advanced liquid applications

- Continuous level and interface measurement in process or storage tanks, reactors and pressure vessels

- Extensive choice of probes for harsh process conditions

- Measuring range: 0.3…60 m / 1…197 ft

- -50…+250°C / -58…+482°F; -1…100 barg / -14.5…1450 psig

OPTIFLEX 7200 C – Compact version with Ø42 mm / 1.65" coaxial probe and HT extension

The OPTIFLEX 7200 is a 2-wire guided radar level transmitter based on the Time Domain Reflectometry (TDR) technology. With its large choice of probe types and materials, this level transmitter is the high-end guided radar for level and interface measurement in the chemical or oil and gas industries. It is suitable for storage or process tanks up to 60 m / 196.85 ft, containing all kind of liquids – from hydrocarbons like slop oil or benzene to solvents and acids to cooling water or condensate.

The OPTIFLEX 7200 can be used at extended temperature and pressure conditions. Various converter and electronic versions like a remote converter or a sensor extension facilitate the access to the device. The level transmitter has approvals for use in hazardous areas.

Product highlights

- Extensive choice of probes for all applications:

- Ø42 mm / 1.65" coaxial probe made of 316L or HC22

- Fully TFM-T62 PTFE-coated rod

- Special materials available on request e.g. Monel®, tantalum, titanium, duplex

- Ceramic process seal system for demanding process conditions

- Reversed interface measurement

- Patented Dynamic Gas-phase Compensation (DGC) without increased blocking distance (in preparation)

- Various converter and electronic versions to facilitate access to the device:

- Available as compact version (C) or with remote converter (F) up to 100 m / 328 ft

- Sensor extension with compact version (S) up to 15 m / 49.2 ft

- Double sensor extension with remote version (D) up to 115 m / 377.3 ft

- Horizontal or vertical housing to suit every installation

- Converter is rotatable and removable under process conditions and compatible with all previous Guided Radar (TDR) level transmitters made by KROHNE

- Stainless steel housing for corrosive environment

- Weather protection - protects the converter in extreme weather conditions

- Diagnosis functions according to NAMUR NE 107

- NACE design MR 0175 (ISO 15156), MR 0103 (ISO 17945) / ASME B31.3

- SIL 2/3 (in preparation)

- ±2 mm /±0.08" accuracy

- Real-time clock for event logging

- 3-year warranty

Typical applications

General

- Level and interface measurement of liquids in storage and process applications

- Reversed interface measurement (e.g. water / tar)

