Portable flow measurement for product transfer in a brewery

Application Report | Food & Beverage

- Mobile flow system for beer, cider and cleaning agents

- Repeatable transfer operation based on ultra-compact flowmeter

- Reliable monitoring of flow rate, total flow and temperature

- Simplicity in operation: no mobile devices needed for set-up

Background

Brewology is one of the UK’s leading suppliers of beverage automation equipment, specialising in cask and keg cleaning and racking, CIP sets, tanks, spares and service contracts, plus state-of-the-art remote automation. They also manufacture canning machines and bottling machines for both food and beverage as well as pharma. Among others, the company produces portable flow solutions for easy product transfer around breweries.

Measurement requirements

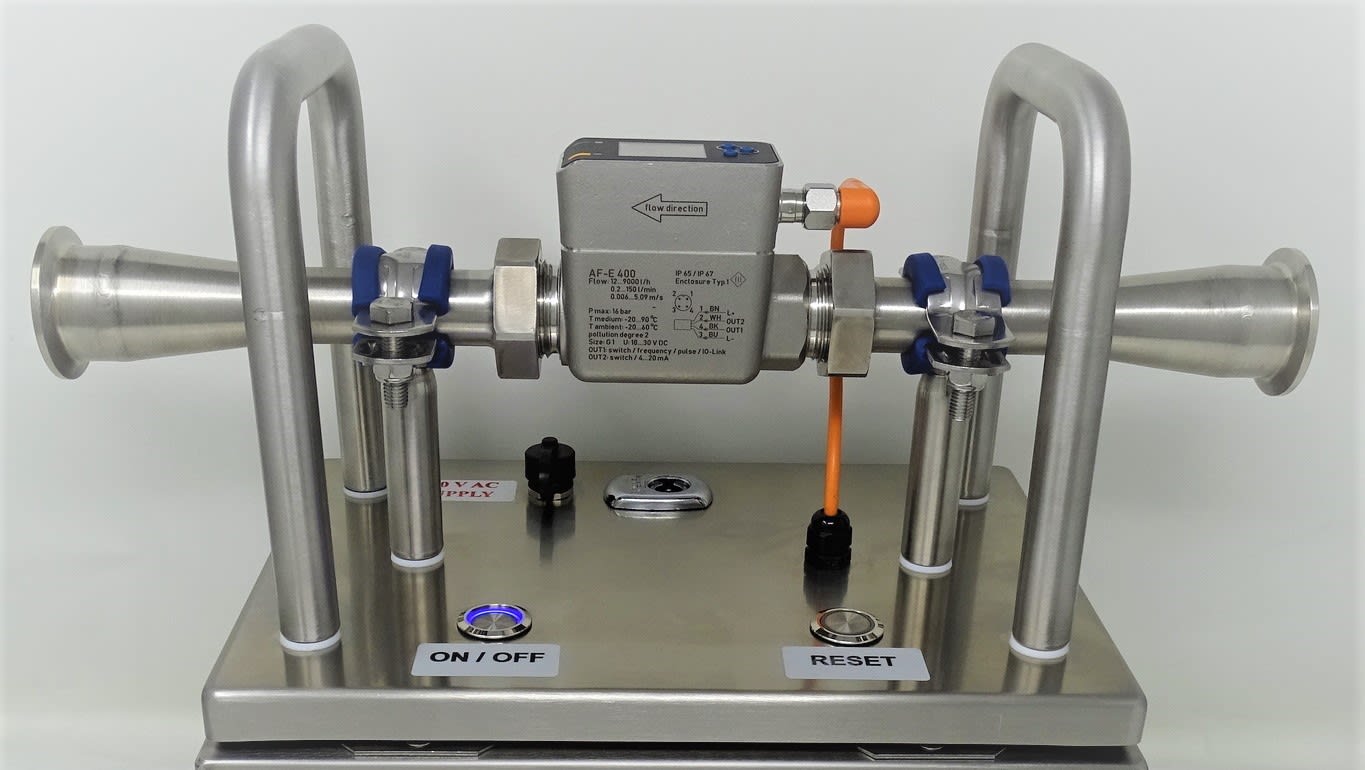

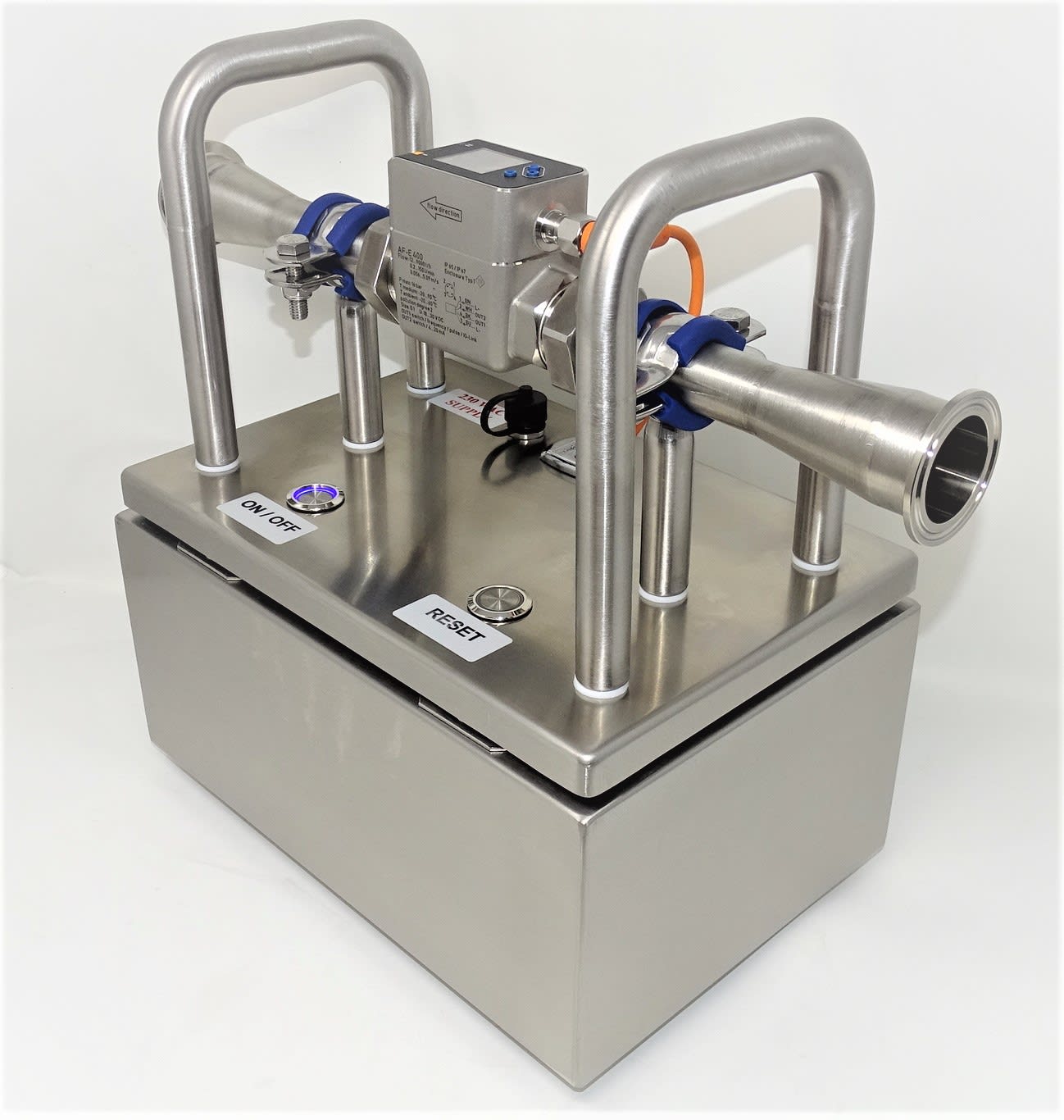

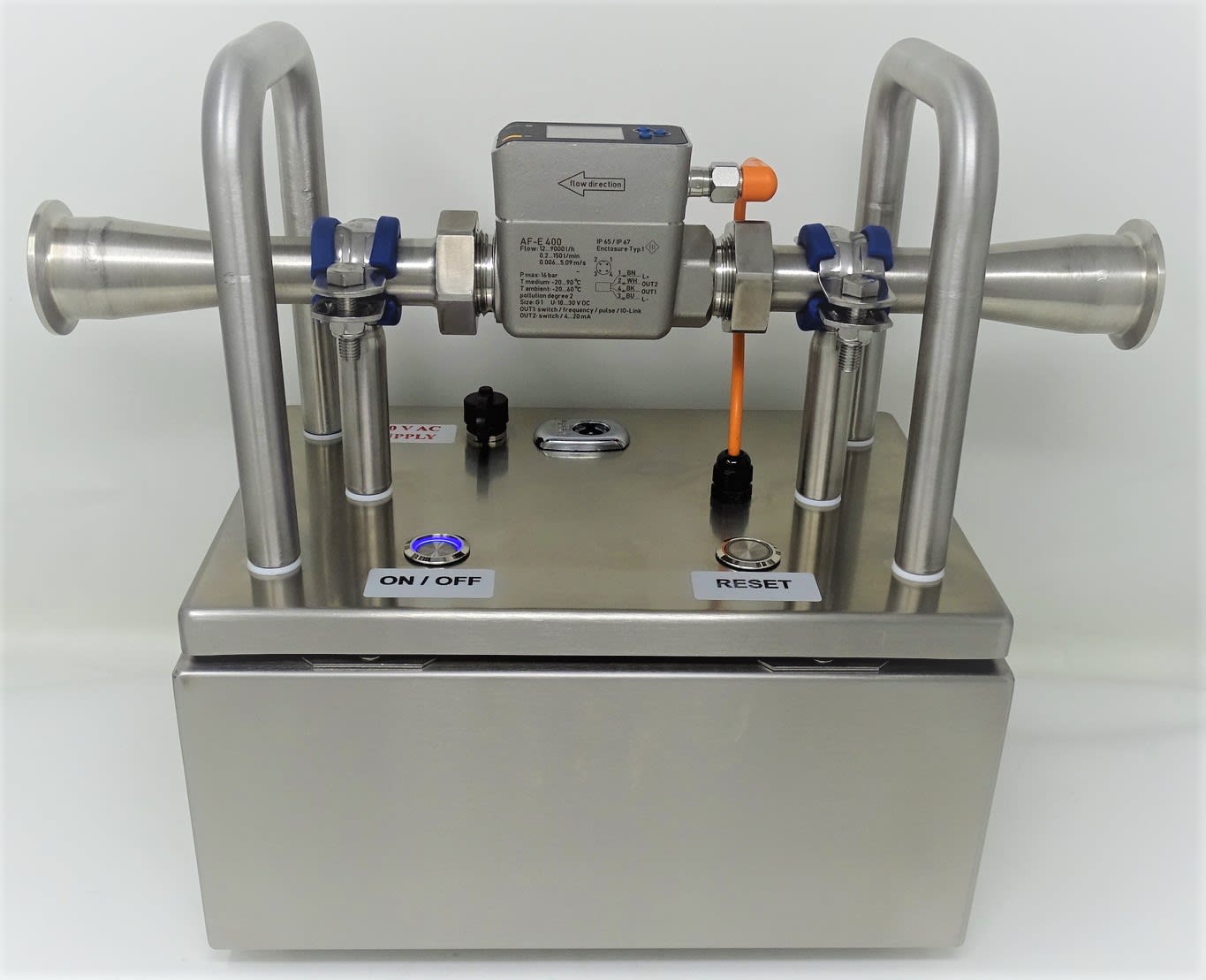

For a craft brewery in North Yorkshire, England, Brewology engineered and manufactured a portable system to measure beer, cider, brewing liquor and many other fluids such as CIP (Clean-in-Place) agents. This is to allow easy product transfer around the brewery. The compact unit is fully equipped with a flowmeter, hygienic process connections, a 240V charger to power the meter as well as carrying handles for transportation purposes.

