Water treatment in the oil & gas industry

Ascertainment of abundant water through the extraction

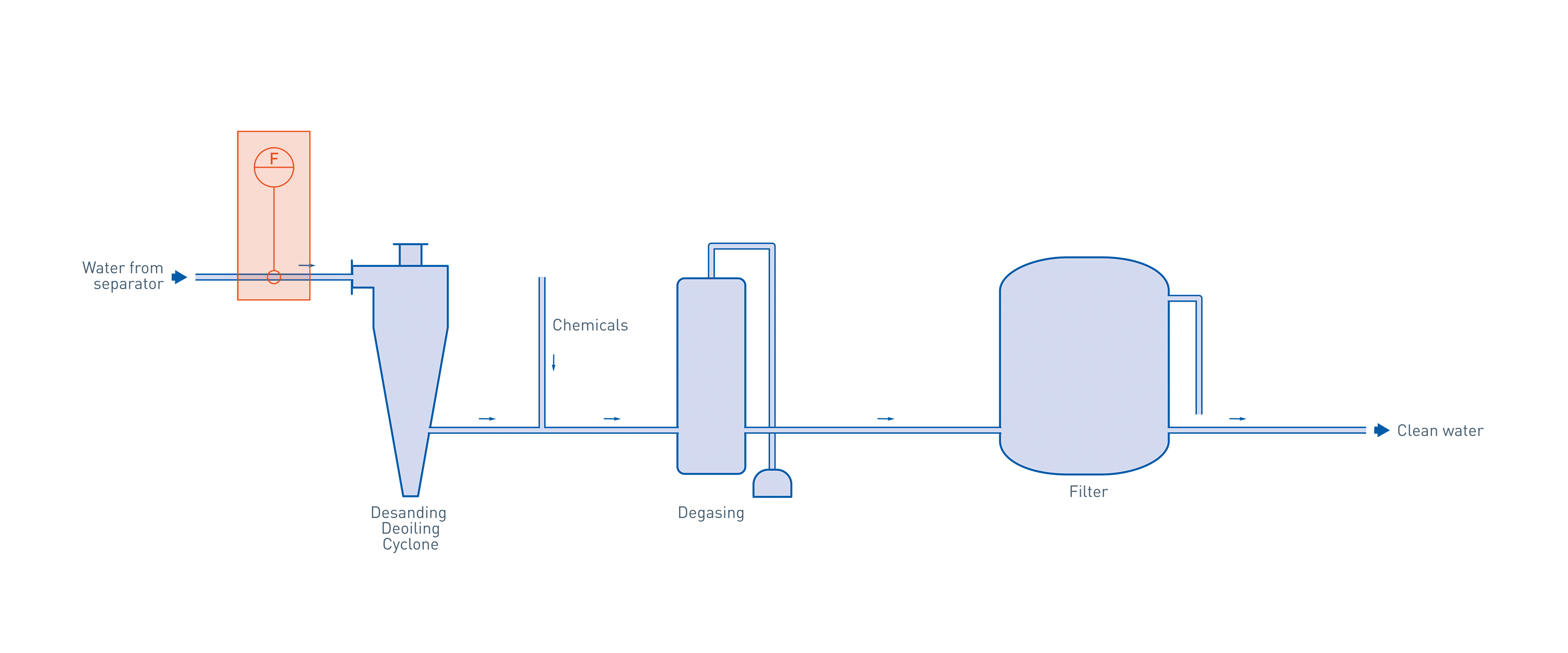

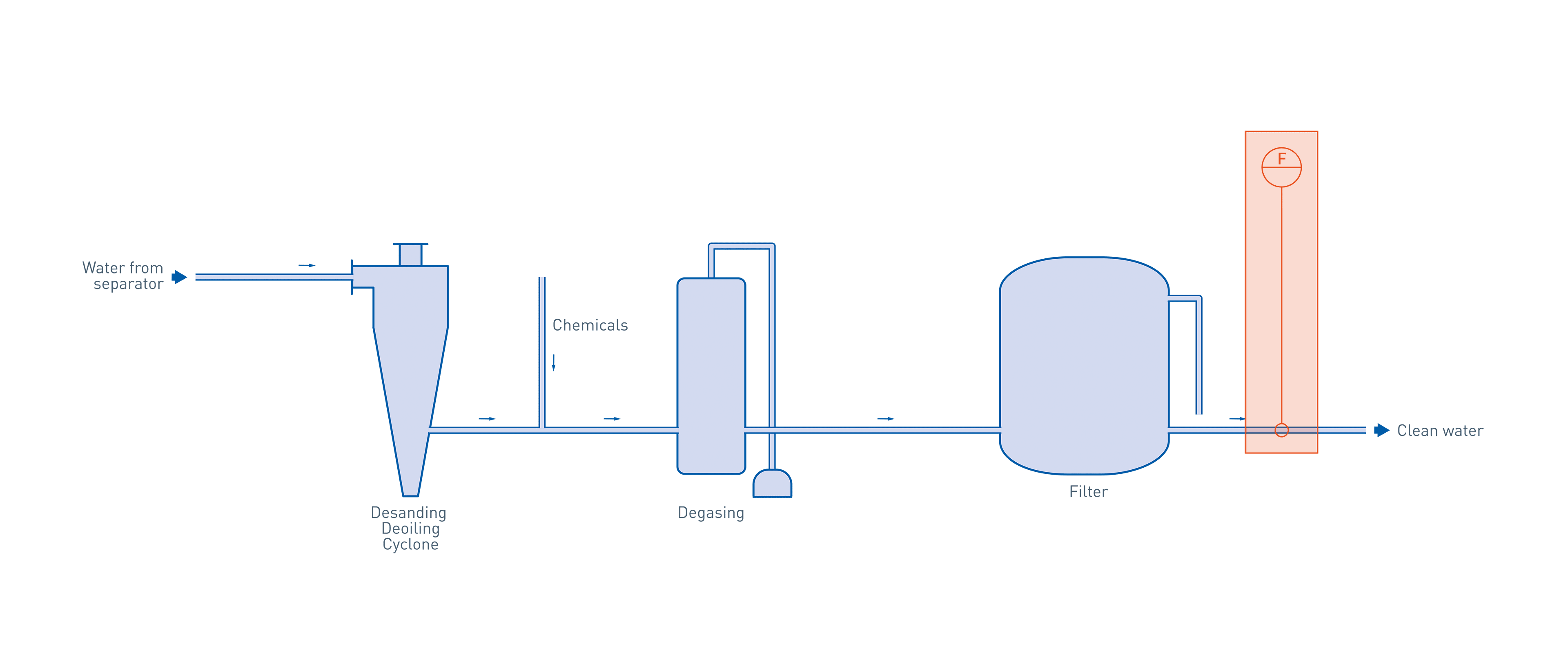

The production and separation processes used in the extraction of oil or gas have a by-product, known as produced water. This comes from water entrained within the oil, and condensing out of the gas: additional water arises when water injection is used to aid the extraction of oil, particularly as the field matures. Significant percentages of water will be present when the field is becoming exhausted, and accurate flow measurement data for produced water is essential.

Such produced water is considered as industrial waste, and needs treatment to remove contaminants before disposal. The techniques used will vary according to whether the water is to be re-injected into the actual production well, or to some different underground formation. If the water is to be used for surface irrigation, evaporation ponds, or for return to the sea, different water treatment processes will be applied, to meet the stricter environmental regulations necessary.

KROHNE has extensive experience in supplying flowmeters, analytical equipment and instrumentation for the water and waste industry, and has developed a complete package of produced water treatment instrumentation. This includes equipment for the analysis, flow measurement, chemical dosing and other processes used in produced water treatment systems - including cyclonic separation, filtration, de-gassing, chemical treatment and flotation.

