Measuring layer thickness in a centrifuge

Application Note | Food & Beverage

- Continuous measurement of layer thickness when filling centrifuge

- Controlling the layer thickness during the spin process

- Automated filling process

Background

A sugar producer fills a centrifuge with hot molasses sugar to press the moisture out of the molasses at high speed. The thickness of the layer of molasses on the wall of the centrifuge is reduced in the process. The layer thickness is thus a measurement of the moisture content of the layer of molasses.

Measurement requirements

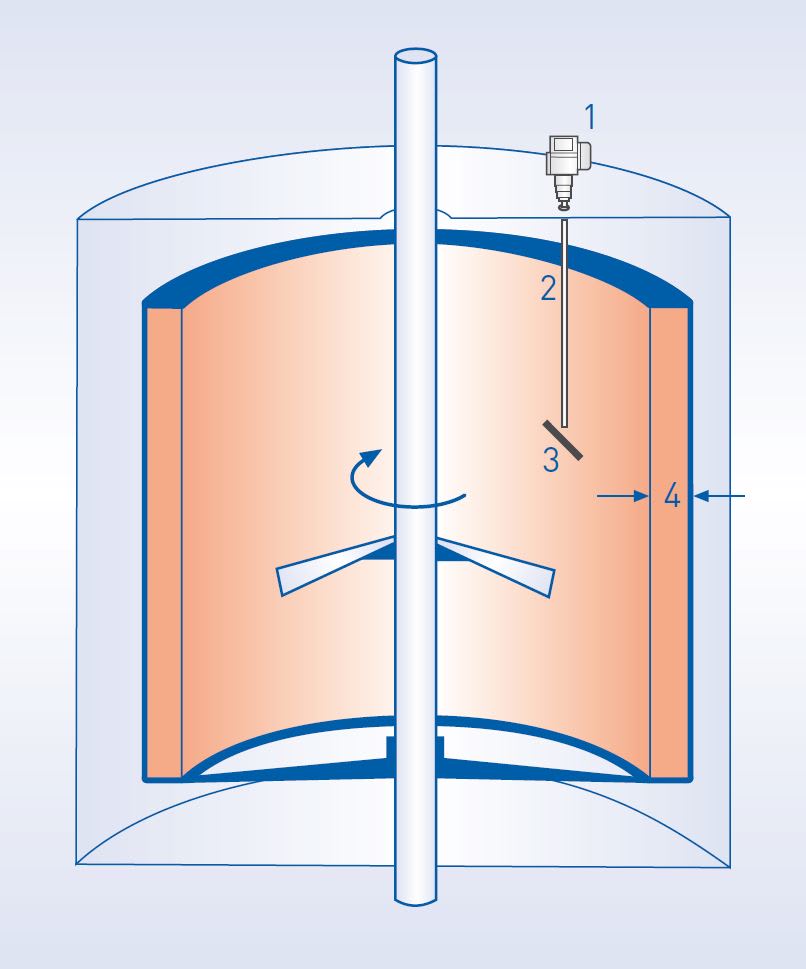

The centrifuge is the shape of an upright barrel with a diameter of approx. 1.5 m/ 5 ft. The filling process only lasts 5 -10 seconds. The layer thickness on the wall of the centrifuge is to be continuously measured during this time so that the filling process can take place completely automatically. The measuring device can only be installed from above but must measure at a 90° angle. This is done using a 45° mirror which is attached to the end of a 700 mm / 2.30 ft waveguide and reroutes the radar waves. There is 150 mm / 0.5 ft between the molasses layer and the waveguide.

