Conche, tempering and filling in chocolate production

Further processing of chocolate mass to the final product

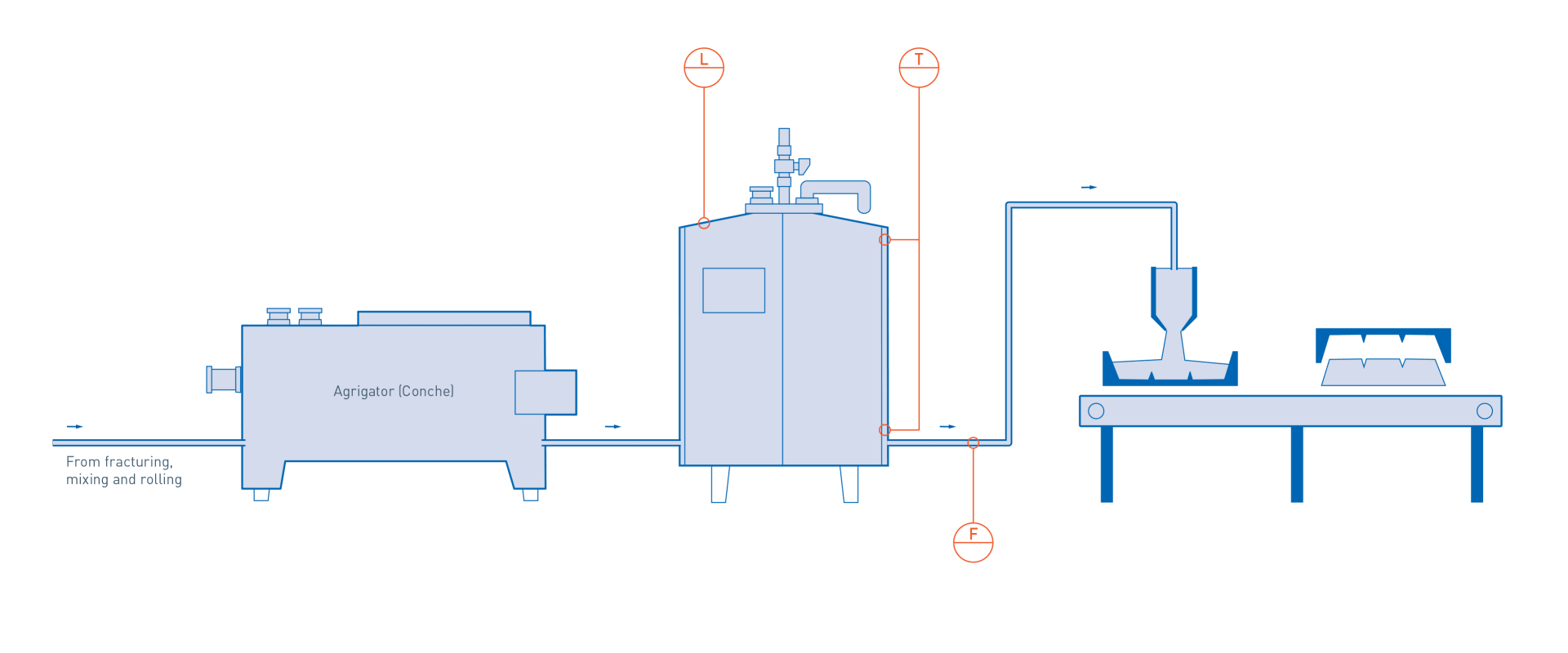

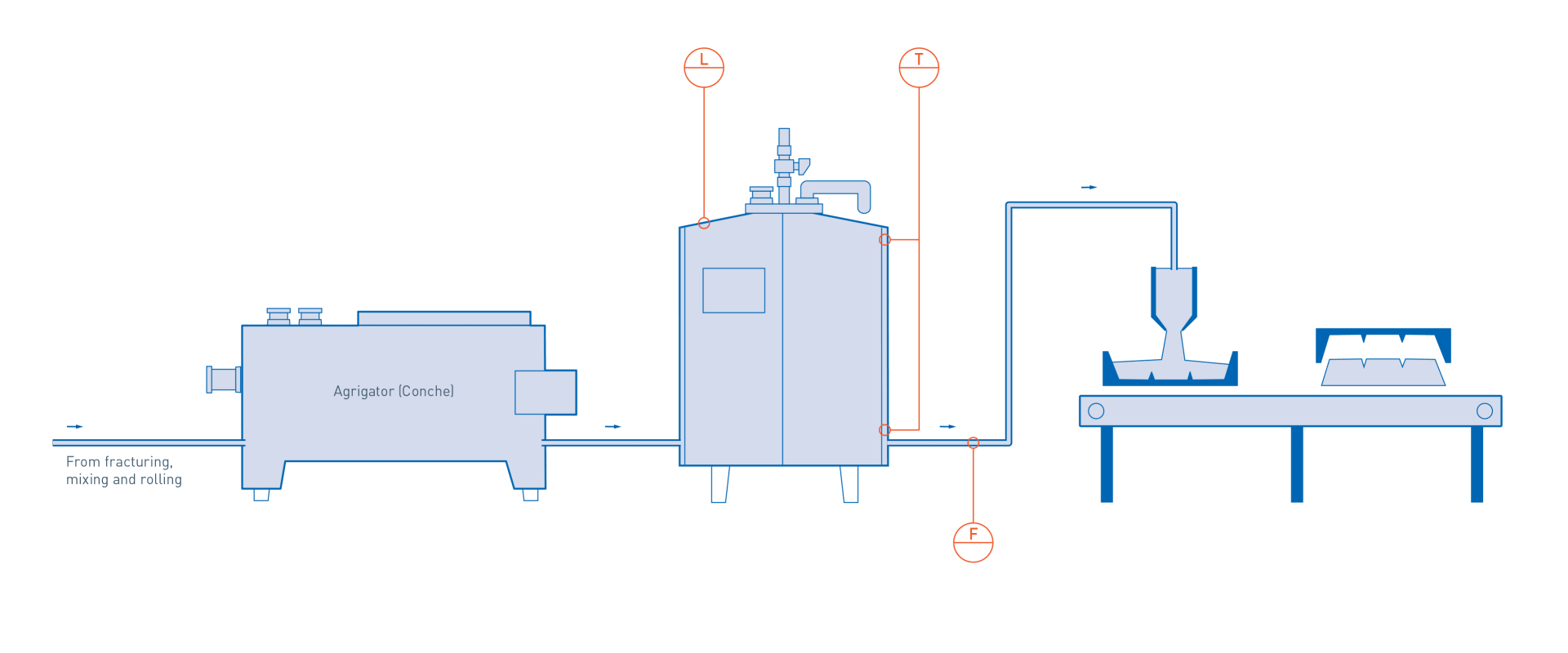

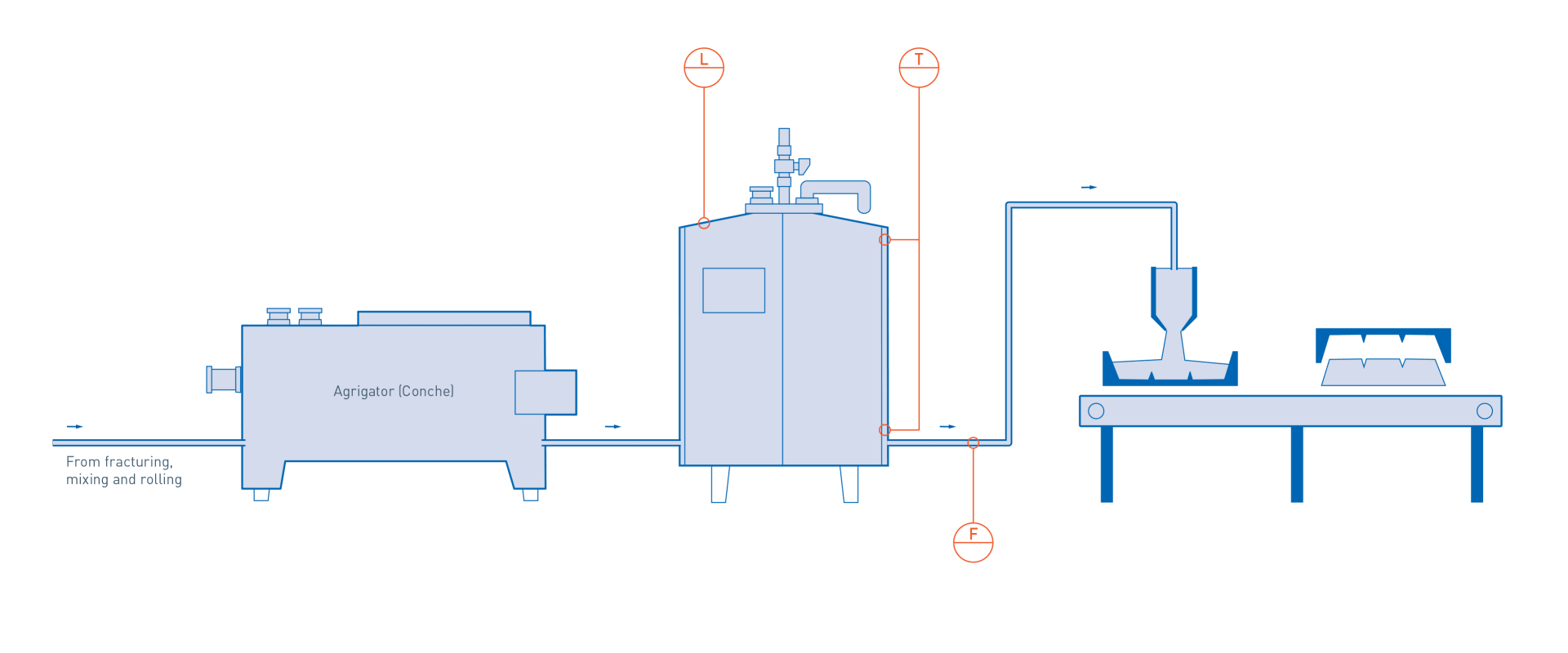

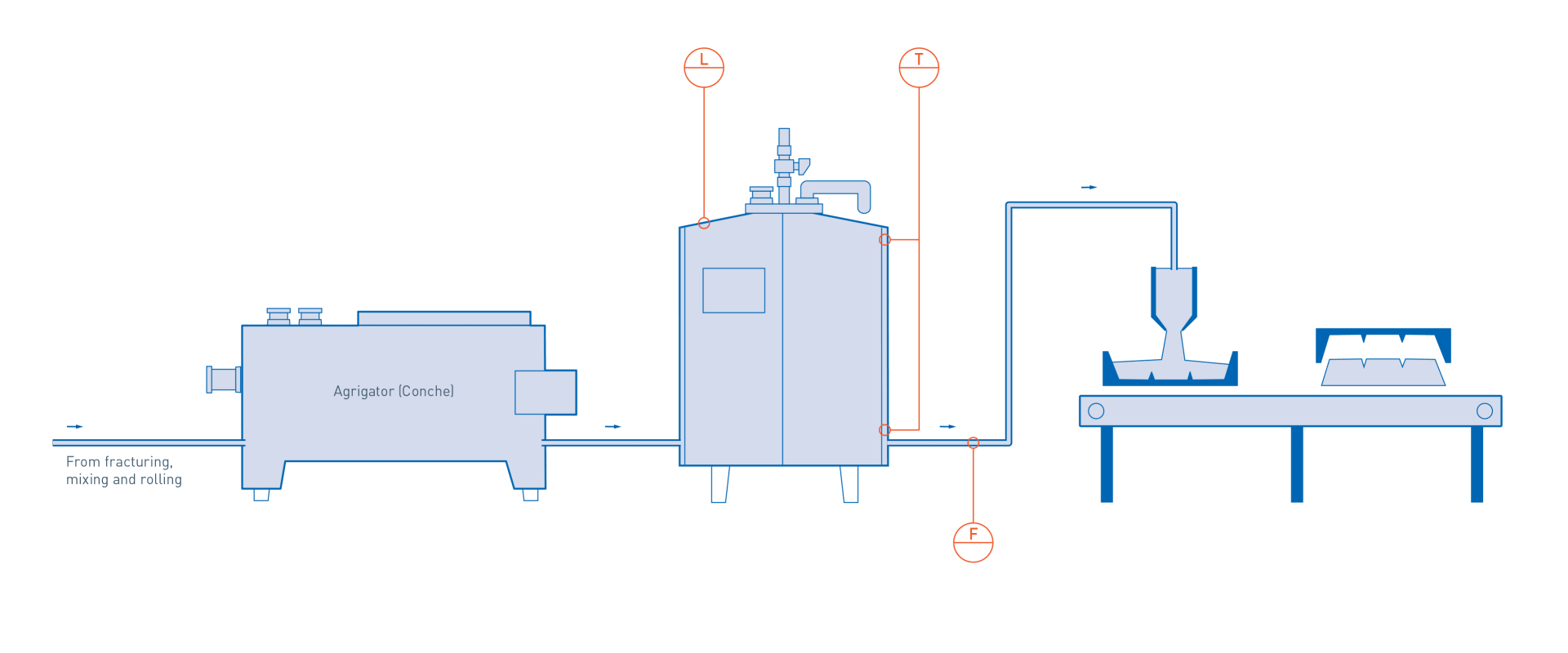

The chocolate is stirred and heated in a conche tank up to around 90°C. The conche is a container with rotating knives (arms) that move in a circle and keep the chocolate mass in a liquid state through frictional heat. By stirring and heating the fat is released and homogeneously distributed, creating a soft, liquid-like flavoured mass. Due to the oxygen and the heat, moisture is removed from the mass, so that the moisture content in the chocolate drops to below 1%. Unwanted odours and aromas (e.g. acetaldehyde, acetone, butanol, ethanol, propanol, ethyl acetate, methanol, diacethyl) are discharged. The subsequent tempering or pre-crystallisation is carried out to achieve a beautiful surface, a firm break and further processing to optimise the required qualities of the chocolate. Tempering takes place in a container that cools the chocolate mass to below 29°C and then, depending on the type of chocolate, reheats it to 30°C or 32°C. Finally the chocolate is poured into its final shape, cooled and packaged.

For the instrumentation of these process steps, KROHNE offers perfectly suitable devices for temperature, level and flow measurement. For example, high-performance straight tube Coriolis flowmeters can precisely measure the mass flow of liquid chocolate. Fast, very precise OPTITEMP temperature sensors and continuous and non-contact OPTIWAVE FMCW radar level measuring devices with a flush hygienic lens antenna can also be used to monitor the temperature and tank contents.

