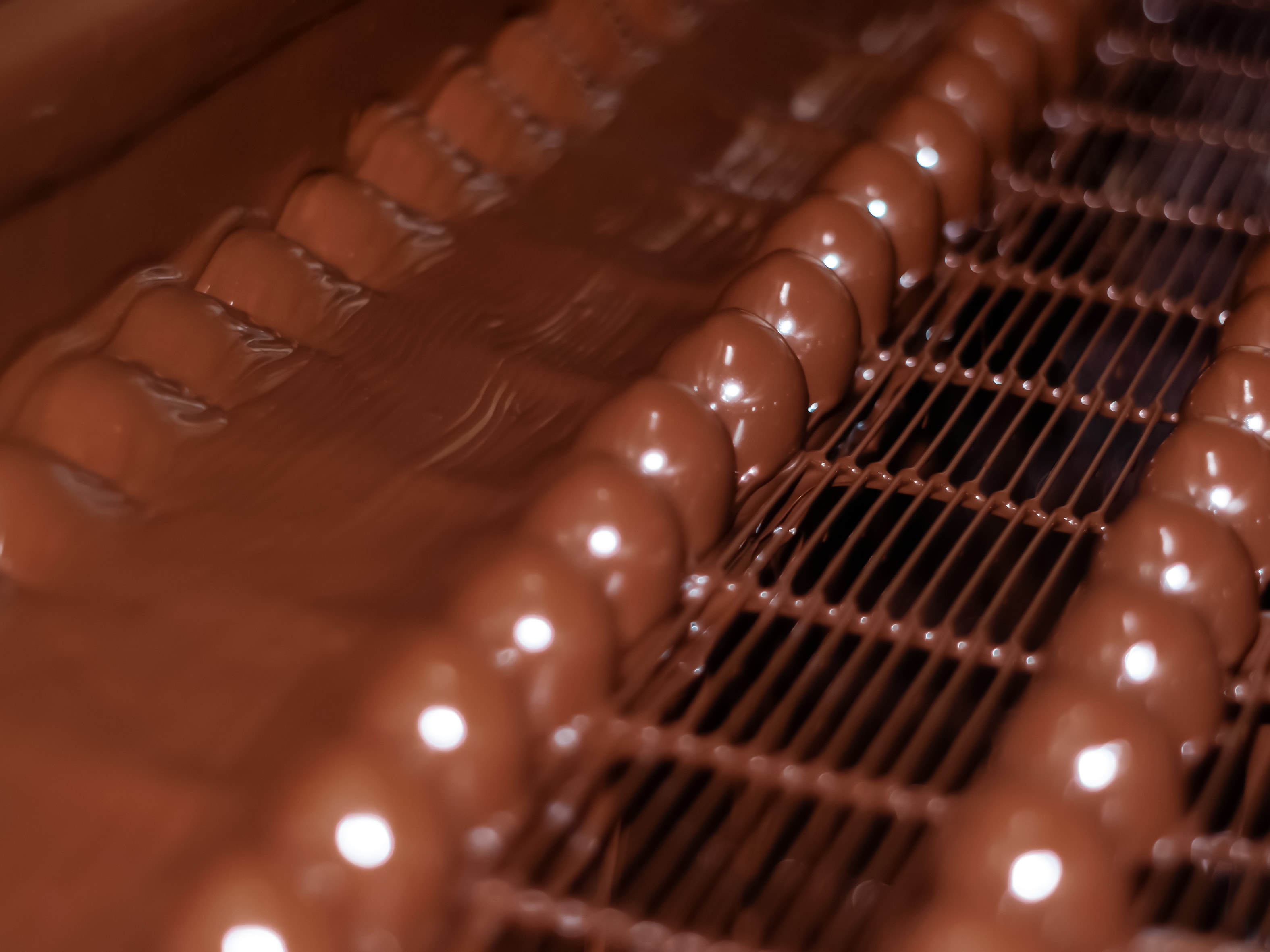

Chocolate production in the food & beverage industry

From fracturing and mixing to tempering and filling

- Precise process monitoring to achieve a consistently high quality of the chocolate product according to recipes

- Tank level, temperature, pressure and flow measurement with entrained gas proportions of up to 100%

- All devices are EHEDG and 3-A certified and meet the requirements of FDA and EC1935 / 2004

Chocolate is made from cocoa beans. In the processing plant, the beans are first cleaned and then separated from their shells. The ‘cocoa nibs’ produced in this way are roasted, and then broken in special mills and finally ground down until a liquid cocoa mass is produced. The next step is to mix with other ingredients, as required. The small cocoa and sugar particles in the cocoa mass are processed into microscopic particles by steel rollers. During ‘conching’, which can take several hours, the chocolate mass is kneaded and stirred and thus “ventilated” so that the bitter-sour aromas can gradually escape. For an appealing look, the chocolate is tempered, i.e. heated, cooled and reheated: this gives it a gloss or matt or shimmering surface and good break resistance. Finally, the chocolate is poured into bars or moulds for other shapes, and packaged. In order to be able to guarantee a consistently high quality for the chocolate, very precise monitoring and management of the individual process steps is necessary.

KROHNE offers precisely tailored measuring devices for these tasks. Fast, extremely accurate and robust temperature sensors provide exact results for simple and demanding hygienic applications. Coriolis mass flowmeters offer the same robust accuracy and hygienic design. The EGM™ technology by KROHNE (Entrained Gas Management) allow the flowmeter to maintain operation over a wide range of gas fractions and complex flow conditions. FMCW radar level transmitters with a large selection of hygienic process connections enable reliable, continuous, non-contact level measurement even in hot process tanks. Capacitive level switches with a short immersion depth in the process, work unaffected by foam, condensate or deposits. All devices are EHEDG and 3-A certified and meet the requirements of FDA and EC1935 / 2004.

Processes related to the Chocolate production in the food & beverage industry

Explore the detailed industry processes and our recommended products, solutions and services:

Applications from the Food & Beverage industry

KROHNE Global Industry Division Food & Beverage

Headquartered in Duisburg, Germany, our Global Industry Division is dedicated to serving customers in the Food & Beverage industry. Being an instrumentation supplier in the industry for over 20 years, we have gained industry- and application-specific know-how that we implemented into our devices and measuring solutions. Our offering extends from elementary process instrumentation up to fully engineered systems, and from engineering consultancy during the design phase, through to on-site commissioning and training. With presence in around 100 countries, local support is usually available from just around the corner. This applies whether the application can be covered by standard instrumentation, or is more challenging, where a one-off solution with dedicated process diagnostics is required.

KROHNE Food & Beverage

Ludwig-Krohne-Str. 5

47058 Duisburg

Germany

Email: foodandbeverage@krohne.com