CIP processes in the food & beverage industry

Periodic cleaning without disassembly

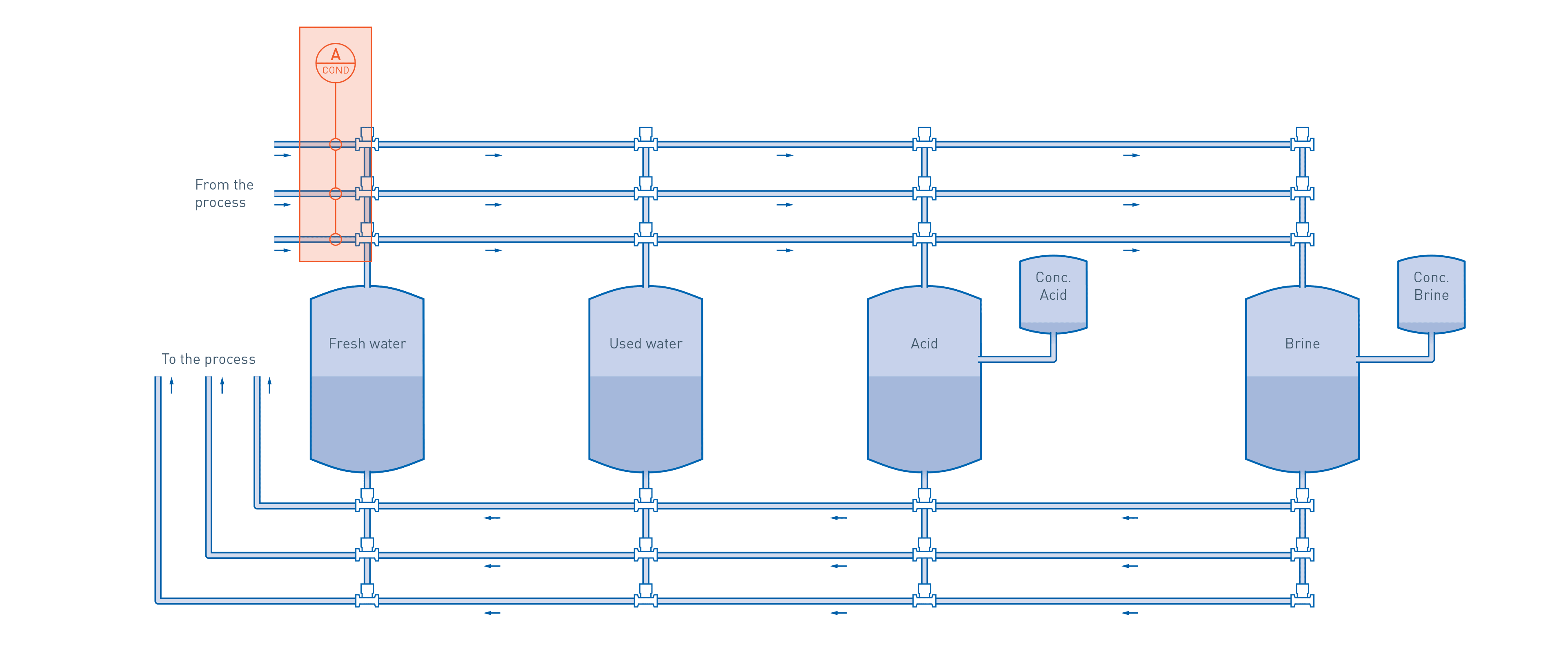

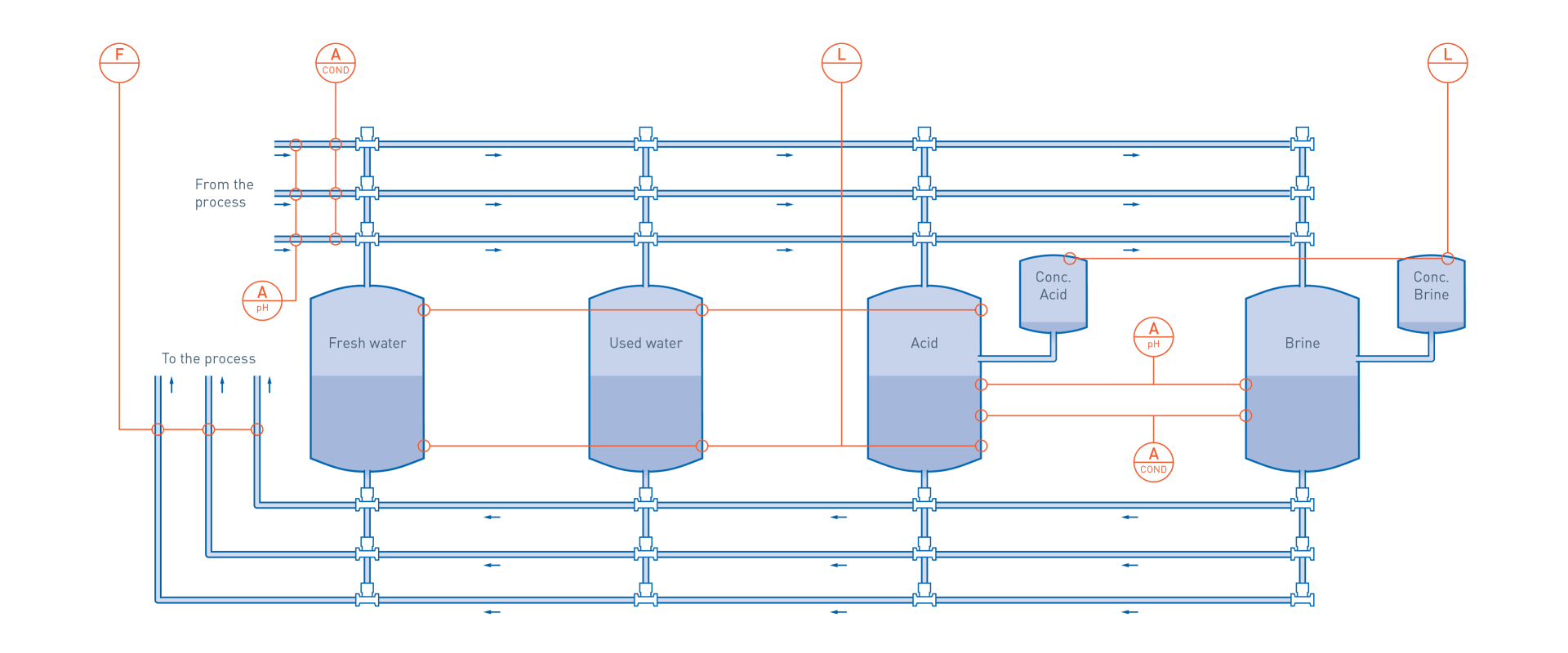

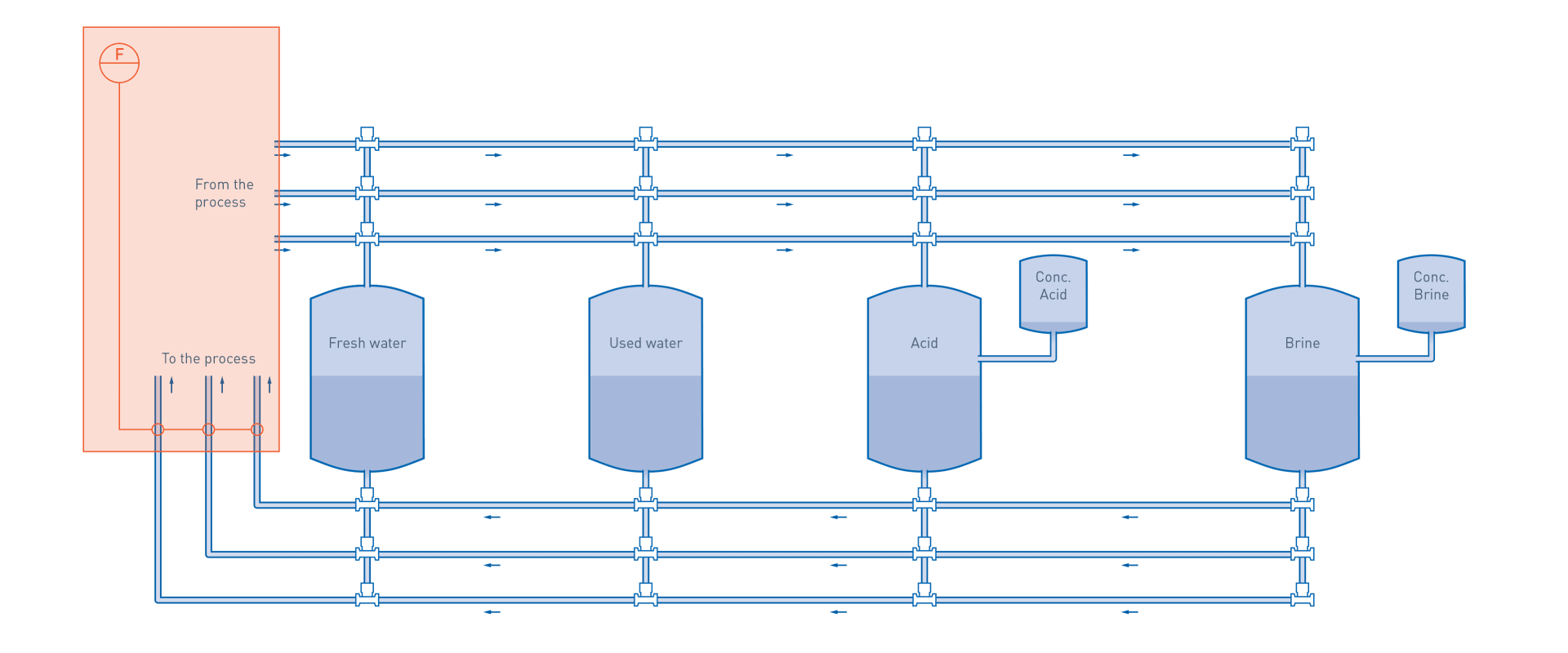

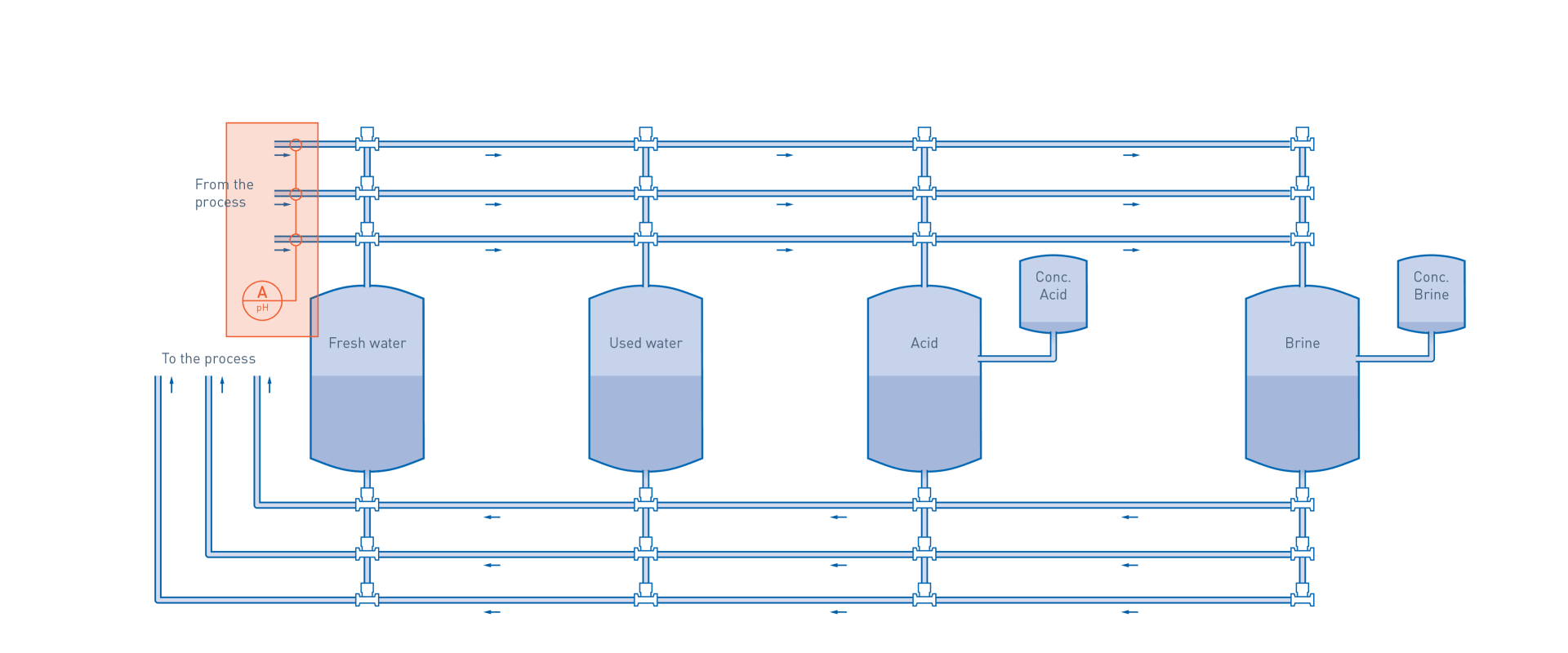

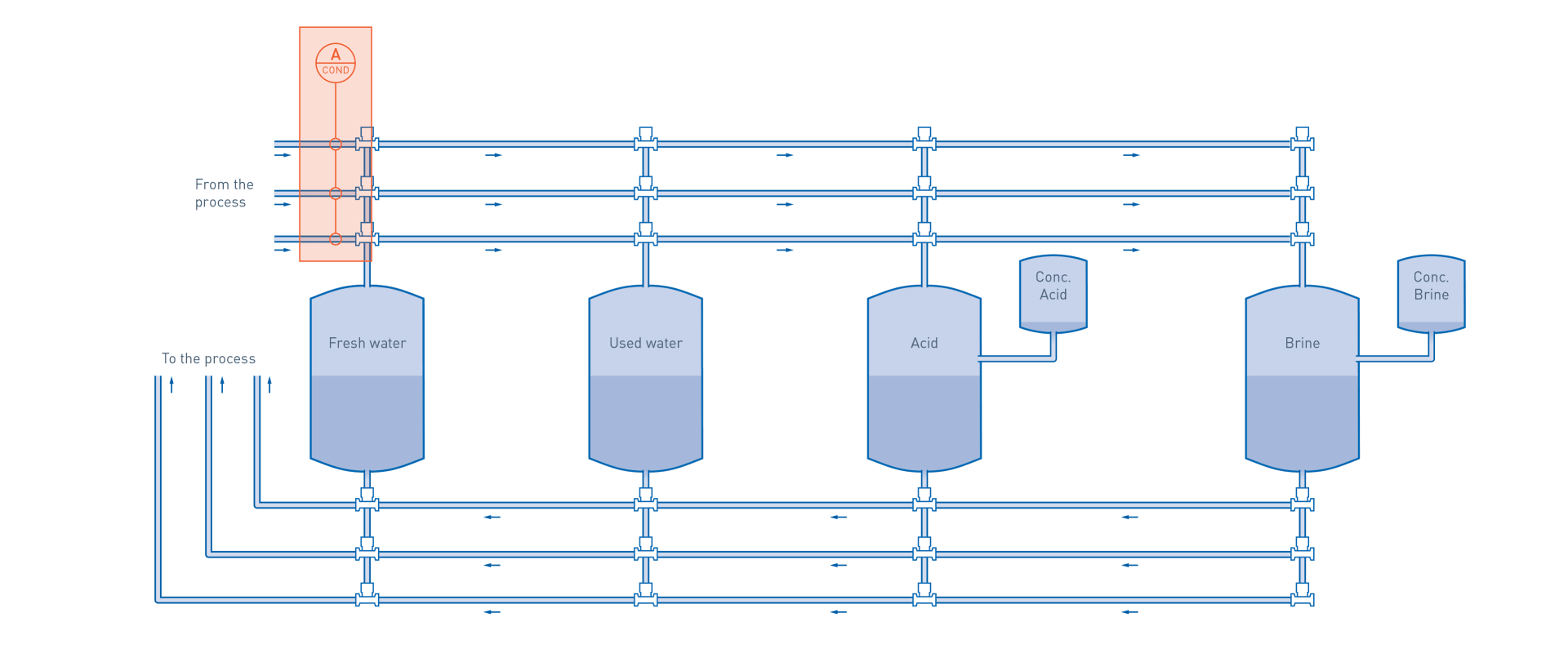

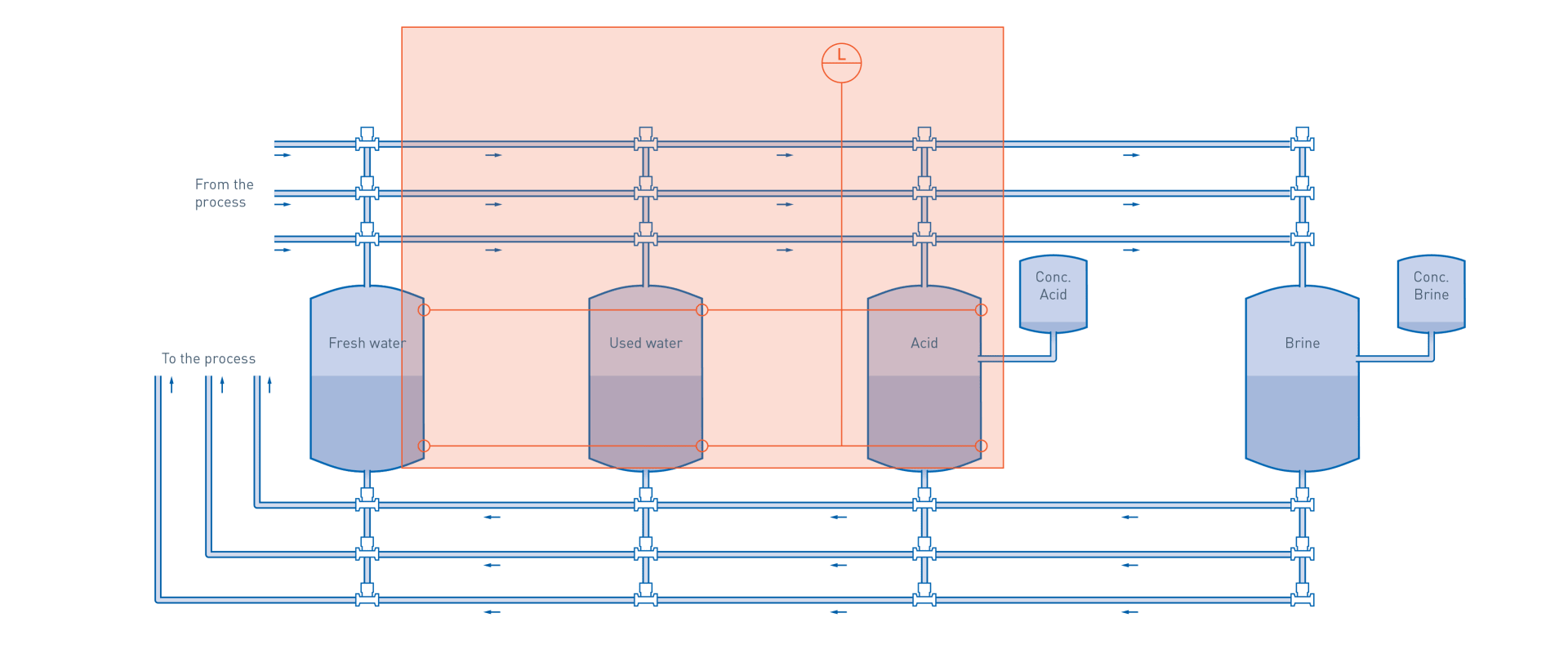

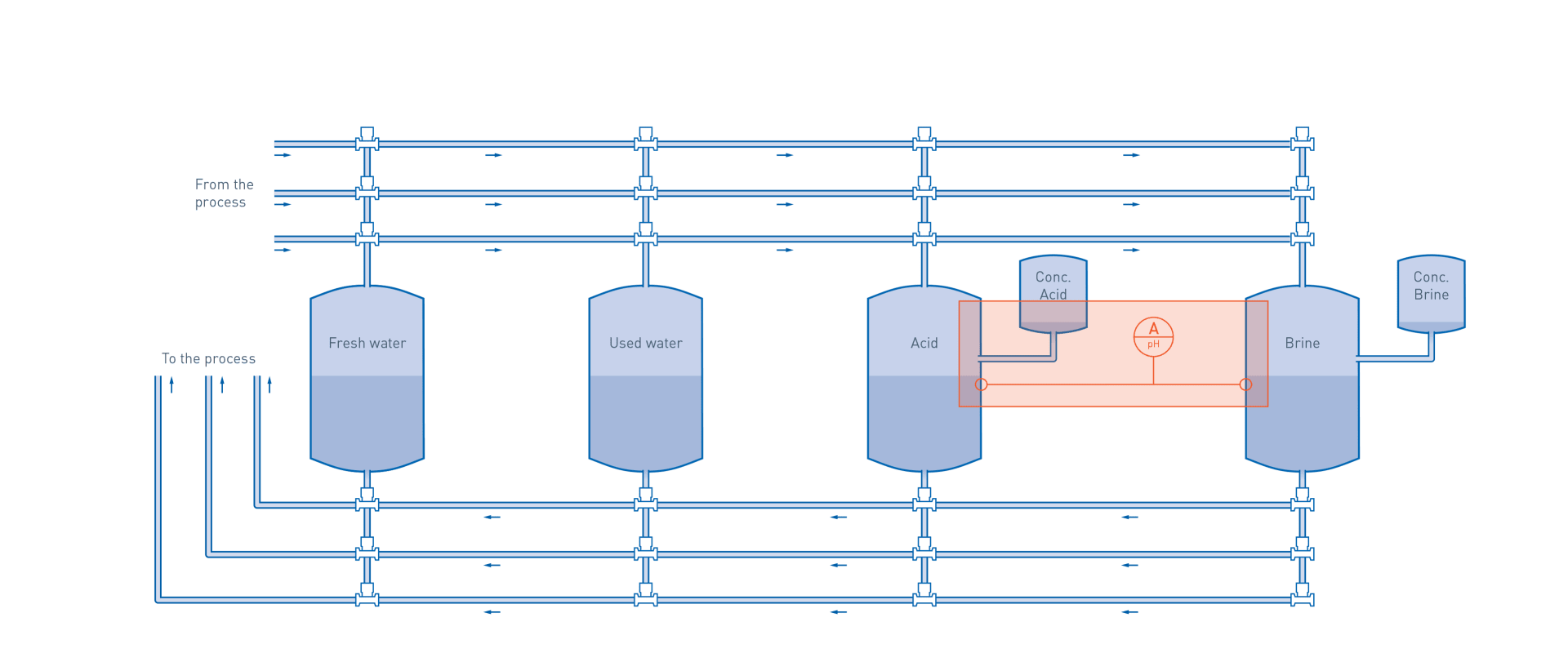

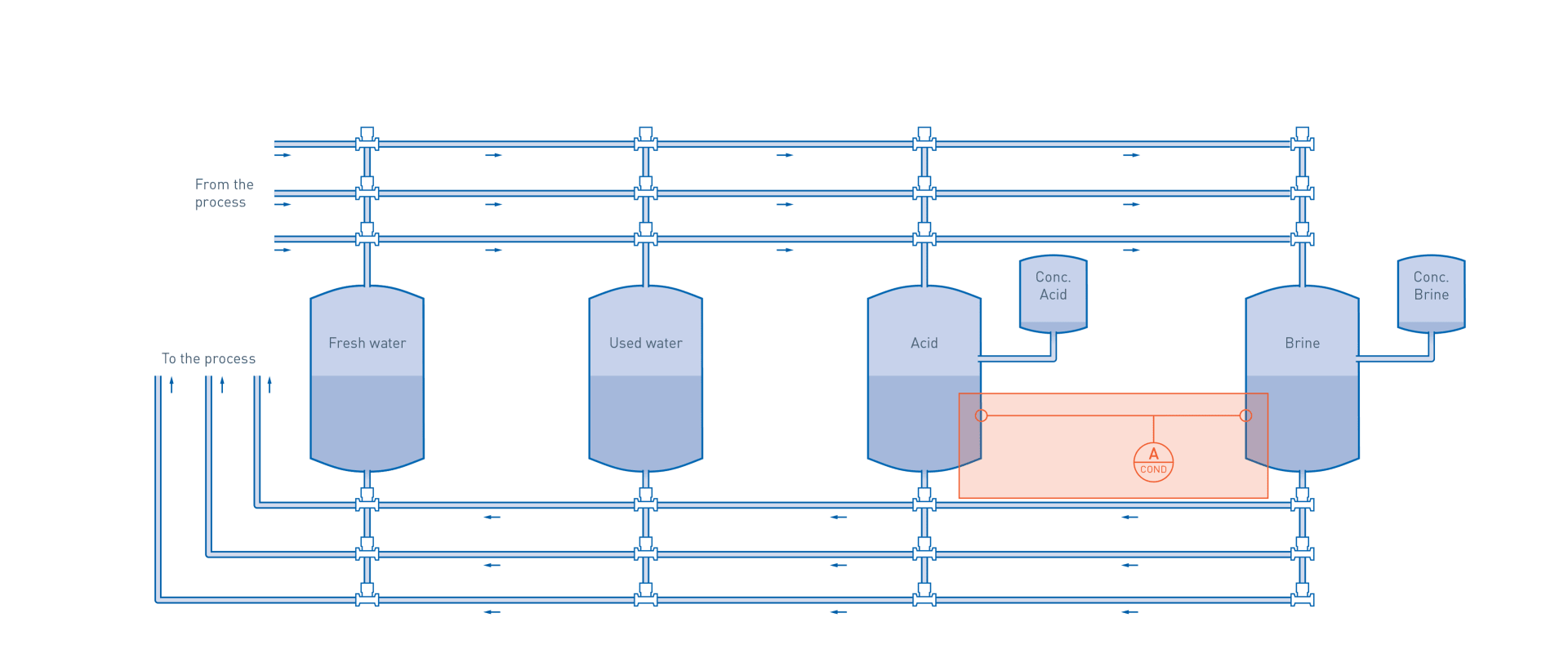

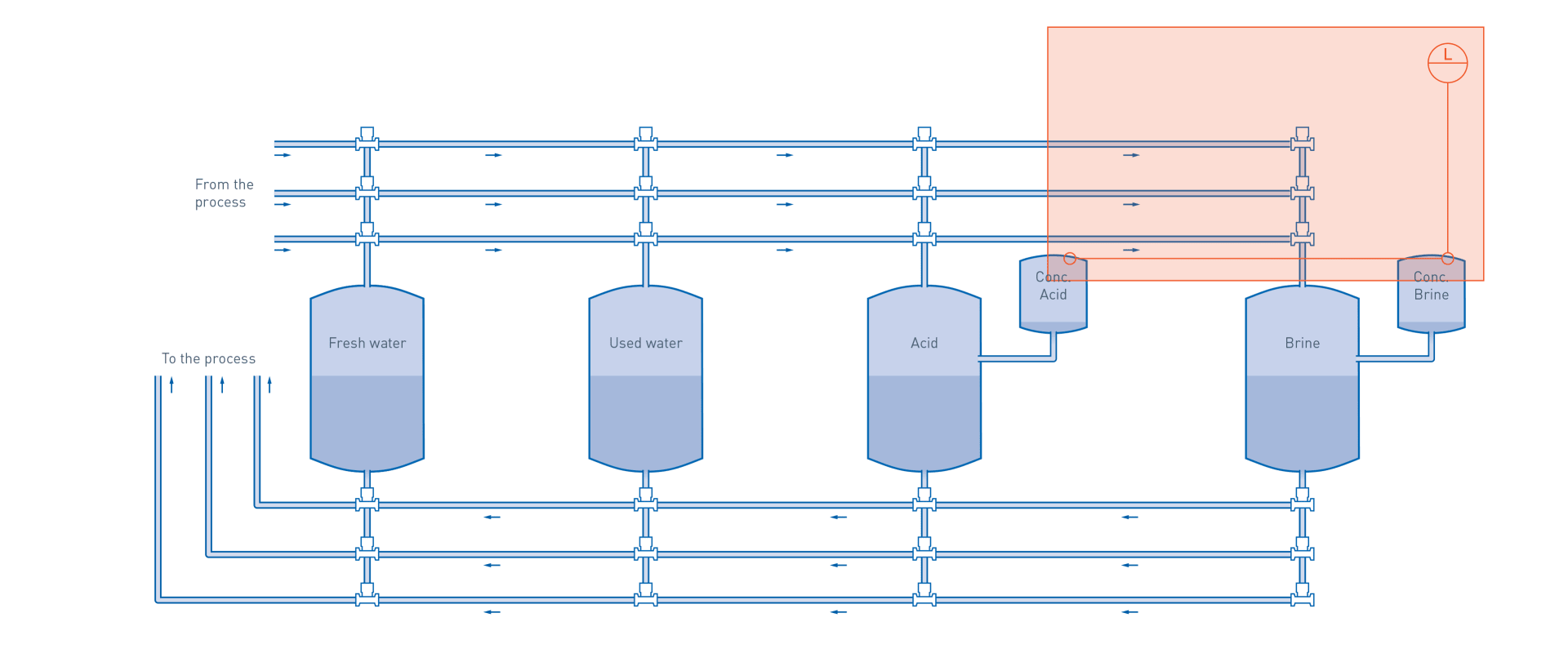

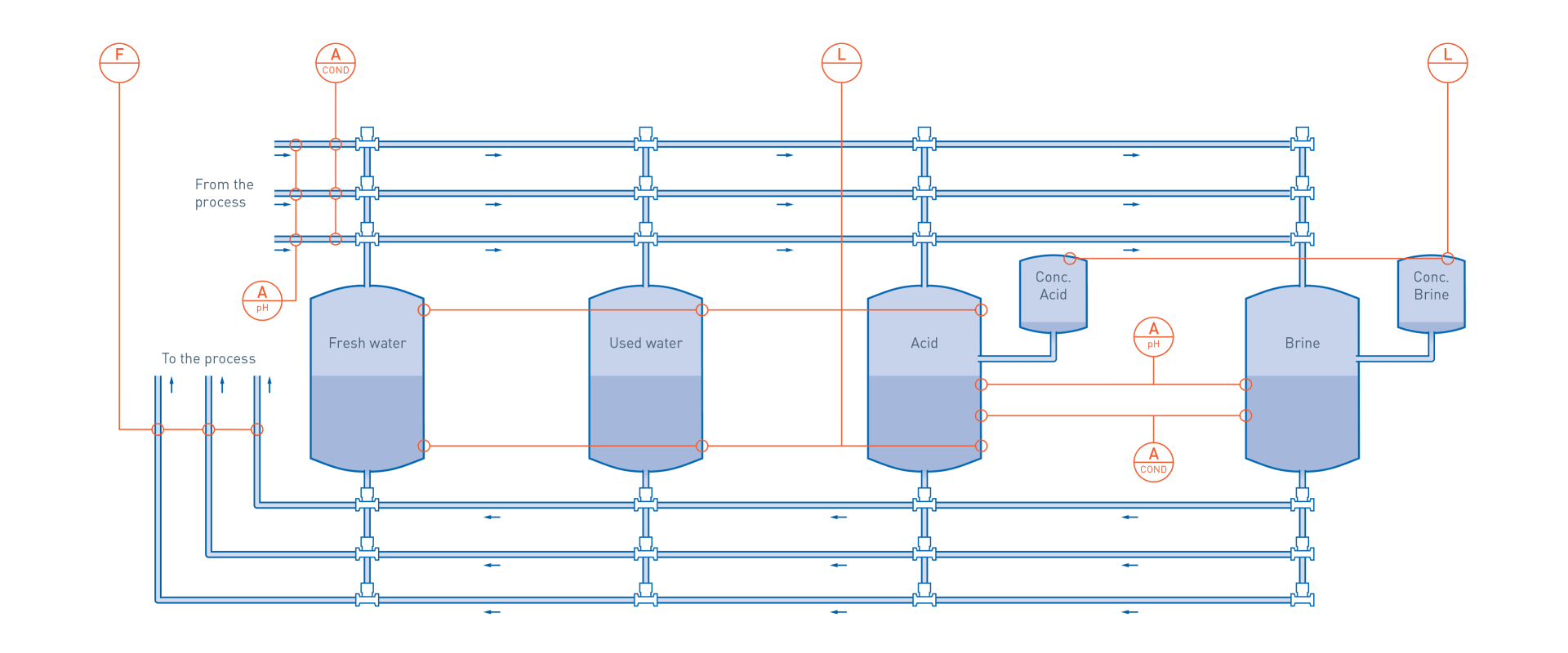

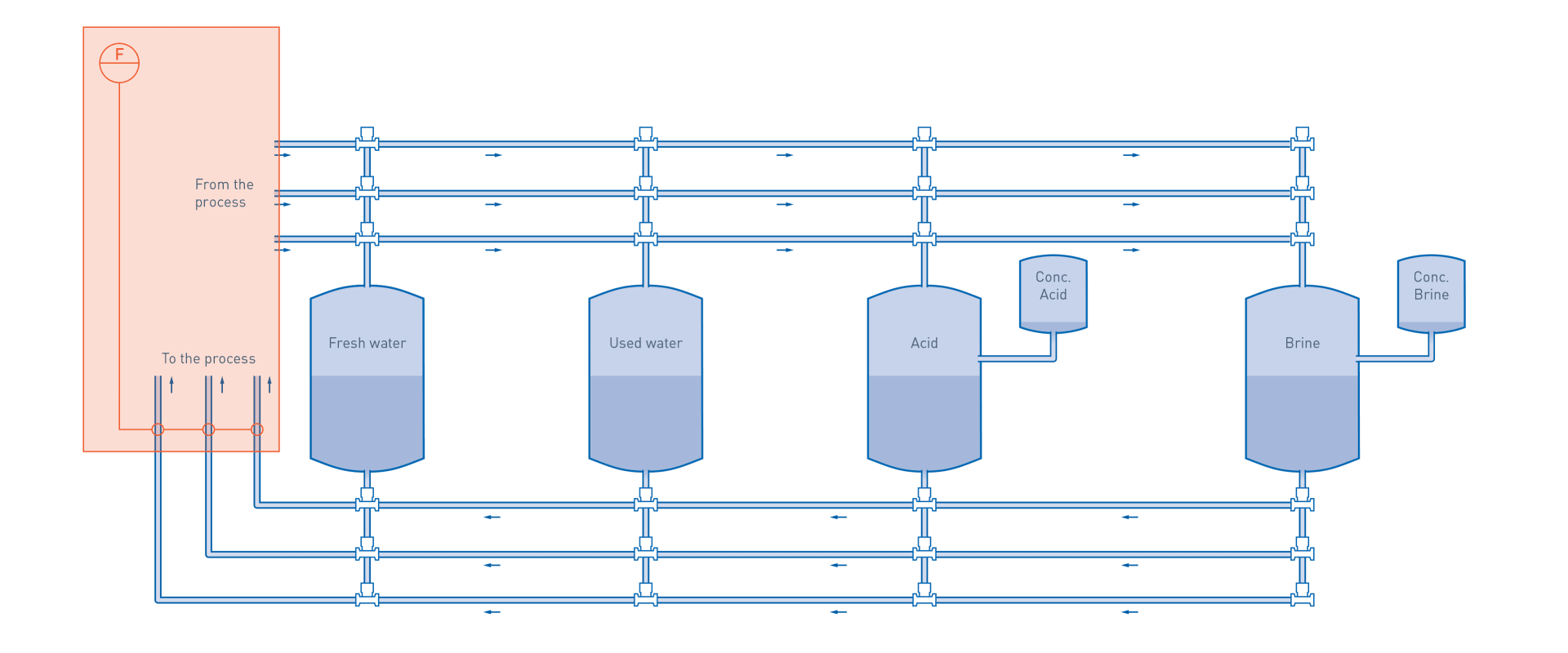

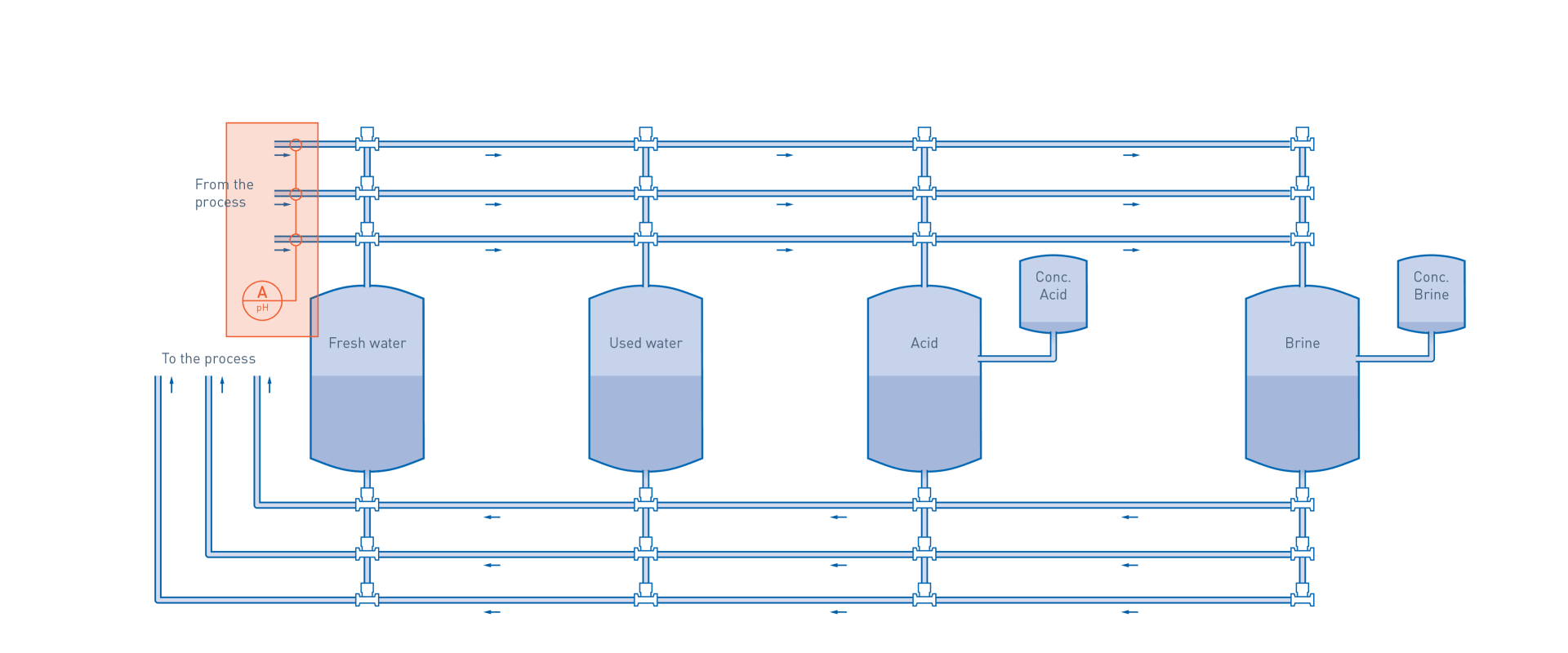

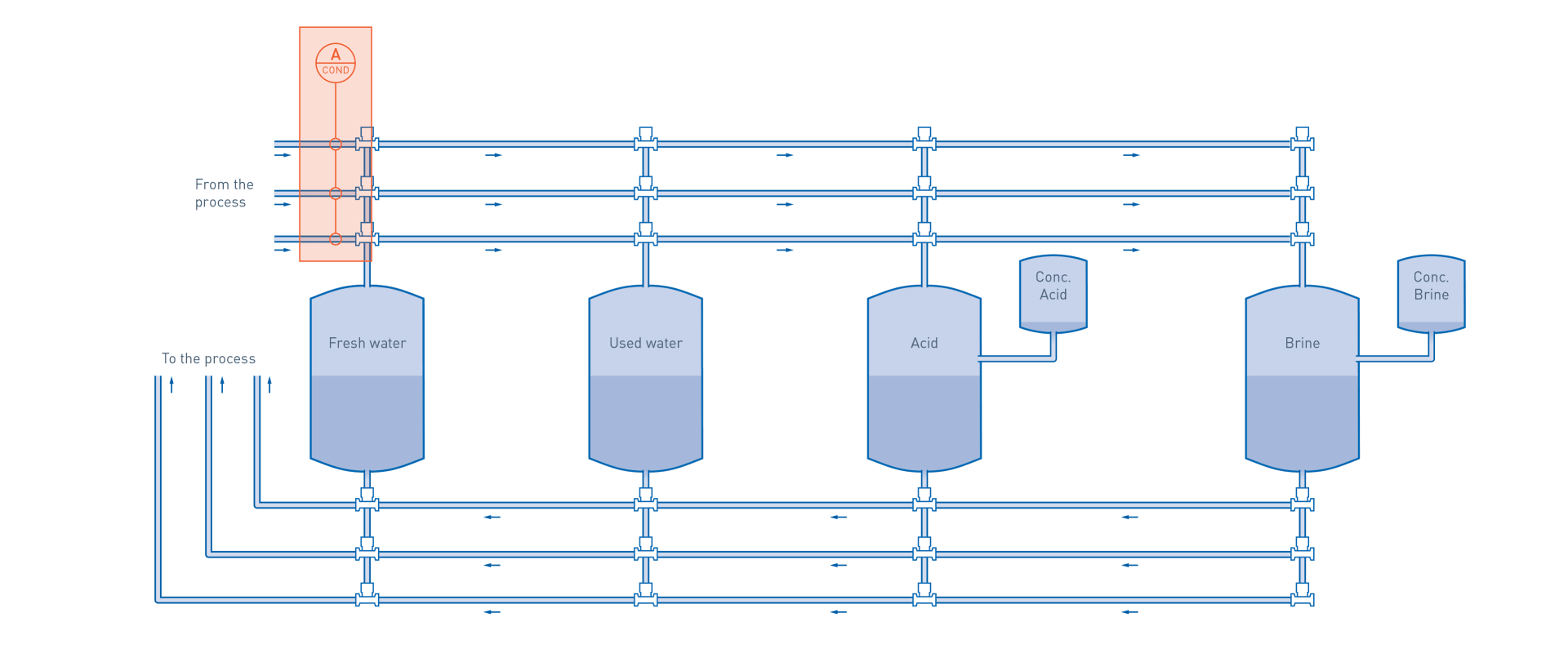

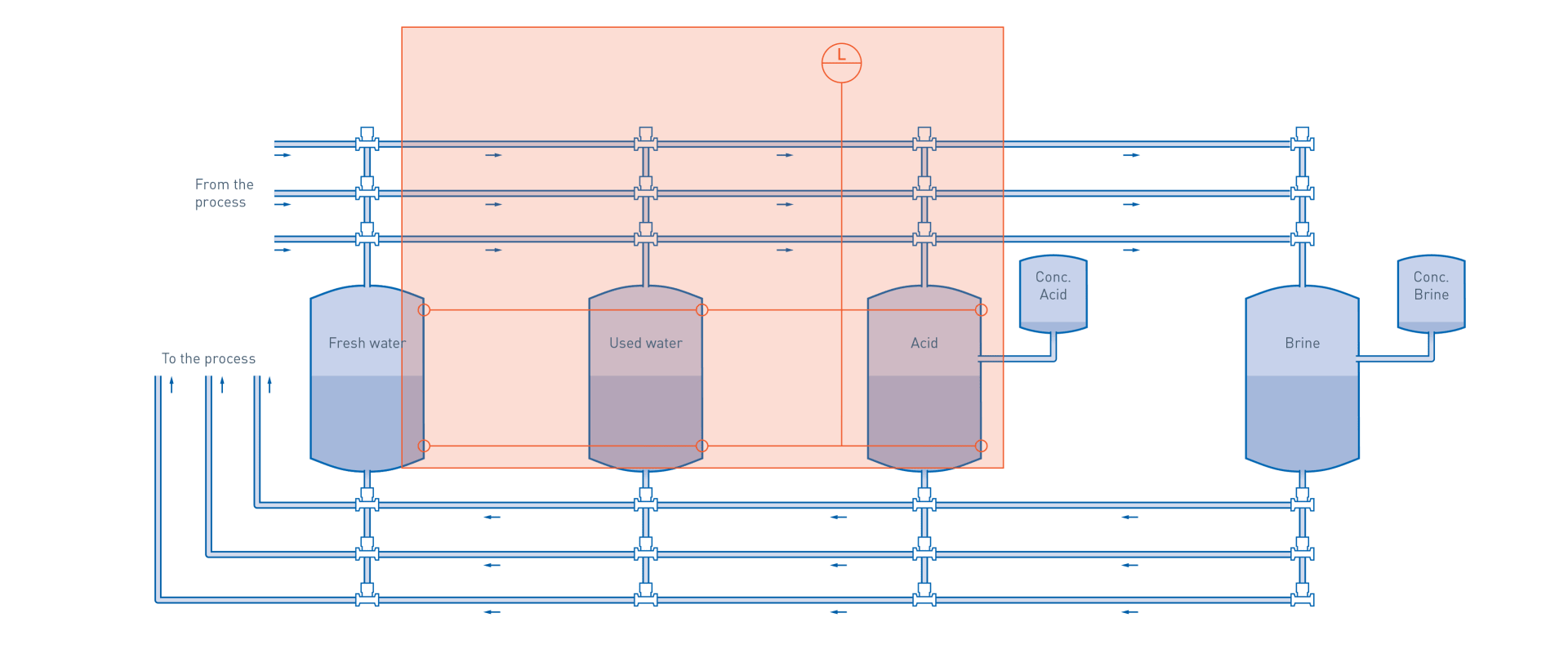

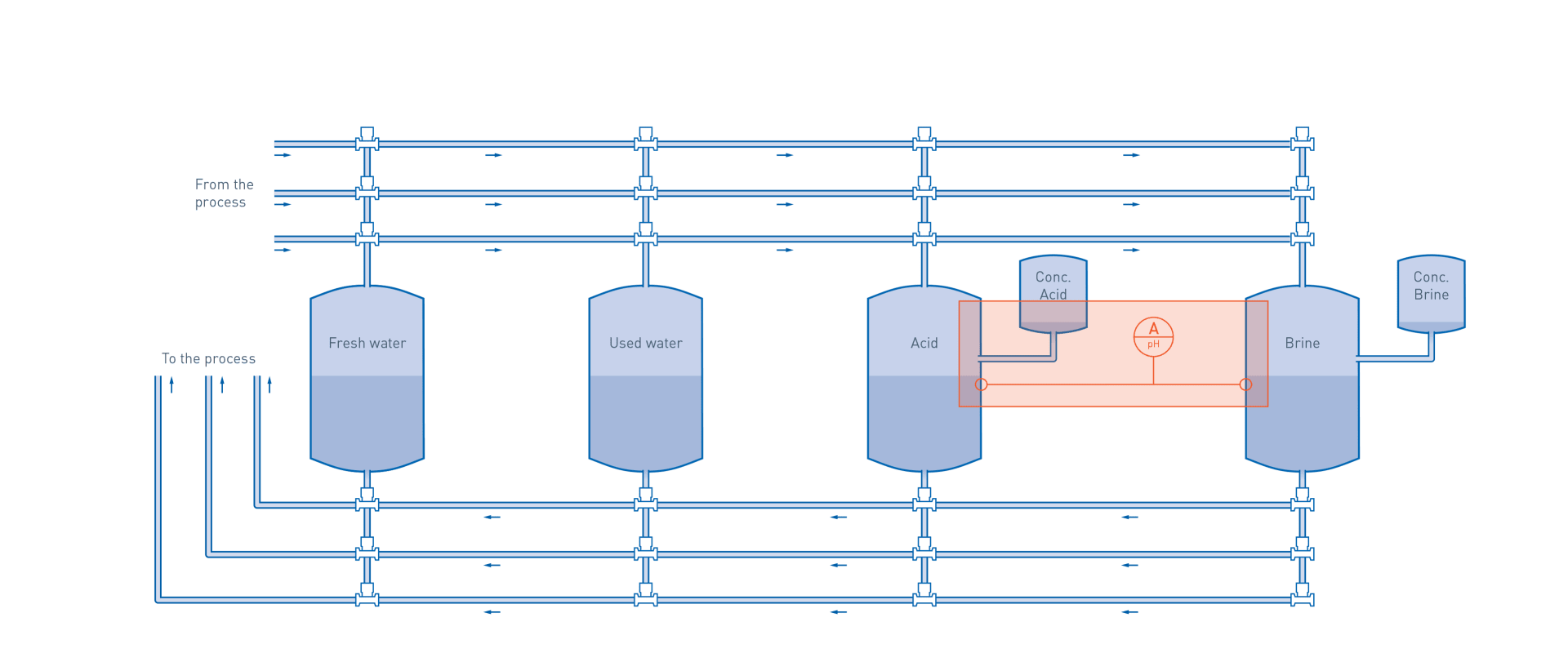

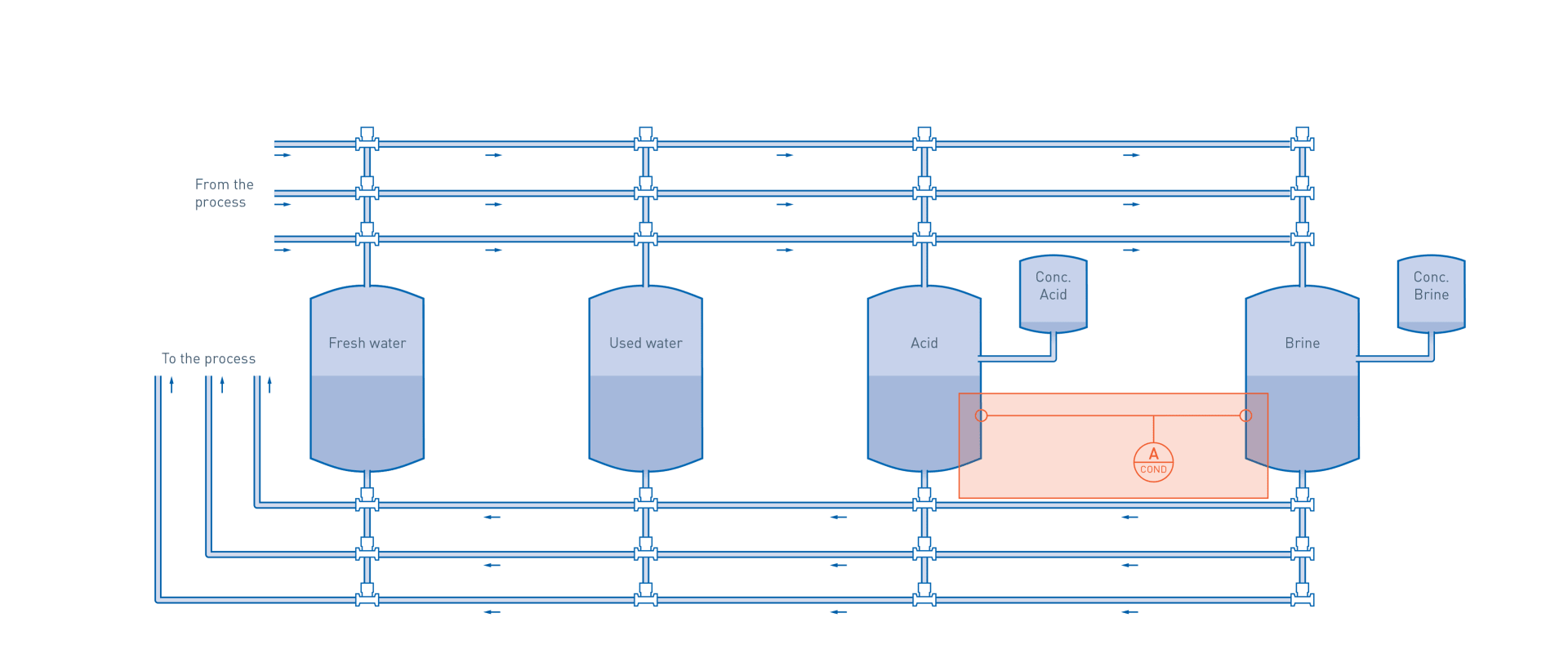

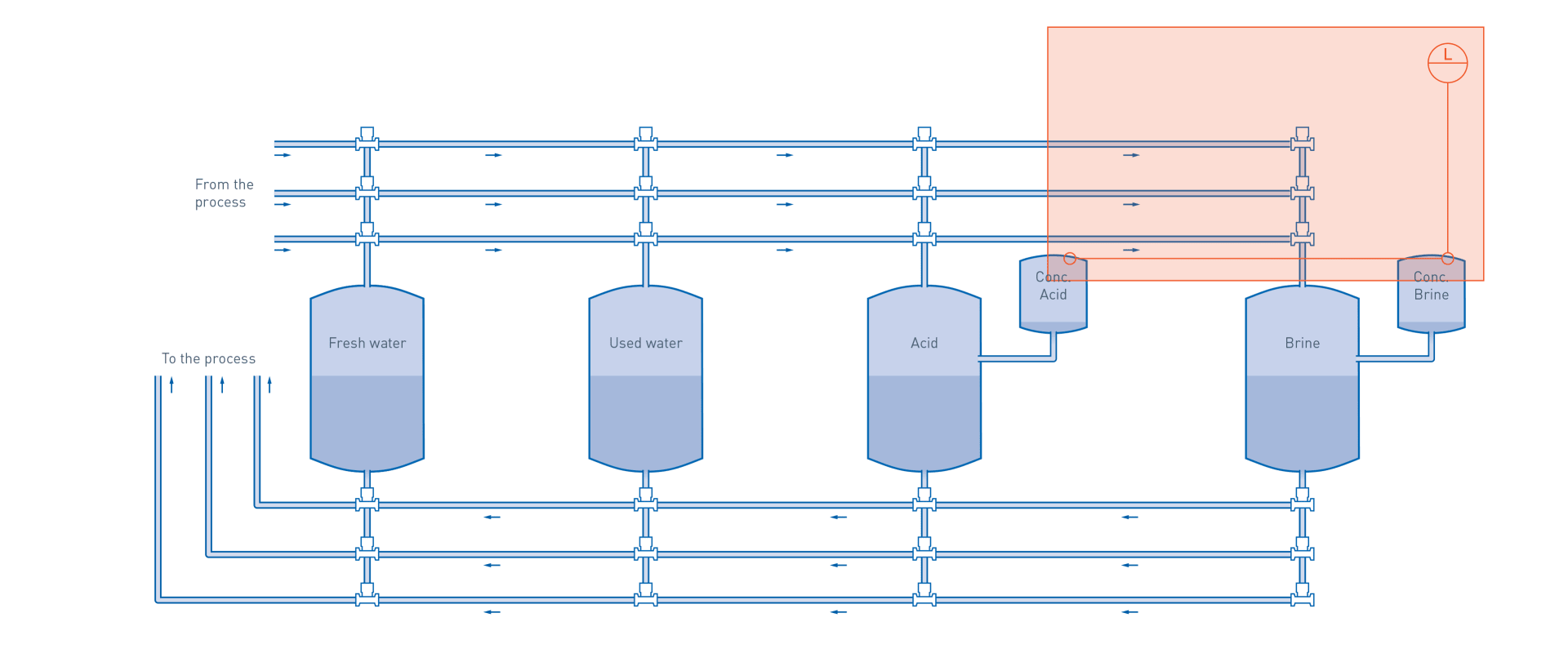

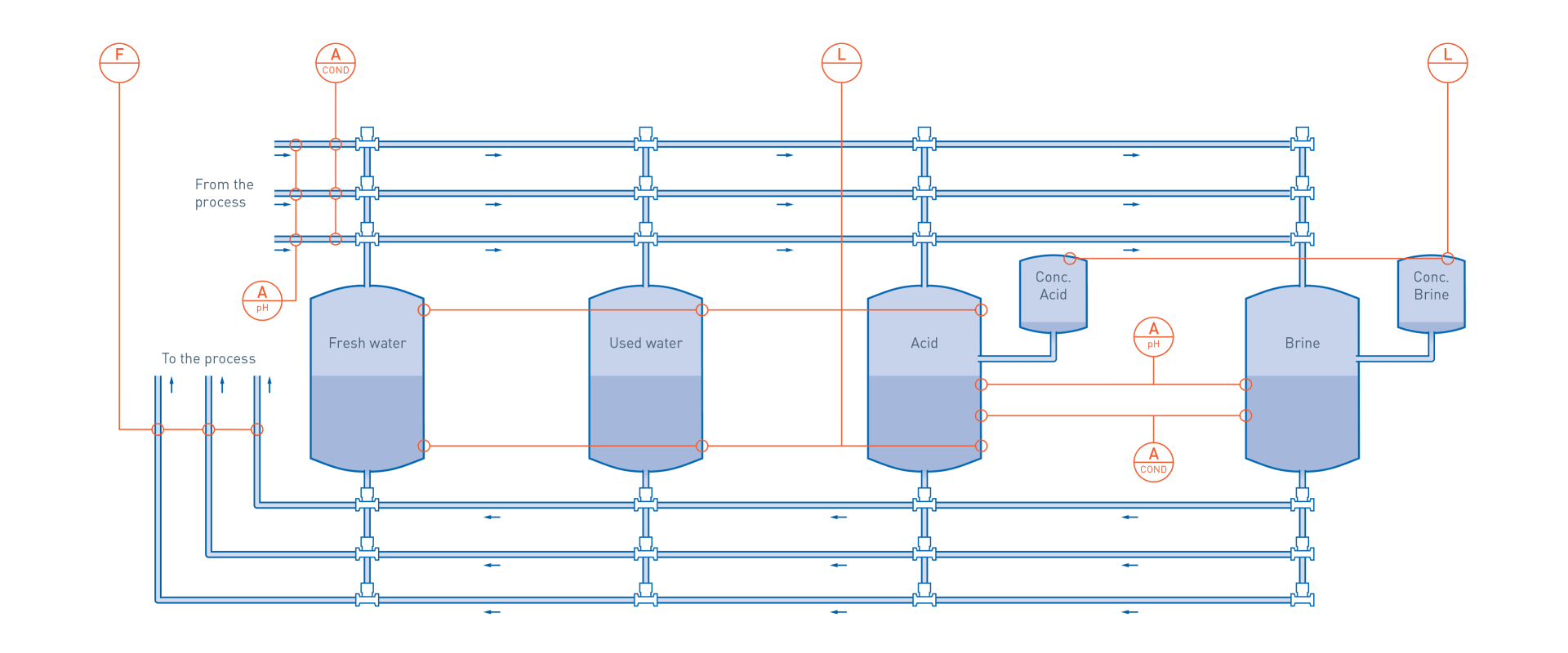

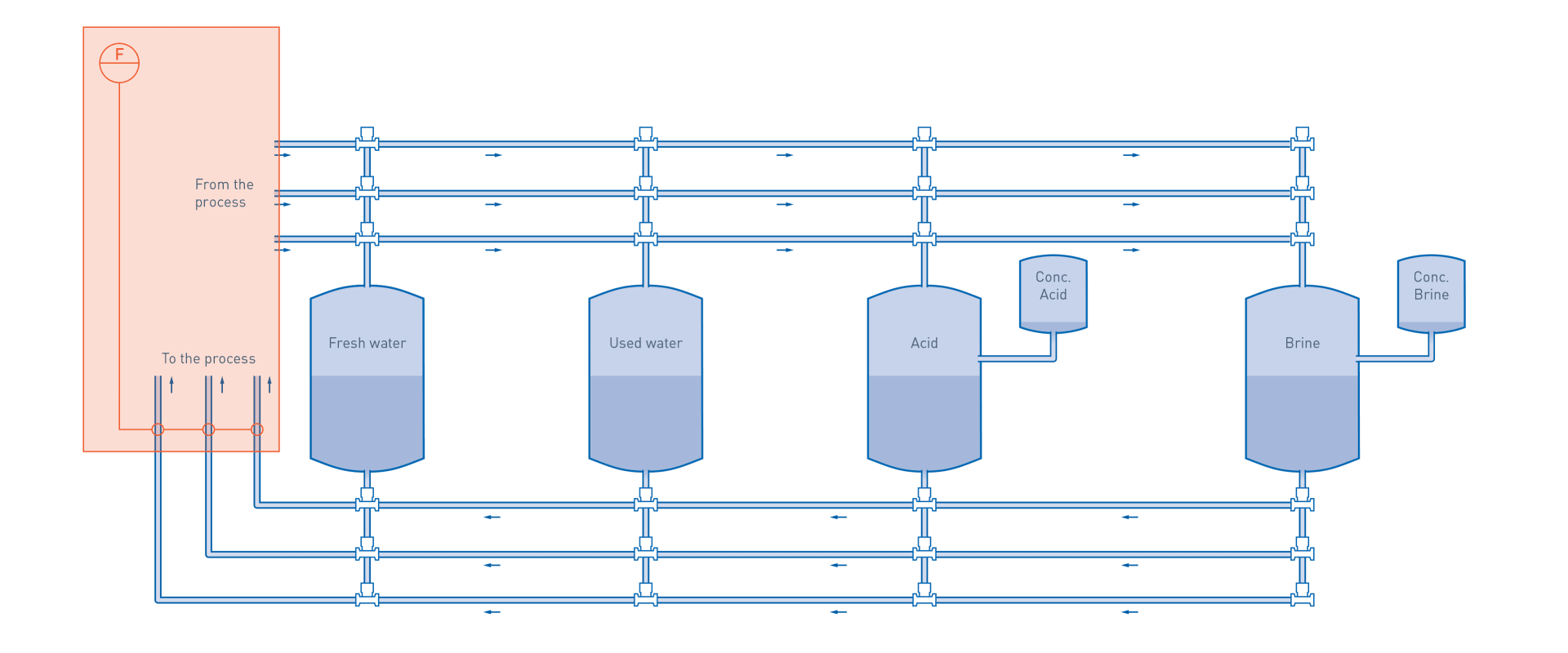

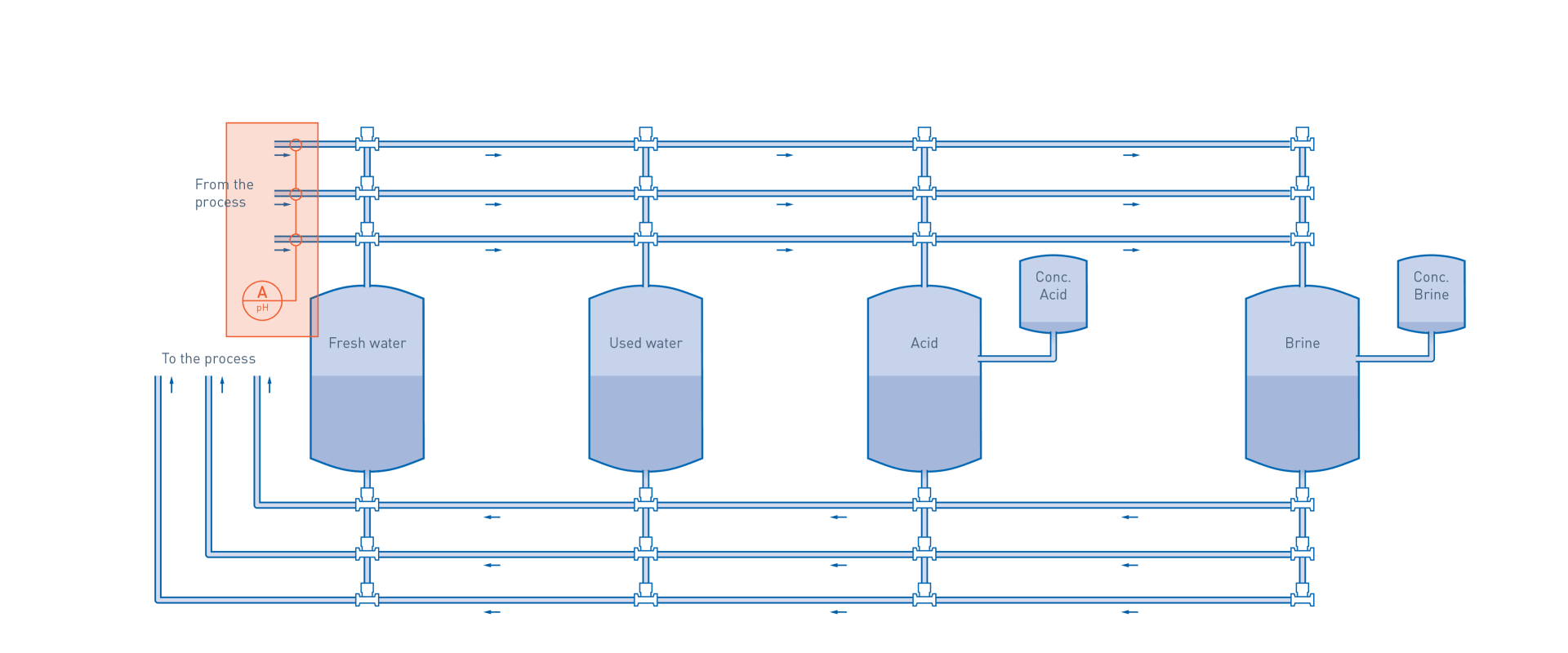

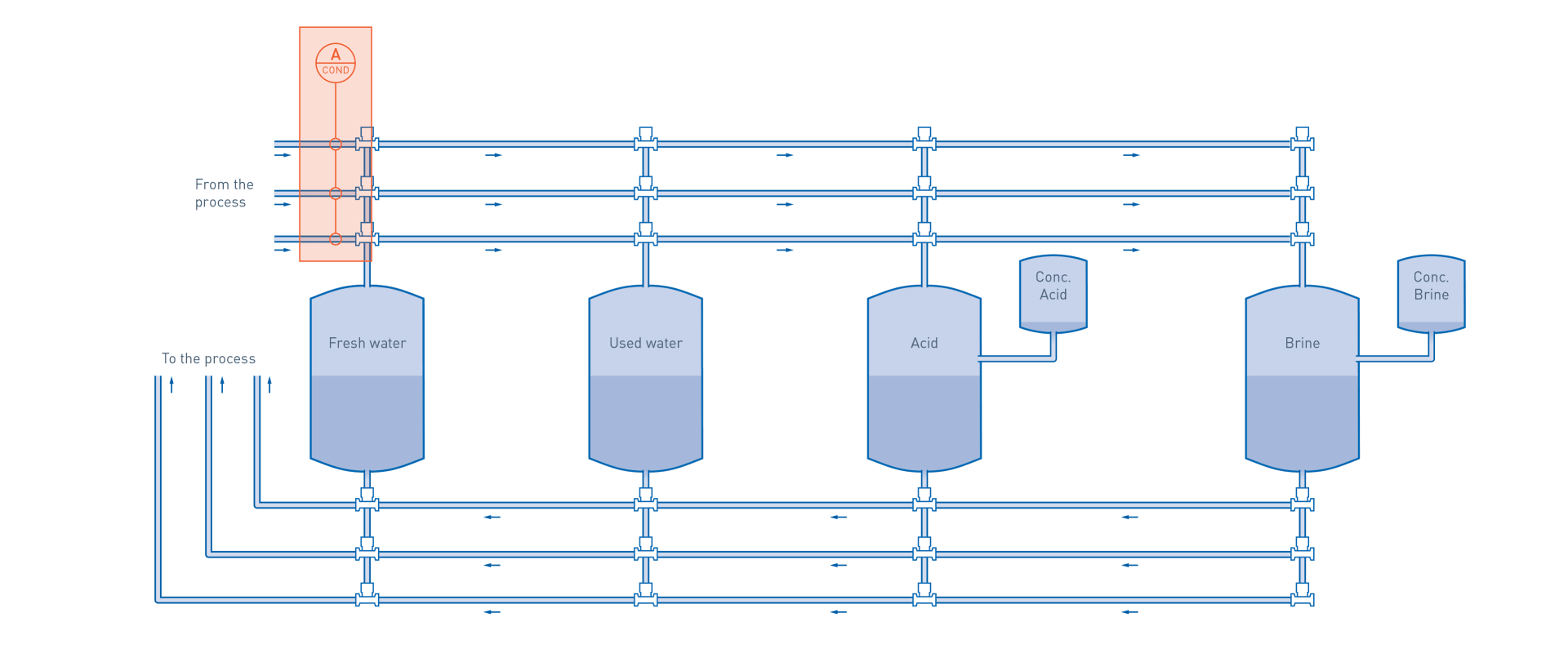

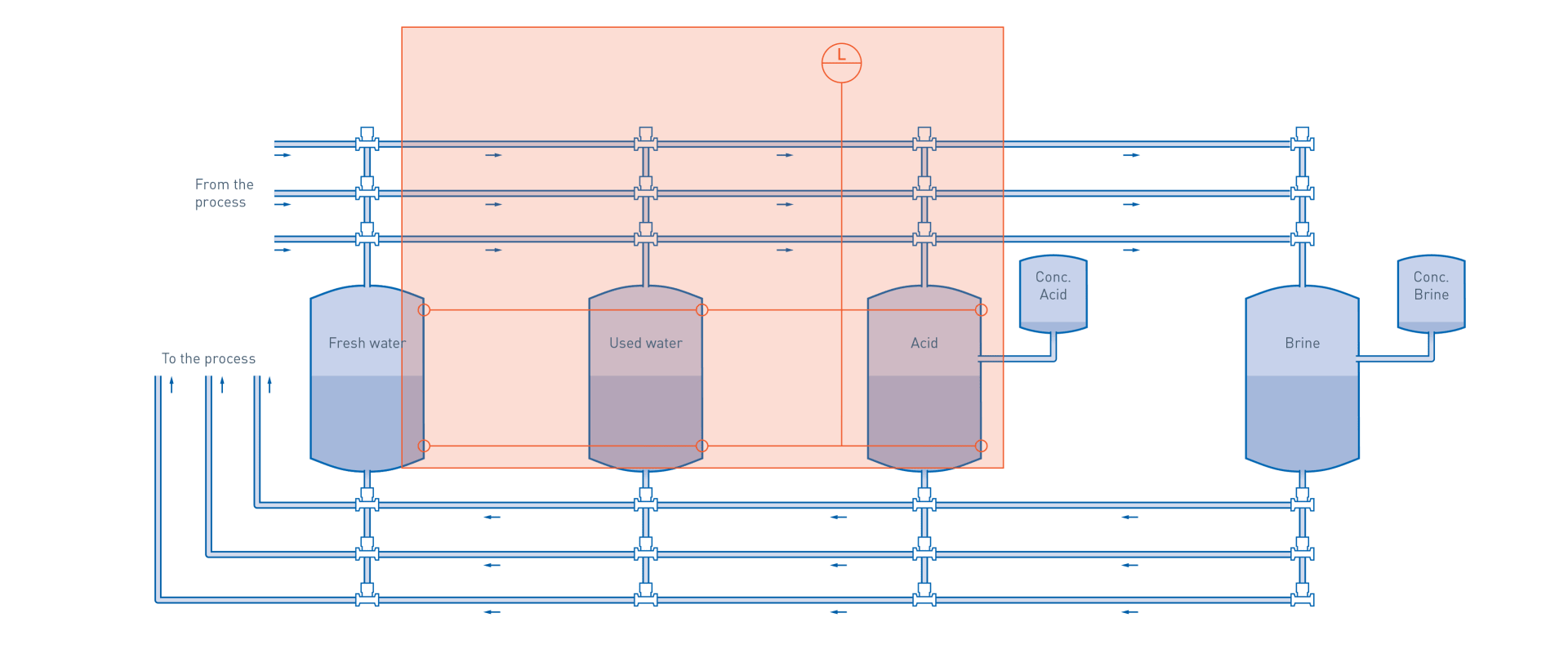

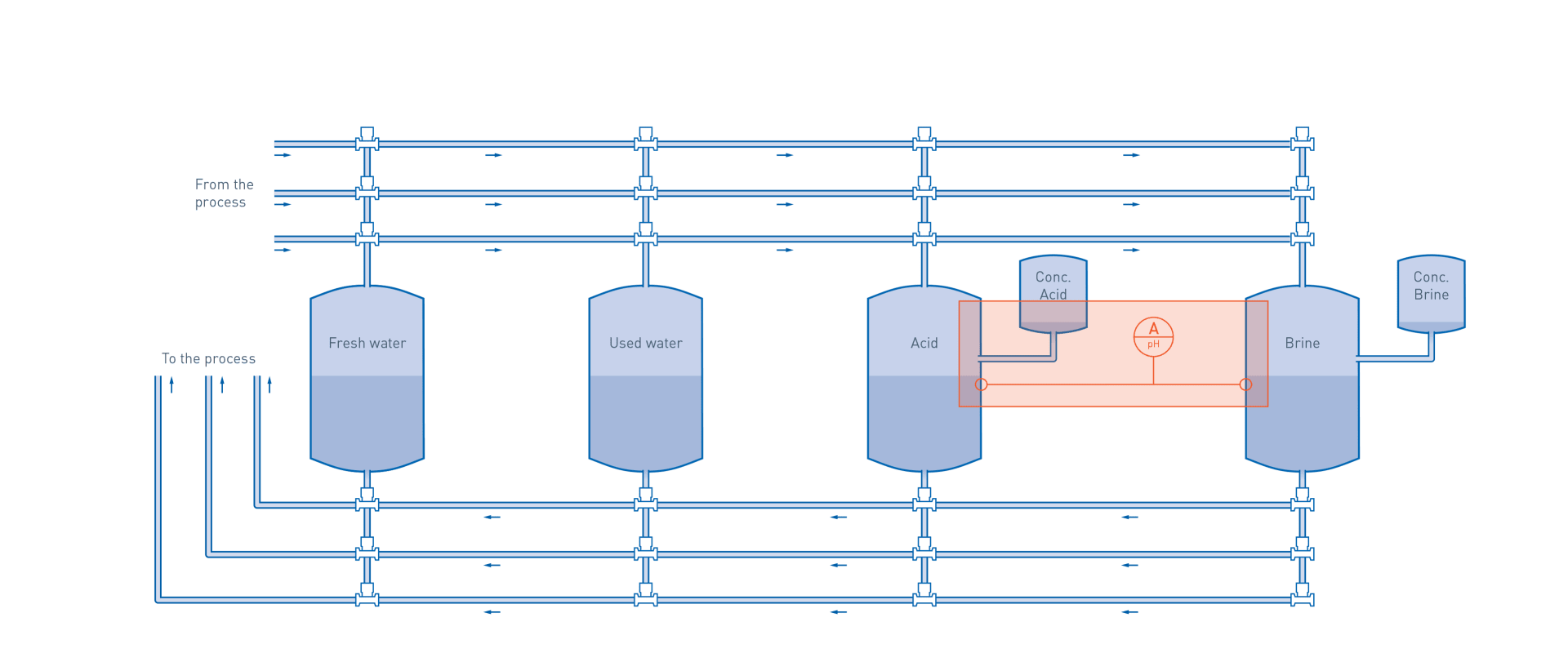

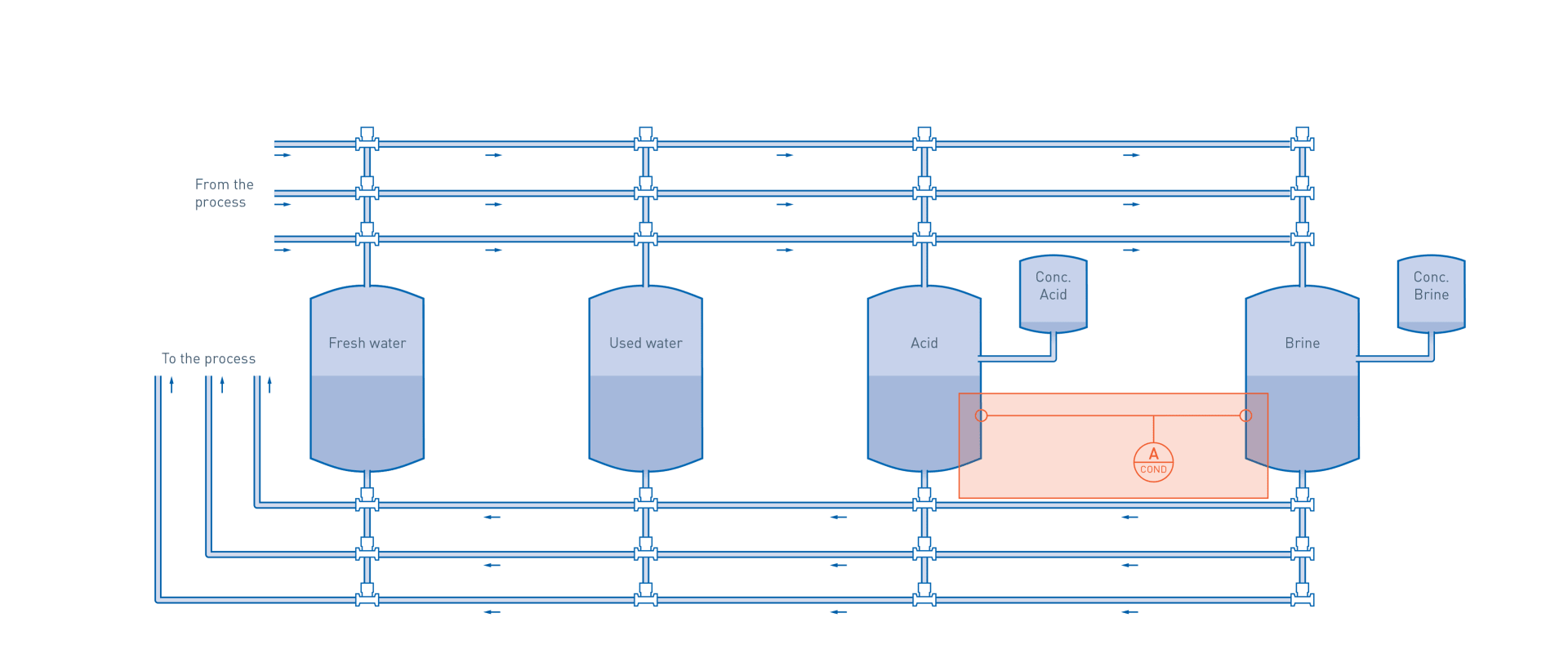

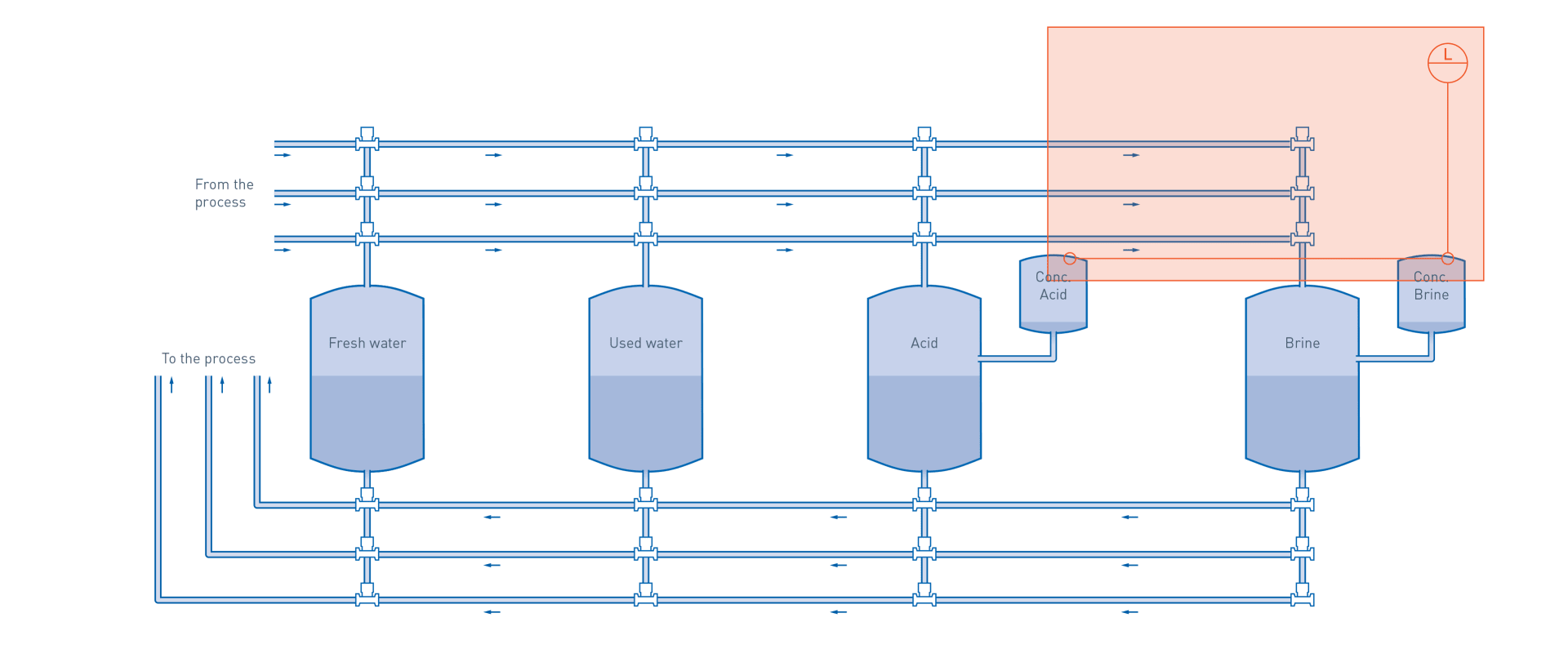

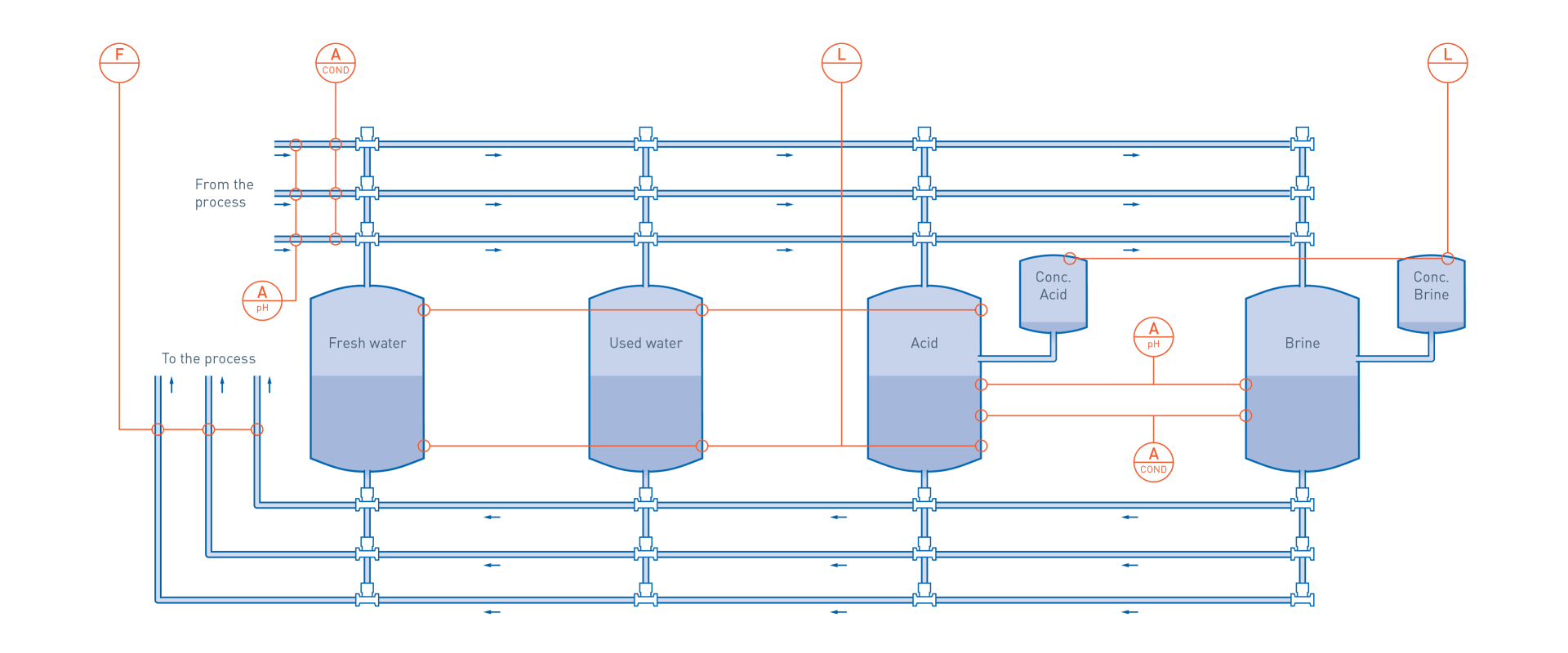

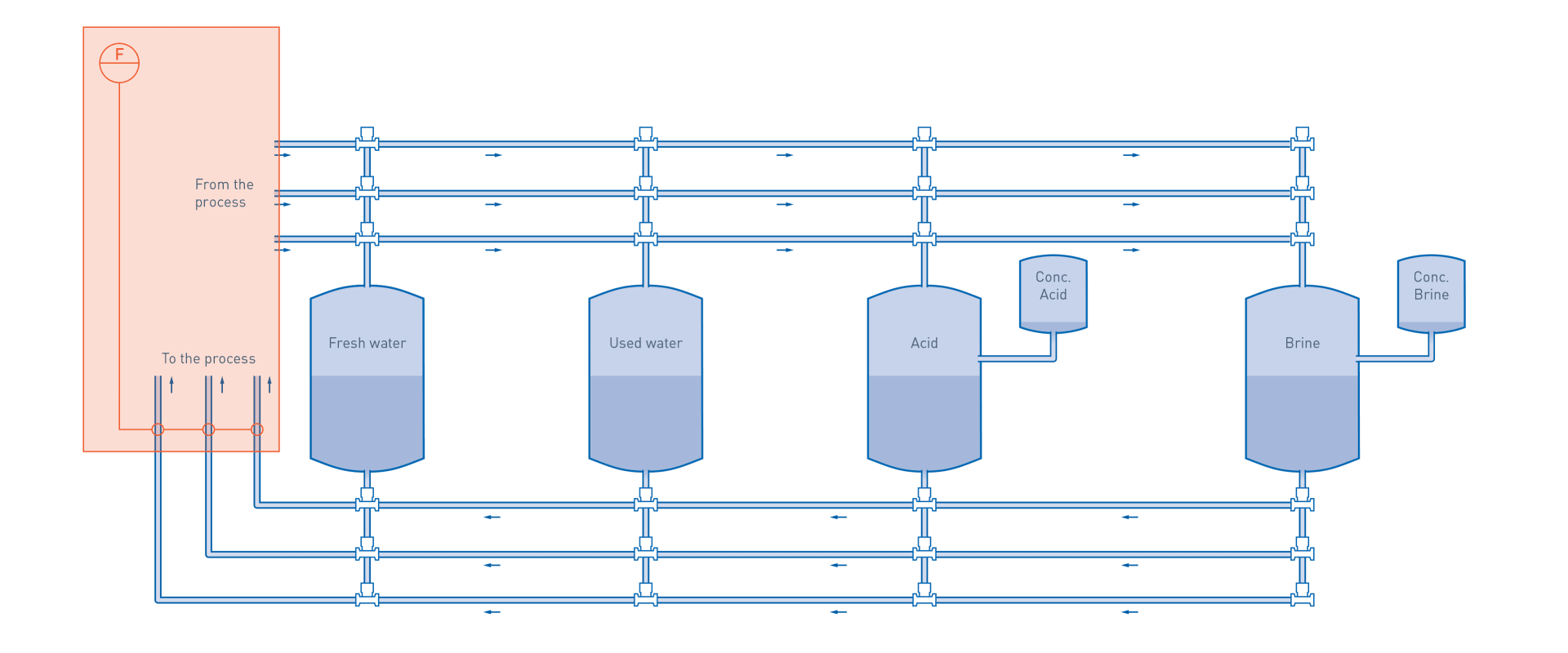

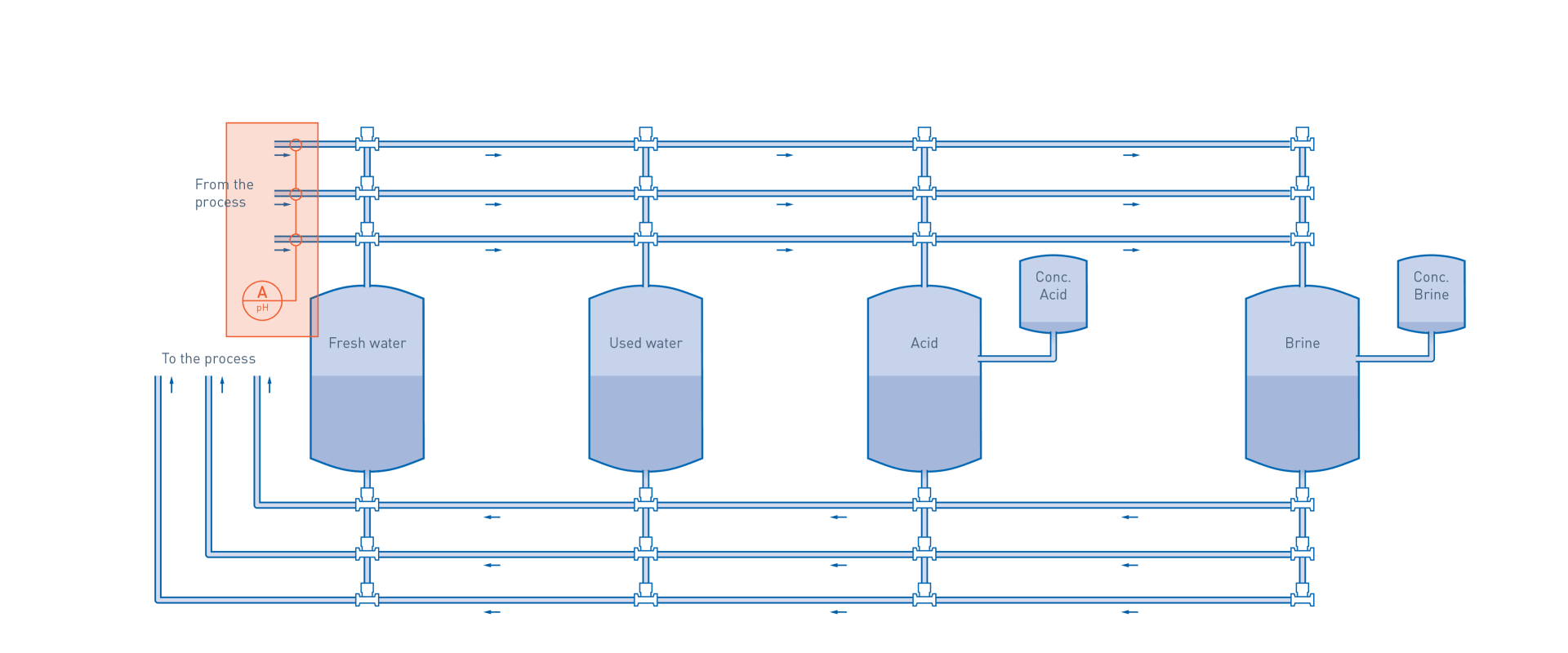

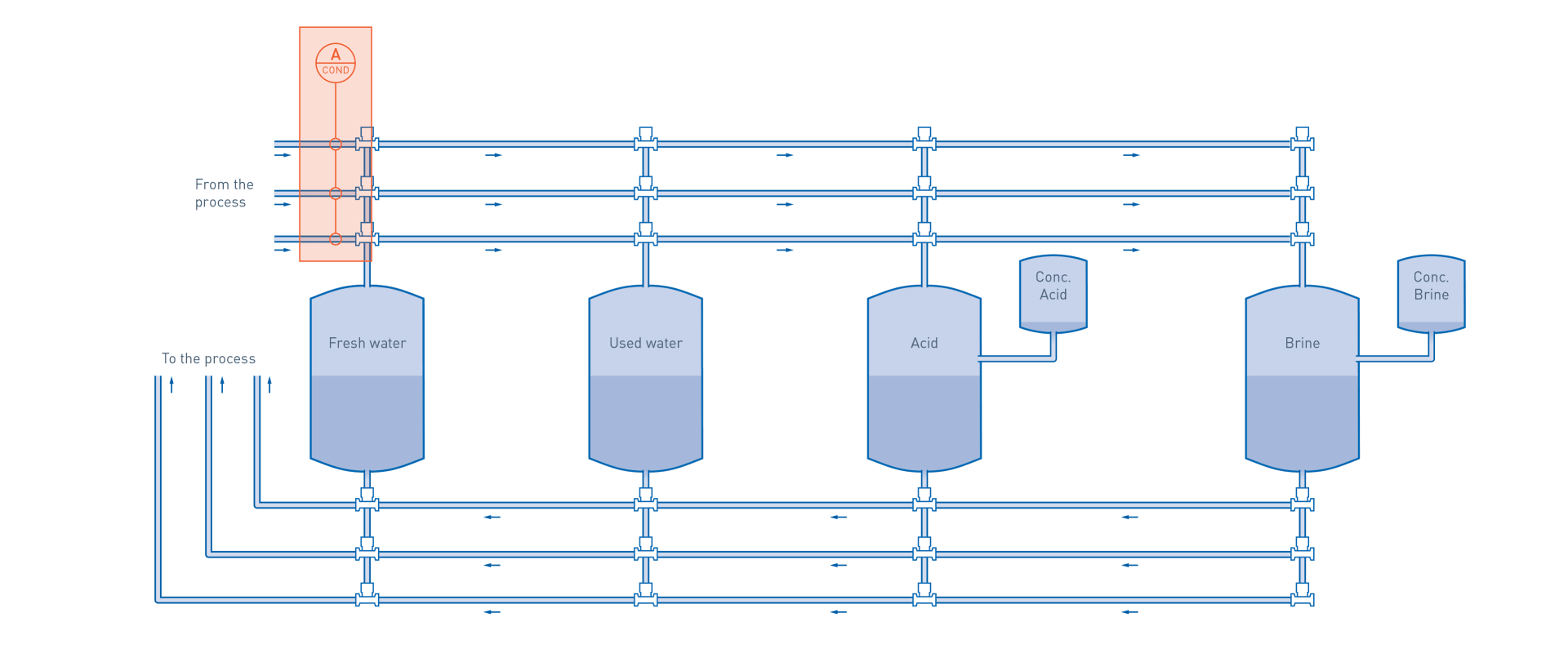

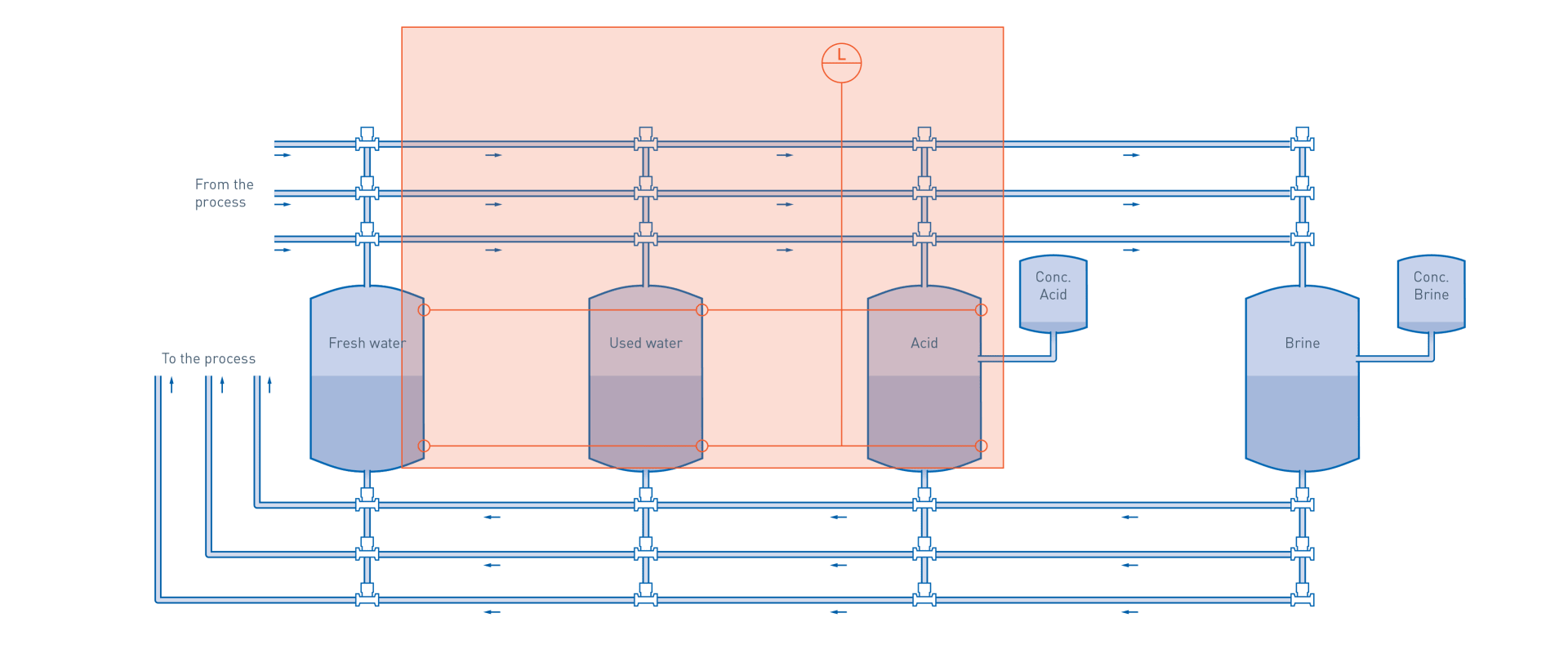

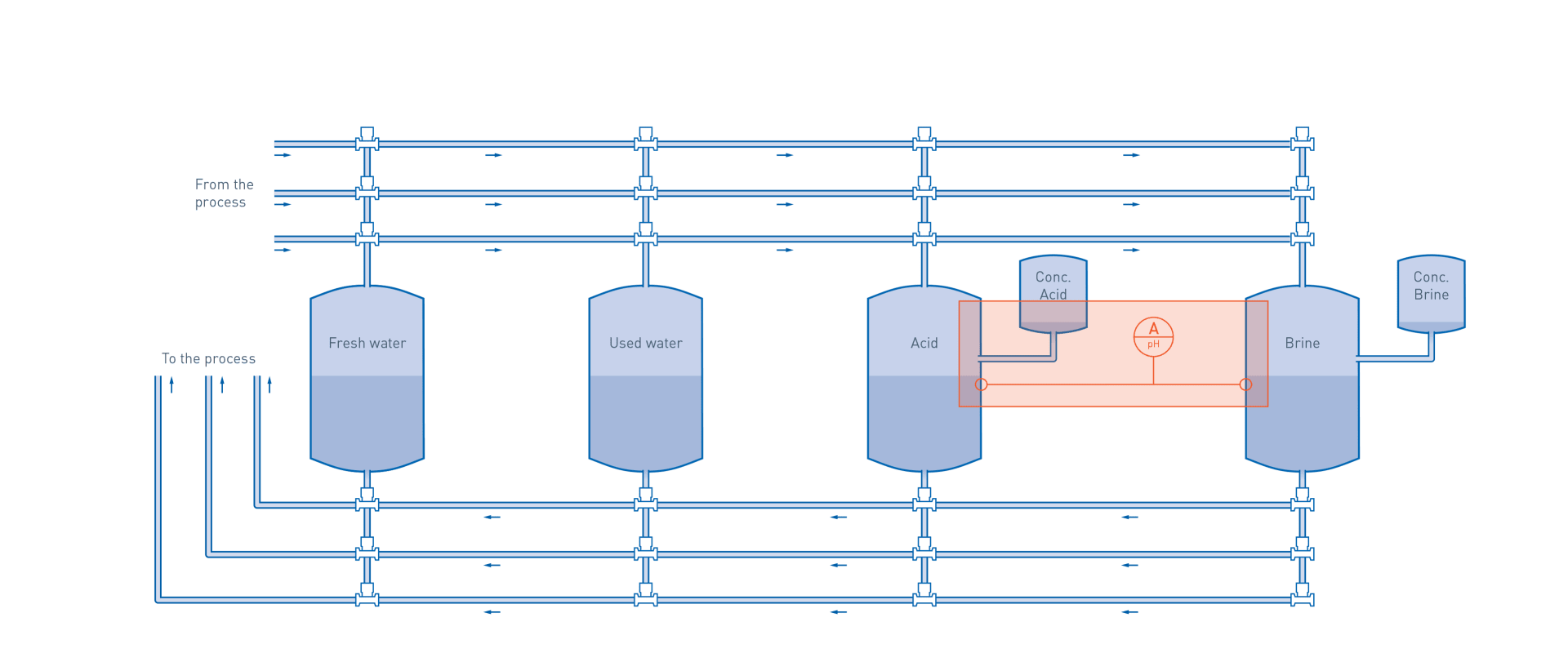

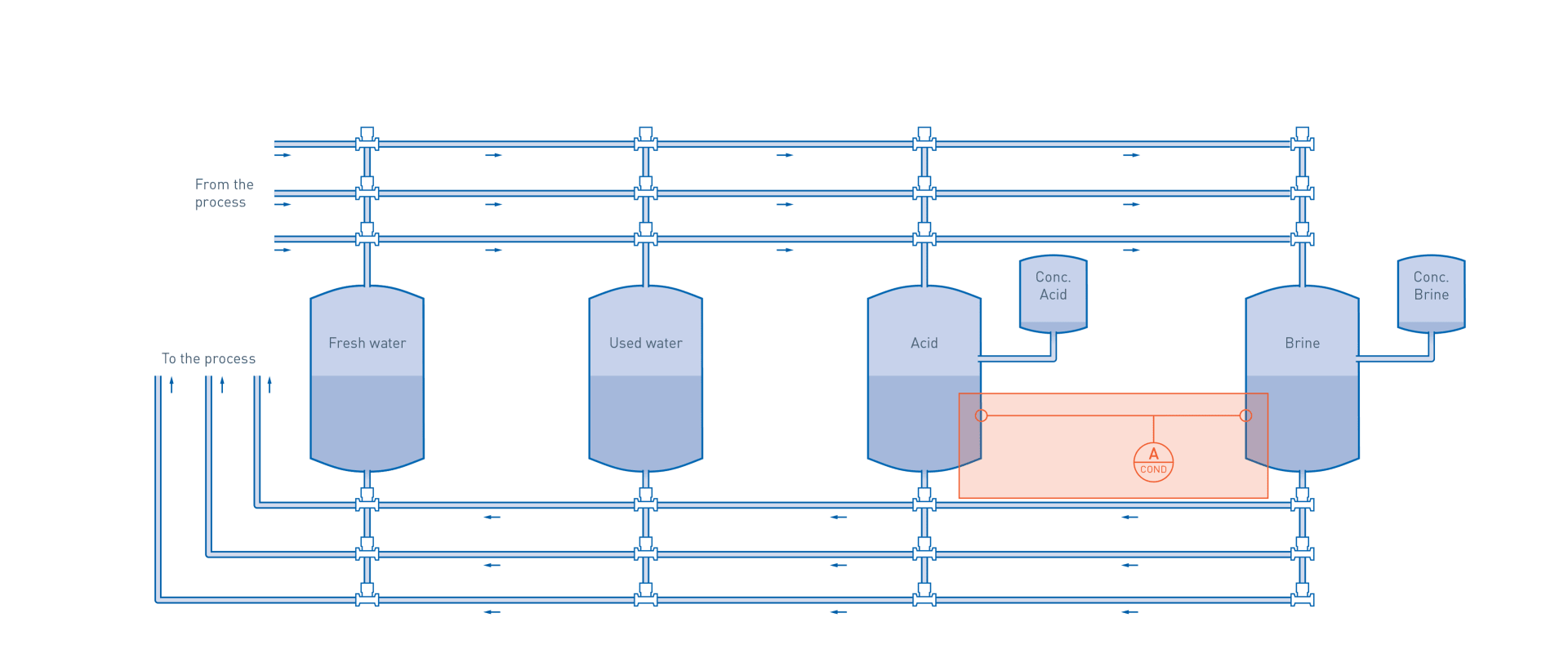

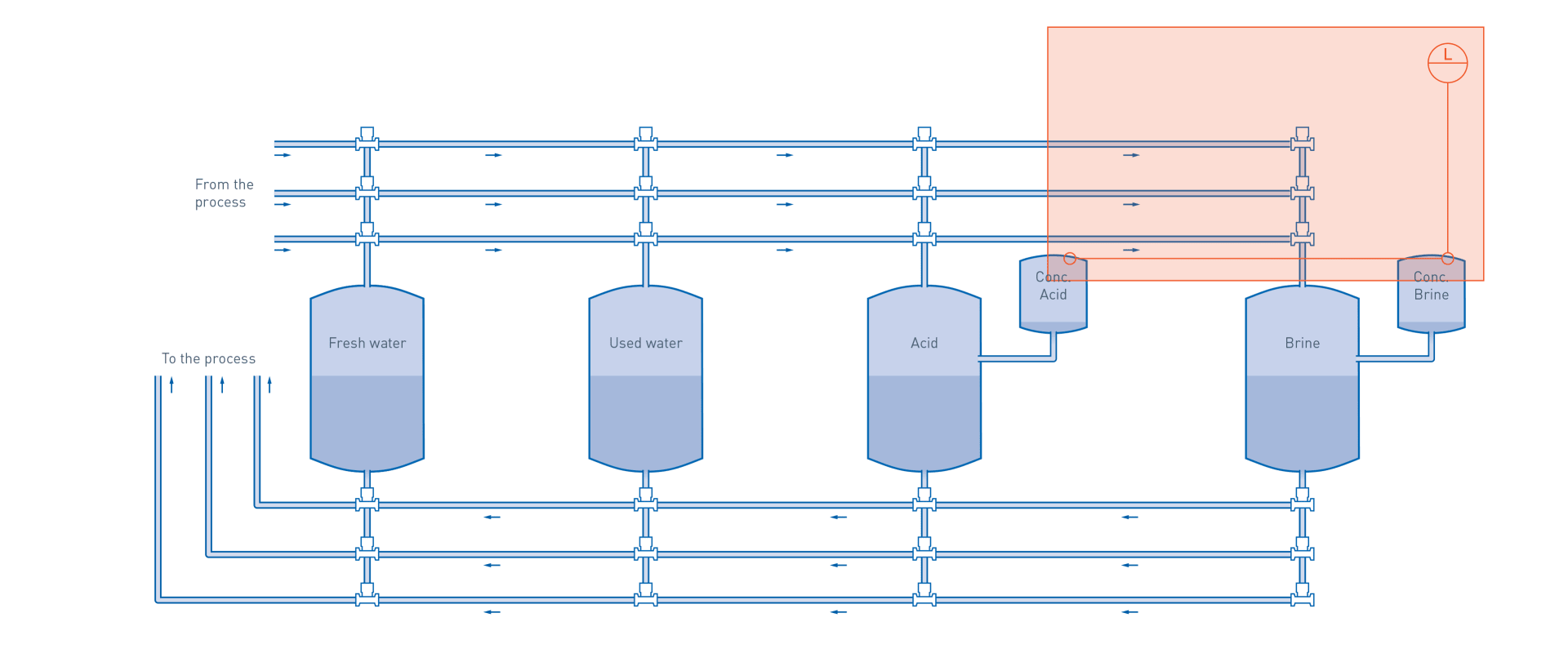

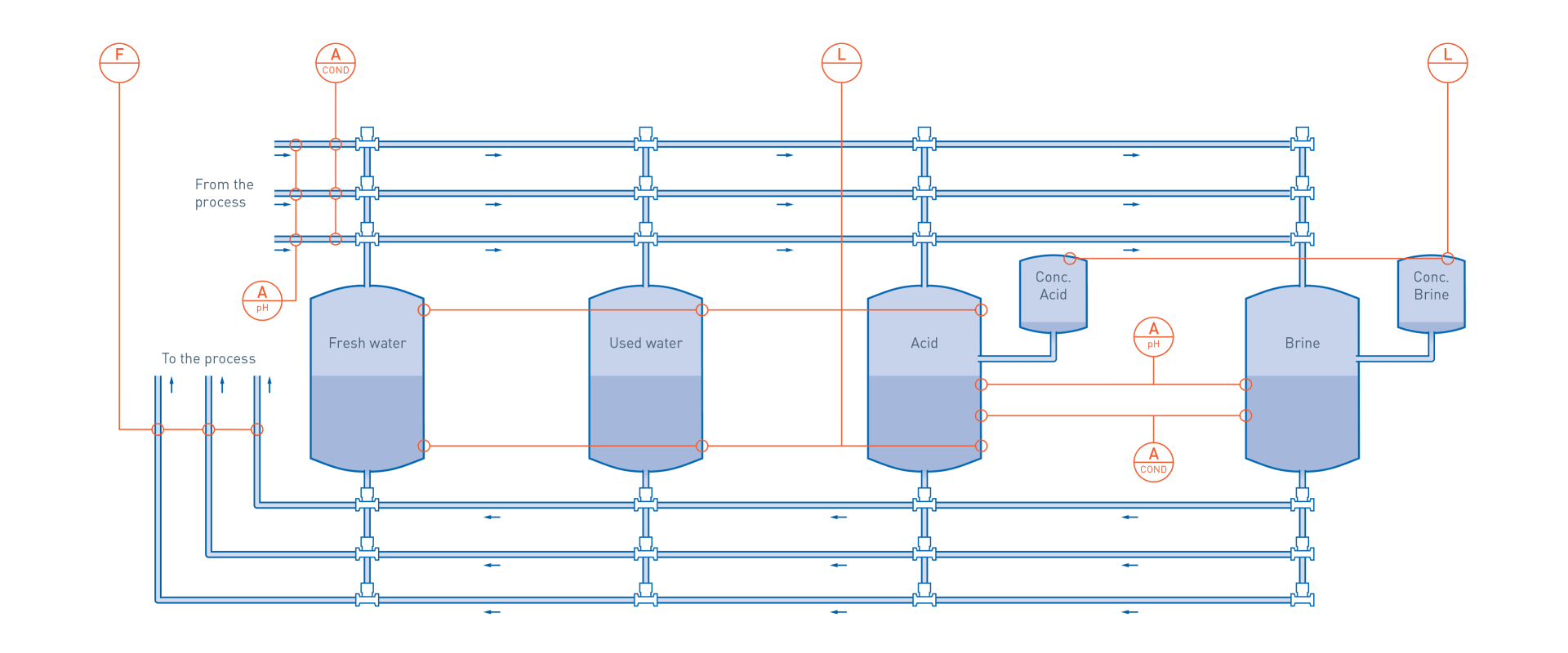

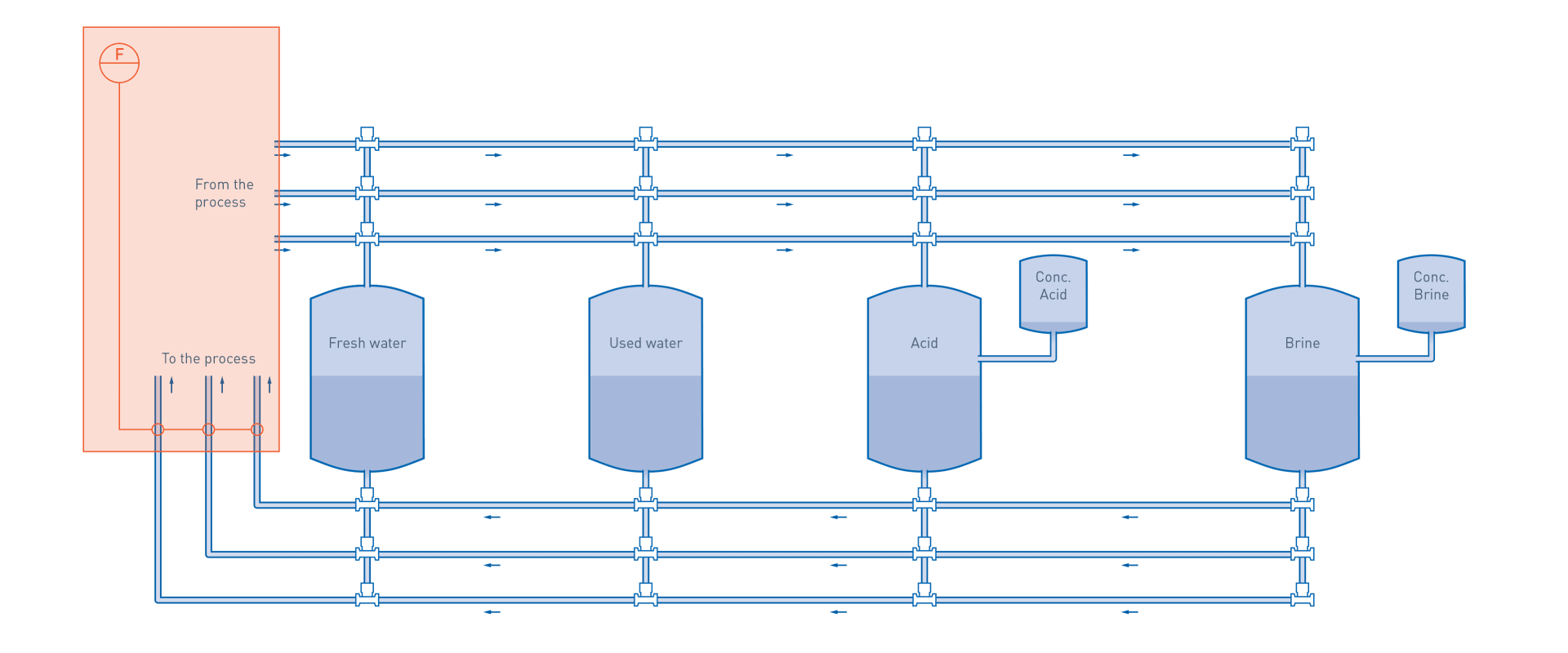

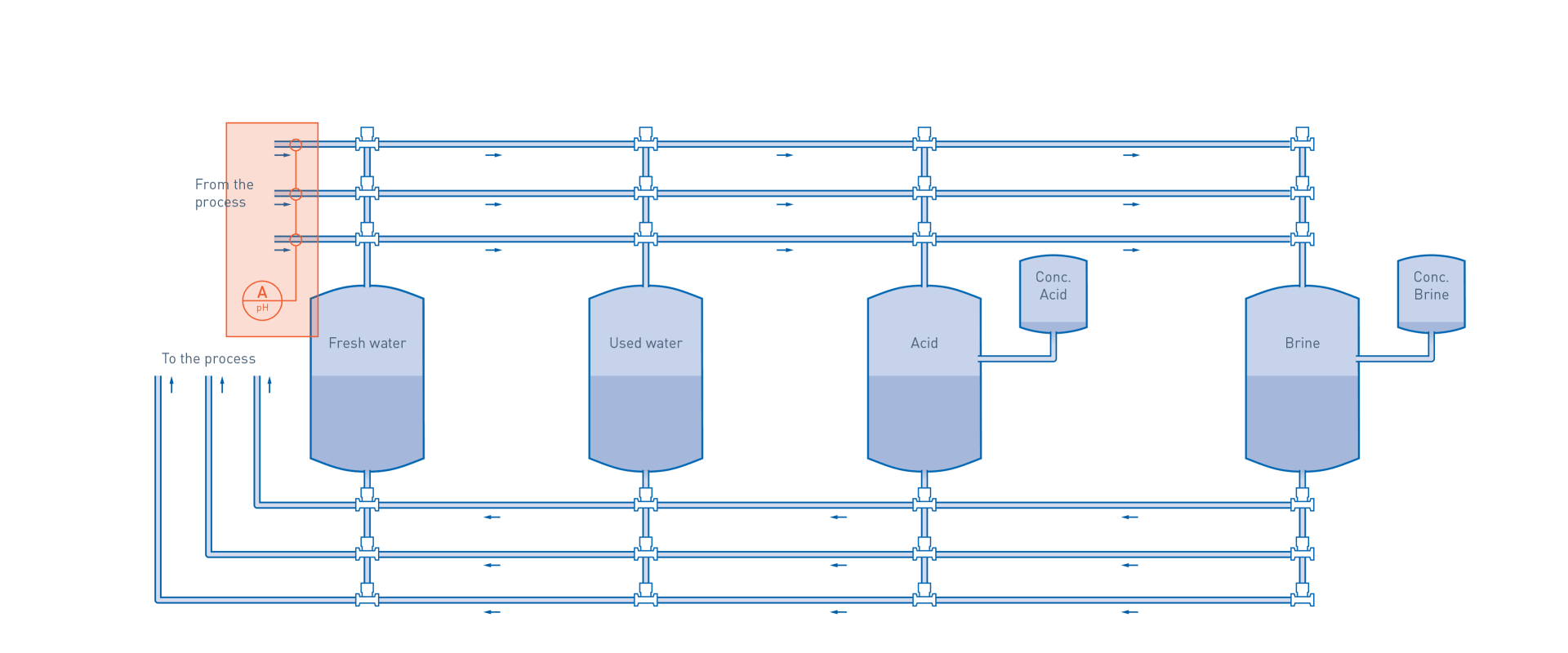

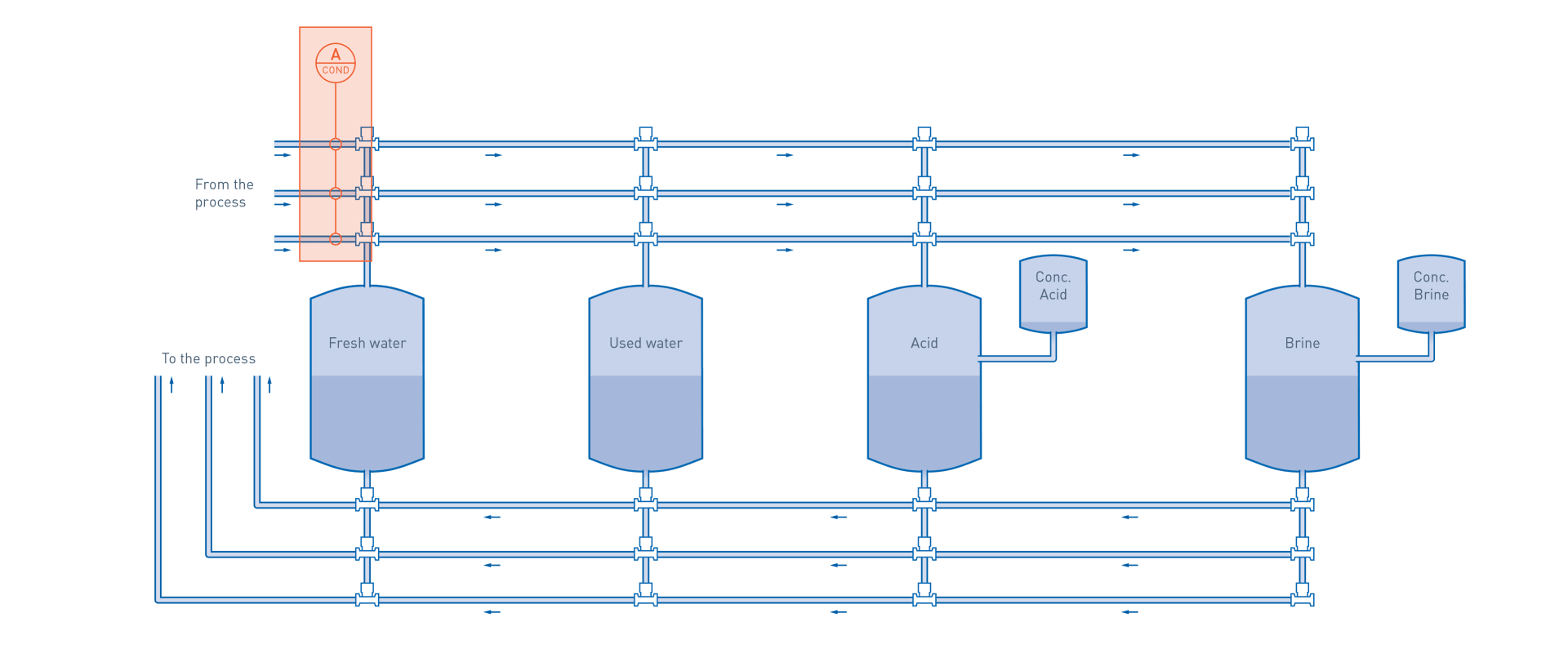

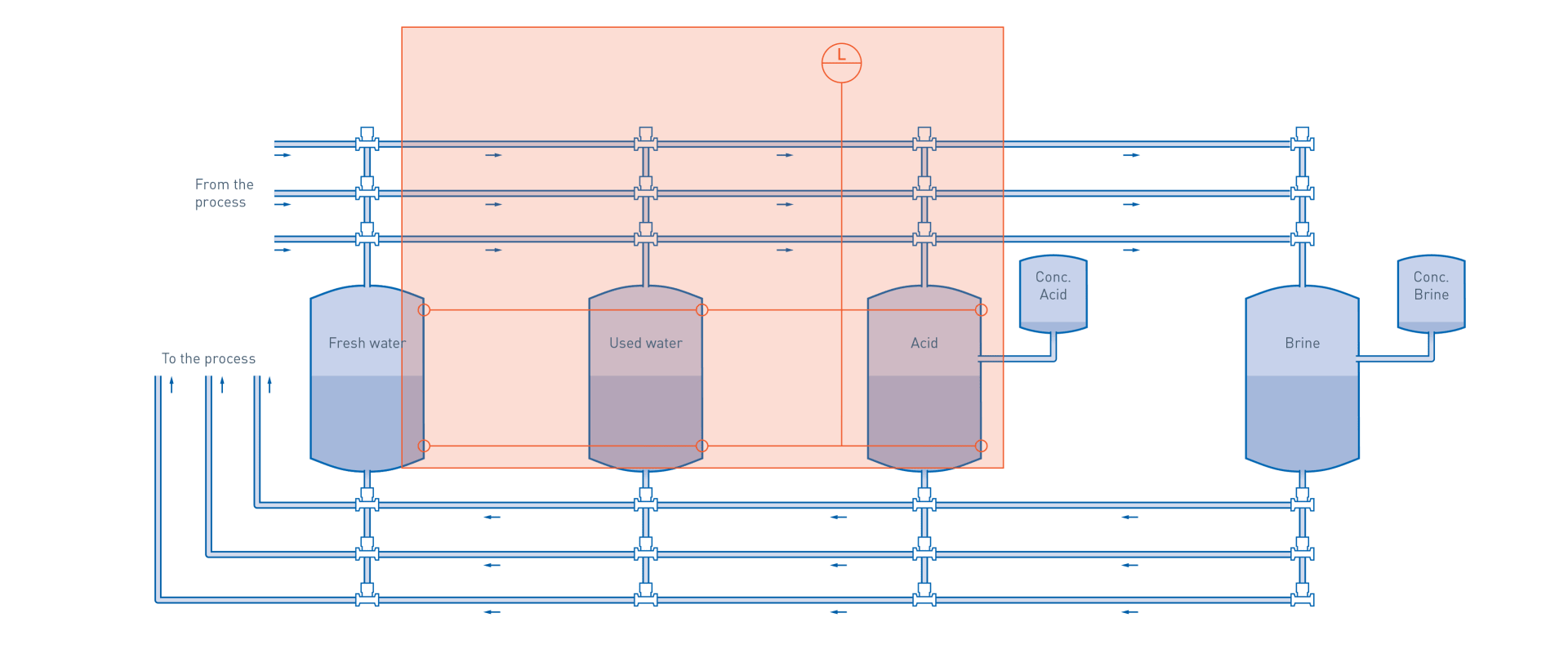

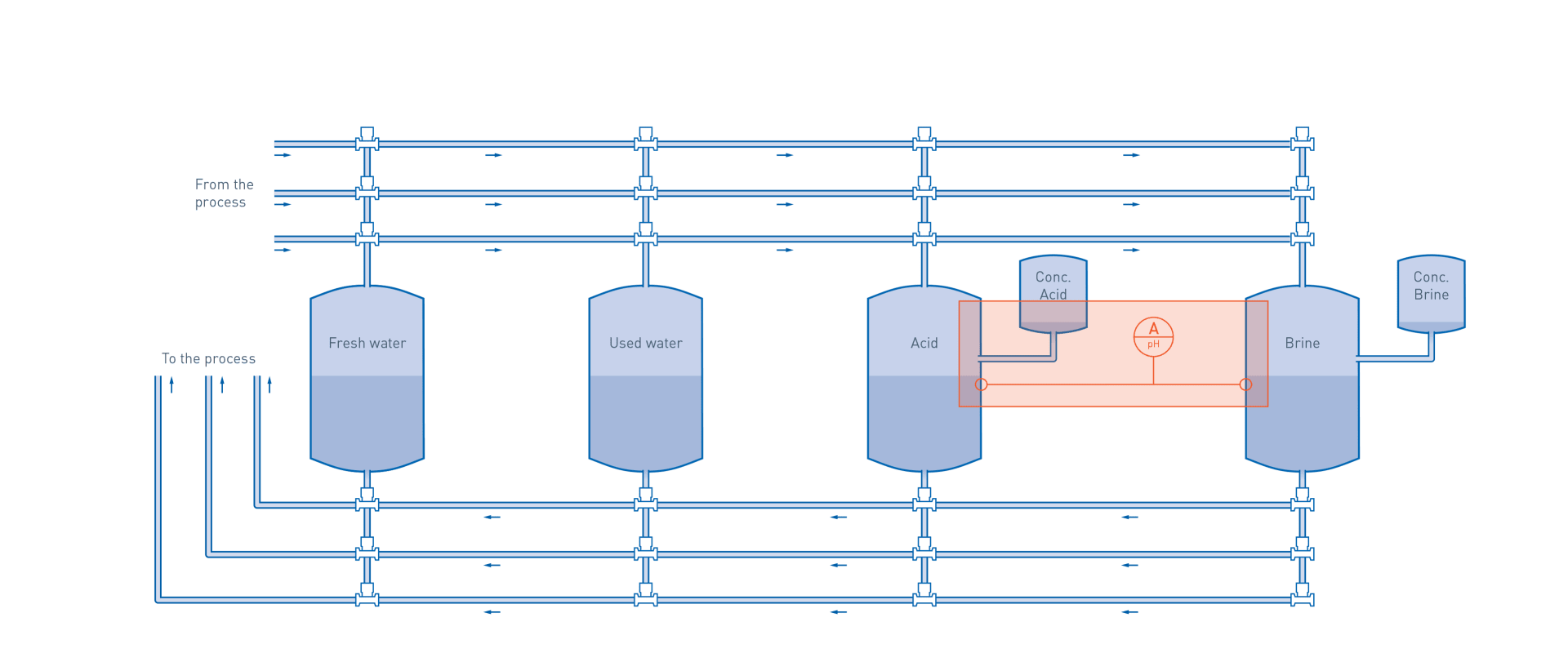

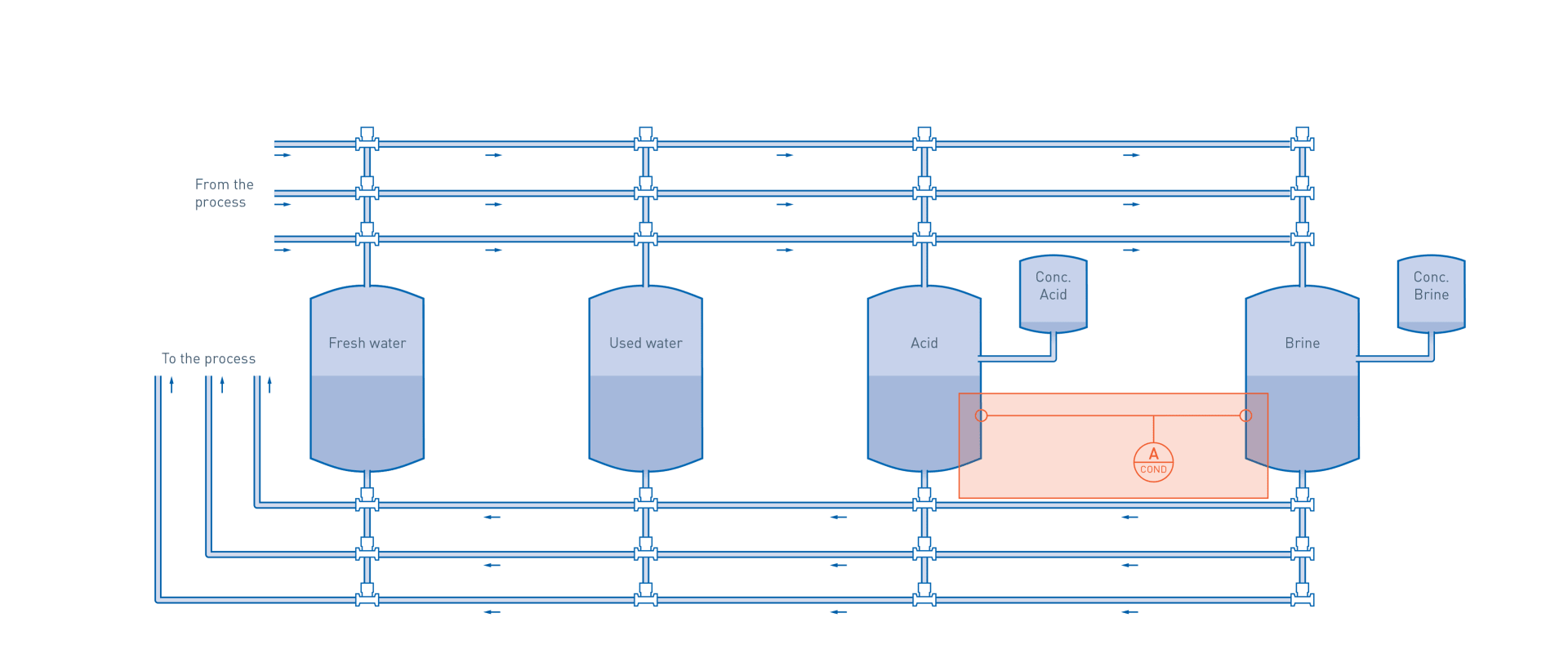

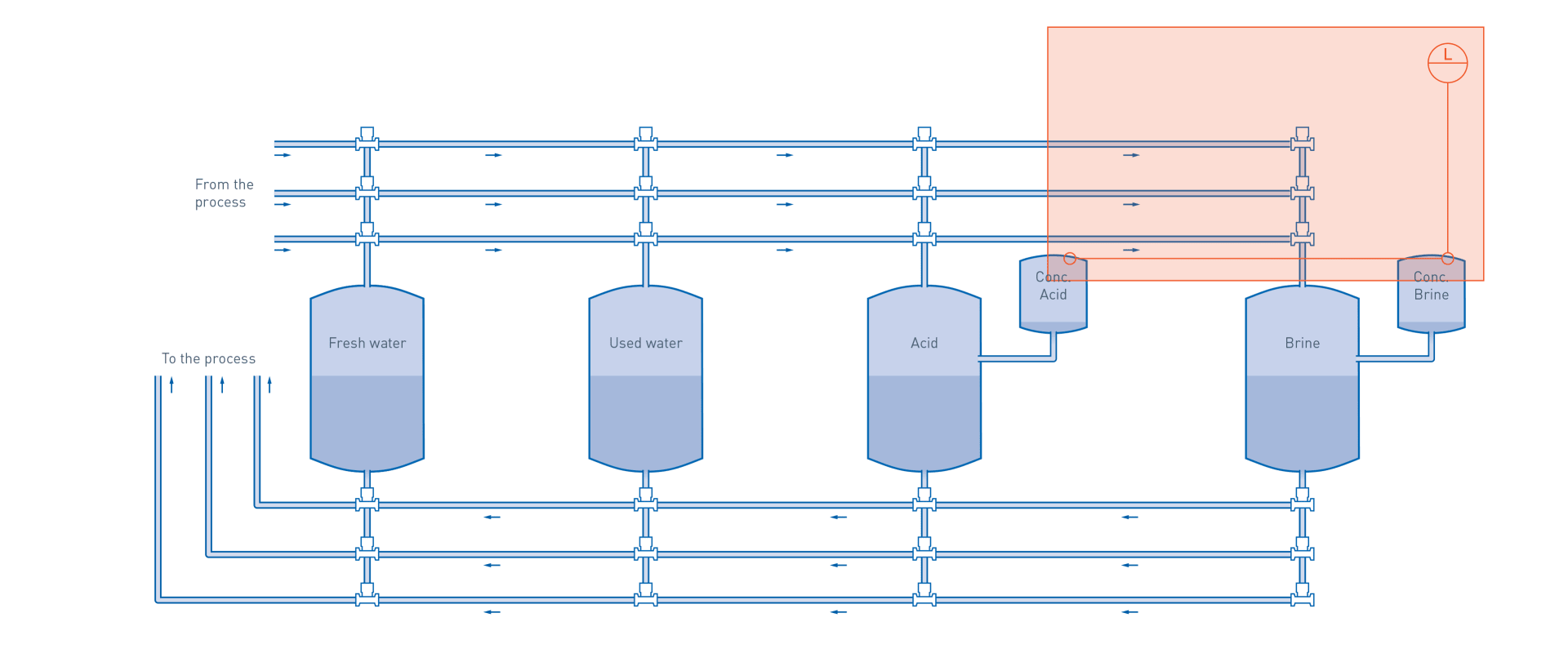

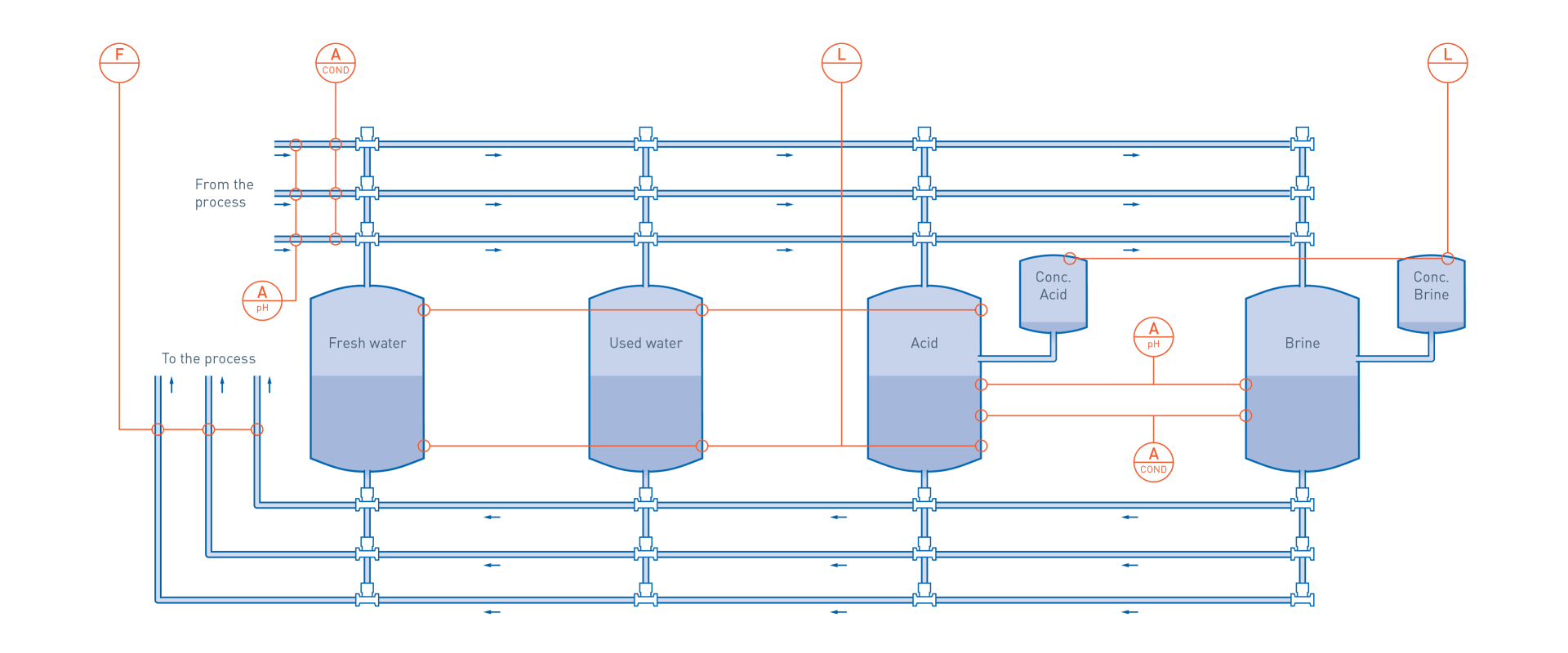

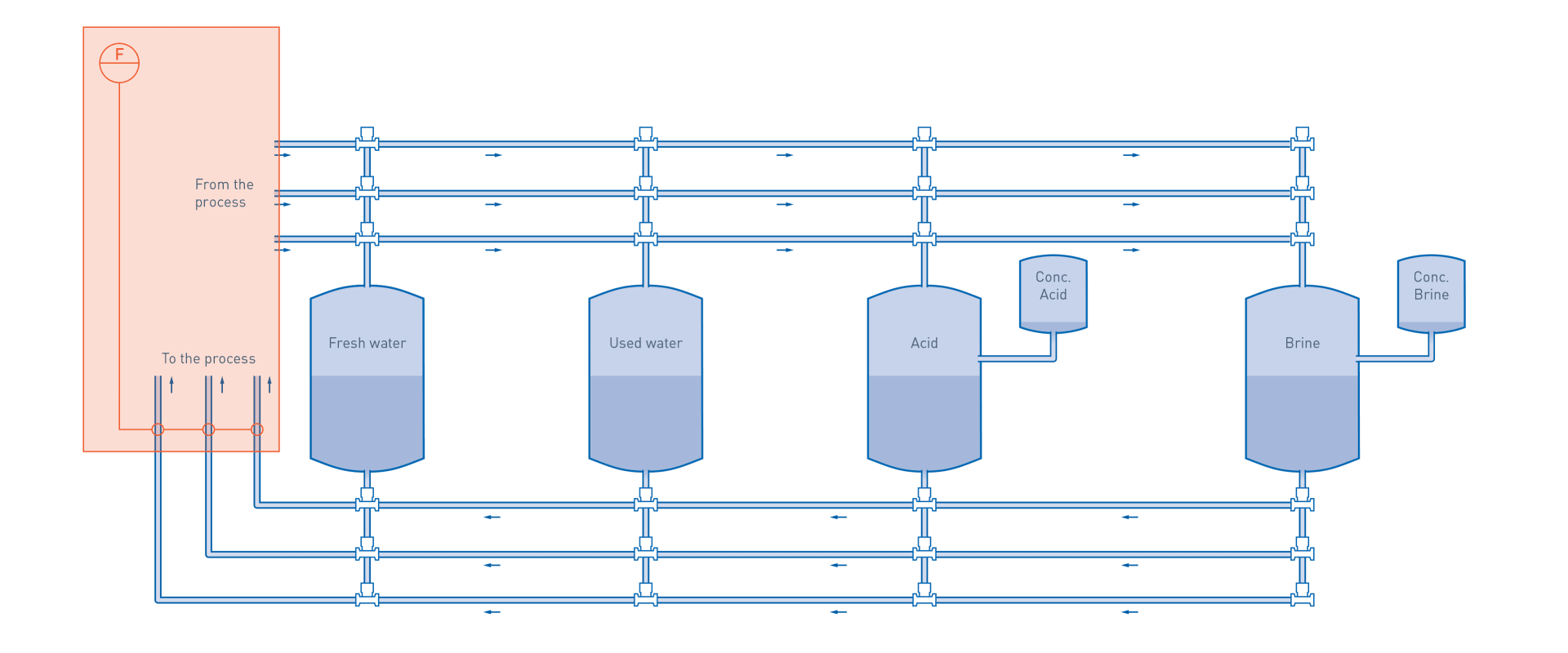

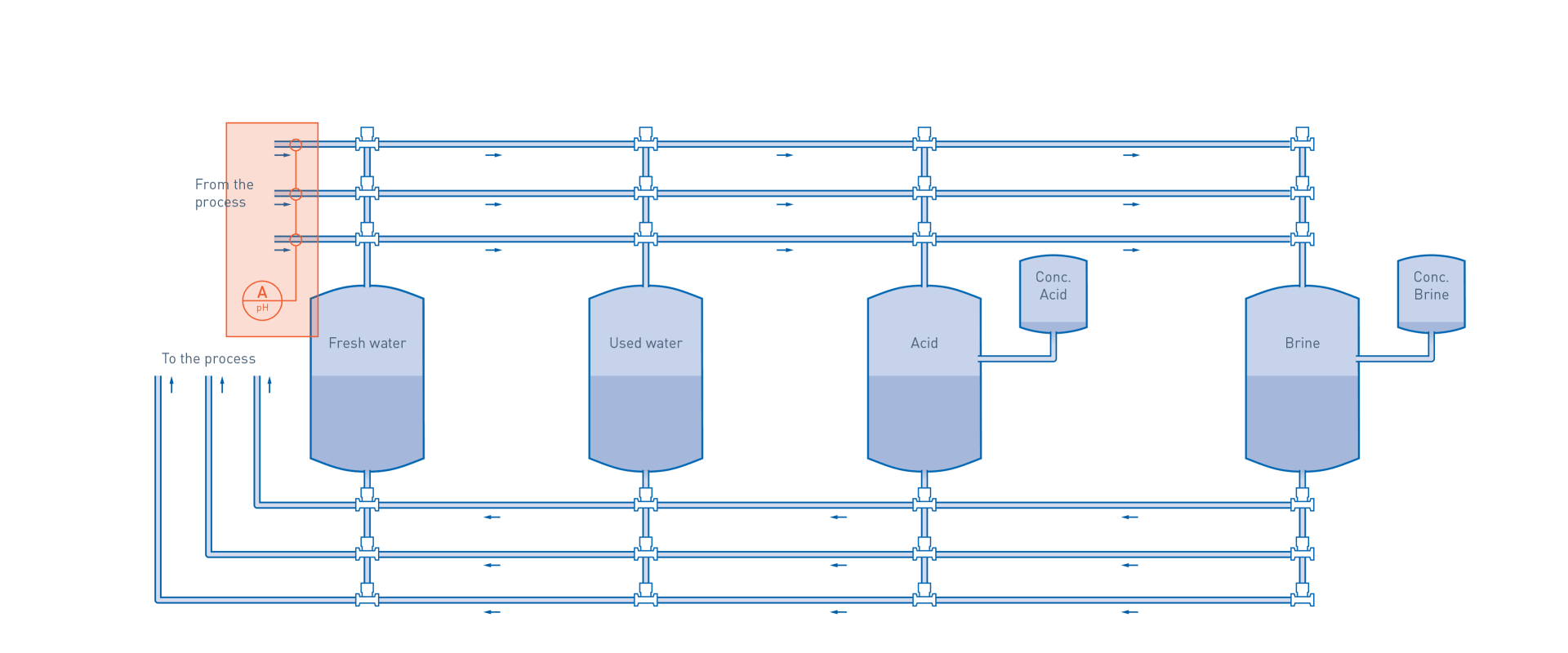

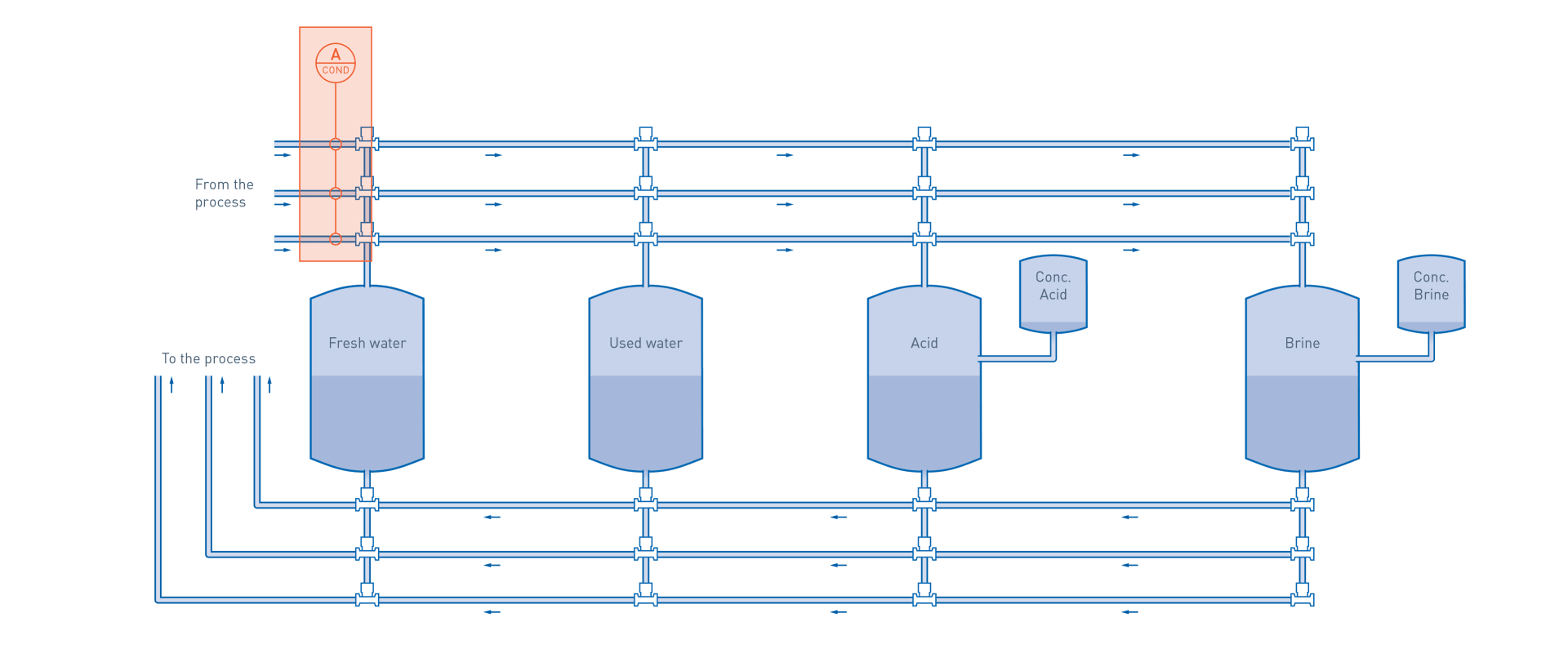

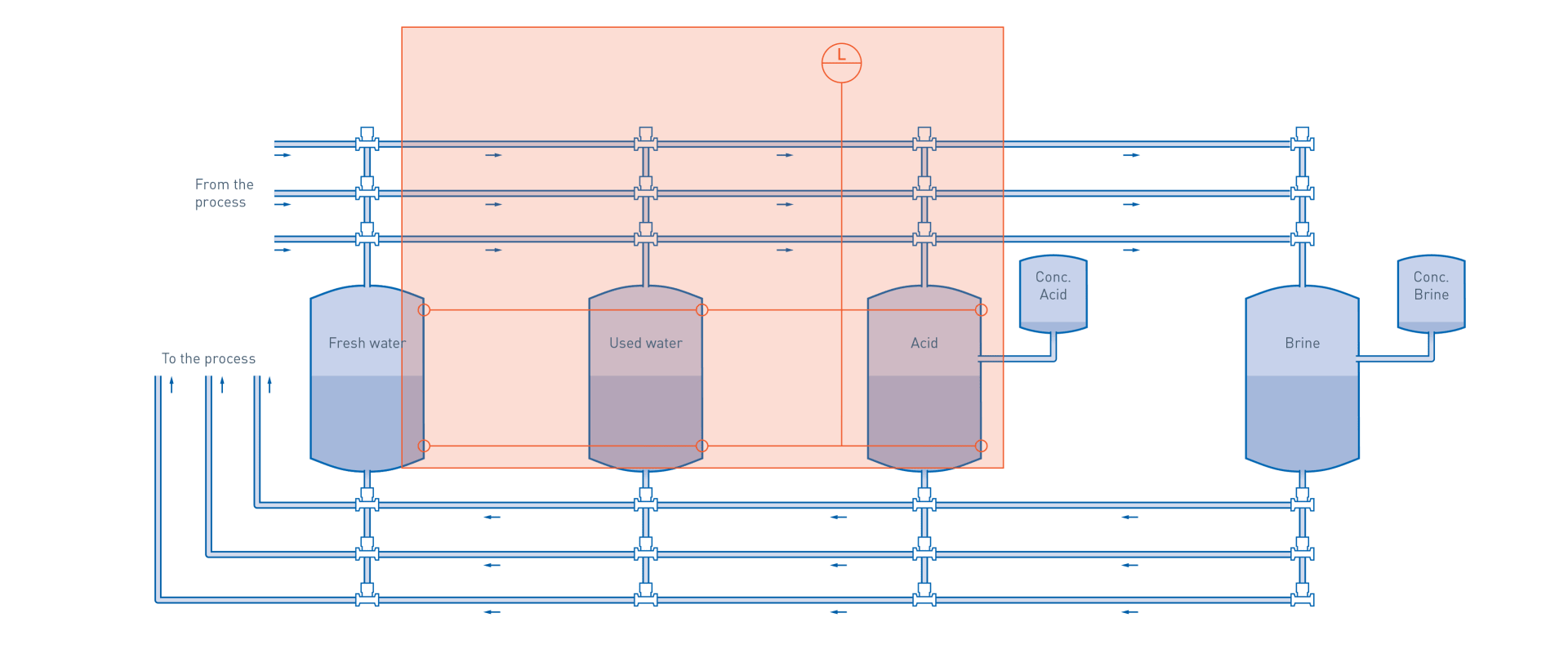

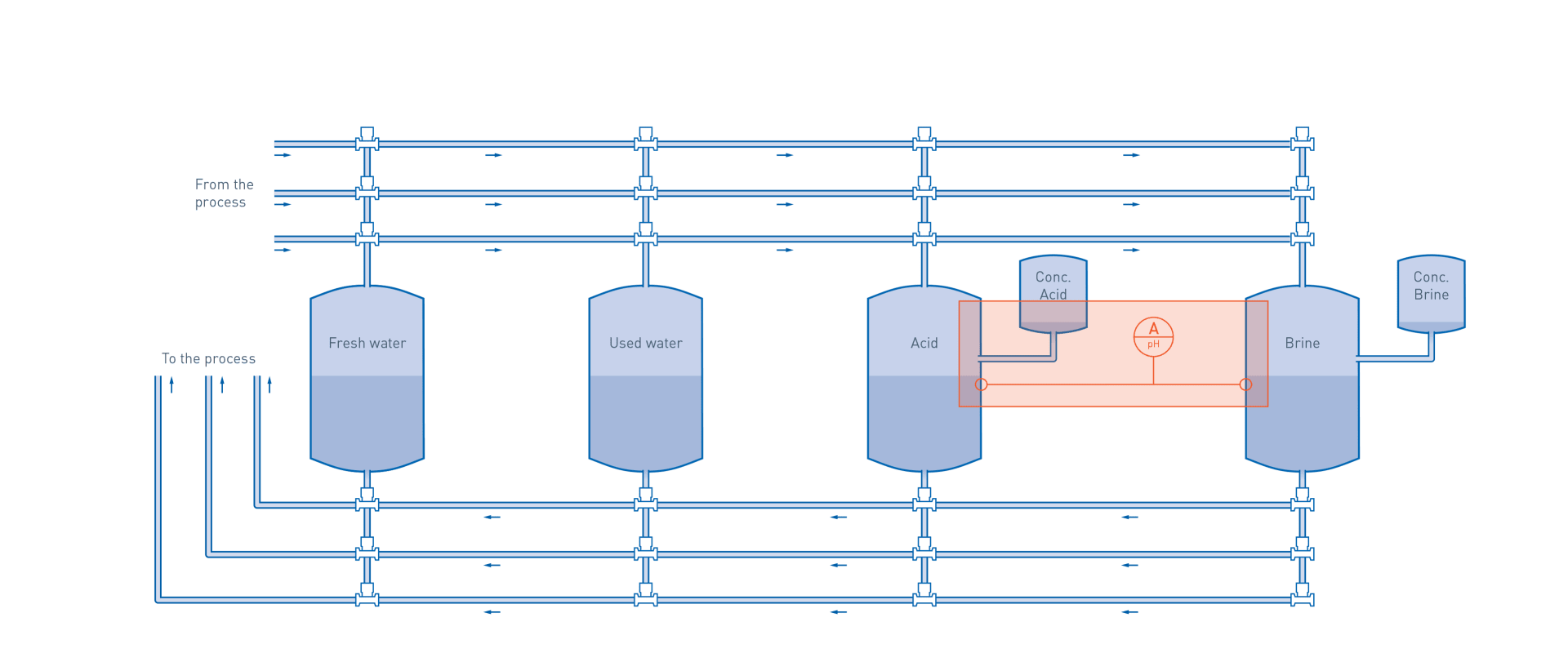

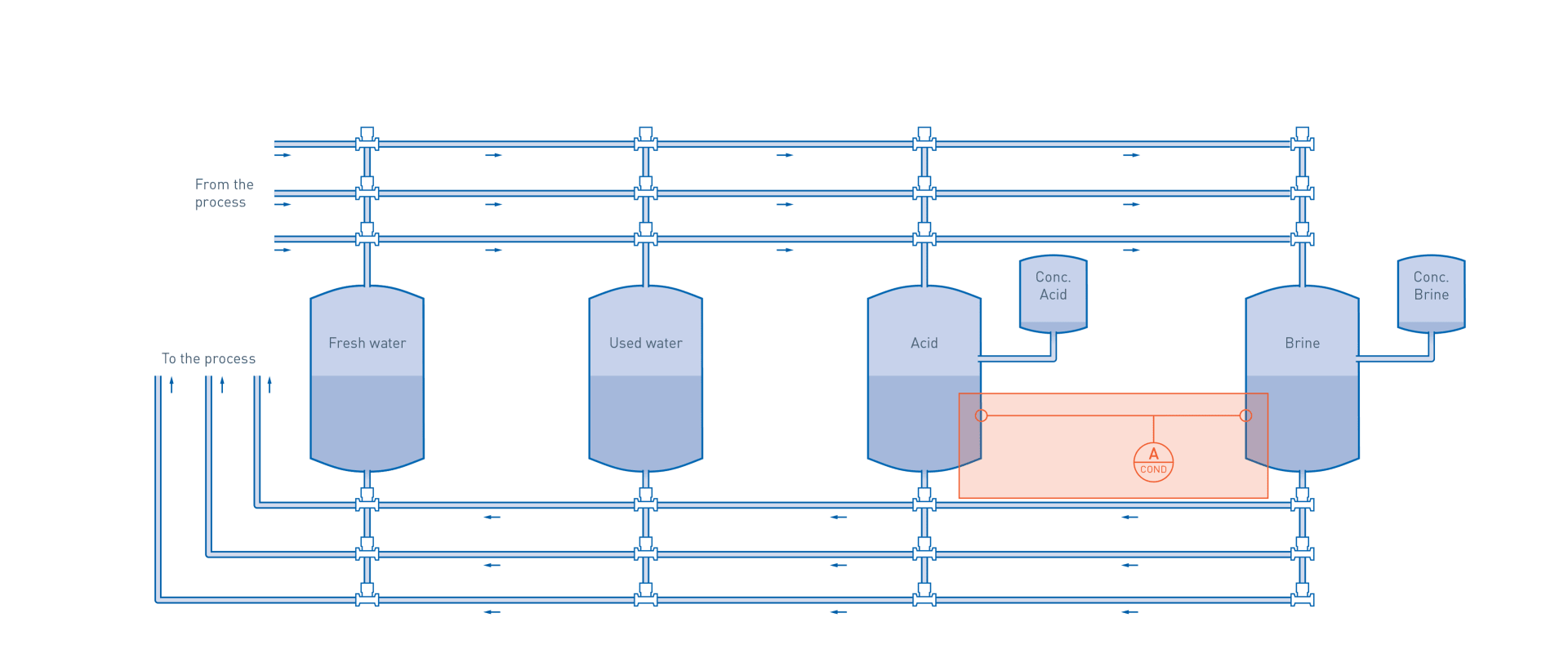

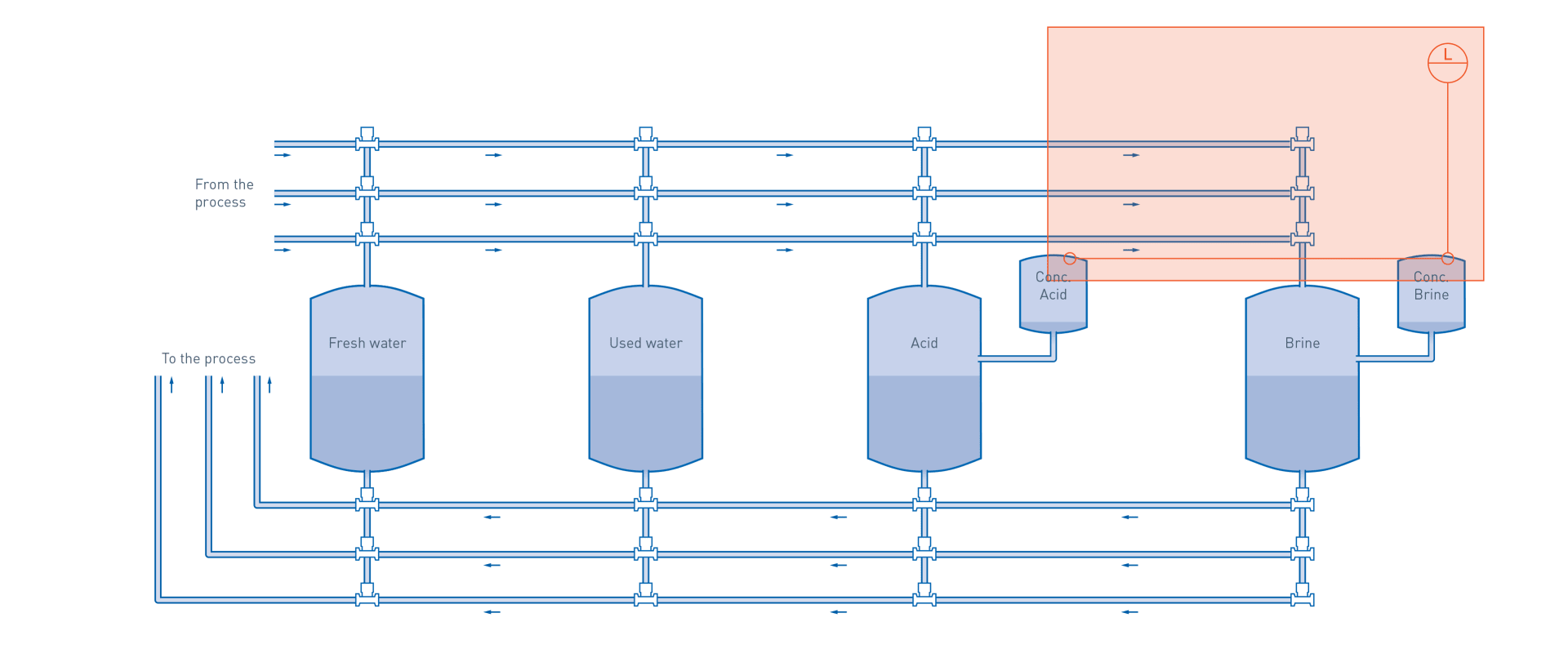

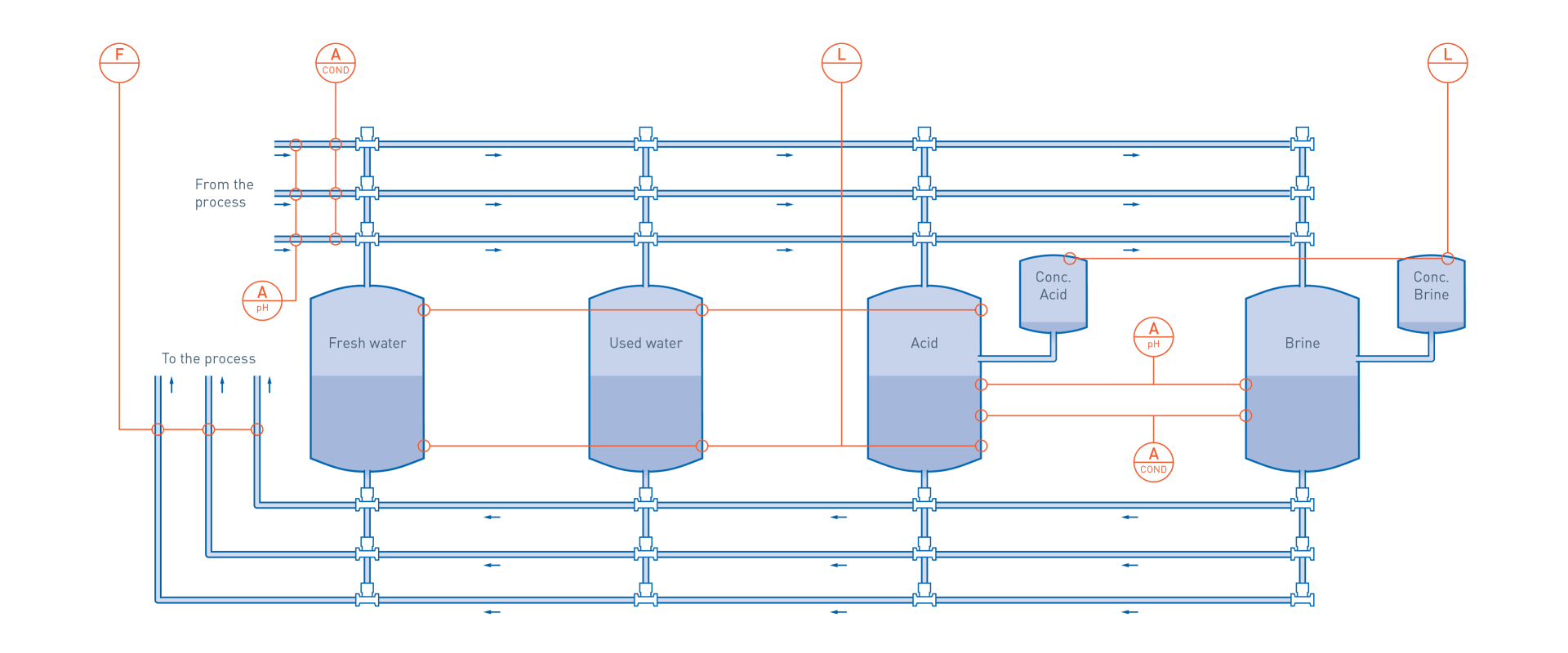

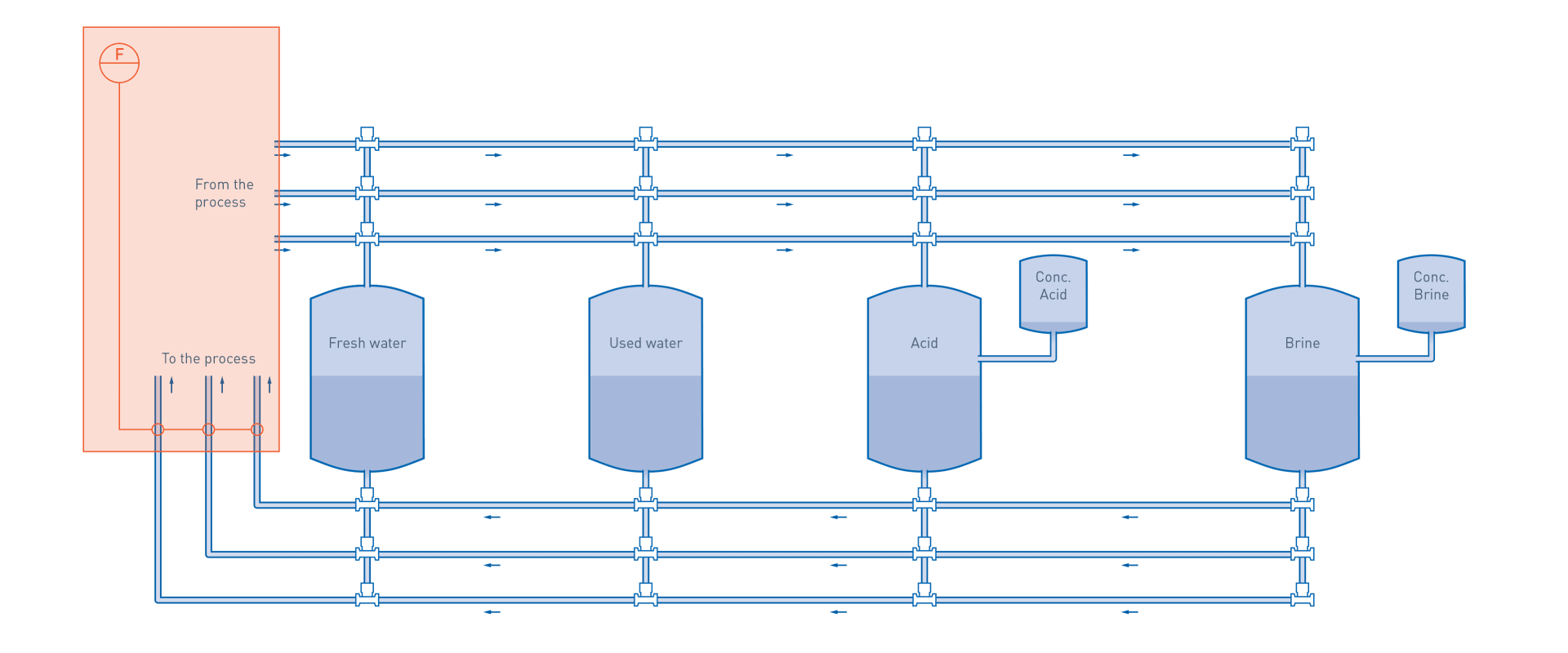

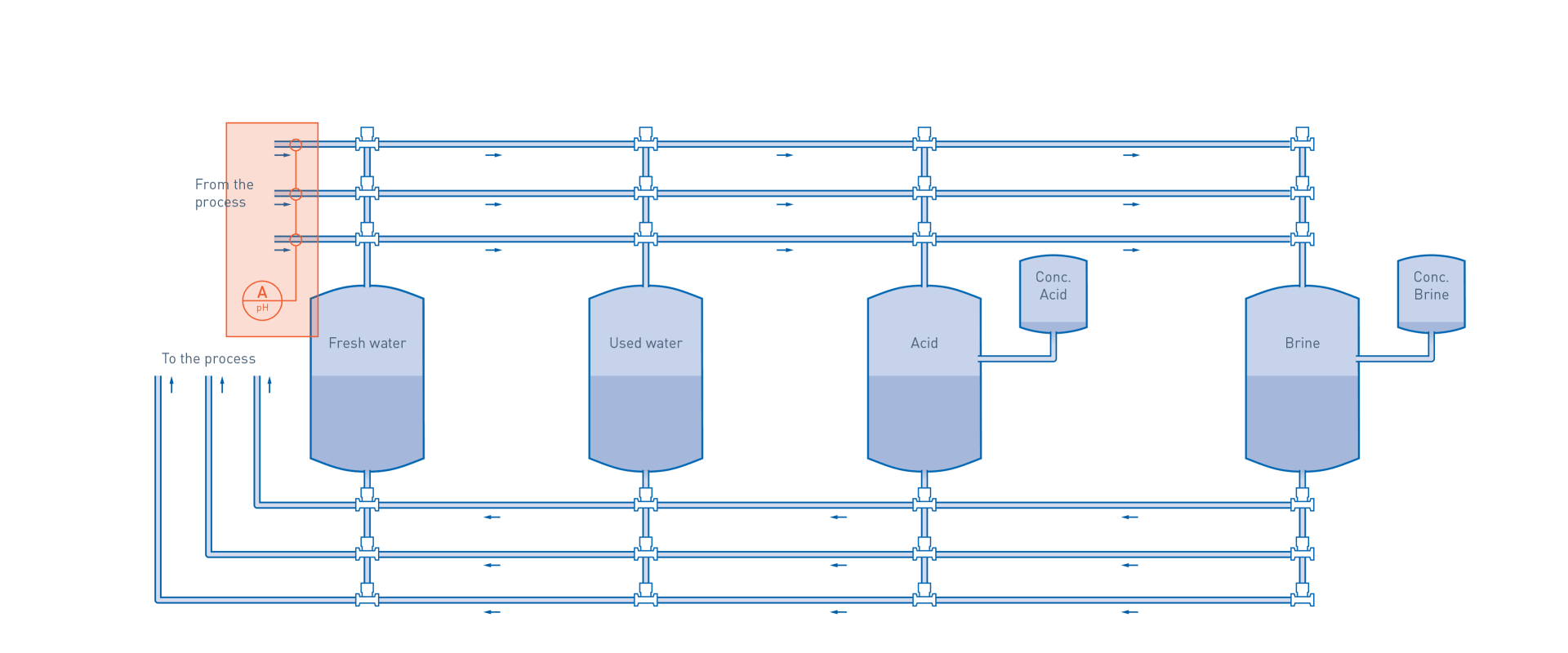

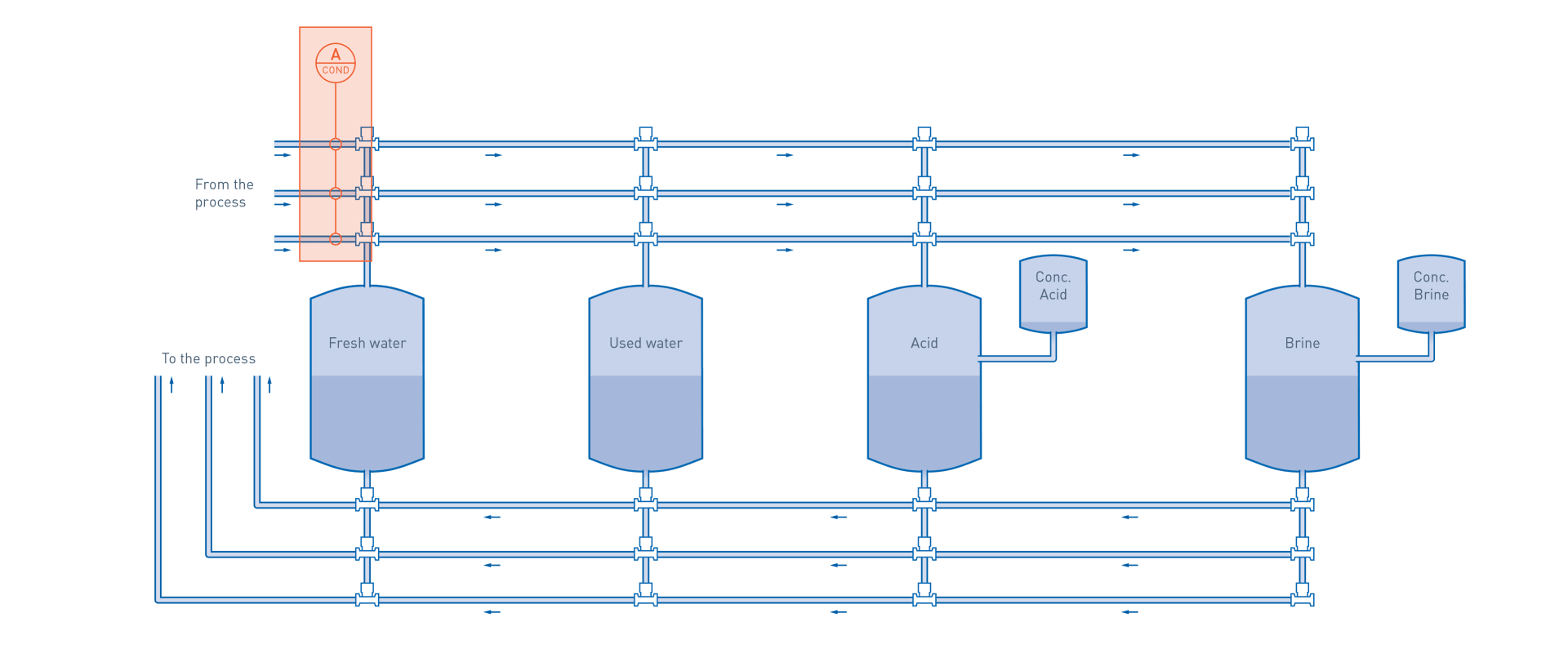

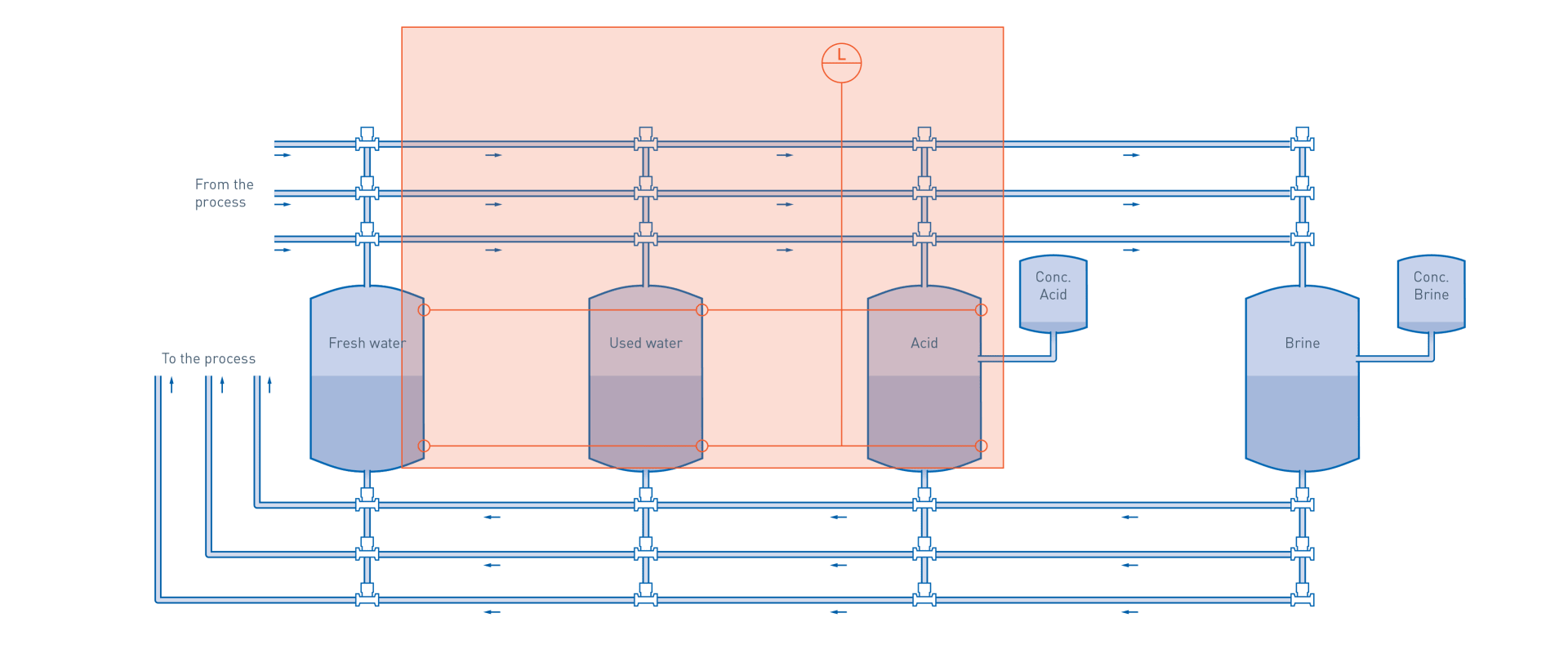

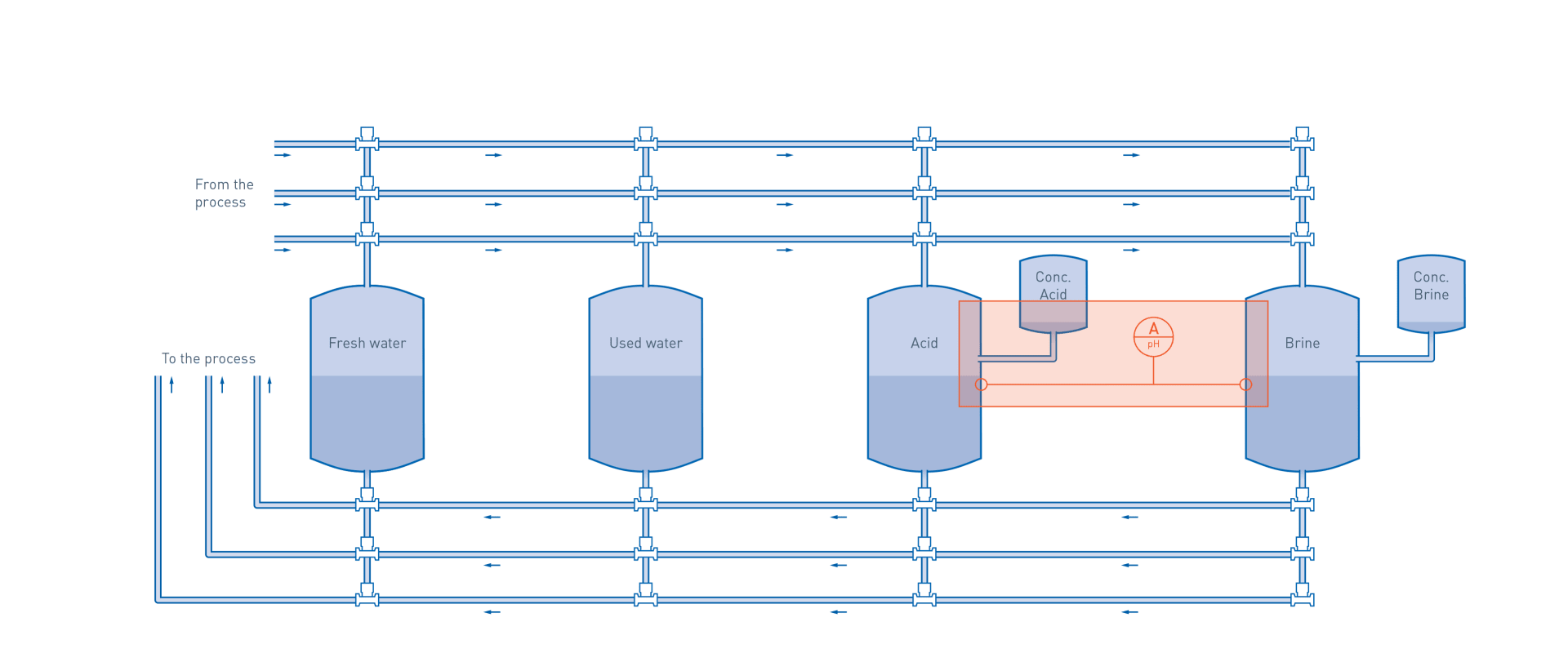

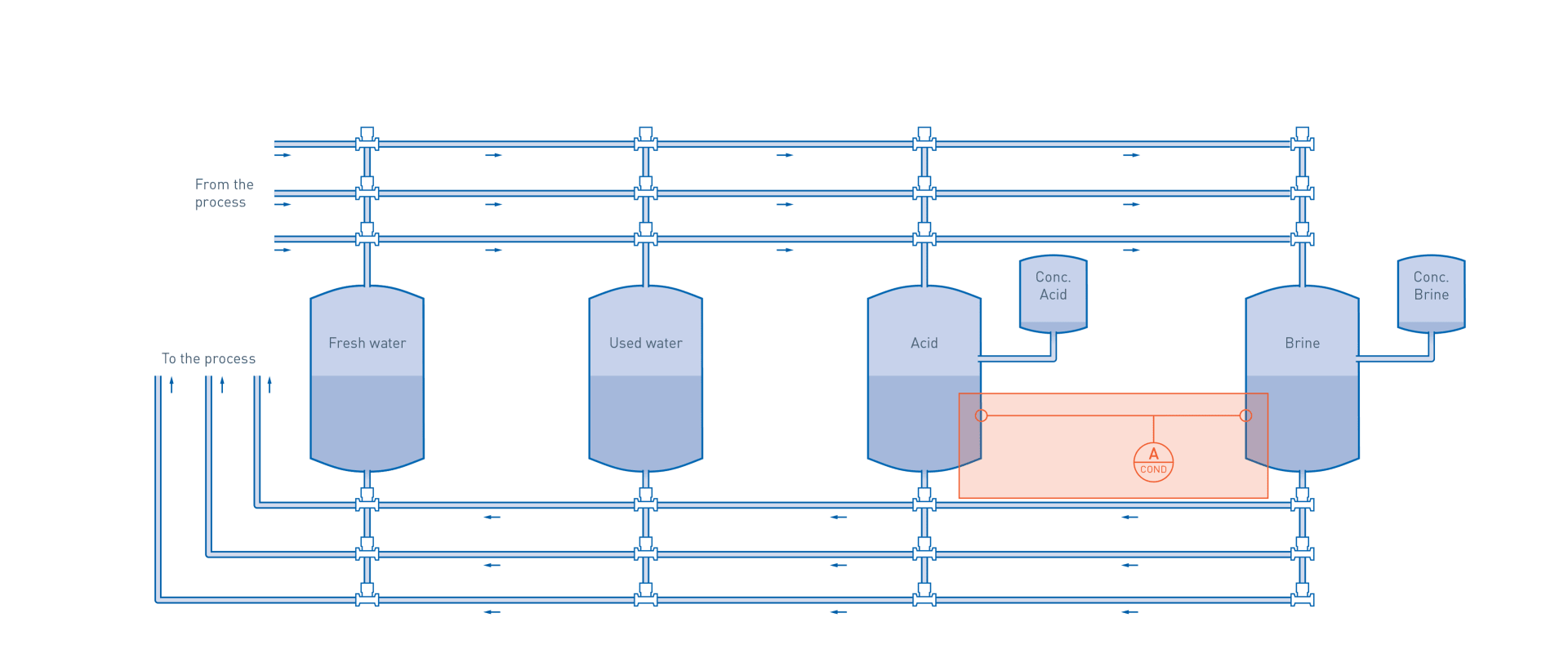

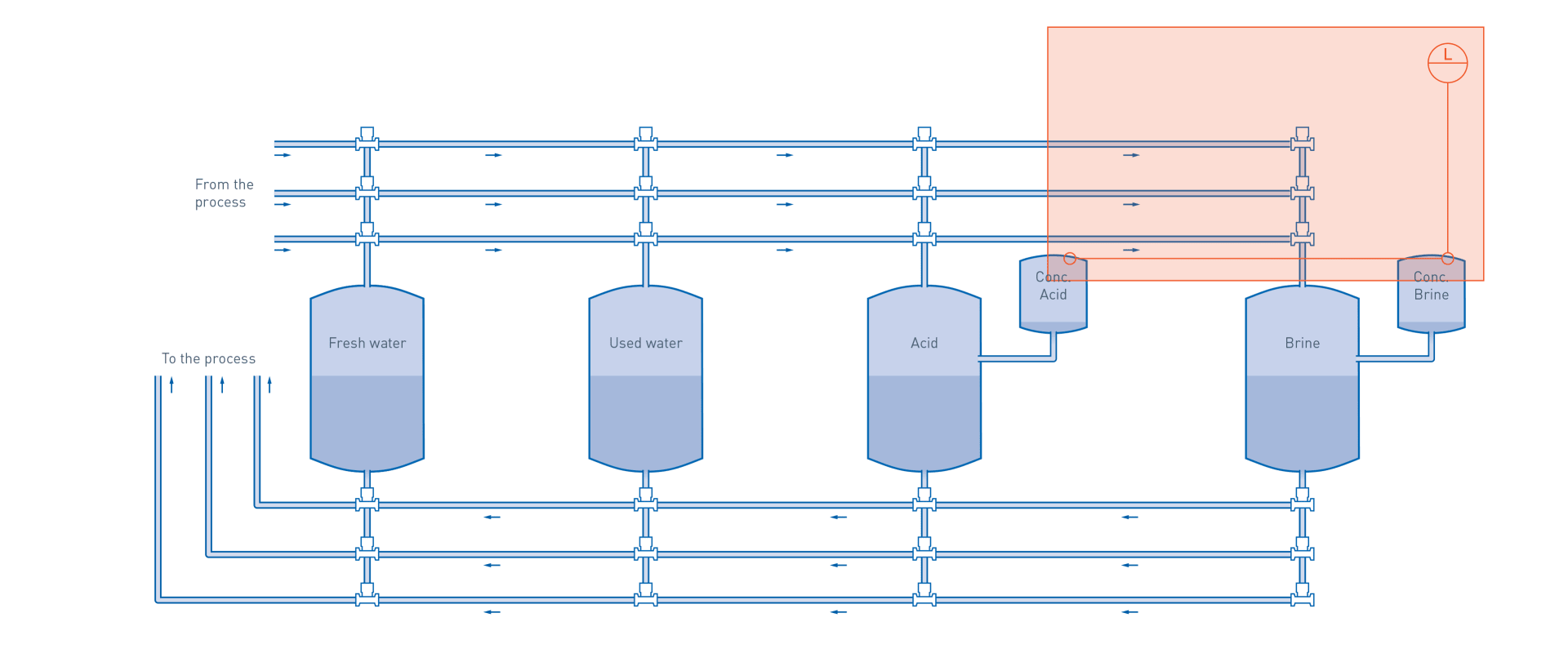

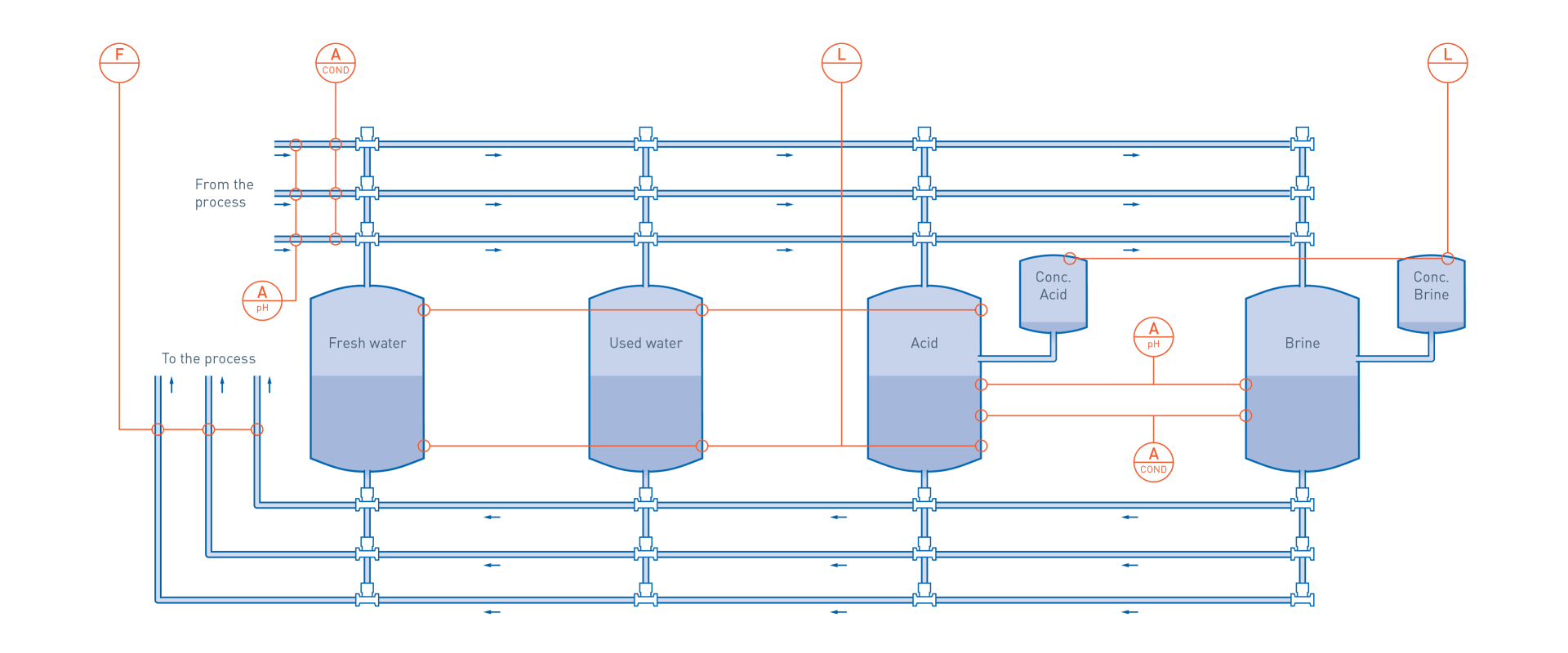

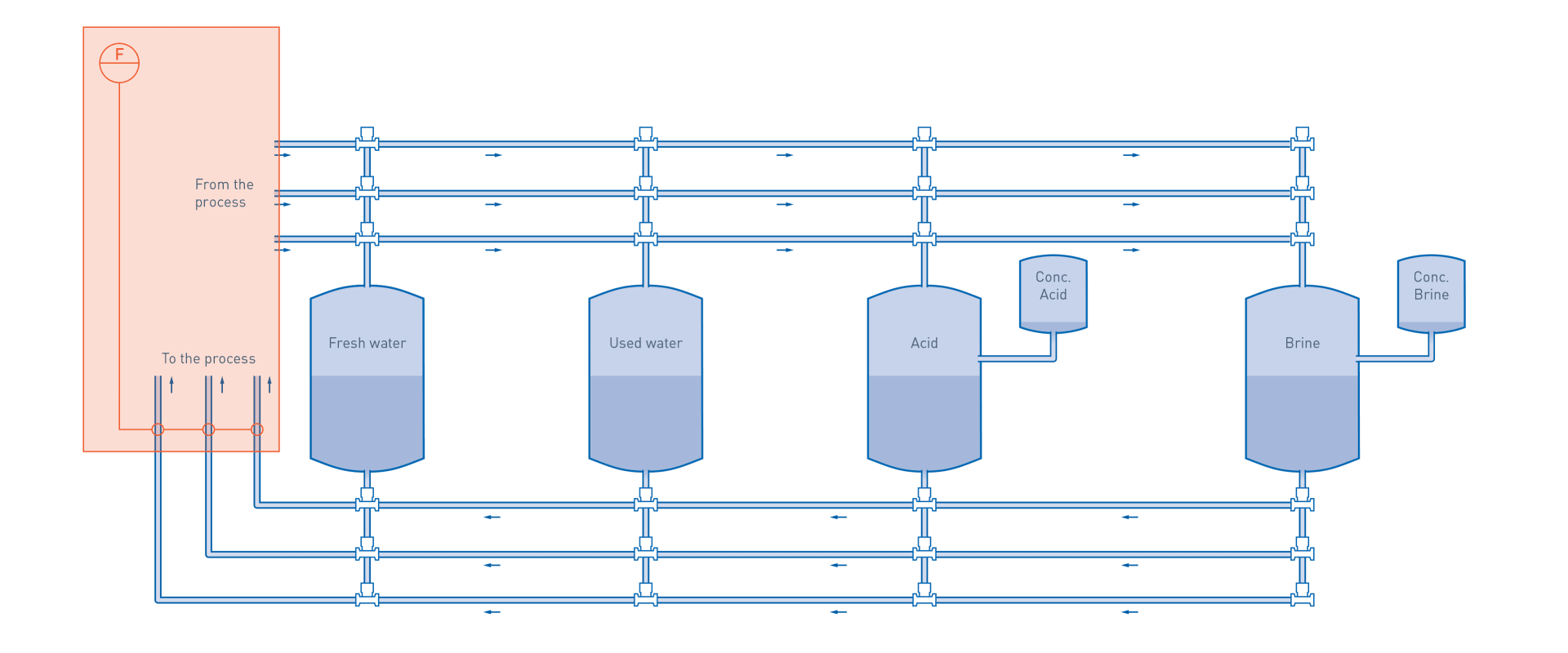

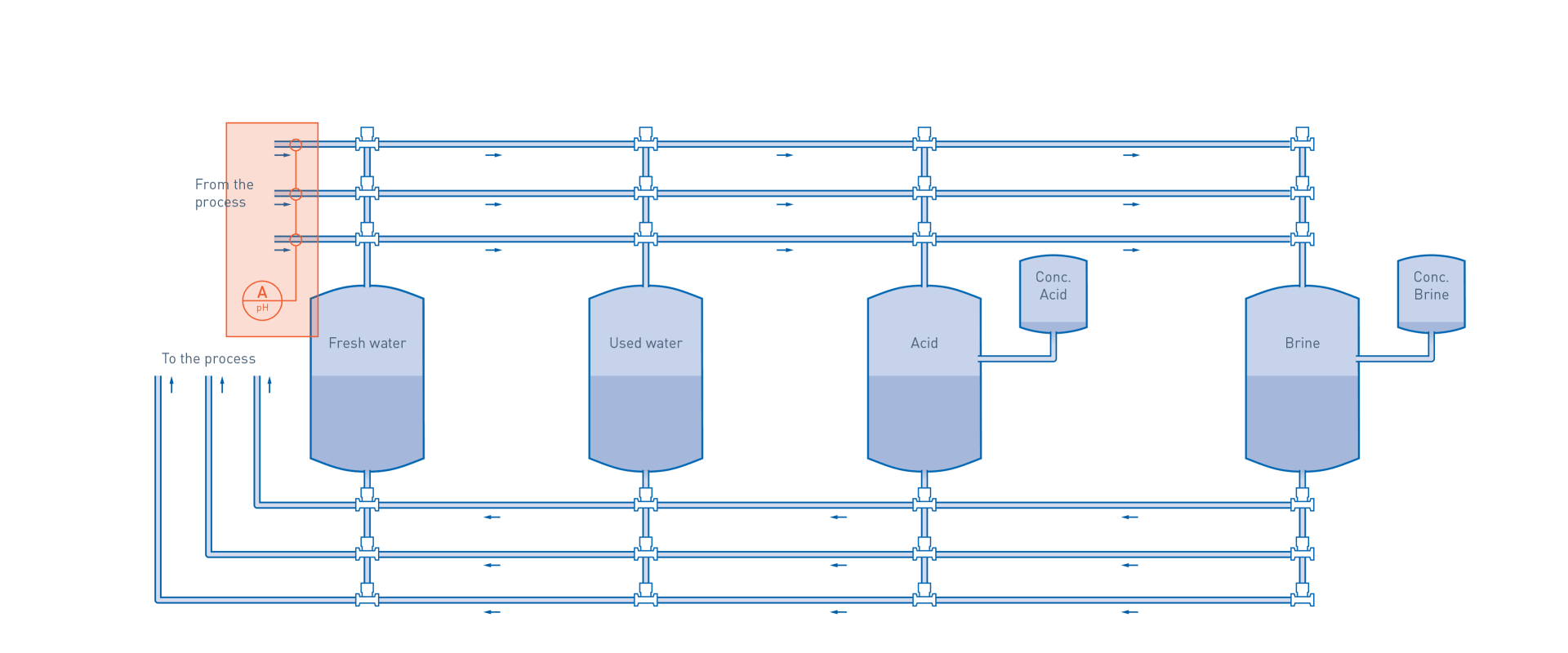

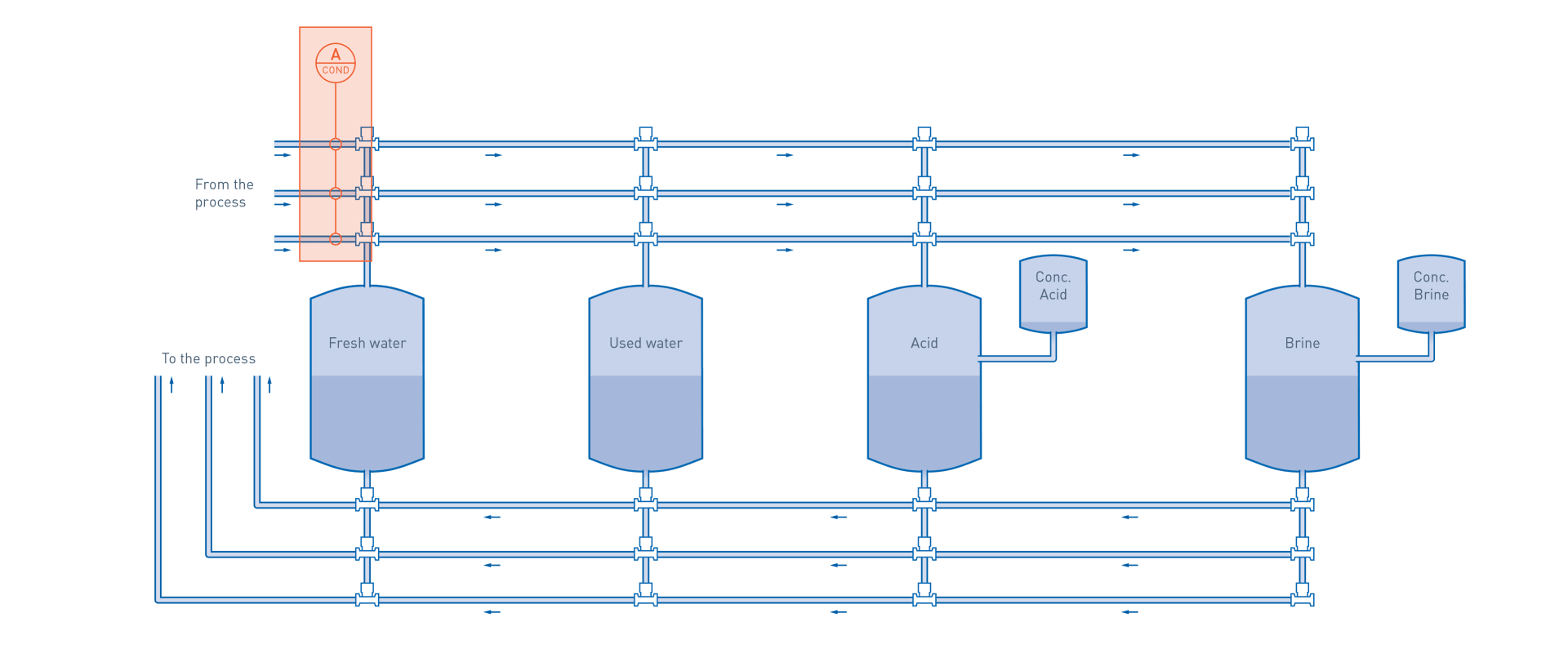

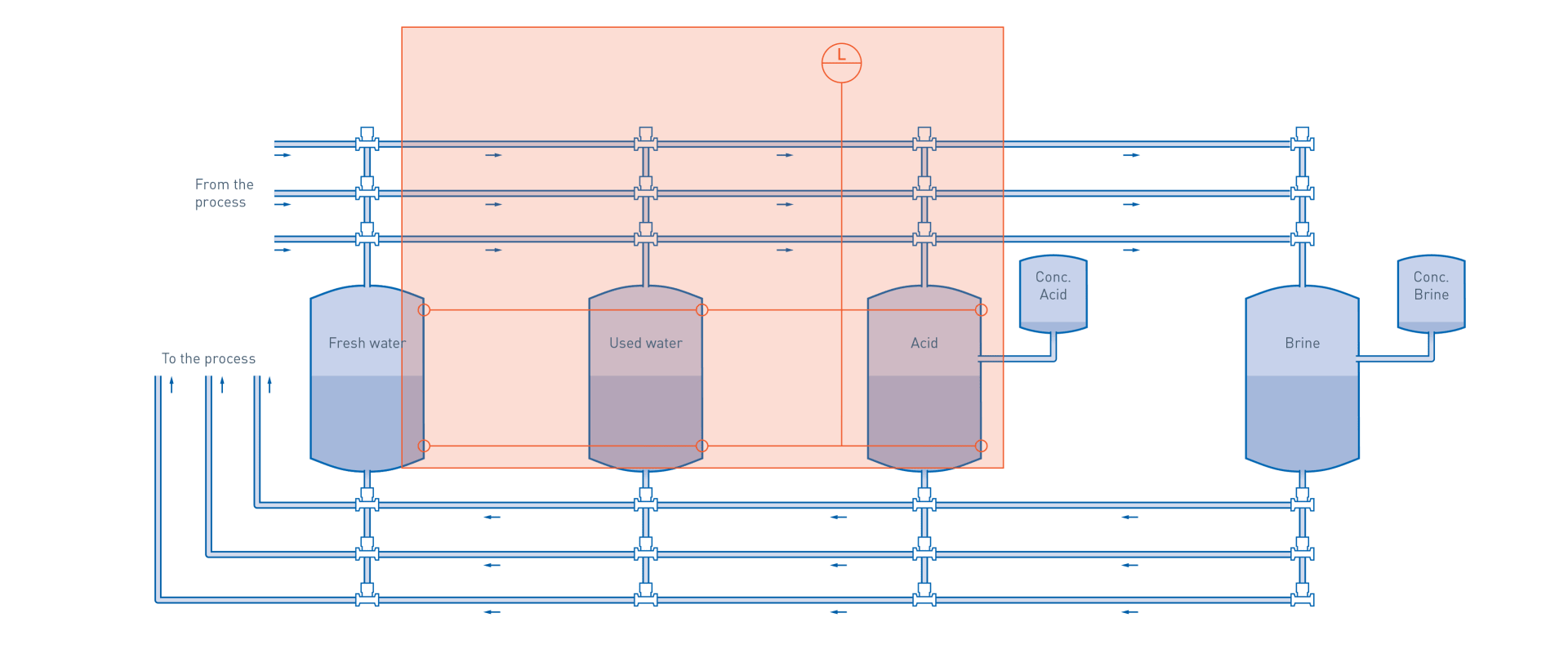

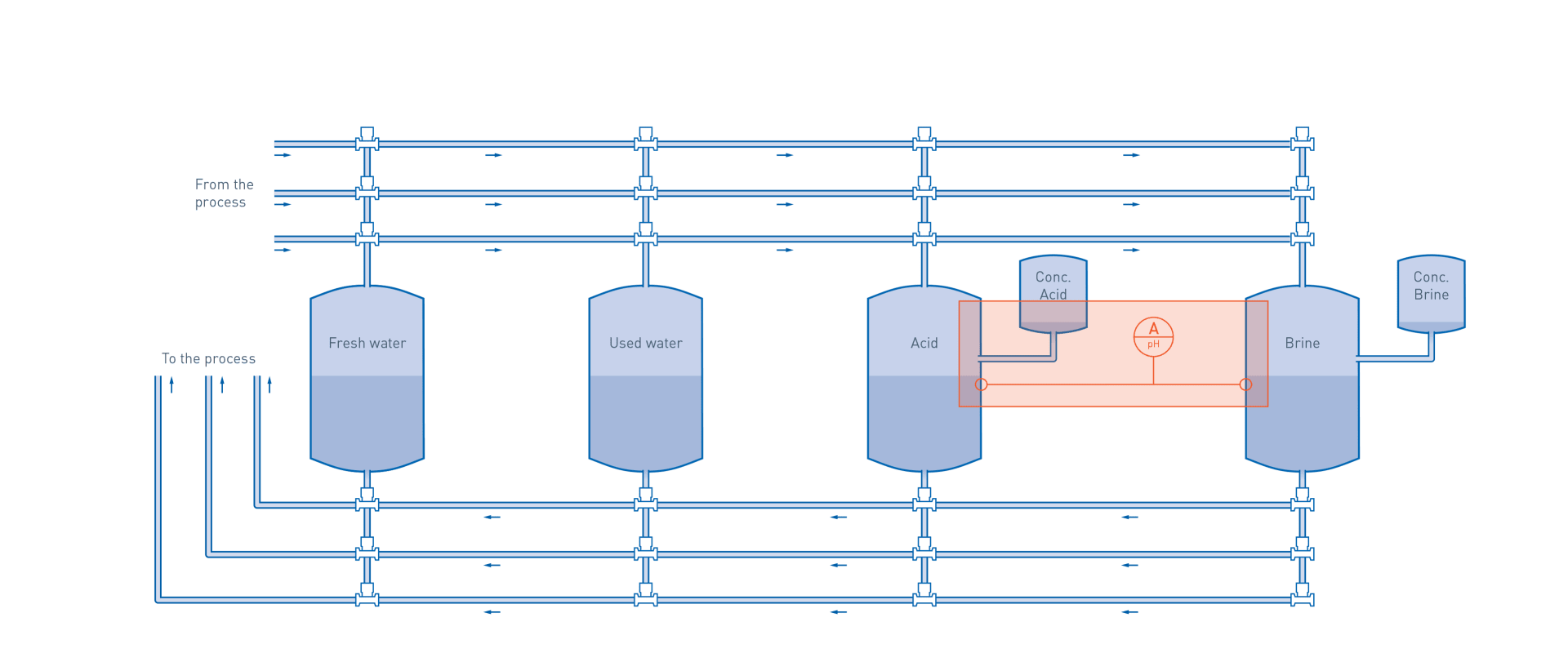

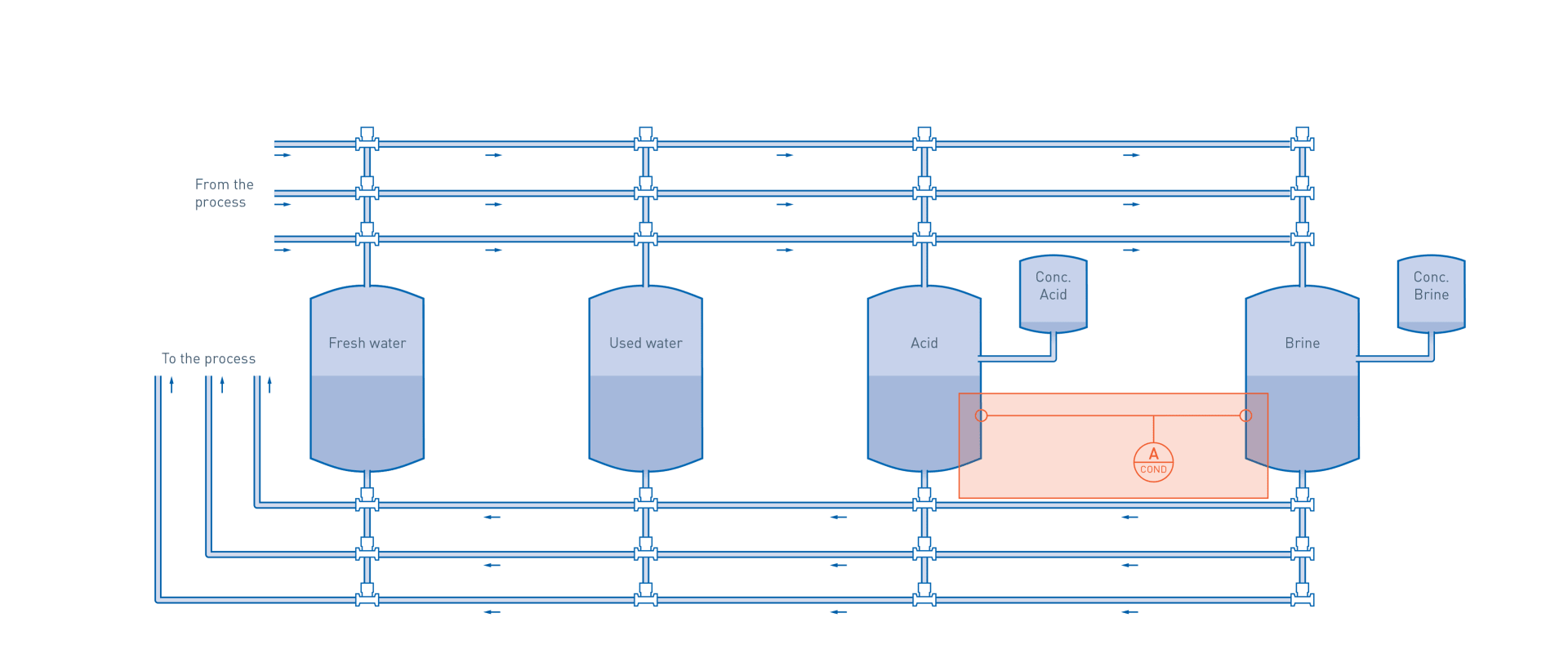

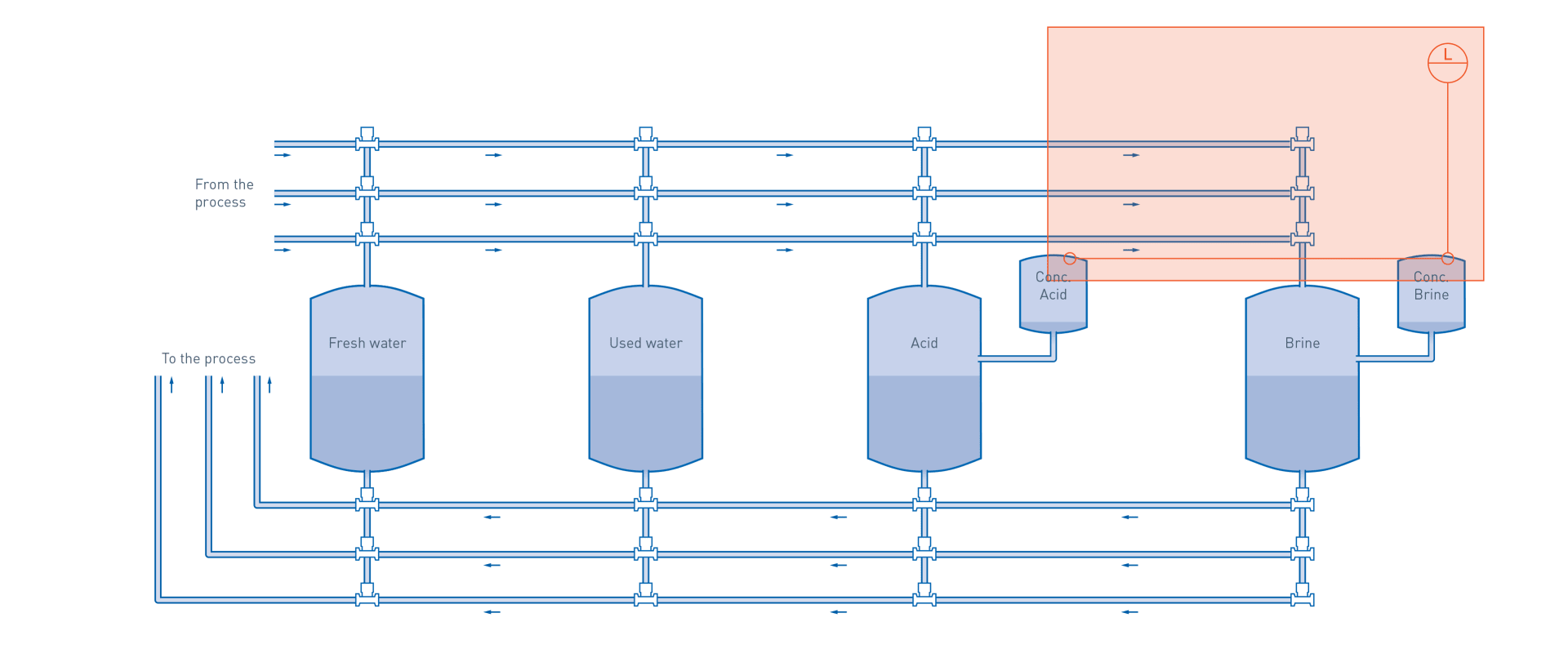

Most of the industrial fabricated food processes require periodic cleaning without disassembly (CIP= clean in place) to remove residue from previous processes and to sanitize both the process piping and tanks. Depending upon the particular products produced, the cleaning can involve alternately flushing with water, caustic solutions, again water, acid solutions and fresh water. Typically the CIP liquids are used multiple times, therefore these liquids are stored again in special allocated tanks.