Process details

Conche, tempering and filling in chocolate production

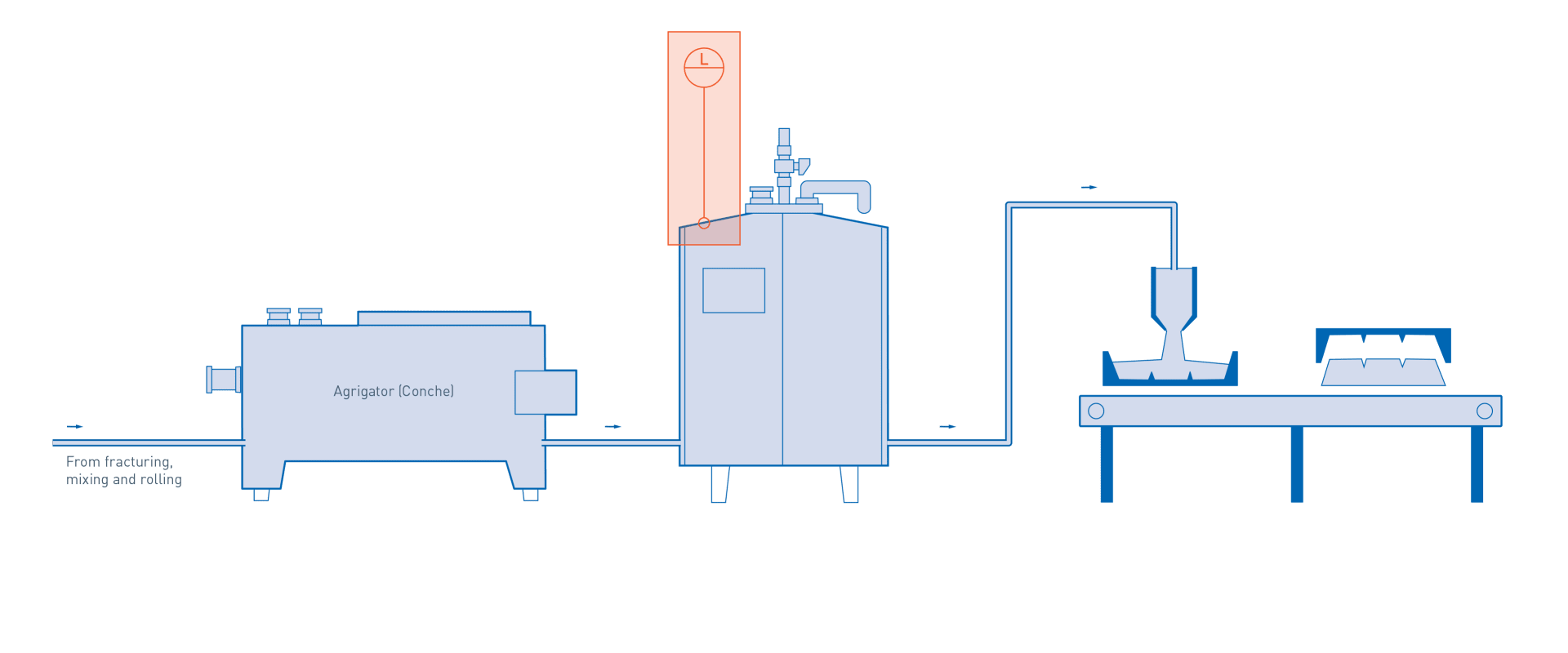

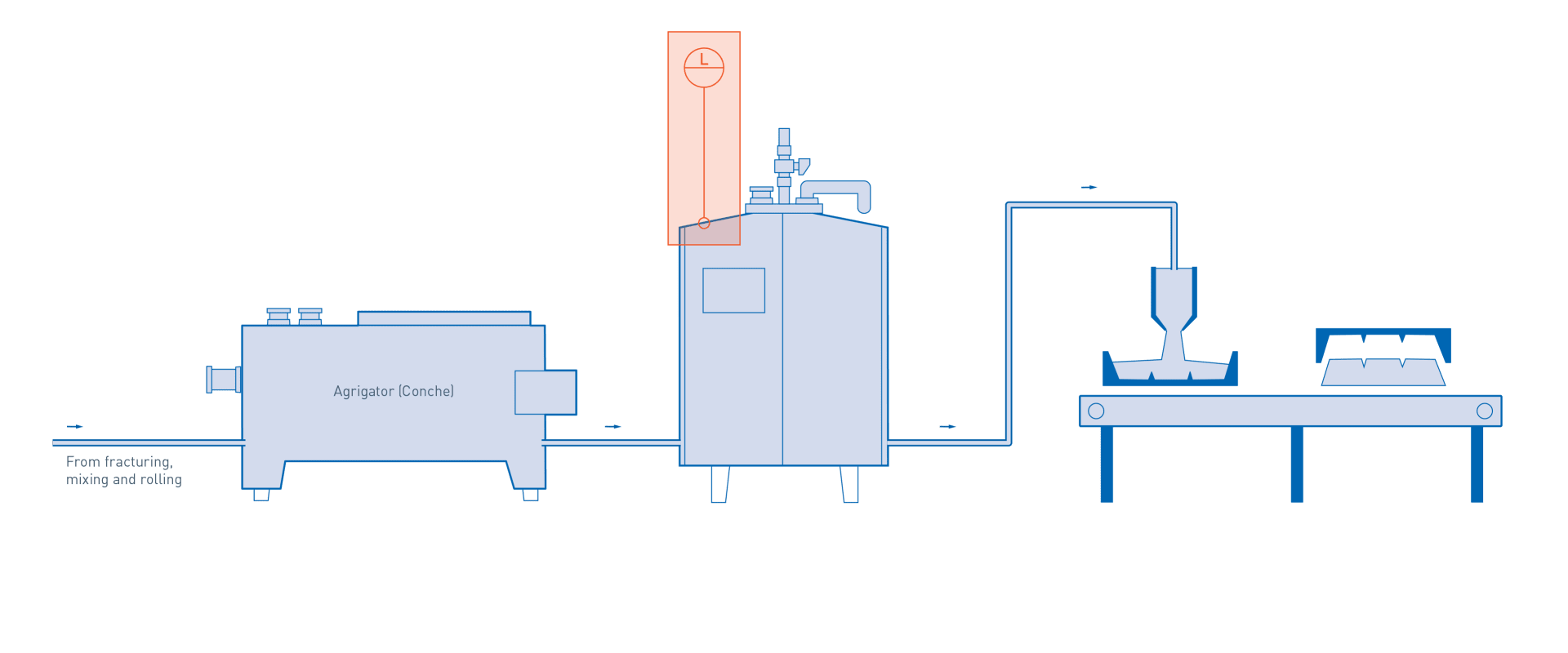

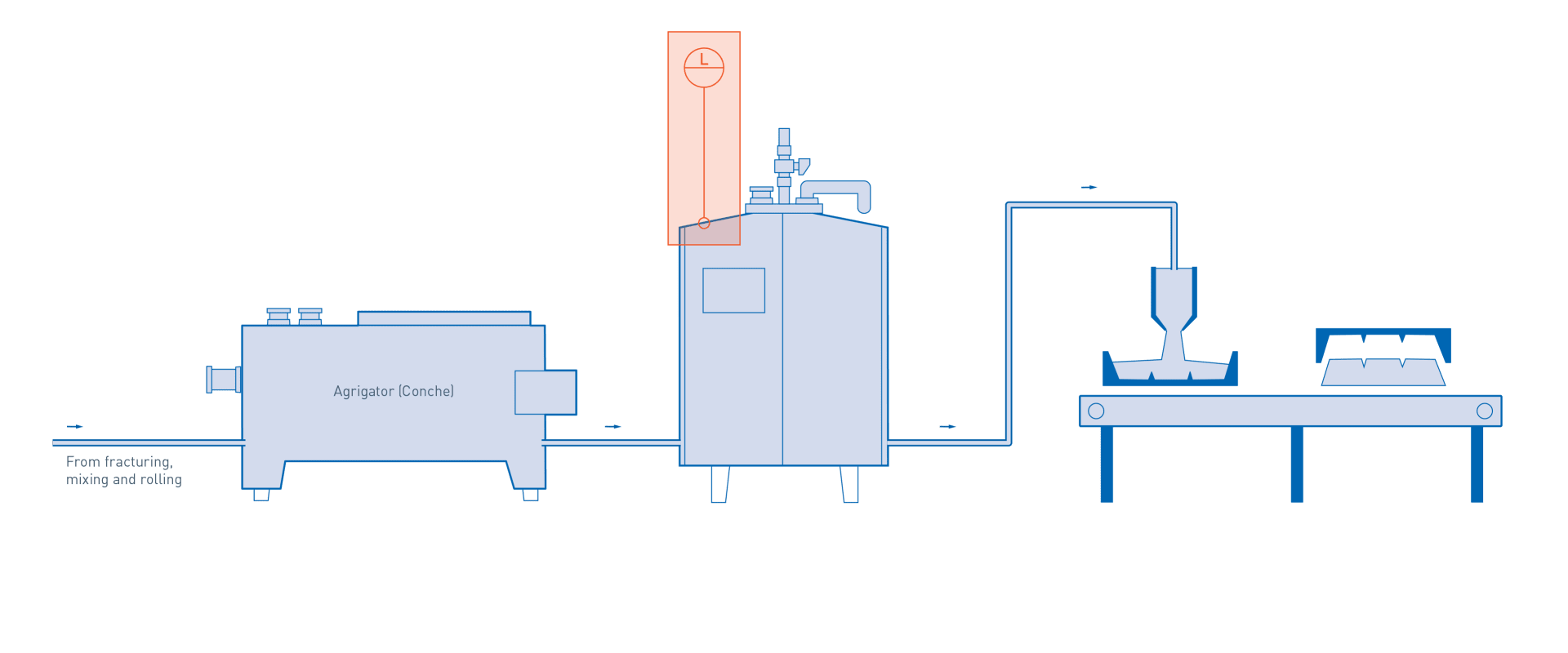

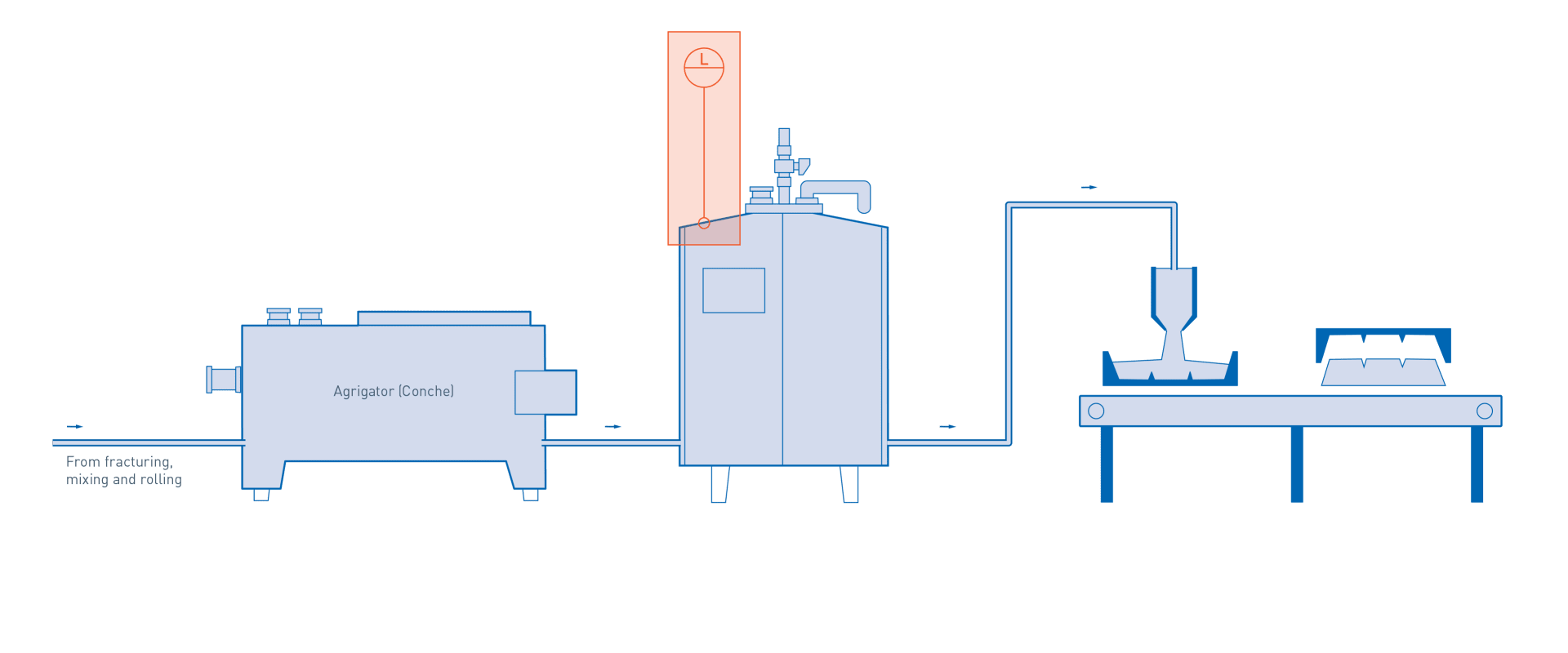

Requirements:

- Moving surface through agitator

Recommended products and solutions:

OPTIWAVE 3500

- Continuous, non-contact level measurement in small and narrow vessels, small storage tanks and agitated tanks

