Equipping a water purification system for electrochemical machining with process instrumentation

Application Report | Machinery & Apparatus

- Measurement technology for a turnkey membrane filtration system

- Vast range of measurement requirements including flow, level, pressure, temperature and analysis

Background

ECM Technologies engineers and supplies solutions for electrochemical machining (ECM), which is a method to precisely cut angles, gaps, edges or other shapes into electrically conductive metals. An ECM process requires an electrolyte to be injected into the workpiece so as to function as a medium between the tool and the workpiece, dissolving the desired parts by way of electrolysis without direct mechanical contact. Through the process of ECM demi water with heavy metal ions is discarded as a waste product which has to be purified using a membrane filtration system. Electrolyte cleansing technology removes the toxic particles from the electrolyte. In order to operate such a purification system properly, a whole range of parameters such as flow, level, temperature, pressure, pH, turbidity or conductivity have to be controlled on a regular basis

Measurement requirements

For a customer in northern Europe ECM Technologies tailored a water purification system for electrochemical machining processes. As the whole installation had to be delivered as a turnkey solution, ECM Technologies required process instrumentation for the various measurement tasks.

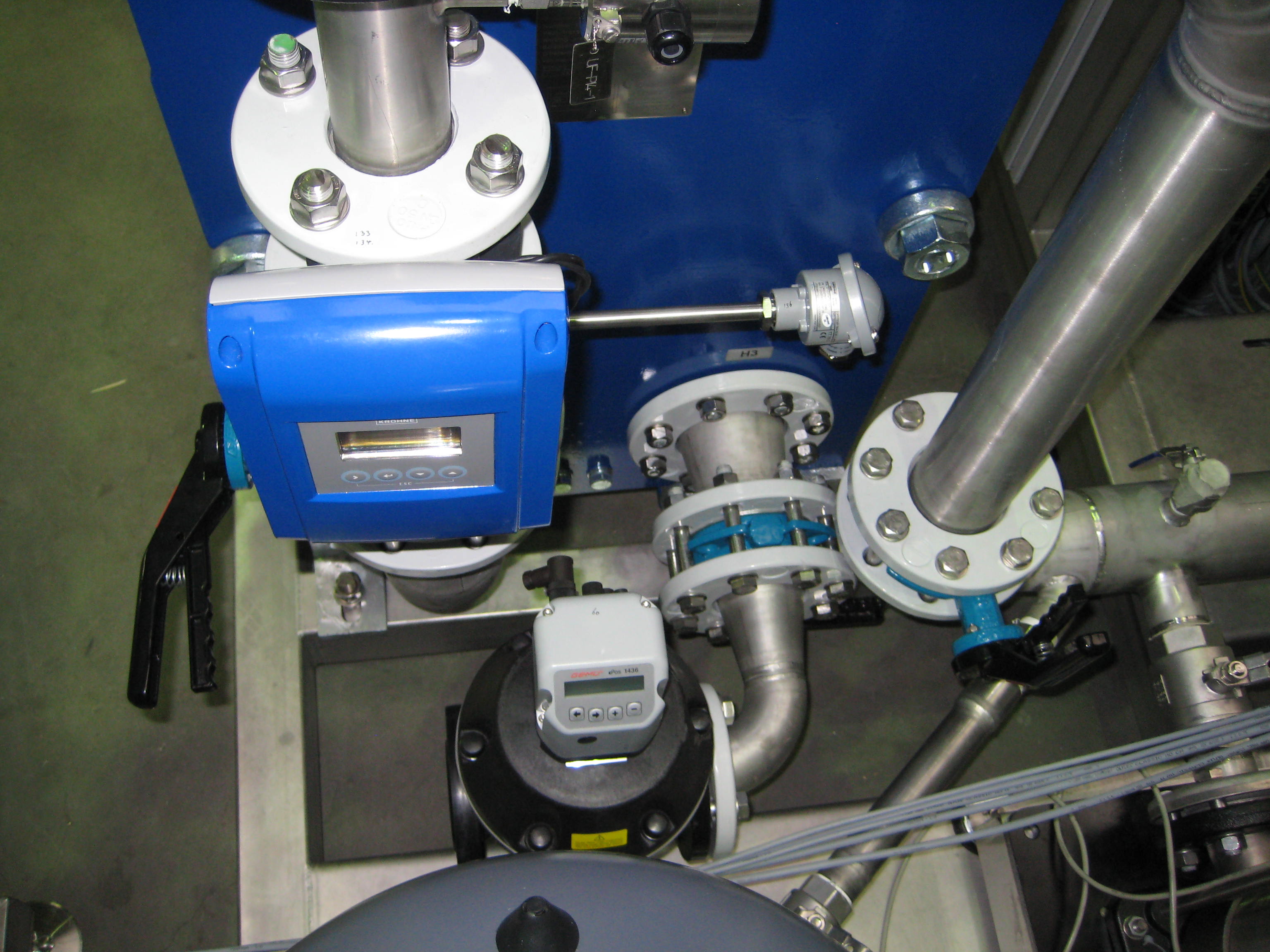

KROHNE Solution

KROHNE equipped the whole water purification system with process instrumentation, including: 9 OPTIFLUX 1100 electromagnetic flowmeters, 1 OPTIMASS 1300 C Coriolis mass flowmeter, 9 OPTIFLEX 1100 Guided Radar (TDR) level meters, 1 DWM 2000 flow controller, 1 OPTITEMP TRA-TS 35 welded multipart thermowell, 3 OPTISENS IND 1000 inductive conductivity sensors, 1 OPTISENS COND 1200 conductivity sensor, 3 OPTISENS PH 8300 pH sensors, 1 OPTISENS TUR 2000 measuring system for turbidity as well as 8 OPTIBAR P 3050 pressure transmitters.

Customer benefits

ECM benefited from the synergy of a single source supplier. KROHNE was able to meet all measurement requirements ranging from flow and flow control, to level, temperature up to analysis for turbidity and conductivity.