Crude desalting in the oil & gas industry

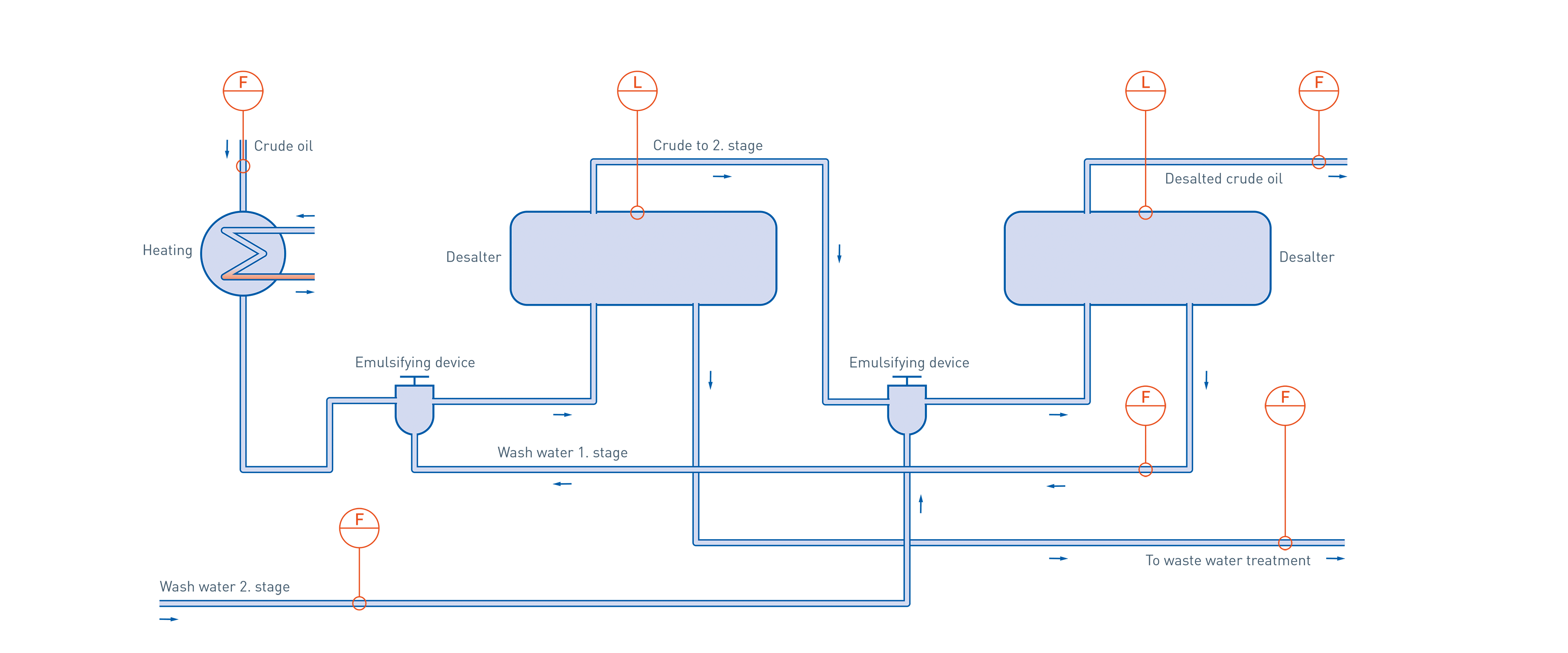

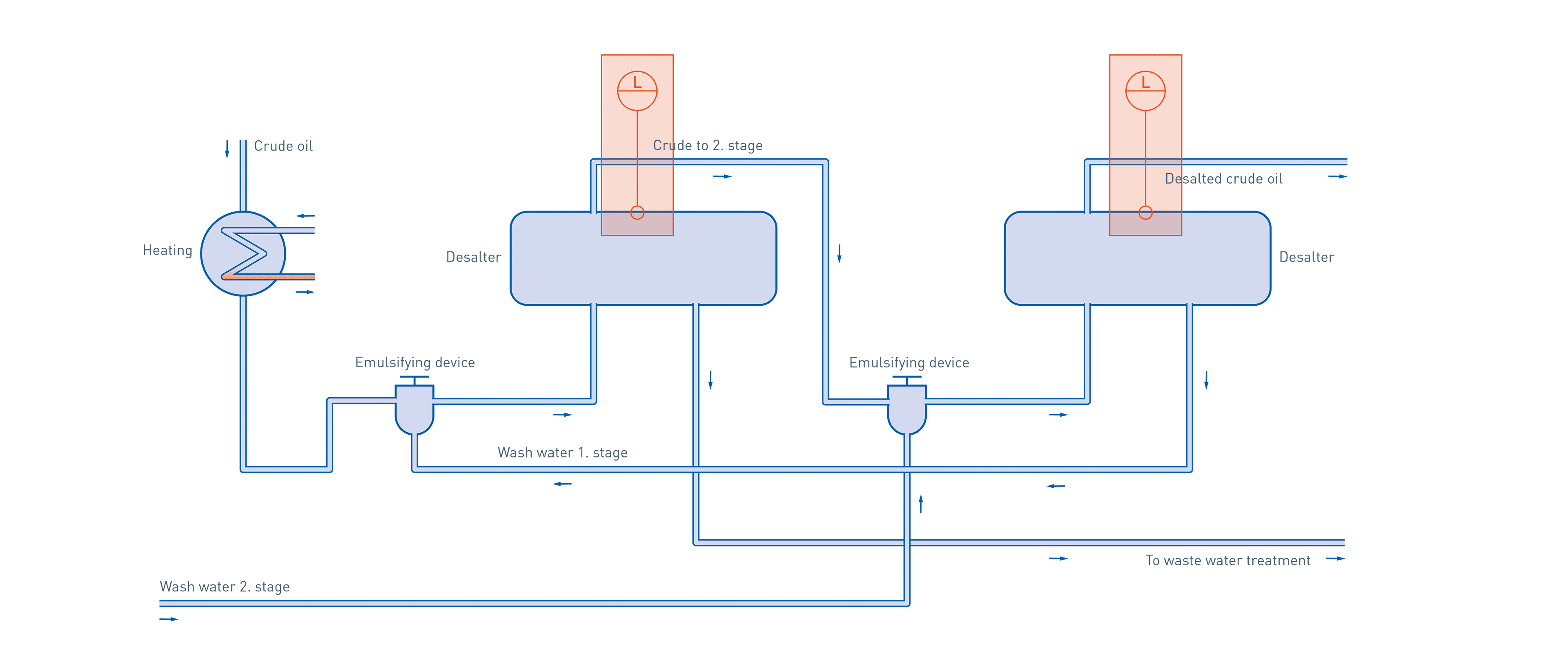

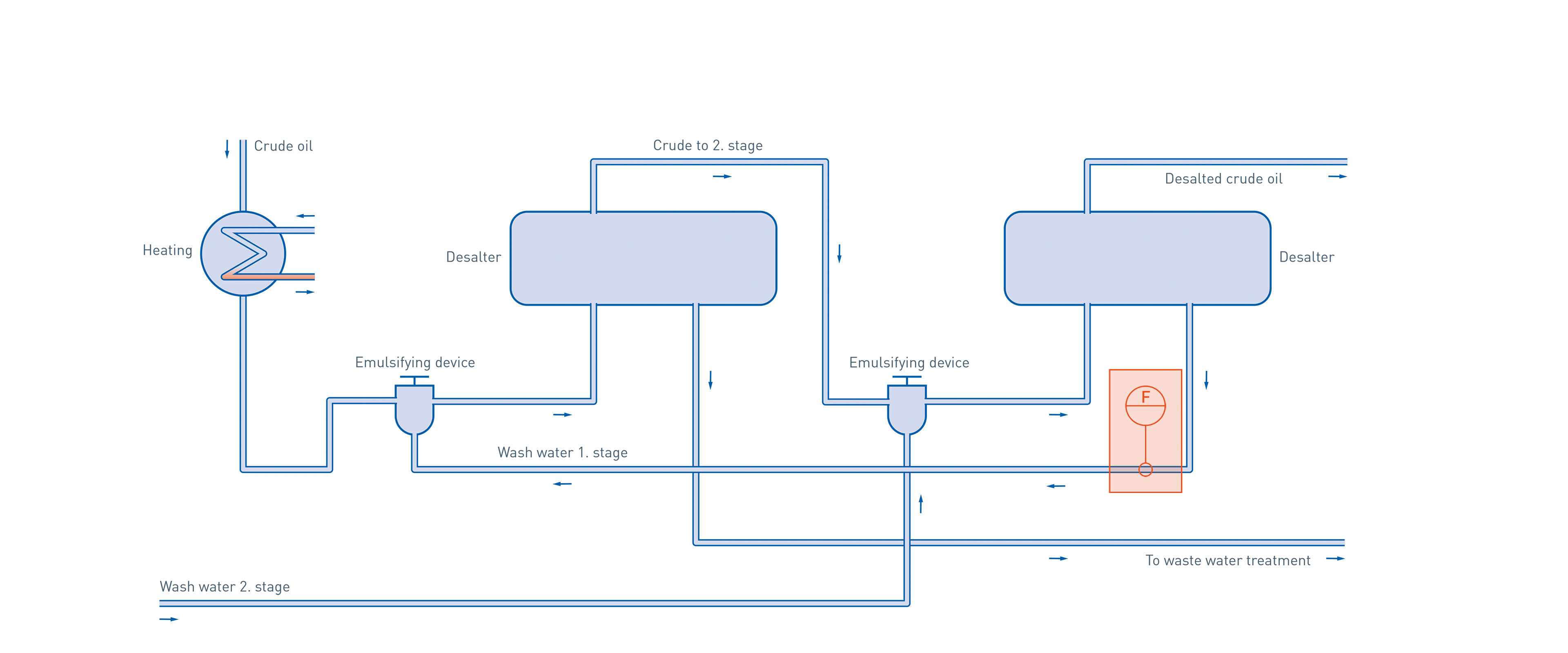

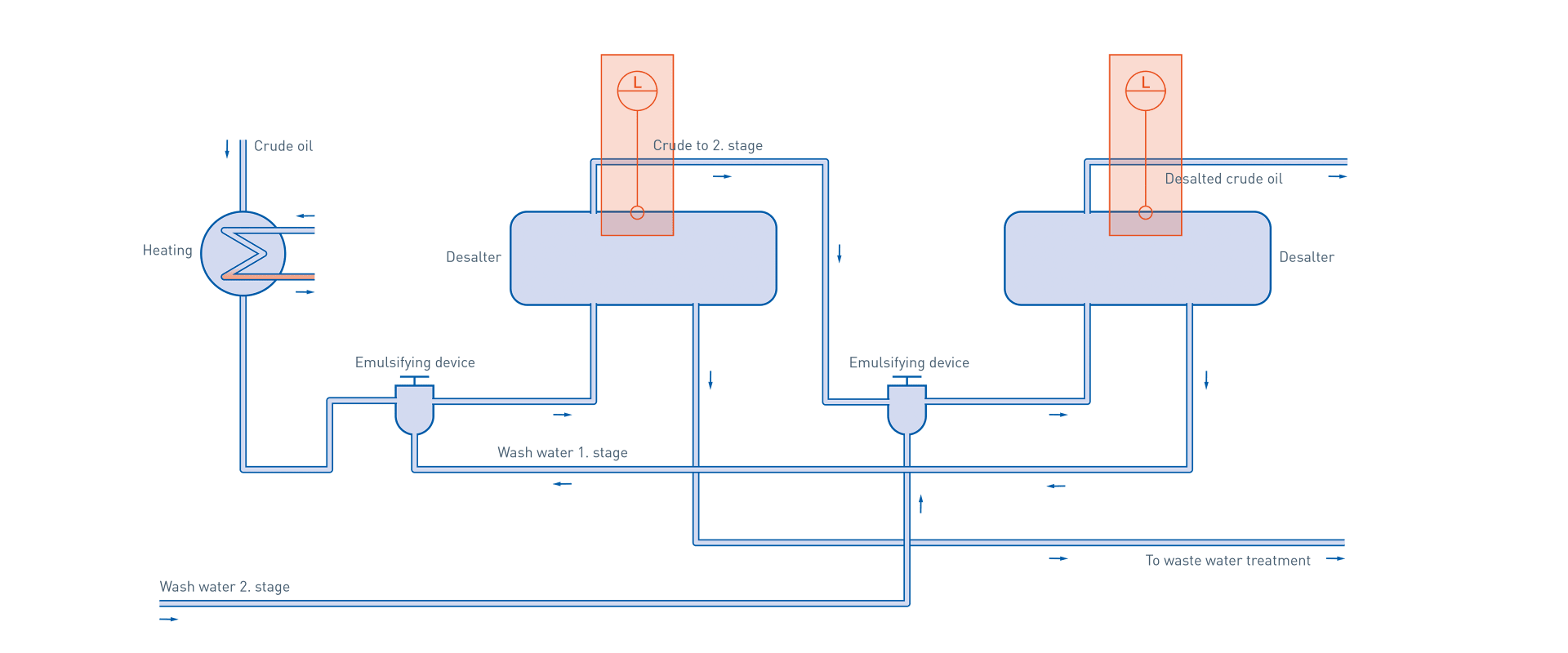

Flow monitoring of crude oil and wash water

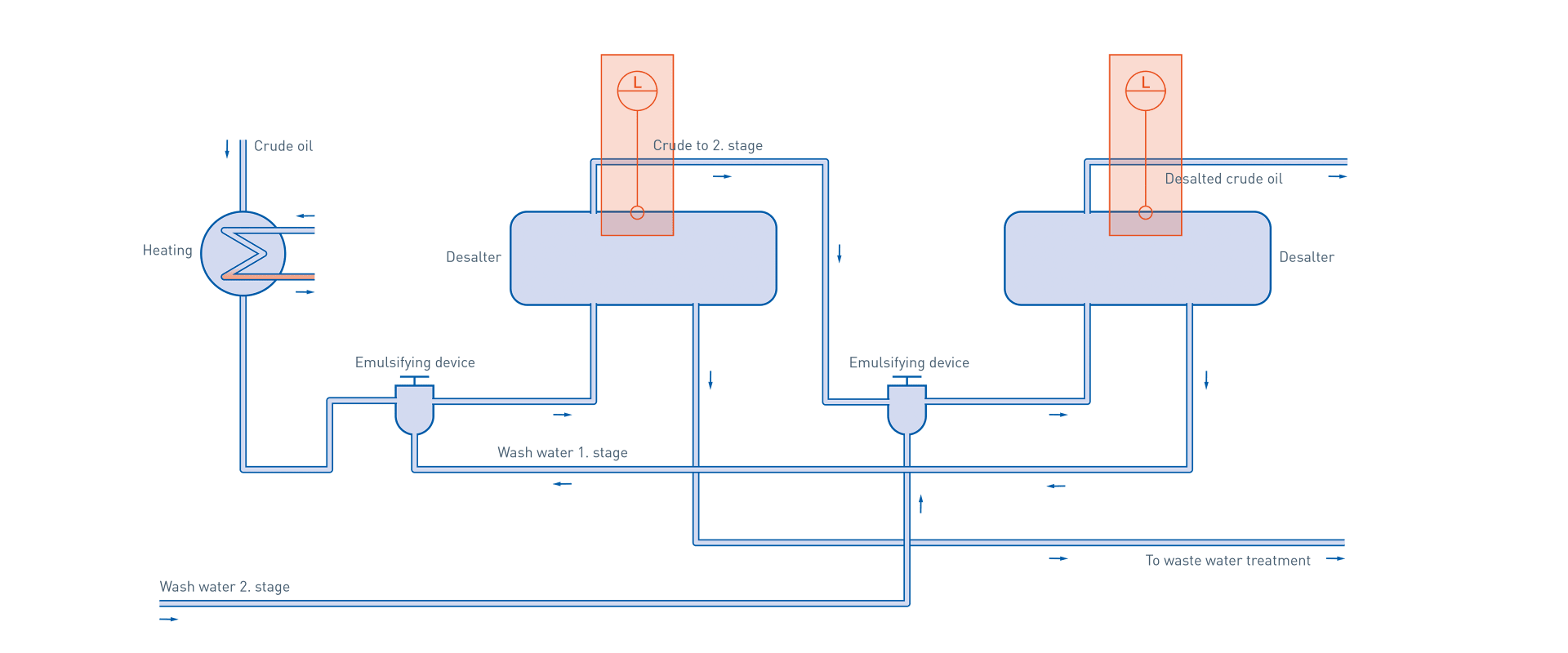

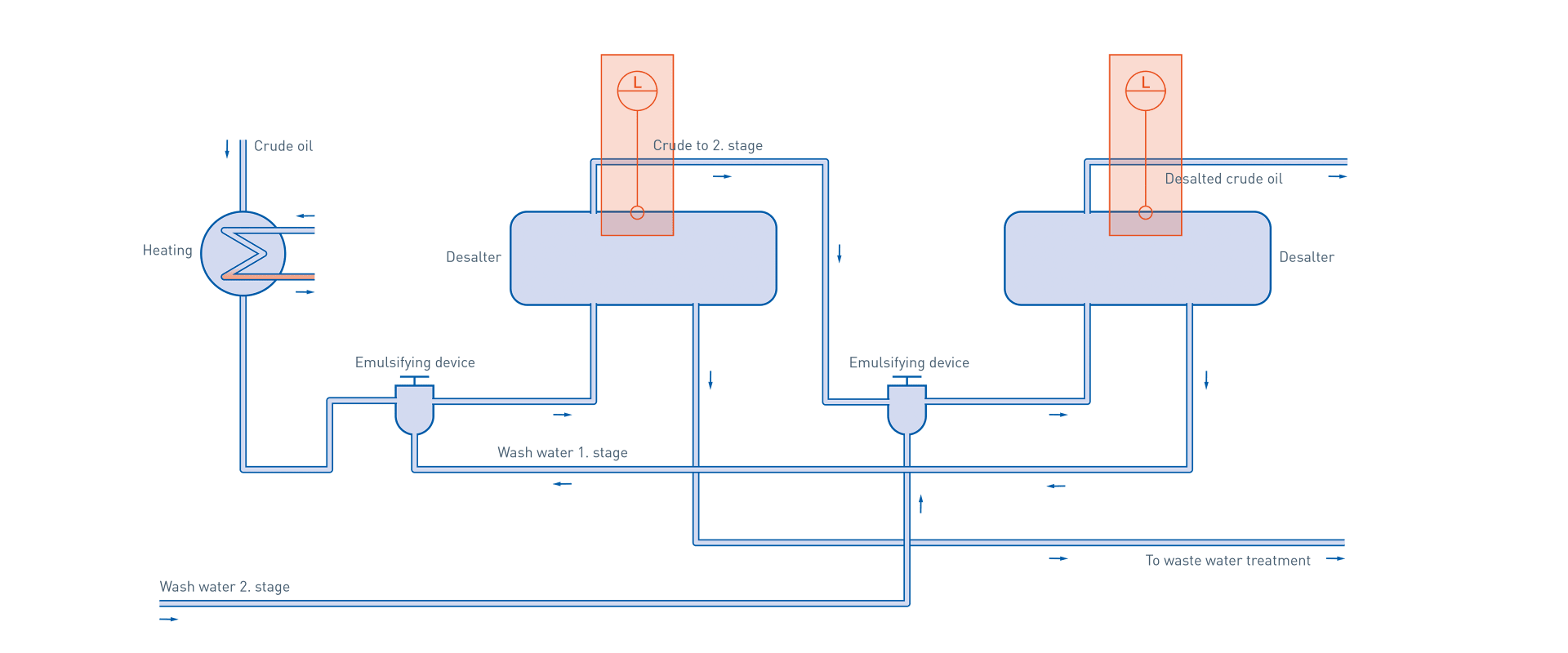

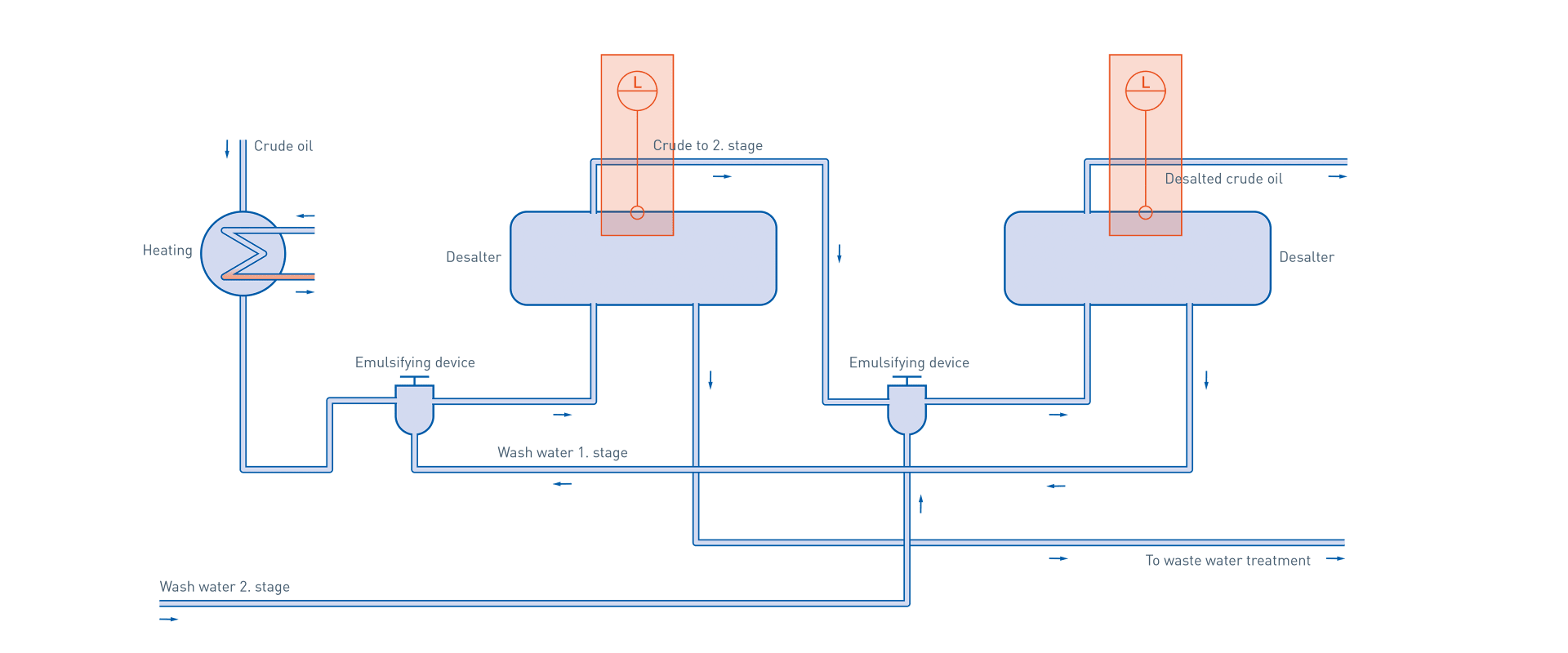

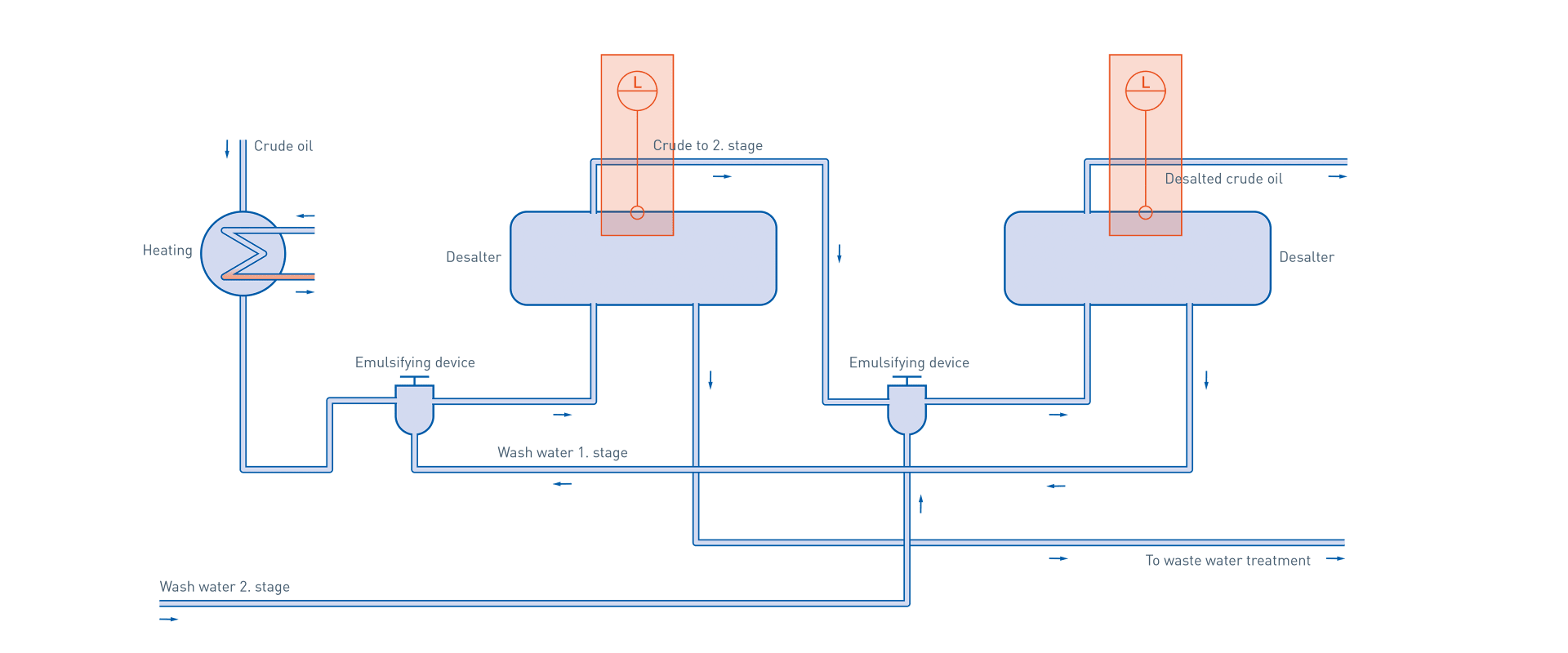

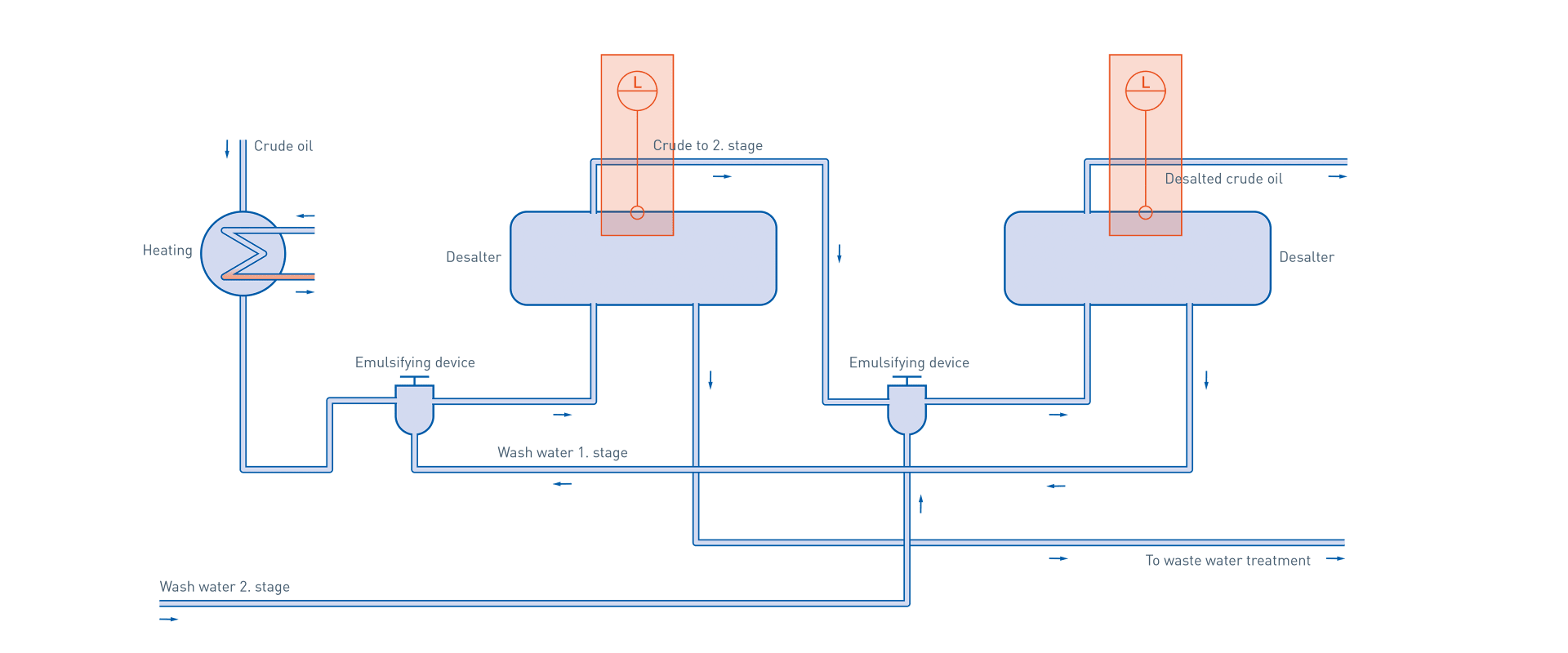

The purpose of desalting is to remove undesirable impurities in the crude oil: these are salts, water and base sediments, which can all cause problems later in the refining process. Water is present in the oil, in an emulsion mixture: salts such as calcium, sodium