KROHNE offers precisely tailored measuring devices for these tasks. Robust and extremely fast conductivity and pH sensors can identify the different liquids in tanks and pipes to guarantee a proper storage of the reused liquids. Compact guided radar level transmitters (TDR) are available with a variety of hygienic connections and allow measurements even in the small compact concentration tanks. OPTIFLUX electromagnetic flowmeters provide exact results for an accurate determination of the cleaning volume. All devices are EHEDG and 3-A certified and meet the requirements of FDA and EC1935 / 2004.

Process details

CIP processes in the food & beverage industry

Recommended products and solutions:

OPTIFLUX 6050

- Cost-effective flow measurement in the food sector

- Meter size: DN2.5…150 / ⅒…6" (EHEDG etc.)

- Many hygienic fittings

- 4…20 mA, pulse, frequency, status, HART®, Modbus

OPTIFLUX 6100

- Reliable dosing and filling in the food sector

- Meter size: DN2.5…150 / ⅒…6"

- Hygienic fittings and certifications

- 4…20 mA, pulse, frequency, status, HART®

Requirements:

- Process control

Recommended products and solutions:

SMARTPAT PH 8570

- 2-wire loop powered, 4…20 mA/HART® 7, for direct connection to a PCS

- Process connection: PG13.5

- 0…14 pH; Max. +140°C / +284°F (SIP/CIP); 12 bar / 174 psi

- Autoclavable glass sensor with ceramic diaphragm and Pt1000 for temperature compensation

Requirements:

- Equipped with fast acting temperature sensor for sharp phase separation

- Compact design for small diameter pipes

Recommended products and solutions:

OPTISYS IND 8100

- 4-wire, 4…20 mA, with head-mounted or remote transmitter

- Process connection: G1 for hygienic adapters

- 0.05…1000 mS/cm; Max. +140°C / +285°F; 10 bar / 145 psi

- Hygienic PEEK sensor, robust (IP69K), with temperature compensation

Recommended products and solutions:

OPTISWITCH 6600

- Point level detection of solids, liquids and liquid-liquid interface

- Wide variety of hygienic process connections available

- -20…+200°C / -4…+392°F; -1…16 barg / -14.5…580 psig

Requirements:

- Quality control

Recommended products and solutions:

SMARTPAT PH 8570

- 2-wire loop powered, 4…20 mA/HART® 7, for direct connection to a PCS

- Process connection: PG13.5

- 0…14 pH; Max. +140°C / +284°F (SIP/CIP); 12 bar / 174 psi

- Autoclavable glass sensor with ceramic diaphragm and Pt1000 for temperature compensation

Requirements:

- Equipped with fast acting temperature sensor for sharp phase separation

Recommended products and solutions:

OPTISYS IND 8100

- 4-wire, 4…20 mA, with head-mounted or remote transmitter

- Process connection: G1 for hygienic adapters

- 0.05…1000 mS/cm; Max. +140°C / +285°F; 10 bar / 145 psi

- Hygienic PEEK sensor, robust (IP69K), with temperature compensation

Requirements:

- Small dead zone

Recommended products and solutions:

OPTIFLEX 3200