Process details

Water treatment in the oil & gas industry

Requirements:

- Determine amount of produced water

- Enable process control

Recommended products and solutions:

OPTIFLUX 4300

- High accuracy (±0.2%), certified for custody transfer

- For low conductivity media (>1 μS/cm) and high solid contents (≤70%)

- Flange: DN2.5…3000 / ⅒…120", max. PN40 / ASME Cl 300

- 3 x 4…20 mA, HART®,Modbus, FF, Profibus-PA/DP, PROFINET

Requirements:

- Measuring of level in the funnel

Recommended products and solutions:

OPTISWITCH 3100

- Point level detection of powders and fine-grained bulk solids

- Probe length: 220 mm / 8.7"

- Density: <8 g/l / <0.49 lb/ft3

- -50…+250°C / -58…+482°F; -1…16 barg / -14.5…232 psig

OPTISWITCH 3300

- Point level detection of solids

- Probe length: up to 6 m / 20 ft

- Density: <8 g/l / <0.49 lb/ft3

- -50…+250°C / -58…+482°F; -1…16 psig / -14.5…232 psig

Requirements:

- Indication of the flow of chemicals

- Ensure continuous injection

Recommended products and solutions:

H250 M40

- Modular design: from mechanical indicator to 4…20 mA/HART®7, FF, Profibus-PA and totalizer

- Any installation position: vertical, horizontal or in fall pipes

- Flange: DN15…150 / ½…6"; also NPT, G, hygienic connections, etc.