and magnesium chlorides are dissolved in the water. At the higher temperatures used in the refinery these could later create hydrochloric acid, which leads to corrosion in the plant. Deposits of the sediments can foul heat exchangers and cause plugging. Also metals like sodium and arsenic can poison the catalysts used in later stages.

The crude desalting process uses a demulsifying agent, which is a combination of chemicals injected into the oil to break and separate the emulsion, and there is a fresh water wash to extract the impurities. This is typically repeated to ensure dilution of the impurity concentrations. The desalter operates at around 150oC, and crude oil desalting instrumentation such as interface level measurement systems control the separation process. The wash water is discharged to a wastewater treatment plant.

KROHNE supplies flowmeters to measure the flow of crude oil and wash water both to and from the desalter. Also, TDR radar level measurement equipment to control the oil/water interface in the separators used in the desalting process is available from KROHNE.

Process details

Crude desalting in the oil & gas industry

Requirements:

- Process control

- Contamination of the crude oil could block mechanical meters

Recommended products and solutions:

OPTIMASS 2400

- For gases and liquids up to 4,600 t/h; maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- CT: OIML R117, MI-005, MI-002; API and AGA compliant

- Flange: DN100…400 / 4…16", max. PN160 / ASME Cl 1500

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

Requirements:

- Determine amount of waste water

- Enable process control

Recommended products and solutions:

OPTIFLUX 4300

- High accuracy (±0.2%), certified for custody transfer

- For low conductivity media (>1 μS/cm) and high solid contents (≤70%)

- Flange: DN2.5…3000 / ⅒…120", max. PN40 / ASME Cl 300

- 3 x 4…20 mA, HART®,Modbus, FF, Profibus-PA/DP, PROFINET

OPTISONIC 6300

- Stationary device, for installation at any location without process interruption or need to cut pipes

- Up to +200°C / +392°F

- Robust stainless steel sensor rail for pipes DN15…4000 / ½…160"

- 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP

Requirements:

- Continuous measurement to prevent oil from entering waste waster

- Varying levels of oil and water

- Corrosive media

Recommended products and solutions:

OPTIFLEX 1300

- Continuous measurement of level, distance, volume, mass or liquid-liquid interface

- Measuring range: 0.2…35 m / 0.7…115 ft (liquids), 0.2…35 m / 0.7…115 ft (solids)

- -50…+300°C / -58…+572°F; -1…300 barg / -14.5…4350 psig

Requirements:

- Process control

- Fluid contains traces of hydrocarbons

- Corrosive media

Recommended products and solutions:

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

Requirements:

- Determine amount of waste water

- Enable process control

Recommended products and solutions:

OPTIFLUX 4300

- High accuracy (±0.2%), certified for custody transfer

- For low conductivity media (>1 μS/cm) and high solid contents (≤70%)

- Flange: DN2.5…3000 / ⅒…120", max. PN40 / ASME Cl 300

- 3 x 4…20 mA, HART®,Modbus, FF, Profibus-PA/DP, PROFINET

Crude desalting in the oil & gas industry

Requirements:

- Process control

- Contamination of the crude oil could block mechanical meters

Recommended products and solutions:

OPTIMASS 2400

- For gases and liquids up to 4,600 t/h; maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- CT: OIML R117, MI-005, MI-002; API and AGA compliant

- Flange: DN100…400 / 4…16", max. PN160 / ASME Cl 1500

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

Requirements:

- Determine amount of waste water

- Enable process control

Recommended products and solutions:

OPTIFLUX 4300

- High accuracy (±0.2%), certified for custody transfer

- For low conductivity media (>1 μS/cm) and high solid contents (≤70%)

- Flange: DN2.5…3000 / ⅒…120", max. PN40 / ASME Cl 300

- 3 x 4…20 mA, HART®,Modbus, FF, Profibus-PA/DP, PROFINET

OPTISONIC 6300

- Stationary device, for installation at any location without process interruption or need to cut pipes

- Up to +200°C / +392°F

- Robust stainless steel sensor rail for pipes DN15…4000 / ½…160"

- 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP

Requirements:

- Continuous measurement to prevent oil from entering waste waster

- Varying levels of oil and water

- Corrosive media

Recommended products and solutions:

OPTIFLEX 1300

- Continuous measurement of level, distance, volume, mass or liquid-liquid interface

- Measuring range: 0.2…35 m / 0.7…115 ft (liquids), 0.2…35 m / 0.7…115 ft (solids)

- -50…+300°C / -58…+572°F; -1…300 barg / -14.5…4350 psig

Requirements:

- Process control

- Fluid contains traces of hydrocarbons

- Corrosive media

Recommended products and solutions:

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

Requirements:

- Determine amount of waste water

- Enable process control

Recommended products and solutions:

OPTIFLUX 4300

- High accuracy (±0.2%), certified for custody transfer

- For low conductivity media (>1 μS/cm) and high solid contents (≤70%)

- Flange: DN2.5…3000 / ⅒…120", max. PN40 / ASME Cl 300

- 3 x 4…20 mA, HART®,Modbus, FF, Profibus-PA/DP, PROFINET

Requirements:

- Process control

- Contamination of the crude oil could block mechanical meters

Recommended products and solutions:

Crude desalting in the oil & gas industry

Requirements:

- Process control

- Contamination of the crude oil could block mechanical meters

Recommended products and solutions:

OPTIMASS 2400

- For gases and liquids up to 4,600 t/h; maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- CT: OIML R117, MI-005, MI-002; API and AGA compliant

- Flange: DN100…400 / 4…16", max. PN160 / ASME Cl 1500

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

Requirements:

- Determine amount of waste water

- Enable process control

Recommended products and solutions:

OPTIFLUX 4300

- High accuracy (±0.2%), certified for custody transfer

- For low conductivity media (>1 μS/cm) and high solid contents (≤70%)

- Flange: DN2.5…3000 / ⅒…120", max. PN40 / ASME Cl 300

- 3 x 4…20 mA, HART®,Modbus, FF, Profibus-PA/DP, PROFINET

OPTISONIC 6300

- Stationary device, for installation at any location without process interruption or need to cut pipes

- Up to +200°C / +392°F

- Robust stainless steel sensor rail for pipes DN15…4000 / ½…160"

- 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP

Requirements:

- Continuous measurement to prevent oil from entering waste waster

- Varying levels of oil and water

- Corrosive media

Recommended products and solutions:

OPTIFLEX 1300

- Continuous measurement of level, distance, volume, mass or liquid-liquid interface

- Measuring range: 0.2…35 m / 0.7…115 ft (liquids), 0.2…35 m / 0.7…115 ft (solids)

- -50…+300°C / -58…+572°F; -1…300 barg / -14.5…4350 psig

Requirements:

- Process control

- Fluid contains traces of hydrocarbons

- Corrosive media

Recommended products and solutions:

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

Requirements:

- Determine amount of waste water

- Enable process control

Recommended products and solutions:

OPTIFLUX 4300

- High accuracy (±0.2%), certified for custody transfer

- For low conductivity media (>1 μS/cm) and high solid contents (≤70%)

- Flange: DN2.5…3000 / ⅒…120", max. PN40 / ASME Cl 300

- 3 x 4…20 mA, HART®,Modbus, FF, Profibus-PA/DP, PROFINET

Requirements:

- Determine amount of waste water

- Enable process control

Recommended products and solutions:

OPTIFLUX 4300

Electromagnetic flowmeter for advanced process and custody transfer (CT) applications

Crude desalting in the oil & gas industry

Requirements:

- Process control

- Contamination of the crude oil could block mechanical meters

Recommended products and solutions:

OPTIMASS 2400

- For gases and liquids up to 4,600 t/h; maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- CT: OIML R117, MI-005, MI-002; API and AGA compliant

- Flange: DN100…400 / 4…16", max. PN160 / ASME Cl 1500

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

Requirements:

- Determine amount of waste water

- Enable process control

Recommended products and solutions:

OPTIFLUX 4300

- High accuracy (±0.2%), certified for custody transfer

- For low conductivity media (>1 μS/cm) and high solid contents (≤70%)

- Flange: DN2.5…3000 / ⅒…120", max. PN40 / ASME Cl 300

- 3 x 4…20 mA, HART®,Modbus, FF, Profibus-PA/DP, PROFINET

OPTISONIC 6300

- Stationary device, for installation at any location without process interruption or need to cut pipes

- Up to +200°C / +392°F

- Robust stainless steel sensor rail for pipes DN15…4000 / ½…160"

- 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP

Requirements:

- Continuous measurement to prevent oil from entering waste waster

- Varying levels of oil and water

- Corrosive media

Recommended products and solutions:

OPTIFLEX 1300

- Continuous measurement of level, distance, volume, mass or liquid-liquid interface

- Measuring range: 0.2…35 m / 0.7…115 ft (liquids), 0.2…35 m / 0.7…115 ft (solids)

- -50…+300°C / -58…+572°F; -1…300 barg / -14.5…4350 psig

Requirements:

- Process control

- Fluid contains traces of hydrocarbons

- Corrosive media

Recommended products and solutions:

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

Requirements:

- Determine amount of waste water

- Enable process control

Recommended products and solutions:

OPTIFLUX 4300

- High accuracy (±0.2%), certified for custody transfer

- For low conductivity media (>1 μS/cm) and high solid contents (≤70%)

- Flange: DN2.5…3000 / ⅒…120", max. PN40 / ASME Cl 300

- 3 x 4…20 mA, HART®,Modbus, FF, Profibus-PA/DP, PROFINET

Requirements:

- Continuous measurement to prevent oil from entering waste waster

- Varying levels of oil and water

- Corrosive media

Recommended products and solutions:

OPTIFLEX 1300

Guided radar (TDR) level transmitter for heavy-duty level and interface applications

Crude desalting in the oil & gas industry

Requirements:

- Process control

- Contamination of the crude oil could block mechanical meters

Recommended products and solutions:

OPTIMASS 2400

- For gases and liquids up to 4,600 t/h; maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- CT: OIML R117, MI-005, MI-002; API and AGA compliant

- Flange: DN100…400 / 4…16", max. PN160 / ASME Cl 1500

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

Requirements:

- Determine amount of waste water

- Enable process control

Recommended products and solutions:

OPTIFLUX 4300

- High accuracy (±0.2%), certified for custody transfer

- For low conductivity media (>1 μS/cm) and high solid contents (≤70%)

- Flange: DN2.5…3000 / ⅒…120", max. PN40 / ASME Cl 300

- 3 x 4…20 mA, HART®,Modbus, FF, Profibus-PA/DP, PROFINET

OPTISONIC 6300

- Stationary device, for installation at any location without process interruption or need to cut pipes

- Up to +200°C / +392°F

- Robust stainless steel sensor rail for pipes DN15…4000 / ½…160"

- 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP

Requirements:

- Continuous measurement to prevent oil from entering waste waster

- Varying levels of oil and water

- Corrosive media

Recommended products and solutions:

OPTIFLEX 1300

- Continuous measurement of level, distance, volume, mass or liquid-liquid interface

- Measuring range: 0.2…35 m / 0.7…115 ft (liquids), 0.2…35 m / 0.7…115 ft (solids)

- -50…+300°C / -58…+572°F; -1…300 barg / -14.5…4350 psig

Requirements:

- Process control

- Fluid contains traces of hydrocarbons

- Corrosive media

Recommended products and solutions:

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

Requirements:

- Determine amount of waste water

- Enable process control

Recommended products and solutions:

OPTIFLUX 4300

- High accuracy (±0.2%), certified for custody transfer

- For low conductivity media (>1 μS/cm) and high solid contents (≤70%)

- Flange: DN2.5…3000 / ⅒…120", max. PN40 / ASME Cl 300

- 3 x 4…20 mA, HART®,Modbus, FF, Profibus-PA/DP, PROFINET

Requirements:

- Process control

- Fluid contains traces of hydrocarbons

- Corrosive media

Recommended products and solutions:

Crude desalting in the oil & gas industry

Requirements:

- Process control

- Contamination of the crude oil could block mechanical meters

Recommended products and solutions:

OPTIMASS 2400

- For gases and liquids up to 4,600 t/h; maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- CT: OIML R117, MI-005, MI-002; API and AGA compliant

- Flange: DN100…400 / 4…16", max. PN160 / ASME Cl 1500

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

Requirements:

- Determine amount of waste water

- Enable process control

Recommended products and solutions:

OPTIFLUX 4300

- High accuracy (±0.2%), certified for custody transfer

- For low conductivity media (>1 μS/cm) and high solid contents (≤70%)

- Flange: DN2.5…3000 / ⅒…120", max. PN40 / ASME Cl 300

- 3 x 4…20 mA, HART®,Modbus, FF, Profibus-PA/DP, PROFINET

OPTISONIC 6300

- Stationary device, for installation at any location without process interruption or need to cut pipes

- Up to +200°C / +392°F

- Robust stainless steel sensor rail for pipes DN15…4000 / ½…160"

- 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP

Requirements:

- Continuous measurement to prevent oil from entering waste waster

- Varying levels of oil and water

- Corrosive media

Recommended products and solutions:

OPTIFLEX 1300

- Continuous measurement of level, distance, volume, mass or liquid-liquid interface

- Measuring range: 0.2…35 m / 0.7…115 ft (liquids), 0.2…35 m / 0.7…115 ft (solids)

- -50…+300°C / -58…+572°F; -1…300 barg / -14.5…4350 psig

Requirements:

- Process control

- Fluid contains traces of hydrocarbons

- Corrosive media

Recommended products and solutions:

OPTISONIC 3400

- Accurate 3-path meter: large dynamic range, maintenance-free, no pressure loss

- Cryogenic (-200°C/-328°F) and HT (+250°C/+482°F) versions; viscosities up to over 1000 cSt

- Flange: DN25…3000 / 1…120", max. PN200 / ASME Cl 1500; also weld-ends

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP

Requirements:

- Determine amount of waste water

- Enable process control

Recommended products and solutions:

OPTIFLUX 4300

- High accuracy (±0.2%), certified for custody transfer

- For low conductivity media (>1 μS/cm) and high solid contents (≤70%)

- Flange: DN2.5…3000 / ⅒…120", max. PN40 / ASME Cl 300

- 3 x 4…20 mA, HART®,Modbus, FF, Profibus-PA/DP, PROFINET

Requirements:

- Determine amount of waste water

- Enable process control

Recommended products and solutions:

OPTIFLUX 4300

Electromagnetic flowmeter for advanced process and custody transfer (CT) applications