- Continuous measurement of level and interface in small and narrow vessels

- Conform to FDA, EC1935/2004, EHEDG

- Measuring range: 0.6…4 m / 2…13 ft

- -50…+150°C / -58…+302°F; -1…40 barg / -14.5…580 psig

CIP processes in the food & beverage industry

Recommended products and solutions:

OPTIFLUX 6050

- Cost-effective flow measurement in the food sector

- Meter size: DN2.5…150 / ⅒…6" (EHEDG etc.)

- Many hygienic fittings

- 4…20 mA, pulse, frequency, status, HART®, Modbus

OPTIFLUX 6100

- Reliable dosing and filling in the food sector

- Meter size: DN2.5…150 / ⅒…6"

- Hygienic fittings and certifications

- 4…20 mA, pulse, frequency, status, HART®

Requirements:

- Process control

Recommended products and solutions:

SMARTPAT PH 8570

- 2-wire loop powered, 4…20 mA/HART® 7, for direct connection to a PCS

- Process connection: PG13.5

- 0…14 pH; Max. +140°C / +284°F (SIP/CIP); 12 bar / 174 psi

- Autoclavable glass sensor with ceramic diaphragm and Pt1000 for temperature compensation

Requirements:

- Equipped with fast acting temperature sensor for sharp phase separation

- Compact design for small diameter pipes

Recommended products and solutions:

OPTISYS IND 8100

- 4-wire, 4…20 mA, with head-mounted or remote transmitter

- Process connection: G1 for hygienic adapters

- 0.05…1000 mS/cm; Max. +140°C / +285°F; 10 bar / 145 psi

- Hygienic PEEK sensor, robust (IP69K), with temperature compensation

Recommended products and solutions:

OPTISWITCH 6600

- Point level detection of solids, liquids and liquid-liquid interface

- Wide variety of hygienic process connections available

- -20…+200°C / -4…+392°F; -1…16 barg / -14.5…580 psig

Requirements:

- Quality control

Recommended products and solutions:

SMARTPAT PH 8570

- 2-wire loop powered, 4…20 mA/HART® 7, for direct connection to a PCS

- Process connection: PG13.5

- 0…14 pH; Max. +140°C / +284°F (SIP/CIP); 12 bar / 174 psi

- Autoclavable glass sensor with ceramic diaphragm and Pt1000 for temperature compensation

Requirements:

- Equipped with fast acting temperature sensor for sharp phase separation

Recommended products and solutions:

OPTISYS IND 8100

- 4-wire, 4…20 mA, with head-mounted or remote transmitter

- Process connection: G1 for hygienic adapters

- 0.05…1000 mS/cm; Max. +140°C / +285°F; 10 bar / 145 psi

- Hygienic PEEK sensor, robust (IP69K), with temperature compensation

Requirements:

- Small dead zone

Recommended products and solutions:

OPTIFLEX 3200

- Continuous measurement of level and interface in small and narrow vessels

- Conform to FDA, EC1935/2004, EHEDG

- Measuring range: 0.6…4 m / 2…13 ft

- -50…+150°C / -58…+302°F; -1…40 barg / -14.5…580 psig

Recommended products and solutions:

CIP processes in the food & beverage industry

Recommended products and solutions:

OPTIFLUX 6050

- Cost-effective flow measurement in the food sector

- Meter size: DN2.5…150 / ⅒…6" (EHEDG etc.)

- Many hygienic fittings

- 4…20 mA, pulse, frequency, status, HART®, Modbus

OPTIFLUX 6100

- Reliable dosing and filling in the food sector

- Meter size: DN2.5…150 / ⅒…6"

- Hygienic fittings and certifications