- -196…+400°C / -320…+752°F; max. 1000 barg / 14500 psig

Requirements:

- Monitor proper functioning of the degasser

Recommended products and solutions:

OPTISWITCH 5100

- Point level detection of liquids

- Large choice of process fittings, housings and electronics

- Density: ≥0.5 g/cm3 / 0.018 lb/in3

- -50…+250°C / -58…+482°F; -1…64 barg / -14.5…928 psig

Requirements:

- Continuous process control

- Measurement of varying flow

Recommended products and solutions:

OPTIFLUX 4300

- High accuracy (±0.2%), certified for custody transfer

- For low conductivity media (>1 μS/cm) and high solid contents (≤70%)

- Flange: DN2.5…3000 / ⅒…120", max. PN40 / ASME Cl 300

- 3 x 4…20 mA, HART®,Modbus, FF, Profibus-PA/DP, PROFINET

Water treatment in the oil & gas industry

Requirements:

- Determine amount of produced water

- Enable process control

Recommended products and solutions:

OPTIFLUX 4300

- High accuracy (±0.2%), certified for custody transfer

- For low conductivity media (>1 μS/cm) and high solid contents (≤70%)

- Flange: DN2.5…3000 / ⅒…120", max. PN40 / ASME Cl 300

- 3 x 4…20 mA, HART®,Modbus, FF, Profibus-PA/DP, PROFINET

Requirements:

- Measuring of level in the funnel

Recommended products and solutions:

OPTISWITCH 3100

- Point level detection of powders and fine-grained bulk solids

- Probe length: 220 mm / 8.7"

- Density: <8 g/l / <0.49 lb/ft3

- -50…+250°C / -58…+482°F; -1…16 barg / -14.5…232 psig

OPTISWITCH 3300

- Point level detection of solids

- Probe length: up to 6 m / 20 ft

- Density: <8 g/l / <0.49 lb/ft3

- -50…+250°C / -58…+482°F; -1…16 psig / -14.5…232 psig

Requirements:

- Indication of the flow of chemicals

- Ensure continuous injection

Recommended products and solutions:

H250 M40

- Modular design: from mechanical indicator to 4…20 mA/HART®7, FF, Profibus-PA and totalizer

- Any installation position: vertical, horizontal or in fall pipes

- Flange: DN15…150 / ½…6"; also NPT, G, hygienic connections, etc.

- -196…+400°C / -320…+752°F; max. 1000 barg / 14500 psig

Requirements:

- Monitor proper functioning of the degasser

Recommended products and solutions:

OPTISWITCH 5100

- Point level detection of liquids

- Large choice of process fittings, housings and electronics

- Density: ≥0.5 g/cm3 / 0.018 lb/in3

- -50…+250°C / -58…+482°F; -1…64 barg / -14.5…928 psig

Requirements:

- Continuous process control

- Measurement of varying flow

Recommended products and solutions:

OPTIFLUX 4300

- High accuracy (±0.2%), certified for custody transfer

- For low conductivity media (>1 μS/cm) and high solid contents (≤70%)

- Flange: DN2.5…3000 / ⅒…120", max. PN40 / ASME Cl 300

- 3 x 4…20 mA, HART®,Modbus, FF, Profibus-PA/DP, PROFINET

Requirements:

- Determine amount of produced water

- Enable process control

Recommended products and solutions:

OPTIFLUX 4300

Electromagnetic flowmeter for advanced process and custody transfer (CT) applications

Water treatment in the oil & gas industry

Requirements:

- Determine amount of produced water

- Enable process control

Recommended products and solutions:

OPTIFLUX 4300

- High accuracy (±0.2%), certified for custody transfer

- For low conductivity media (>1 μS/cm) and high solid contents (≤70%)

- Flange: DN2.5…3000 / ⅒…120", max. PN40 / ASME Cl 300

- 3 x 4…20 mA, HART®,Modbus, FF, Profibus-PA/DP, PROFINET

Requirements:

- Measuring of level in the funnel

Recommended products and solutions:

OPTISWITCH 3100

- Point level detection of powders and fine-grained bulk solids

- Probe length: 220 mm / 8.7"

- Density: <8 g/l / <0.49 lb/ft3

- -50…+250°C / -58…+482°F; -1…16 barg / -14.5…232 psig

OPTISWITCH 3300

- Point level detection of solids

- Probe length: up to 6 m / 20 ft

- Density: <8 g/l / <0.49 lb/ft3

- -50…+250°C / -58…+482°F; -1…16 psig / -14.5…232 psig

Requirements:

- Indication of the flow of chemicals

- Ensure continuous injection

Recommended products and solutions:

H250 M40

- Modular design: from mechanical indicator to 4…20 mA/HART®7, FF, Profibus-PA and totalizer

- Any installation position: vertical, horizontal or in fall pipes

- Flange: DN15…150 / ½…6"; also NPT, G, hygienic connections, etc.

