Monitoring water abstraction from deep wells

Application Report | Food & Beverage

- Measuring water volumes for the production of mineral water and soft drinks

- Electromagnetic flow measurement in accordance with drinking water regulations

- Replacement of mechanical water meters with non-wearing measurement devices

Background

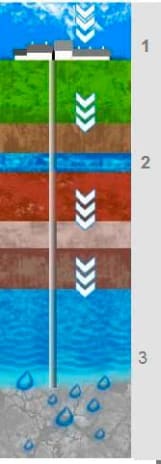

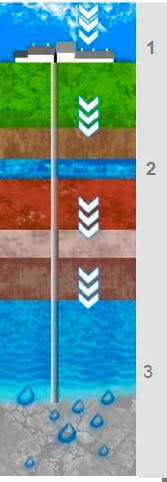

Harzer Mineralquelle Blankenburg GmbH is a medium-sized, owner-operated mineral well company in Germany. It sells high quality mineral waters as well as lemonade and other soft drinks. The mineral water used in these drinks comes from an underground water resource deep in the Harz mountains which is protected against contamination.

Measurement requirements

The company operates two deep wells for water abstraction. The amount of deep water abstracted using the on-site well must be continuously measured and recorded in accordance with the water permit issued by the local water authority. The mineral water producer used to use two mechanical water meters to determine the volume flow. These suffered continuous wear and tear because of the mechanics inside the measuring tube. These turbine flowmeters regularly got clogged with dirt and sludge particles. This meant that the customer had to keep replacing the instruments, thereby incurring high investment and installation costs. Harzer Mineralquelle therefore decided to replace the water meters with non-mechanical, non-wearing flowmeters, which do not require built-in components and moving parts. The necessary measuring instruments had to be certified for drinking water use as per DVGW (German Technical and Scientific Association for Gas and Water) and meet the requirements of the "Guideline for the hygienic assessment of organic materials in contact with drinking water" (KTW guideline) issued by the German Environmental Agency.

KROHNE Solution

Based on the professional advice and the excellent price-performance ratio, the customer opted for the WATERFLUX 3100 C electromagnetic flowmeter (EMF). One device was fitted in each of the two deep well pipes with a nominal size of DN 50. The fact that these stainless steel pipes are reduced just before the measuring point does not affect the measurement. The measuring instrument does not require a straight inlet or outlet and can, therefore, be installed directly behind an elbow or reducer.

The WATERFLUX 3100 has a patented rectangular and reduced pipe cross section which optimises the average flow velocity and the flow profile. The installation conditions are, therefore, virtually irrelevant for this measuring device, unlike conventional EMFs. The non-wearing construction with Rilsan® liner means that the measurement device is impervious to solid contents in the well water. The WATERFLUX 3100 holds the required drinking water approvals as per DVGW and KTW.

Customer benefits

Harzer Mineralquelle now benefits from a non-wearing and maintenance-free measuring device. Unlike mechanical water meters, the WATERFLUX 3100 is durable and does not need constant cleaning or regular replacement. This guarantees the company major cost savings. The risk of process disruption due to faulty measuring devices is now minimal.