- 4…20 mA, pulse, frequency, status, HART®

Requirements:

- Process control

Recommended products and solutions:

SMARTPAT PH 8570

- 2-wire loop powered, 4…20 mA/HART® 7, for direct connection to a PCS

- Process connection: PG13.5

- 0…14 pH; Max. +140°C / +284°F (SIP/CIP); 12 bar / 174 psi

- Autoclavable glass sensor with ceramic diaphragm and Pt1000 for temperature compensation

Requirements:

- Equipped with fast acting temperature sensor for sharp phase separation

- Compact design for small diameter pipes

Recommended products and solutions:

OPTISYS IND 8100

- 4-wire, 4…20 mA, with head-mounted or remote transmitter

- Process connection: G1 for hygienic adapters

- 0.05…1000 mS/cm; Max. +140°C / +285°F; 10 bar / 145 psi

- Hygienic PEEK sensor, robust (IP69K), with temperature compensation

Recommended products and solutions:

OPTISWITCH 6600

- Point level detection of solids, liquids and liquid-liquid interface

- Wide variety of hygienic process connections available

- -20…+200°C / -4…+392°F; -1…16 barg / -14.5…580 psig

Requirements:

- Quality control

Recommended products and solutions:

SMARTPAT PH 8570

- 2-wire loop powered, 4…20 mA/HART® 7, for direct connection to a PCS

- Process connection: PG13.5

- 0…14 pH; Max. +140°C / +284°F (SIP/CIP); 12 bar / 174 psi

- Autoclavable glass sensor with ceramic diaphragm and Pt1000 for temperature compensation

Requirements:

- Equipped with fast acting temperature sensor for sharp phase separation

Recommended products and solutions:

OPTISYS IND 8100

- 4-wire, 4…20 mA, with head-mounted or remote transmitter

- Process connection: G1 for hygienic adapters

- 0.05…1000 mS/cm; Max. +140°C / +285°F; 10 bar / 145 psi

- Hygienic PEEK sensor, robust (IP69K), with temperature compensation

Requirements:

- Small dead zone

Recommended products and solutions:

OPTIFLEX 3200

- Continuous measurement of level and interface in small and narrow vessels

- Conform to FDA, EC1935/2004, EHEDG

- Measuring range: 0.6…4 m / 2…13 ft

- -50…+150°C / -58…+302°F; -1…40 barg / -14.5…580 psig

Requirements:

- Process control

Recommended products and solutions:

SMARTPAT PH 8570

Potentiometric pH sensor for food, beverage and pharmaceutical applications

CIP processes in the food & beverage industry

Recommended products and solutions:

OPTIFLUX 6050

- Cost-effective flow measurement in the food sector

- Meter size: DN2.5…150 / ⅒…6" (EHEDG etc.)

- Many hygienic fittings

- 4…20 mA, pulse, frequency, status, HART®, Modbus

OPTIFLUX 6100

- Reliable dosing and filling in the food sector

- Meter size: DN2.5…150 / ⅒…6"

- Hygienic fittings and certifications

- 4…20 mA, pulse, frequency, status, HART®

Requirements:

- Process control

Recommended products and solutions:

SMARTPAT PH 8570

- 2-wire loop powered, 4…20 mA/HART® 7, for direct connection to a PCS

- Process connection: PG13.5

- 0…14 pH; Max. +140°C / +284°F (SIP/CIP); 12 bar / 174 psi

- Autoclavable glass sensor with ceramic diaphragm and Pt1000 for temperature compensation

Requirements:

- Equipped with fast acting temperature sensor for sharp phase separation