- -196…+400°C / -320…+752°F; max. 1000 barg / 14500 psig

Requirements:

- Monitor proper functioning of the degasser

Recommended products and solutions:

OPTISWITCH 5100

- Point level detection of liquids

- Large choice of process fittings, housings and electronics

- Density: ≥0.5 g/cm3 / 0.018 lb/in3

- -50…+250°C / -58…+482°F; -1…64 barg / -14.5…928 psig

Requirements:

- Continuous process control

- Measurement of varying flow

Recommended products and solutions:

OPTIFLUX 4300

- High accuracy (±0.2%), certified for custody transfer

- For low conductivity media (>1 μS/cm) and high solid contents (≤70%)

- Flange: DN2.5…3000 / ⅒…120", max. PN40 / ASME Cl 300

- 3 x 4…20 mA, HART®,Modbus, FF, Profibus-PA/DP, PROFINET

Requirements:

- Measuring of level in the funnel

Recommended products and solutions:

OPTISWITCH 3300

Vibration level switch with rigid extension for solid applications

Water treatment in the oil & gas industry

Requirements:

- Determine amount of produced water

- Enable process control

Recommended products and solutions:

OPTIFLUX 4300

- High accuracy (±0.2%), certified for custody transfer

- For low conductivity media (>1 μS/cm) and high solid contents (≤70%)

- Flange: DN2.5…3000 / ⅒…120", max. PN40 / ASME Cl 300

- 3 x 4…20 mA, HART®,Modbus, FF, Profibus-PA/DP, PROFINET

Requirements:

- Measuring of level in the funnel

Recommended products and solutions:

OPTISWITCH 3100

- Point level detection of powders and fine-grained bulk solids

- Probe length: 220 mm / 8.7"

- Density: <8 g/l / <0.49 lb/ft3

- -50…+250°C / -58…+482°F; -1…16 barg / -14.5…232 psig

OPTISWITCH 3300

- Point level detection of solids

- Probe length: up to 6 m / 20 ft

- Density: <8 g/l / <0.49 lb/ft3

- -50…+250°C / -58…+482°F; -1…16 psig / -14.5…232 psig

Requirements:

- Indication of the flow of chemicals

- Ensure continuous injection

Recommended products and solutions:

H250 M40

- Modular design: from mechanical indicator to 4…20 mA/HART®7, FF, Profibus-PA and totalizer

- Any installation position: vertical, horizontal or in fall pipes

- Flange: DN15…150 / ½…6"; also NPT, G, hygienic connections, etc.

- -196…+400°C / -320…+752°F; max. 1000 barg / 14500 psig

Requirements:

- Monitor proper functioning of the degasser

Recommended products and solutions:

OPTISWITCH 5100

- Point level detection of liquids

- Large choice of process fittings, housings and electronics

- Density: ≥0.5 g/cm3 / 0.018 lb/in3

- -50…+250°C / -58…+482°F; -1…64 barg / -14.5…928 psig

Requirements:

- Continuous process control

- Measurement of varying flow

Recommended products and solutions:

OPTIFLUX 4300

- High accuracy (±0.2%), certified for custody transfer

- For low conductivity media (>1 μS/cm) and high solid contents (≤70%)

- Flange: DN2.5…3000 / ⅒…120", max. PN40 / ASME Cl 300

- 3 x 4…20 mA, HART®,Modbus, FF, Profibus-PA/DP, PROFINET

Requirements:

- Indication of the flow of chemicals

- Ensure continuous injection

Recommended products and solutions:

Water treatment in the oil & gas industry

Requirements:

- Determine amount of produced water

- Enable process control

Recommended products and solutions:

OPTIFLUX 4300

- High accuracy (±0.2%), certified for custody transfer

- For low conductivity media (>1 μS/cm) and high solid contents (≤70%)

- Flange: DN2.5…3000 / ⅒…120", max. PN40 / ASME Cl 300

- 3 x 4…20 mA, HART®,Modbus, FF, Profibus-PA/DP, PROFINET

Requirements:

- Measuring of level in the funnel

Recommended products and solutions:

OPTISWITCH 3100

- Point level detection of powders and fine-grained bulk solids

- Probe length: 220 mm / 8.7"

- Density: <8 g/l / <0.49 lb/ft3

- -50…+250°C / -58…+482°F; -1…16 barg / -14.5…232 psig

OPTISWITCH 3300

- Point level detection of solids

- Probe length: up to 6 m / 20 ft

- Density: <8 g/l / <0.49 lb/ft3

- -50…+250°C / -58…+482°F; -1…16 psig / -14.5…232 psig

Requirements:

- Indication of the flow of chemicals

- Ensure continuous injection

Recommended products and solutions:

H250 M40

- Modular design: from mechanical indicator to 4…20 mA/HART®7, FF, Profibus-PA and totalizer

- Any installation position: vertical, horizontal or in fall pipes

- Flange: DN15…150 / ½…6"; also NPT, G, hygienic connections, etc.

- -196…+400°C / -320…+752°F; max. 1000 barg / 14500 psig

Requirements:

- Monitor proper functioning of the degasser

Recommended products and solutions:

OPTISWITCH 5100

- Point level detection of liquids

- Large choice of process fittings, housings and electronics

- Density: ≥0.5 g/cm3 / 0.018 lb/in3

- -50…+250°C / -58…+482°F; -1…64 barg / -14.5…928 psig

Requirements:

- Continuous process control

- Measurement of varying flow

Recommended products and solutions:

OPTIFLUX 4300

- High accuracy (±0.2%), certified for custody transfer

- For low conductivity media (>1 μS/cm) and high solid contents (≤70%)

- Flange: DN2.5…3000 / ⅒…120", max. PN40 / ASME Cl 300

- 3 x 4…20 mA, HART®,Modbus, FF, Profibus-PA/DP, PROFINET

Requirements:

- Monitor proper functioning of the degasser

Recommended products and solutions:

Water treatment in the oil & gas industry

Requirements:

- Determine amount of produced water

- Enable process control

Recommended products and solutions:

OPTIFLUX 4300

- High accuracy (±0.2%), certified for custody transfer

- For low conductivity media (>1 μS/cm) and high solid contents (≤70%)

- Flange: DN2.5…3000 / ⅒…120", max. PN40 / ASME Cl 300

- 3 x 4…20 mA, HART®,Modbus, FF, Profibus-PA/DP, PROFINET

Requirements:

- Measuring of level in the funnel

Recommended products and solutions:

OPTISWITCH 3100

- Point level detection of powders and fine-grained bulk solids

- Probe length: 220 mm / 8.7"

- Density: <8 g/l / <0.49 lb/ft3

- -50…+250°C / -58…+482°F; -1…16 barg / -14.5…232 psig

OPTISWITCH 3300

- Point level detection of solids

- Probe length: up to 6 m / 20 ft

- Density: <8 g/l / <0.49 lb/ft3

- -50…+250°C / -58…+482°F; -1…16 psig / -14.5…232 psig

Requirements:

- Indication of the flow of chemicals

- Ensure continuous injection

Recommended products and solutions:

H250 M40

- Modular design: from mechanical indicator to 4…20 mA/HART®7, FF, Profibus-PA and totalizer

- Any installation position: vertical, horizontal or in fall pipes

- Flange: DN15…150 / ½…6"; also NPT, G, hygienic connections, etc.

- -196…+400°C / -320…+752°F; max. 1000 barg / 14500 psig

Requirements:

- Monitor proper functioning of the degasser

Recommended products and solutions:

OPTISWITCH 5100

- Point level detection of liquids

- Large choice of process fittings, housings and electronics

- Density: ≥0.5 g/cm3 / 0.018 lb/in3

- -50…+250°C / -58…+482°F; -1…64 barg / -14.5…928 psig

Requirements:

- Continuous process control

- Measurement of varying flow

Recommended products and solutions:

OPTIFLUX 4300

- High accuracy (±0.2%), certified for custody transfer

- For low conductivity media (>1 μS/cm) and high solid contents (≤70%)

- Flange: DN2.5…3000 / ⅒…120", max. PN40 / ASME Cl 300

- 3 x 4…20 mA, HART®,Modbus, FF, Profibus-PA/DP, PROFINET

Requirements:

- Continuous process control

- Measurement of varying flow

Recommended products and solutions:

OPTIFLUX 4300

Electromagnetic flowmeter for advanced process and custody transfer (CT) applications