- Installation on magnetic level indicators (MLI) or in bypass chambers

Chemical and petrochemical industry

- Ethylene, propylene, additives, corrosion inhibitors, butadiene

- Solvents, alcohols, acids, bases

- Benzene, hydraulic oil, fuels, biodiesel

- Foaming agents

- Level control on CO2 skids

Oil and gas industry

- Slop oil, biodiesel, benzene, fuels, lubricant oil, various other hydrocarbons

- Liquefied gases, condensates

Power generation

- Hydraulic oil, lubricant oil

- Fuel control of emergency generators

- Cooling water, condensates

- Lime milk

Metals industry, minerals and mining industry

- Water tar mixtures

Product variants

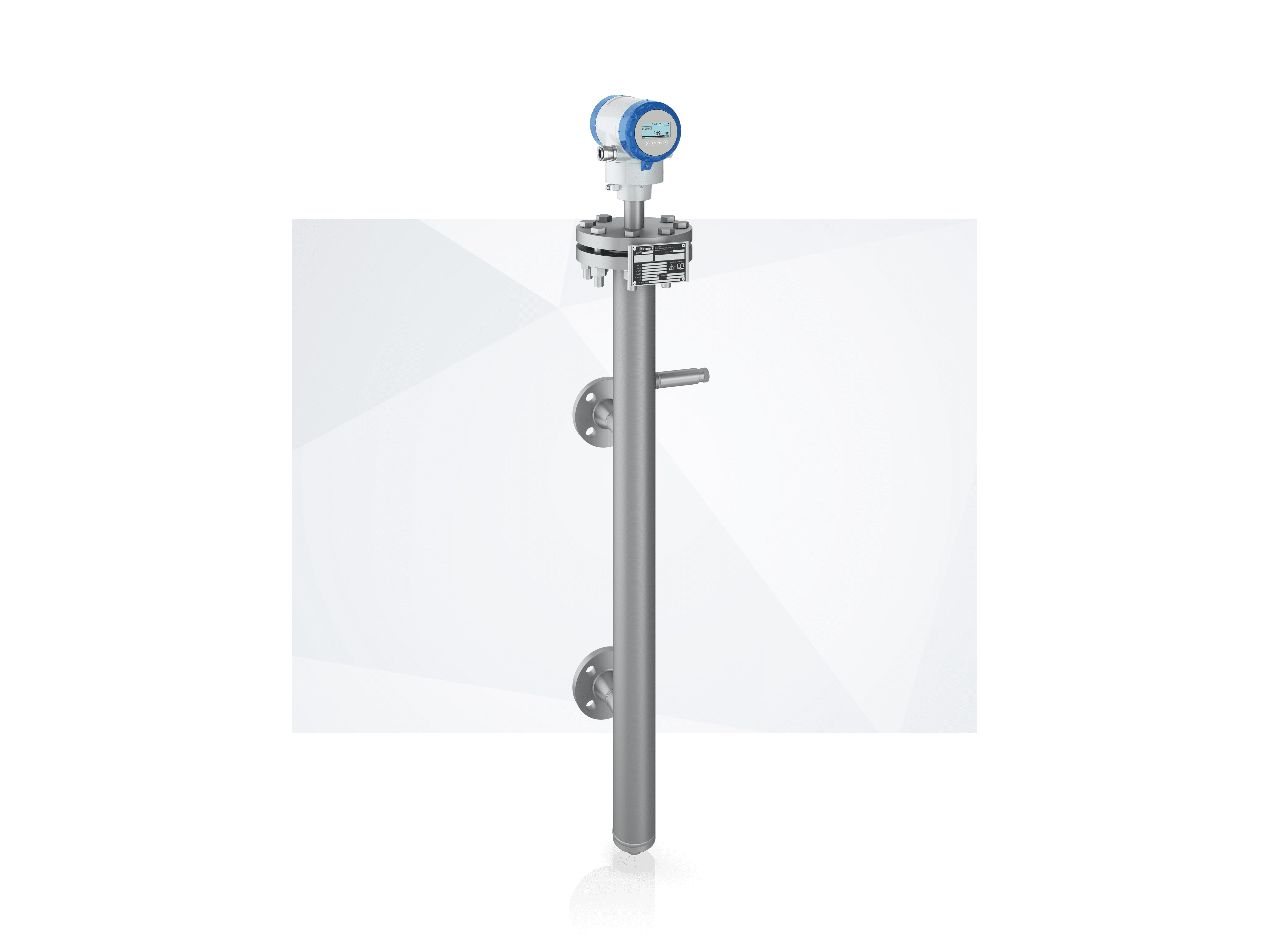

OPTIFLEX 7200 with BM26A-5000

Guided radar (TDR) level transmitter with bypass chamber

- All-in-one solution with TDR guided radar and bypass chamber

- Large choice of bypass chamber materials e.g. 316L, 304L, alloy C276, alloy 625

- Level or interface measurement up to 5.5 m / 18 ft (other dimensions on request)

- Ideal for difficult process conditions, e.g. turbulence, foam

Applications

General information

| Measurement principle | Guided radar |

| Level measurement type | Continuous measurement |

| Measured media | Liquid/liquid interface, Liquids |

| Contact to measured medium | Yes |

| Interface measurement | Yes |

| Probe diameter |

|

| Probe length | 0.3...60 m 0.98...196.85 ft |

| Measuring range (liquids) | 0.3…60 m/ 0.98…196.85 ft |

| Process pressure | -1… 100 barg/ -14.5… 1450 psig |

| Process temperature | -50…+250°C/ -58…+482°F |

| Wetted parts | Austenitic stainless steel (1.4404/316L), Austenitic alloy (2.4602/Alloy 22), Ceramic, Polytetrafluoroethylene (PTFE) |

| Gaskets | Ceramic, Ethylene propylene diene monomer (EPDM), Fluoroelastomer rubber (FKM/FPM), Kalrez® 6375, Kalrez® 7075, Polytetrafluoroethylene (PTFE) |

| Accuracy (liquids) | ±2 mm/ ±0.08 in |

Approvals/Standards

| Certificates/Approvals Ex | ATEX, cQPSus, IECEx, INMETRO, NEPSI |

| Certificates/Approvals Safety | SIL 2 |

| Certificates/Approvals Others | NACE |

| Ingress protection | IP66/68, NEMA4X/6P |

| NAMUR compliance | NE 107, NE 21, NE 43, NE 53 |

Communication

| Digital outputs | HART® |

| Discrete outputs | Relay |

| Analogue outputs | 4…20 mA |

Process connections

| Flange connections | DN25…150/ 1…8”/ 40…150A |

| Thread connections | Male: G¾, G1, G1½ ¾ NPT, 1 NPT, 1½ NPT |

Download Center

OPTIFLEX 7200

Download Center

- Technical datasheets and handbooks

- Flyers and brochures

- Certificates and approvals

- Software and driver