- Compact design for small diameter pipes

Recommended products and solutions:

OPTISYS IND 8100

- 4-wire, 4…20 mA, with head-mounted or remote transmitter

- Process connection: G1 for hygienic adapters

- 0.05…1000 mS/cm; Max. +140°C / +285°F; 10 bar / 145 psi

- Hygienic PEEK sensor, robust (IP69K), with temperature compensation

Recommended products and solutions:

OPTISWITCH 6600

- Point level detection of solids, liquids and liquid-liquid interface

- Wide variety of hygienic process connections available

- -20…+200°C / -4…+392°F; -1…16 barg / -14.5…580 psig

Requirements:

- Quality control

Recommended products and solutions:

SMARTPAT PH 8570

- 2-wire loop powered, 4…20 mA/HART® 7, for direct connection to a PCS

- Process connection: PG13.5

- 0…14 pH; Max. +140°C / +284°F (SIP/CIP); 12 bar / 174 psi

- Autoclavable glass sensor with ceramic diaphragm and Pt1000 for temperature compensation

Requirements:

- Equipped with fast acting temperature sensor for sharp phase separation

Recommended products and solutions:

OPTISYS IND 8100

- 4-wire, 4…20 mA, with head-mounted or remote transmitter

- Process connection: G1 for hygienic adapters

- 0.05…1000 mS/cm; Max. +140°C / +285°F; 10 bar / 145 psi

- Hygienic PEEK sensor, robust (IP69K), with temperature compensation

Requirements:

- Small dead zone

Recommended products and solutions:

OPTIFLEX 3200

- Continuous measurement of level and interface in small and narrow vessels

- Conform to FDA, EC1935/2004, EHEDG

- Measuring range: 0.6…4 m / 2…13 ft

- -50…+150°C / -58…+302°F; -1…40 barg / -14.5…580 psig

Requirements:

- Equipped with fast acting temperature sensor for sharp phase separation

- Compact design for small diameter pipes

Recommended products and solutions:

OPTISYS IND 8100

Inductive conductivity measuring system for food and beverage applications

CIP processes in the food & beverage industry

Recommended products and solutions:

OPTIFLUX 6050

- Cost-effective flow measurement in the food sector

- Meter size: DN2.5…150 / ⅒…6" (EHEDG etc.)

- Many hygienic fittings

- 4…20 mA, pulse, frequency, status, HART®, Modbus

OPTIFLUX 6100

- Reliable dosing and filling in the food sector

- Meter size: DN2.5…150 / ⅒…6"

- Hygienic fittings and certifications

- 4…20 mA, pulse, frequency, status, HART®

Requirements:

- Process control

Recommended products and solutions:

SMARTPAT PH 8570

- 2-wire loop powered, 4…20 mA/HART® 7, for direct connection to a PCS

- Process connection: PG13.5

- 0…14 pH; Max. +140°C / +284°F (SIP/CIP); 12 bar / 174 psi

- Autoclavable glass sensor with ceramic diaphragm and Pt1000 for temperature compensation

Requirements:

- Equipped with fast acting temperature sensor for sharp phase separation

- Compact design for small diameter pipes

Recommended products and solutions:

OPTISYS IND 8100

- 4-wire, 4…20 mA, with head-mounted or remote transmitter

- Process connection: G1 for hygienic adapters

- 0.05…1000 mS/cm; Max. +140°C / +285°F; 10 bar / 145 psi

- Hygienic PEEK sensor, robust (IP69K), with temperature compensation

Recommended products and solutions:

