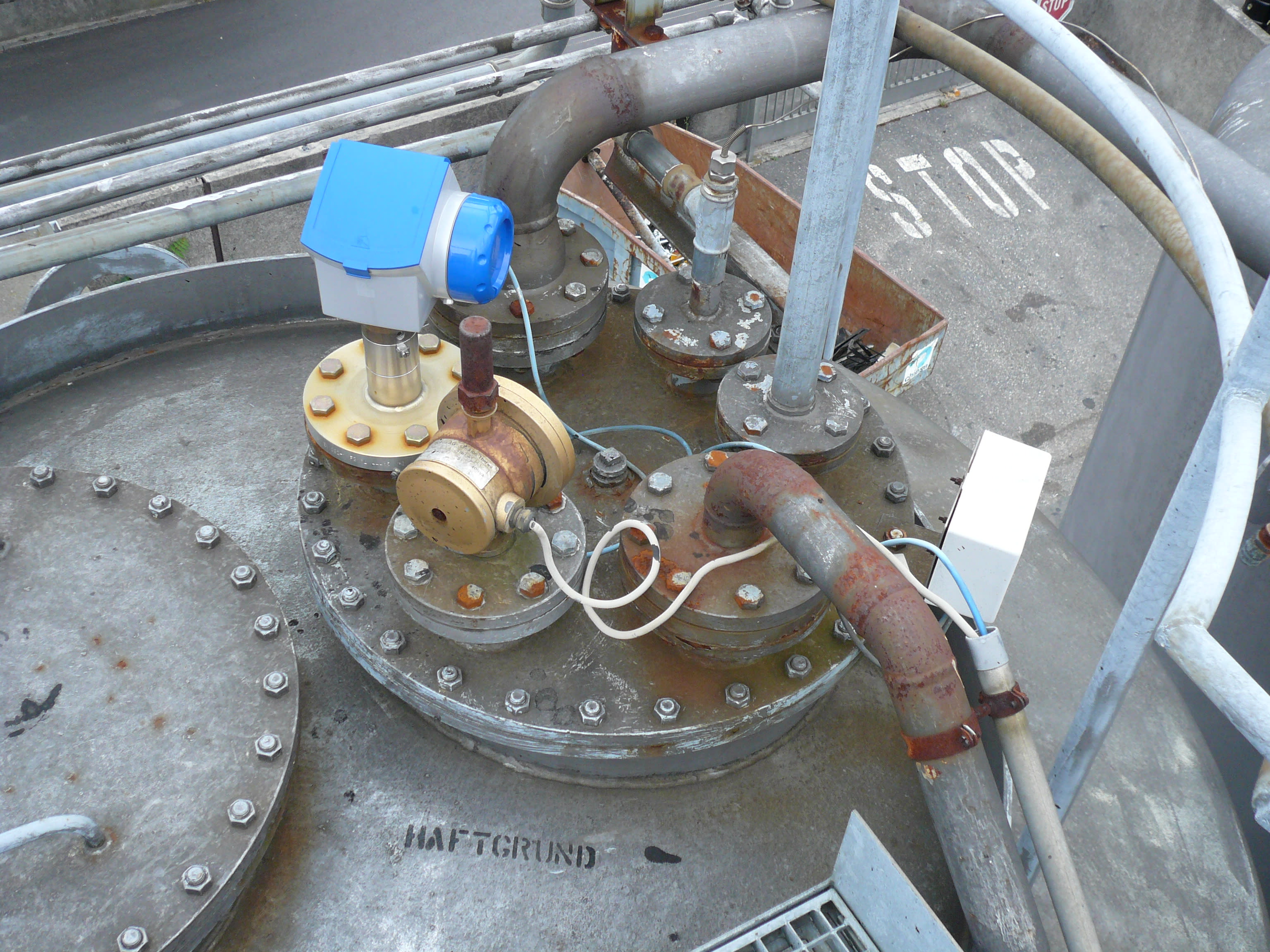

Tank farm for solvents at a road building materials manufacturer

Application Note | Chemical

- Continuous monitoring of current tank inventory

- 2-wire connection technology

- Maintenance-free, non-contact level measurement

Background

A Swiss customer operates a tank farm for solvents required in the production of road building materials. In the past, measuring devices based on mechanical measuring principles were used to measure the levels in the tanks. They were extremely inaccurate and required significant maintenance.

The end products are

- standardised, special binding agents for road surfaces containing bitumen,

- bitumen emulsions for repairing and building roads,

- special emulsions for surface recycling and slurry surfacing.

- binders for the surface treatment as well as

- special products to protect, repair and reconstructing road surfaces.

Measurement requirements

Radar level measuring devices were the only option when it came to upgrading the tank farm as ultrasonic devices are not suited to the properties of the products. Non-contact measurement was also an important requirement for using radar measuring devices. One further requirement was the two-wire connection technology used to keep wiring costs to a minimum. A special measuring principle was required for the lower chamber of one 2-chamber tank. This level measurement now takes place using a bypass measuring device which also meets the requirements outlined above. The measuring devices must be easy to configure using communication technology from one measuring station and they must support the remote retrieval of measured values.

KROHNE Solution

KROHNE supplied 7 OPTIWAVE 7300 C radar level measuring devices and one BM 26 W radar bypass measuring device.

All devices function based on the FMCW radar measuring principle.

The PACTware and DTMs included as standard make it possible to configure and record the measured values of the level measuring devices from the measuring station.

Customer benefits

From the measuring station it is now possible to continuously monitor the current inventory. As soon as the preset maximum limit has been reached when filling the tank, the pumps are switched off. This eliminates the need for time-consuming onsite monitoring. Once the preset minimum level has been reached, new supplies can be ordered. The bypass solution for the 2-chamber tank with the BM 26 W functions as reliably as the KROHNE OPTIWAVE 7300 C FMCW radar measuring devices installed on the tanks.

The measuring devices have already proven themselves in practice and are working smoothly.