Fly ash level measurement

Application Note | Metal & Mining

- Storing fine ash powder in a conical silo

- Monitoring of low reflective medium in a dusty environment

- Managing supply inventory without process interruption

Background

A manufacturer of building and construction materials operates a production site in the United States, where coal combustion by-products from an adjacent power plant are turned into high quality fly ash. When combined with other materials (e.g. lime), this fine grey powder can be further processed into cement supplements for concrete or asphalt.

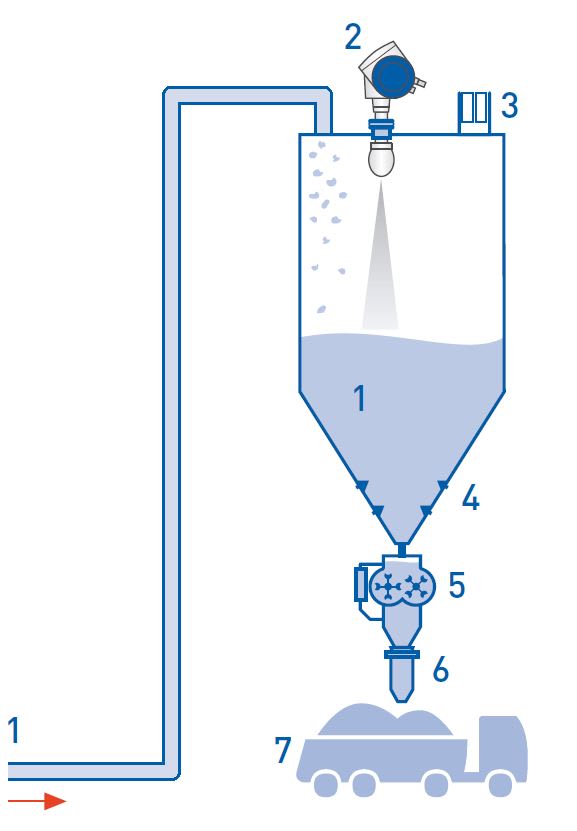

For delivery purposes the fly ash is stored in a conical silo 20 m / 65 ft high with a diameter of 6 m / 20 ft. The product is loaded onto dump trucks underneath the silo using a discharge system and a loading spout. To guarantee that the trucks get filled without delay, a stock monitoring system is needed to ensure that there is always a sufficient amount of fly ash available in the silo.

Measurement requirements

To monitor the fly ash stored in the silo, the materials manufacturer had previously used an ultrasonic level meter from a competitor. However, given the challenging product surface of fly ash with its low dielectric constant (3.3 εr) and its tendency to cause heavy build-up, the instrument consistently failed. This resulted in process interruption on various occasions when the ultrasonic level meter indicated a full silo while it was in fact empty, leading to the trucks waiting for hours to be loaded. This unacceptable situation prompted the company to search for a reliable level meter with a track record of successful installations in solid applications. An Ex approval for hazardous dust areas was compulsory for this device.

KROHNE Solution

The customer decided in favour of the OPTIWAVE 6300 C. This 24…26 GHz non-contact FMCW radar level meter generates a powerful wave signal for accurate and reliable measurement even in the dusty atmosphere of the fly ash silo.

The KROHNE device was installed with a DN 150 / 6" Drop antenna made of PP, using a 6" flange (150 lb RF). The measuring signal is transmitted by a 4…20 mA signal to a control room, where the level of the silo is constantly monitored. The OPTIWAVE 6300 was provided with Ex approval (FM XP IS/DIP Class I/II/III).

Customer benefits

The materials company is finally benefitting from improved stock monitoring utilizing the OPTIWAVE 6300. Inefficient loading and costly delays caused by false level indication are no longer an issue. Given the shape of the Drop antenna and the very small beam angle, the OPTIWAVE 6300 C is not only able to minimize product build-up in a very dusty environment, but also to measure a medium such as fly ash that features a low dielectric constant. Unlike with the previous ultrasonic level meter, climbing onto the top of the silo to clean the sensor is no longer necessary. The OPTIWAVE 6300 doesn’t need any expensive purging systems (e.g. with compressed air), thus keeping operating costs low. The customer appreciated the robust overall construction of the level meter due to its suitability for rough solid applications. Repeatability and reliability – the customer’s main requirements – have been greatly achieved. The manufacturer is very satisfied and already ordered a further three devices for other U.S. production plants.