OPTISWITCH 6600

- Point level detection of solids, liquids and liquid-liquid interface

- Wide variety of hygienic process connections available

- -20…+200°C / -4…+392°F; -1…16 barg / -14.5…580 psig

Requirements:

- Quality control

Recommended products and solutions:

SMARTPAT PH 8570

- 2-wire loop powered, 4…20 mA/HART® 7, for direct connection to a PCS

- Process connection: PG13.5

- 0…14 pH; Max. +140°C / +284°F (SIP/CIP); 12 bar / 174 psi

- Autoclavable glass sensor with ceramic diaphragm and Pt1000 for temperature compensation

Requirements:

- Equipped with fast acting temperature sensor for sharp phase separation

Recommended products and solutions:

OPTISYS IND 8100

- 4-wire, 4…20 mA, with head-mounted or remote transmitter

- Process connection: G1 for hygienic adapters

- 0.05…1000 mS/cm; Max. +140°C / +285°F; 10 bar / 145 psi

- Hygienic PEEK sensor, robust (IP69K), with temperature compensation

Requirements:

- Small dead zone

Recommended products and solutions:

OPTIFLEX 3200

- Continuous measurement of level and interface in small and narrow vessels

- Conform to FDA, EC1935/2004, EHEDG

- Measuring range: 0.6…4 m / 2…13 ft

- -50…+150°C / -58…+302°F; -1…40 barg / -14.5…580 psig

Recommended products and solutions:

OPTISWITCH 6600

Capacitance level switch for hygienic and industrial applications

CIP processes in the food & beverage industry

Recommended products and solutions:

OPTIFLUX 6050

- Cost-effective flow measurement in the food sector

- Meter size: DN2.5…150 / ⅒…6" (EHEDG etc.)

- Many hygienic fittings

- 4…20 mA, pulse, frequency, status, HART®, Modbus

OPTIFLUX 6100

- Reliable dosing and filling in the food sector

- Meter size: DN2.5…150 / ⅒…6"

- Hygienic fittings and certifications

- 4…20 mA, pulse, frequency, status, HART®

Requirements:

- Process control

Recommended products and solutions:

SMARTPAT PH 8570

- 2-wire loop powered, 4…20 mA/HART® 7, for direct connection to a PCS

- Process connection: PG13.5

- 0…14 pH; Max. +140°C / +284°F (SIP/CIP); 12 bar / 174 psi

- Autoclavable glass sensor with ceramic diaphragm and Pt1000 for temperature compensation

Requirements:

- Equipped with fast acting temperature sensor for sharp phase separation

- Compact design for small diameter pipes

Recommended products and solutions:

OPTISYS IND 8100

- 4-wire, 4…20 mA, with head-mounted or remote transmitter

- Process connection: G1 for hygienic adapters

- 0.05…1000 mS/cm; Max. +140°C / +285°F; 10 bar / 145 psi

- Hygienic PEEK sensor, robust (IP69K), with temperature compensation

Recommended products and solutions:

OPTISWITCH 6600

- Point level detection of solids, liquids and liquid-liquid interface

- Wide variety of hygienic process connections available

- -20…+200°C / -4…+392°F; -1…16 barg / -14.5…580 psig

Requirements:

- Quality control

Recommended products and solutions:

SMARTPAT PH 8570

- 2-wire loop powered, 4…20 mA/HART® 7, for direct connection to a PCS

- Process connection: PG13.5

- 0…14 pH; Max. +140°C / +284°F (SIP/CIP); 12 bar / 174 psi

- Autoclavable glass sensor with ceramic diaphragm and Pt1000 for temperature compensation