- 80 GHz radar, flush-mounted Lens antenna

- Measuring range: 0…50 m / 164 ft

- -40…+150°C / +302°F; -1…25 barg / -14.5…362 psig

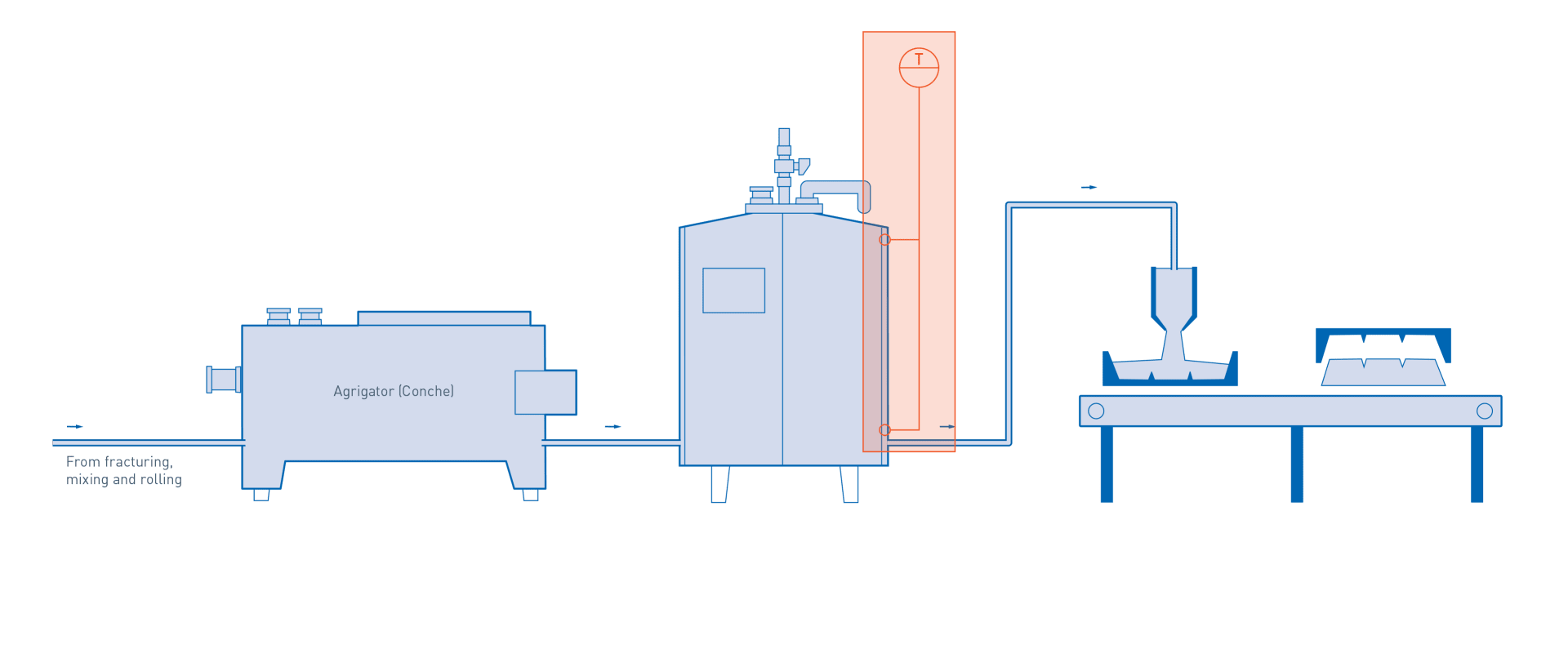

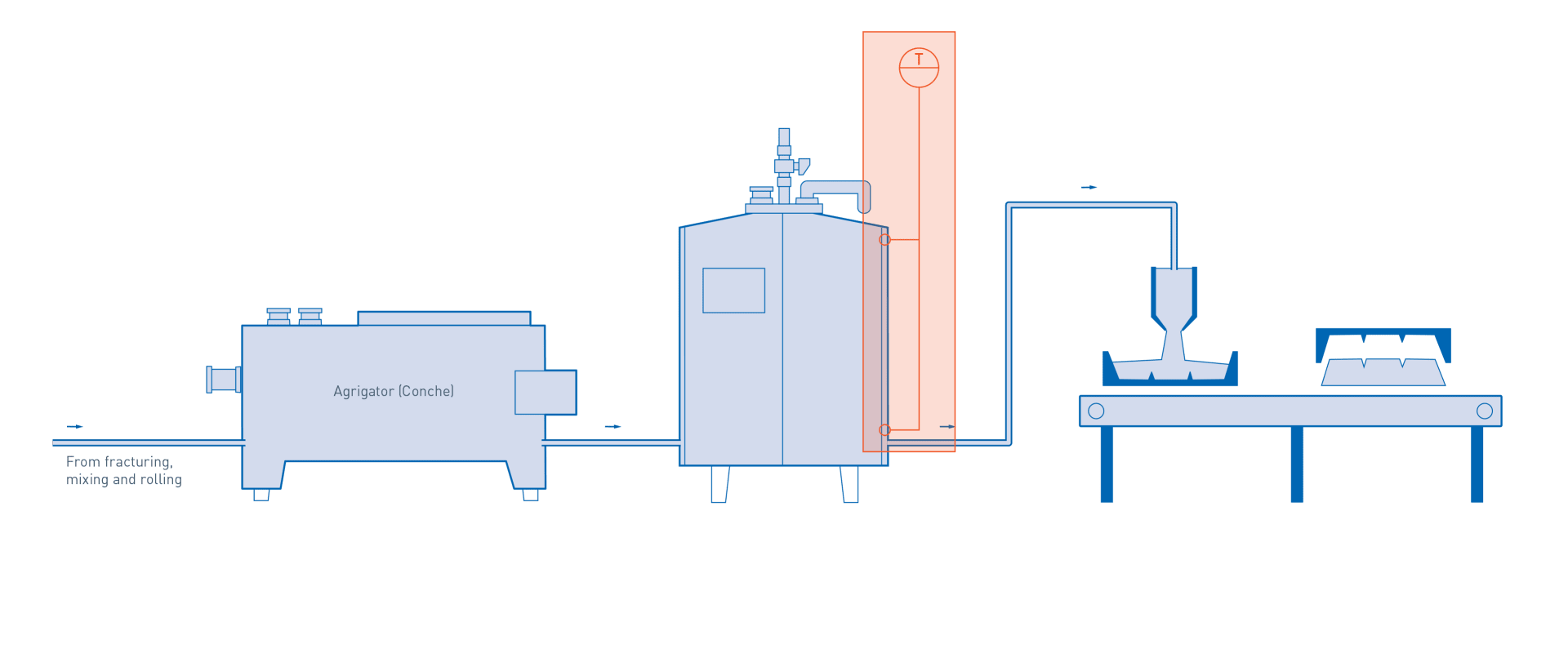

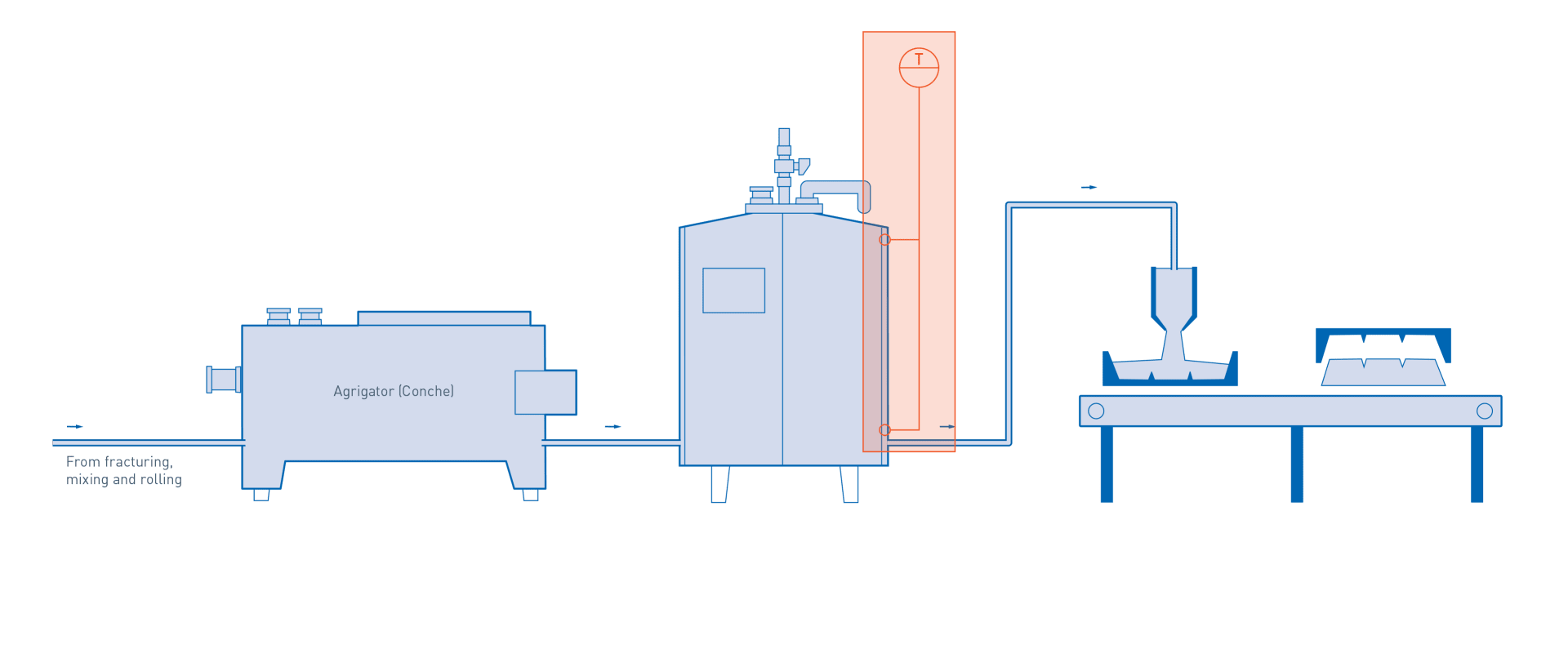

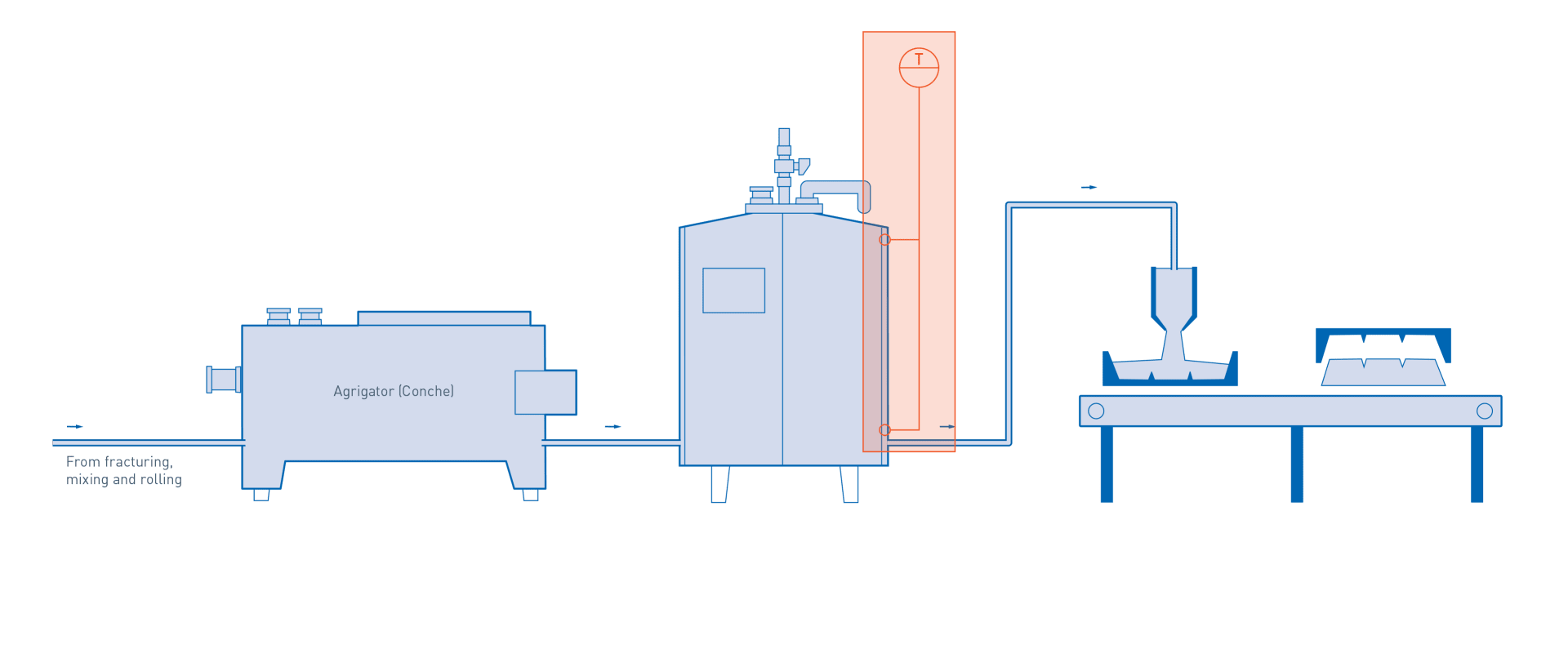

Requirements:

- Critical for cystallisation point

Recommended products and solutions:

OPTITEMP TRA-H61

- G½ thread with VARIVENT®, DIN 11851, SMS 1145 and other hygienic adapters

- Stainless steel thermowell with reduced tip (FDA, EC1935/2004 conform; optional IP69)

- -50…+200°C / -58…+390°F

OPTITEMP TRA-H65

- Welded clamp connection

- Stainless steel thermowell with reduced tip (3A certified, FDA, EC1935/2004 conform; optional IP69)

- -50…+200°C / -58…+390°F

OPTITEMP TRA-C61

- Hygienic G½ thread with VARIVENT®, DIN 11851, SMS 1145 and other hygienic adapters

- Built-in transmitter and stainless steel sheath (FDA, EC1935/2004 conform, optional IP69)

- -50…+200°C / -58…+392°F

OPTITEMP TRA-C65

- Welded clamp connection

- Built-in transmitter and stainless steel sheath (3A certified, FDA-, EC1935/2004 conform; optional IP69)

