Sludge level measurement in secondary clarifiers in a municipal wastewater treatment plant

Application Report | Water & Wastewater

- Prevention of sludge washout into the effluent

- High operational safety thanks to the continuous monitoring of sedimentation and wastewater / sludge interface

- Complete solution consisting of optical (NIR) sludge measuring system and wireless system for data transmission

Background

The Municipal Waste Association (GAV) in Amstetten, Austria, operates a sewer system and associated wastewater treatment plant. The state-of-the-art plant features integrated biogas production. It is self-sufficient in terms of energy, optimised for energy efficiency with simultaneous nitrification and denitrification and designed for wastewater loads for a 150,000 population equivalent.

Measurement requirements

To guarantee increased process reliability in the final cleaning step before the effluent, the operator wants to monitor the sludge collected in the four secondary clarifiers through which the product flows horizontally. The aim is to prevent a sludge overload (sludge washout) and to protect the drain filter. To do so, it is necessary to continuously measure the interface between the settled sludge and the treated wastewater located above it. The measured values form the basis for de-sludging. In addition, an alarm was to be automatically triggered in the control room if the specified limits are exceeded when measuring the sludge level.

KROHNE Solution

After several months of running comparative tests on ultrasonic measurement technology from competitors, the operator decided on the OPTISYS SLM 2100 optical sludge measuring system. The NIR LED-based KROHNE system detects all sludge phases and provides accurate concentration and sludge level measurements. In this way, it is also able to measure the sludge level continuously (zone tracking) and hence monitor one specific "zone" (e.g. for pump control during de-sludging).

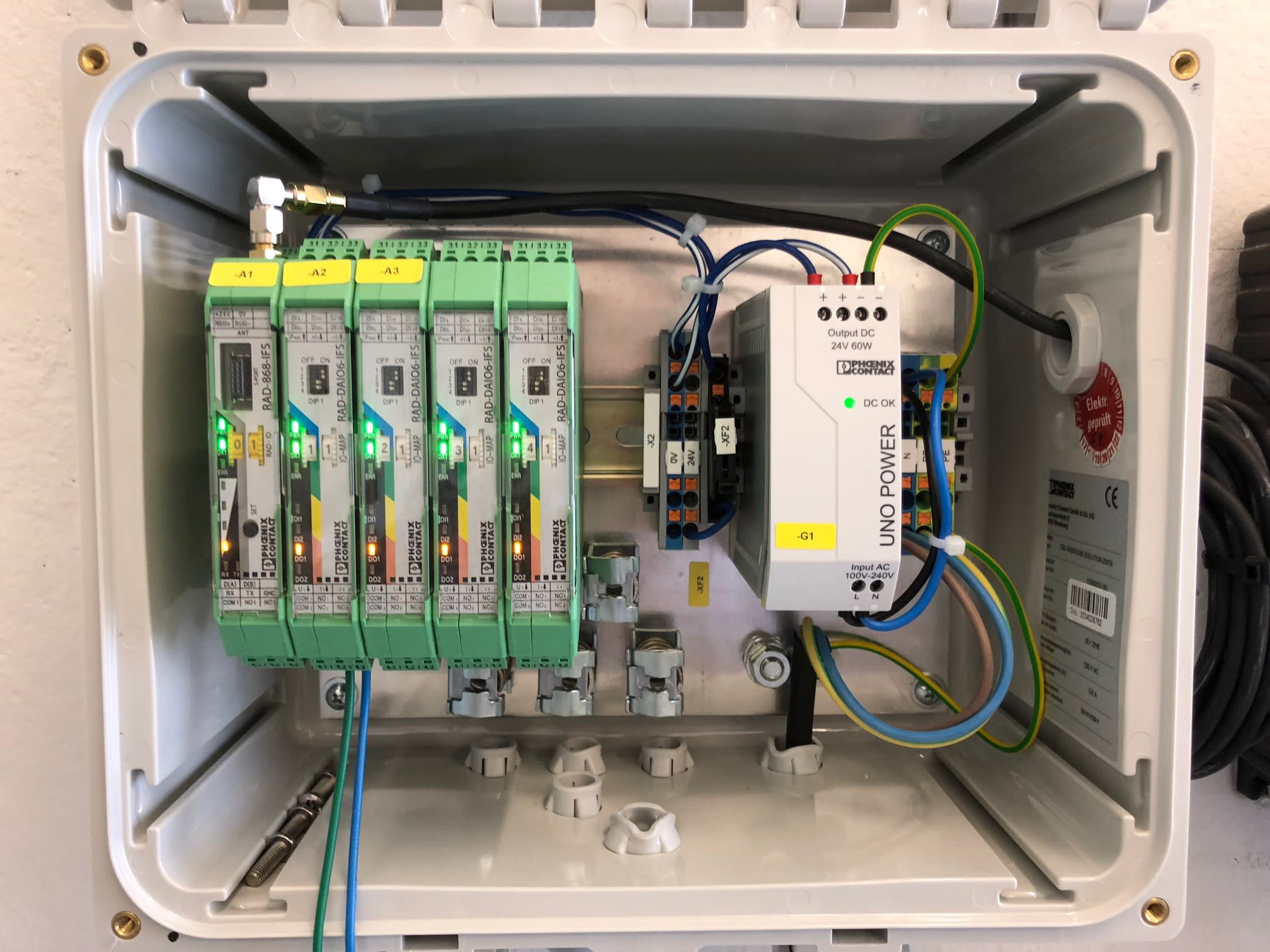

The customer uses the measuring system in all four secondary clarifiers. The OPTISYS SLM 2100 is attached to the railing of the scraper bridge using a holder supplied by KROHNE. The 4…20 mA signal is transmitted to the control room via Phoenix Contact remote transmission technology. The measuring systems are associated with the licence free Radioline wireless system. The transmitting station of this Radioline system was pre-wired on the scraper with wireless and I / O modules in waterproof (IP 68) boxes. In addition, corresponding modules were also centrally installed in the control room as receiving stations. The wireless technology was easily put into operation by turning the thumb wheel on the module. No programming required.

Customer benefits

The combined solution of a sludge measuring system and wireless communication makes monitoring the sedimentation process in the secondary clarifiers both safe and consistent. Thanks to the reliable remote transmission, the measured values are provided in real time in the control room. Sludge formation is continuously optimised. Even with increased physical feeding, the operator can prevent the sludge from intruding into the flow of the cleaned wastewater. If the limits are exceeded, the measuring solution triggers an alarm and the sludge is quickly removed.

Unlike with the ultrasound-based sludge level meters from the comparative tests, the NIR LED technology in the OPTISYS SLM 2010 does not cause echo returns from the walls. There is also no signal damping by fluff or floating sludge that cause false measurements. The combination made up of the OPTISYS SLM 2100 and the Radioline is just one of several industry-specific partner solutions offered by KROHNE and Phoenix Contact for the water and wastewater industry.