Requirements:

- Equipped with fast acting temperature sensor for sharp phase separation

Recommended products and solutions:

OPTISYS IND 8100

- 4-wire, 4…20 mA, with head-mounted or remote transmitter

- Process connection: G1 for hygienic adapters

- 0.05…1000 mS/cm; Max. +140°C / +285°F; 10 bar / 145 psi

- Hygienic PEEK sensor, robust (IP69K), with temperature compensation

Requirements:

- Small dead zone

Recommended products and solutions:

OPTIFLEX 3200

- Continuous measurement of level and interface in small and narrow vessels

- Conform to FDA, EC1935/2004, EHEDG

- Measuring range: 0.6…4 m / 2…13 ft

- -50…+150°C / -58…+302°F; -1…40 barg / -14.5…580 psig

Requirements:

- Quality control

Recommended products and solutions:

SMARTPAT PH 8570

Potentiometric pH sensor for food, beverage and pharmaceutical applications

CIP processes in the food & beverage industry

Recommended products and solutions:

OPTIFLUX 6050

- Cost-effective flow measurement in the food sector

- Meter size: DN2.5…150 / ⅒…6" (EHEDG etc.)

- Many hygienic fittings

- 4…20 mA, pulse, frequency, status, HART®, Modbus

OPTIFLUX 6100

- Reliable dosing and filling in the food sector

- Meter size: DN2.5…150 / ⅒…6"

- Hygienic fittings and certifications

- 4…20 mA, pulse, frequency, status, HART®

Requirements:

- Process control

Recommended products and solutions:

SMARTPAT PH 8570

- 2-wire loop powered, 4…20 mA/HART® 7, for direct connection to a PCS

- Process connection: PG13.5

- 0…14 pH; Max. +140°C / +284°F (SIP/CIP); 12 bar / 174 psi

- Autoclavable glass sensor with ceramic diaphragm and Pt1000 for temperature compensation

Requirements:

- Equipped with fast acting temperature sensor for sharp phase separation

- Compact design for small diameter pipes

Recommended products and solutions:

OPTISYS IND 8100

- 4-wire, 4…20 mA, with head-mounted or remote transmitter

- Process connection: G1 for hygienic adapters

- 0.05…1000 mS/cm; Max. +140°C / +285°F; 10 bar / 145 psi

- Hygienic PEEK sensor, robust (IP69K), with temperature compensation

Recommended products and solutions:

OPTISWITCH 6600

- Point level detection of solids, liquids and liquid-liquid interface

- Wide variety of hygienic process connections available

- -20…+200°C / -4…+392°F; -1…16 barg / -14.5…580 psig

Requirements:

- Quality control

Recommended products and solutions:

SMARTPAT PH 8570

- 2-wire loop powered, 4…20 mA/HART® 7, for direct connection to a PCS

- Process connection: PG13.5

- 0…14 pH; Max. +140°C / +284°F (SIP/CIP); 12 bar / 174 psi

- Autoclavable glass sensor with ceramic diaphragm and Pt1000 for temperature compensation

Requirements:

- Equipped with fast acting temperature sensor for sharp phase separation

Recommended products and solutions:

OPTISYS IND 8100

- 4-wire, 4…20 mA, with head-mounted or remote transmitter

- Process connection: G1 for hygienic adapters

- 0.05…1000 mS/cm; Max. +140°C / +285°F; 10 bar / 145 psi

- Hygienic PEEK sensor, robust (IP69K), with temperature compensation

Requirements:

- Small dead zone