- -50…+200°C / -58…+392°F

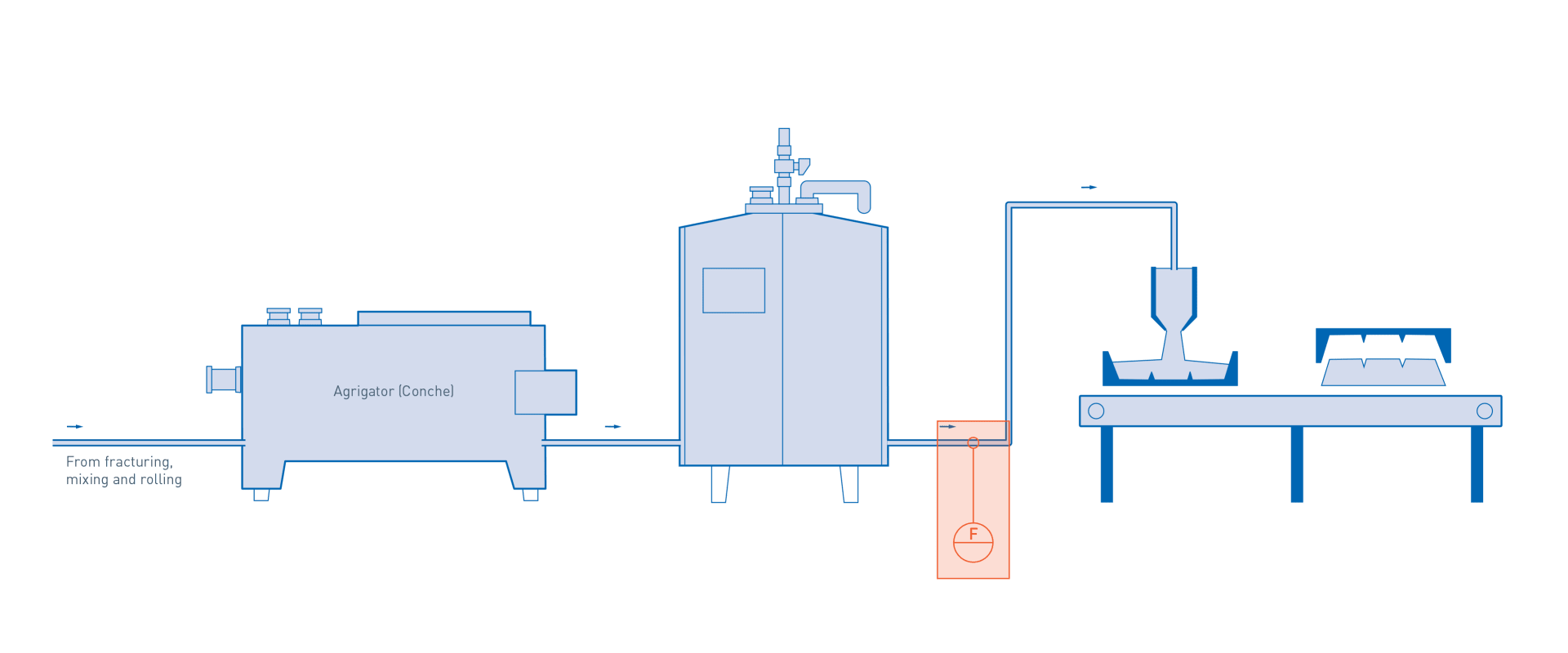

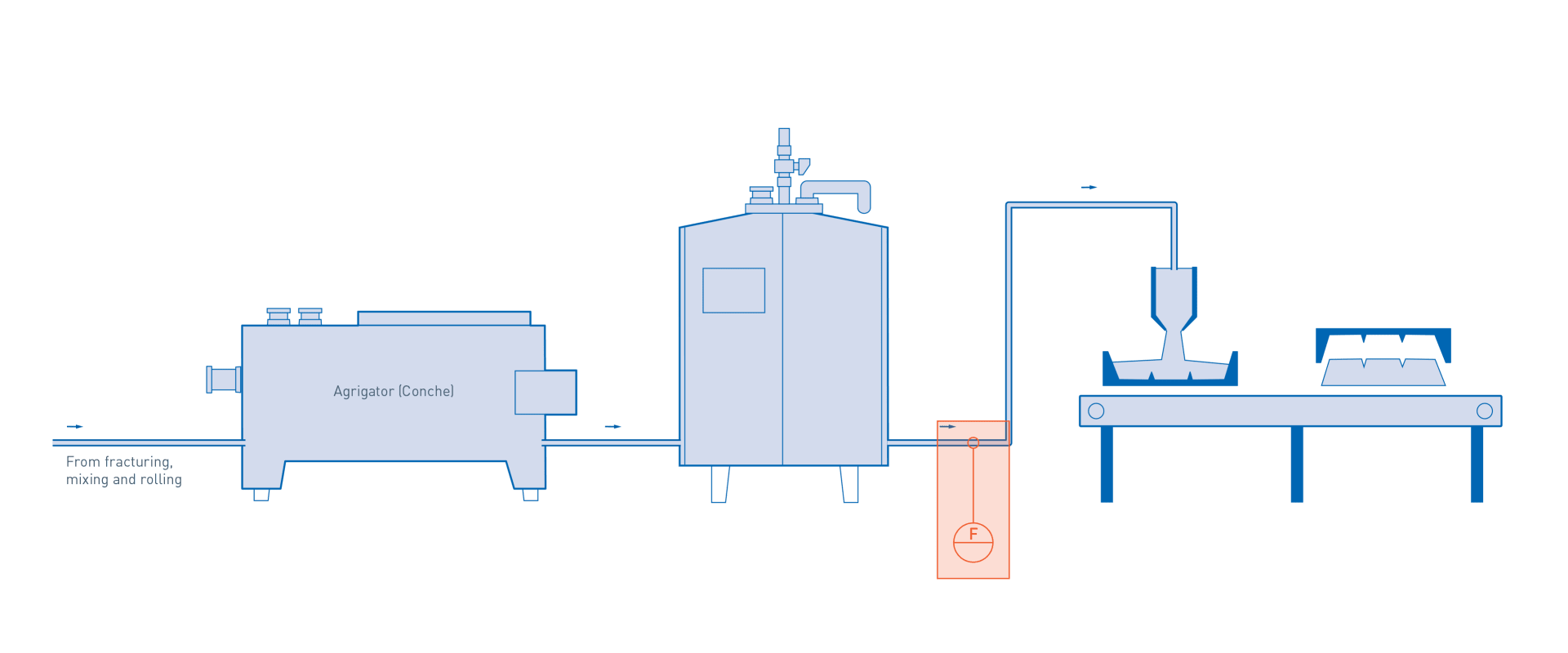

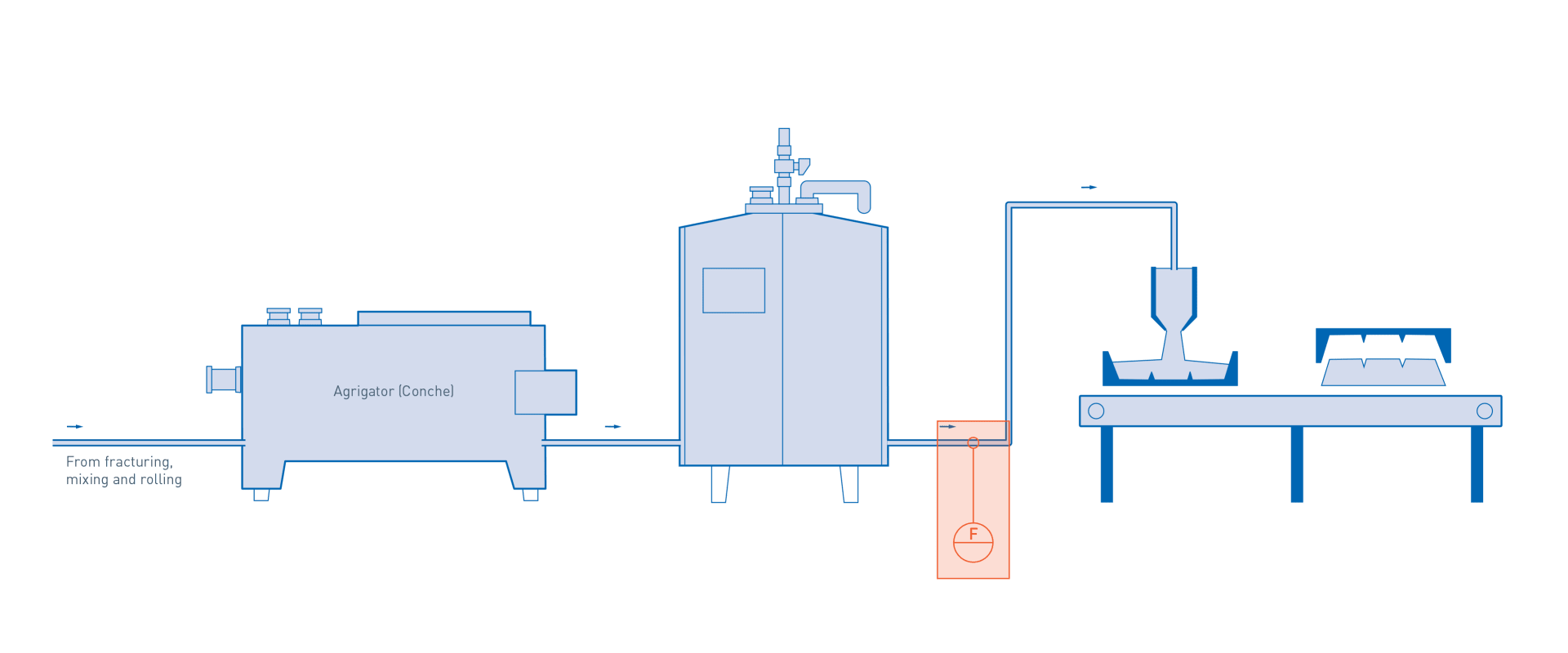

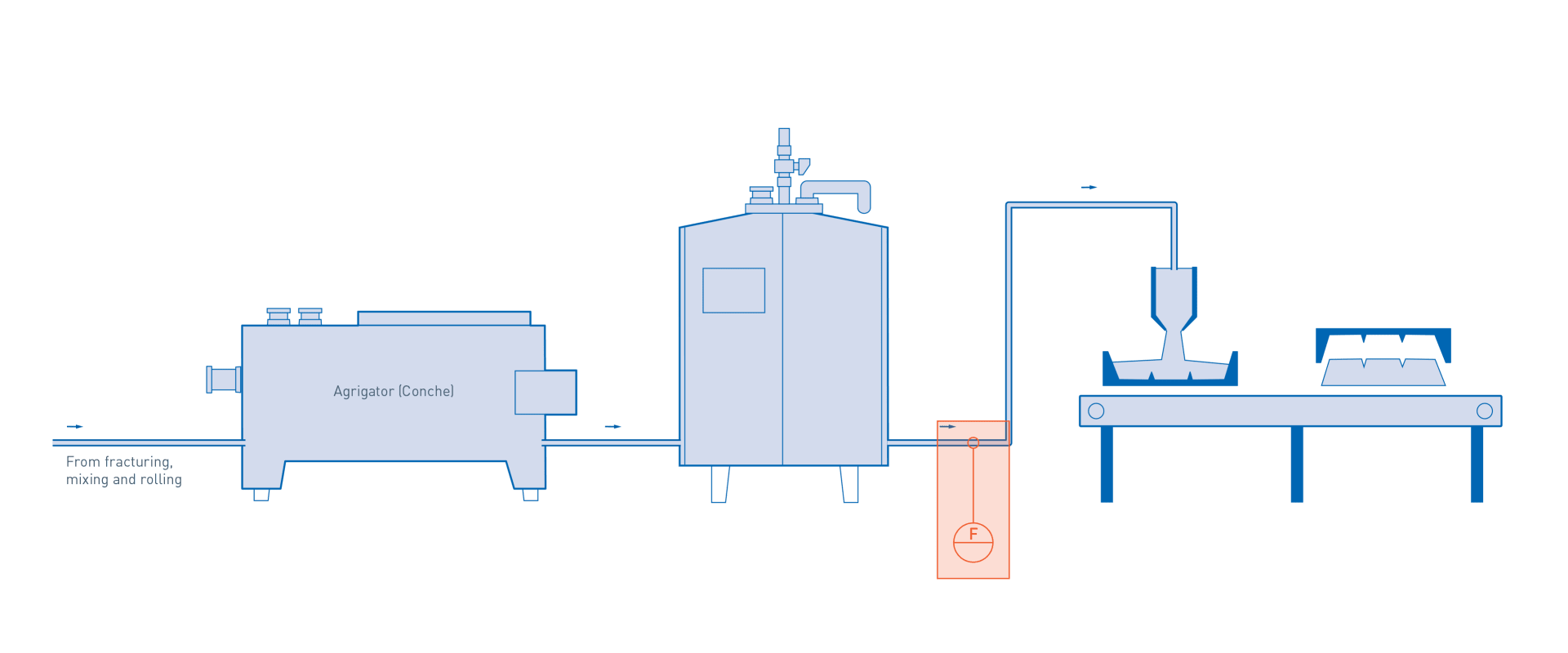

Requirements:

- High viscosity and density

- Handling of air entrainment

Recommended products and solutions:

OPTIMASS 7400

- High accuracy (±0.1%), for viscous, aggressive or shear-sensitive media; maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- CT: OIML R117, MI-005; API; hygienic certifications

- Flange: DN10…100 / ½…4", max. PN100 / ASME Cl 600; others

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

Conche, tempering and filling in chocolate production

Requirements:

- Moving surface through agitator

Recommended products and solutions:

OPTIWAVE 3500

- Continuous, non-contact level measurement in small and narrow vessels, small storage tanks and agitated tanks

- 80 GHz radar, flush-mounted Lens antenna

- Measuring range: 0…50 m / 164 ft

- -40…+150°C / +302°F; -1…25 barg / -14.5…362 psig

Requirements:

- Critical for cystallisation point

Recommended products and solutions:

OPTITEMP TRA-H61

- G½ thread with VARIVENT®, DIN 11851, SMS 1145 and other hygienic adapters

- Stainless steel thermowell with reduced tip (FDA, EC1935/2004 conform; optional IP69)

- -50…+200°C / -58…+390°F

OPTITEMP TRA-H65

- Welded clamp connection

- Stainless steel thermowell with reduced tip (3A certified, FDA, EC1935/2004 conform; optional IP69)

- -50…+200°C / -58…+390°F

OPTITEMP TRA-C61

- Hygienic G½ thread with VARIVENT®, DIN 11851, SMS 1145 and other hygienic adapters

- Built-in transmitter and stainless steel sheath (FDA, EC1935/2004 conform, optional IP69)

- -50…+200°C / -58…+392°F

OPTITEMP TRA-C65

- Welded clamp connection

- Built-in transmitter and stainless steel sheath (3A certified, FDA-, EC1935/2004 conform; optional IP69)

- -50…+200°C / -58…+392°F

Requirements:

- High viscosity and density

- Handling of air entrainment

Recommended products and solutions:

OPTIMASS 7400

- High accuracy (±0.1%), for viscous, aggressive or shear-sensitive media; maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- CT: OIML R117, MI-005; API; hygienic certifications

- Flange: DN10…100 / ½…4", max. PN100 / ASME Cl 600; others

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

Requirements:

- Moving surface through agitator

Recommended products and solutions:

OPTIWAVE 3500

Radar (FMCW) level transmitter for liquids with hygienic requirements

Conche, tempering and filling in chocolate production

Requirements:

- Moving surface through agitator

Recommended products and solutions:

OPTIWAVE 3500

- Continuous, non-contact level measurement in small and narrow vessels, small storage tanks and agitated tanks

- 80 GHz radar, flush-mounted Lens antenna

- Measuring range: 0…50 m / 164 ft

- -40…+150°C / +302°F; -1…25 barg / -14.5…362 psig

Requirements:

- Critical for cystallisation point

Recommended products and solutions:

OPTITEMP TRA-H61

- G½ thread with VARIVENT®, DIN 11851, SMS 1145 and other hygienic adapters