KROHNE Solution

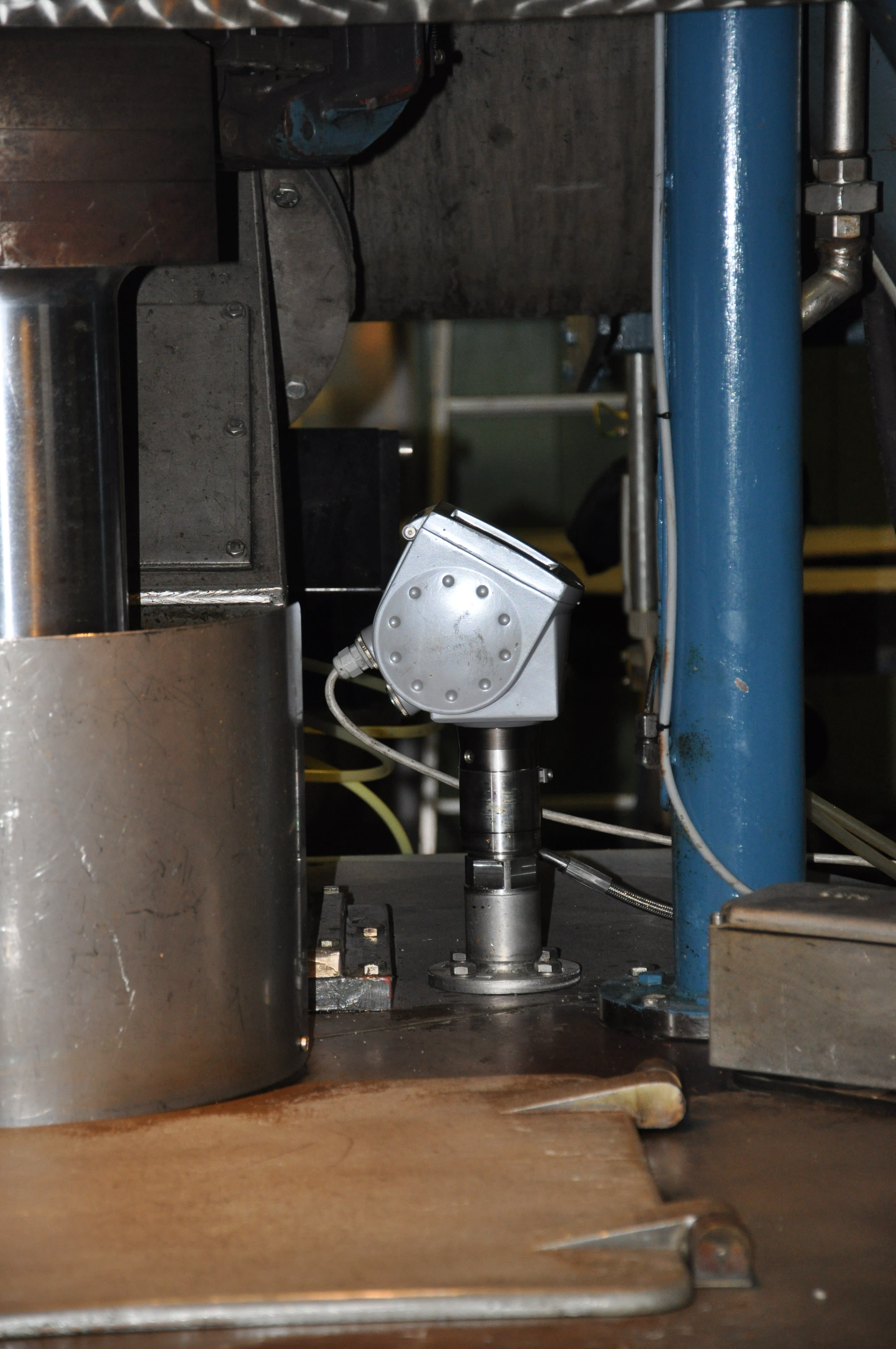

For this type of application, KROHNE supplied 4 OPTIWAVE 7300 C radar transmitters with DN 50 / 2" horn antennas and G 1½" connection. The existing constructions were used for mounting.

Thanks to FMCW radar technology, the OPTIWAVE level transmitters measure over a very wide dynamic range. That is why neither the minimally reflective surface of the molasses layer nor the high speed of the centrifugewhen filling and during the spinning process affect the measurement of the layer thickness.

Following each spin cycle, all parts that come into contact with the molasses sugar are automatically cleaned with water to avoid any caking.

Customer benefits

The customer is now in a position to completely monitor and automate the entire process of extracting the moisture from the molasses sugar. At any time, both while filling the centrifuge and during the spin cycle, the layer thickness on the wall of the centrifuge can be measured and the production process can be controlled accordingly, saving both time and money.