Recommended products and solutions:

OPTIFLEX 3200

- Continuous measurement of level and interface in small and narrow vessels

- Conform to FDA, EC1935/2004, EHEDG

- Measuring range: 0.6…4 m / 2…13 ft

- -50…+150°C / -58…+302°F; -1…40 barg / -14.5…580 psig

Requirements:

- Equipped with fast acting temperature sensor for sharp phase separation

Recommended products and solutions:

OPTISYS IND 8100

Inductive conductivity measuring system for food and beverage applications

CIP processes in the food & beverage industry

Recommended products and solutions:

OPTIFLUX 6050

- Cost-effective flow measurement in the food sector

- Meter size: DN2.5…150 / ⅒…6" (EHEDG etc.)

- Many hygienic fittings

- 4…20 mA, pulse, frequency, status, HART®, Modbus

OPTIFLUX 6100

- Reliable dosing and filling in the food sector

- Meter size: DN2.5…150 / ⅒…6"

- Hygienic fittings and certifications

- 4…20 mA, pulse, frequency, status, HART®

Requirements:

- Process control

Recommended products and solutions:

SMARTPAT PH 8570

- 2-wire loop powered, 4…20 mA/HART® 7, for direct connection to a PCS

- Process connection: PG13.5

- 0…14 pH; Max. +140°C / +284°F (SIP/CIP); 12 bar / 174 psi

- Autoclavable glass sensor with ceramic diaphragm and Pt1000 for temperature compensation

Requirements:

- Equipped with fast acting temperature sensor for sharp phase separation

- Compact design for small diameter pipes

Recommended products and solutions:

OPTISYS IND 8100

- 4-wire, 4…20 mA, with head-mounted or remote transmitter

- Process connection: G1 for hygienic adapters

- 0.05…1000 mS/cm; Max. +140°C / +285°F; 10 bar / 145 psi

- Hygienic PEEK sensor, robust (IP69K), with temperature compensation

Recommended products and solutions:

OPTISWITCH 6600

- Point level detection of solids, liquids and liquid-liquid interface

- Wide variety of hygienic process connections available

- -20…+200°C / -4…+392°F; -1…16 barg / -14.5…580 psig

Requirements:

- Quality control

Recommended products and solutions:

SMARTPAT PH 8570

- 2-wire loop powered, 4…20 mA/HART® 7, for direct connection to a PCS

- Process connection: PG13.5

- 0…14 pH; Max. +140°C / +284°F (SIP/CIP); 12 bar / 174 psi

- Autoclavable glass sensor with ceramic diaphragm and Pt1000 for temperature compensation

Requirements:

- Equipped with fast acting temperature sensor for sharp phase separation

Recommended products and solutions:

OPTISYS IND 8100

- 4-wire, 4…20 mA, with head-mounted or remote transmitter

- Process connection: G1 for hygienic adapters

- 0.05…1000 mS/cm; Max. +140°C / +285°F; 10 bar / 145 psi

- Hygienic PEEK sensor, robust (IP69K), with temperature compensation

Requirements:

- Small dead zone

Recommended products and solutions:

OPTIFLEX 3200

- Continuous measurement of level and interface in small and narrow vessels

- Conform to FDA, EC1935/2004, EHEDG

- Measuring range: 0.6…4 m / 2…13 ft

- -50…+150°C / -58…+302°F; -1…40 barg / -14.5…580 psig

Requirements:

- Small dead zone

Recommended products and solutions:

OPTIFLEX 3200

Guided radar (TDR) level transmitter for liquids with hygienic requirements