- Stainless steel thermowell with reduced tip (FDA, EC1935/2004 conform; optional IP69)

- -50…+200°C / -58…+390°F

OPTITEMP TRA-H65

- Welded clamp connection

- Stainless steel thermowell with reduced tip (3A certified, FDA, EC1935/2004 conform; optional IP69)

- -50…+200°C / -58…+390°F

OPTITEMP TRA-C61

- Hygienic G½ thread with VARIVENT®, DIN 11851, SMS 1145 and other hygienic adapters

- Built-in transmitter and stainless steel sheath (FDA, EC1935/2004 conform, optional IP69)

- -50…+200°C / -58…+392°F

OPTITEMP TRA-C65

- Welded clamp connection

- Built-in transmitter and stainless steel sheath (3A certified, FDA-, EC1935/2004 conform; optional IP69)

- -50…+200°C / -58…+392°F

Requirements:

- High viscosity and density

- Handling of air entrainment

Recommended products and solutions:

OPTIMASS 7400

- High accuracy (±0.1%), for viscous, aggressive or shear-sensitive media; maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- CT: OIML R117, MI-005; API; hygienic certifications

- Flange: DN10…100 / ½…4", max. PN100 / ASME Cl 600; others

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

Requirements:

- Critical for cystallisation point

Recommended products and solutions:

OPTITEMP TRA-H61

Resistance (RTD) temperature assembly for hygienic applications

OPTITEMP TRA-H65

Resistance (RTD) temperature assembly for hygienic applications

Conche, tempering and filling in chocolate production

Requirements:

- Moving surface through agitator

Recommended products and solutions:

OPTIWAVE 3500

- Continuous, non-contact level measurement in small and narrow vessels, small storage tanks and agitated tanks

- 80 GHz radar, flush-mounted Lens antenna

- Measuring range: 0…50 m / 164 ft

- -40…+150°C / +302°F; -1…25 barg / -14.5…362 psig

Requirements:

- Critical for cystallisation point

Recommended products and solutions:

OPTITEMP TRA-H61

- G½ thread with VARIVENT®, DIN 11851, SMS 1145 and other hygienic adapters

- Stainless steel thermowell with reduced tip (FDA, EC1935/2004 conform; optional IP69)

- -50…+200°C / -58…+390°F

OPTITEMP TRA-H65

- Welded clamp connection

- Stainless steel thermowell with reduced tip (3A certified, FDA, EC1935/2004 conform; optional IP69)

- -50…+200°C / -58…+390°F

OPTITEMP TRA-C61

- Hygienic G½ thread with VARIVENT®, DIN 11851, SMS 1145 and other hygienic adapters

- Built-in transmitter and stainless steel sheath (FDA, EC1935/2004 conform, optional IP69)

- -50…+200°C / -58…+392°F

OPTITEMP TRA-C65

- Welded clamp connection

- Built-in transmitter and stainless steel sheath (3A certified, FDA-, EC1935/2004 conform; optional IP69)

- -50…+200°C / -58…+392°F

Requirements:

- High viscosity and density

- Handling of air entrainment

Recommended products and solutions:

OPTIMASS 7400

- High accuracy (±0.1%), for viscous, aggressive or shear-sensitive media; maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- CT: OIML R117, MI-005; API; hygienic certifications

- Flange: DN10…100 / ½…4", max. PN100 / ASME Cl 600; others

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

Requirements:

- High viscosity and density

- Handling of air entrainment