In the past, the automation equipment supplier fitted those units with a compact electromagnetic flowmeter (EMF) from a competitor. Some technical issues with this device caused Brewology to address other leading suppliers of process instrumentation for a replacement.

Measured media: Beer, cider; CIP agents

(3% caustic solution, 0.1% peracetic acid)

Flow rate: 100 l/min (max.)

Pressure: 4 barg / 58 psig (max.)

Temperature: +85°C / +185°F (max.)

KROHNE Solution

Brewology decided on the AF-E 400 electromagnetic flowmeter. This ultra-compact KROHNE flowmeter is designed for flow measurement of conductive liquids on mobile flow systems, dosing skids and other applications in industrial automation. It features a high turn-down ratio and best-in-class accuracy in every flow range. The flowmeter comes with multiple application and device data ranging from volume and total flow to medium temperature to various self-diagnostics such as low supply voltage or exceeding flow range. This makes the AF-E 400 so versatile as to be used for flow measurement of beer, cider or cleaning agents as well as to control CIP parameters like temperature.

With a light weight of less than 750 g, the mag meter is ideally suited for installation on the portable system. The KROHNE device comes with a robust hygienic cast stainless steel housing and was provided with a 1” PEEK flow tube and PEEK electrodes. PEEK does not only comply with hygienic requirements, but it is also more resilient against increased pressure. The device was mounted with a G thread connecting it to a piping with hygienic clamp connection. Given the hygienic environment of the end-user, hygienic EPDM was selected as wetted material for the gaskets in this application. Power is supplied by the charger via the common M12 connector that is part of the AF-E package. The factory settings of the device allowed plug-and-play installation.

Customer benefits

The versatile, yet cost-effective and simple design of the AF-E 400 convinced Brewology and their end-user. Simple handling was preferred and that is just what the AF-E 400 delivers. There is no need for mobile devices and a dedicated app to set up the system. Monitoring via a smartphone or tablet was also not desired. Given the bright and rotatable display of the KROHNE flowmeter, there is also no need for this as excellent readability from every angle is provided. All parameters can be checked on-site via the easy-to-operate display. The AF-E 400 provides accurate and stable flow measurement and has all what is needed for repeatable product transfer