Detecting the leakage of coolant in a blast furnace

Application Report | Metal & Mining

- Protection of furnace lining and shell through internal cooling system

- Electromagnetic flow measurement of chemically purified water

- Advanced leakage monitoring system with over 530 flowmeters

Background

PJSC Yenakiieve Iron and Steel Works (EMZ), a subsidiary of the international vertically integrated steel and mining company Metinvest, is one of the leading metallurgical companies in the Ukraine. The companies’ production facilities comprise of three blast furnaces, a BOF (Basic Oxygen Furnace) steelmaking plant with three BOF units, two continuous casting machines and three rolling mills.

In order to increase the capacity of hot metal production to 3 million tons per year, EMZ has seen major investments in recent years. One part of this investment was dedicated to completing the reconstruction of two of the three blast furnaces, making them the most efficient in the Ukraine.

Measurement requirements

Against the backdrop of that reconstruction, closed loop cooling circuits were implemented deeply into the furnace to prevent its shell and lining from overheating and burning through. These cooling systems are fed with chemically purifi ed water with a conductivity of 1400…1600 μSm/cm ( μmho/cm). The coolant medium has a volume fl ow rate of up to 10 m/s / 32.8 ft/s at pressures of 6…12 barg / 87…174 psig. The temperature of the liquid varies between 40 °C…60 °C / 104 °F…140 °F, but can reach as high as 104 °C / 219 °F in some places.

Given the explosive potential of water in contact with the molten smelting materials in the furnace, a reliable leakage monitoring that prevents the ingress of water into the high temperature atmosphere of often more than 2000 °C / 3630 °F is crucial to the safety of the plant and its employees. In order to implement an advanced leakage monitoring system, the customer required a vast number of fl ow measuring devices. The instruments were to perform its measurements with great accuracy and repeatability to detect any changes in the volume fl ow of the coolant at the earliest stage. It was compulsory that the fl owmeters hold a MPA (Metrological Pattern Approval) certifi cate for measuring instruments.

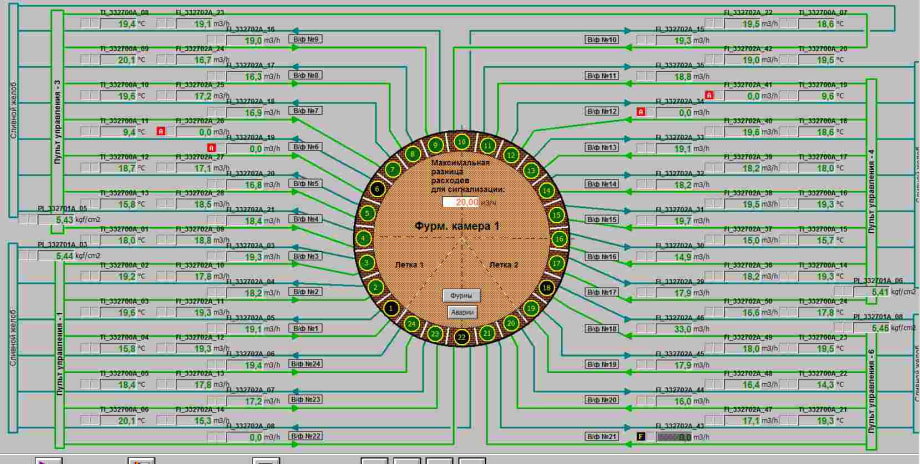

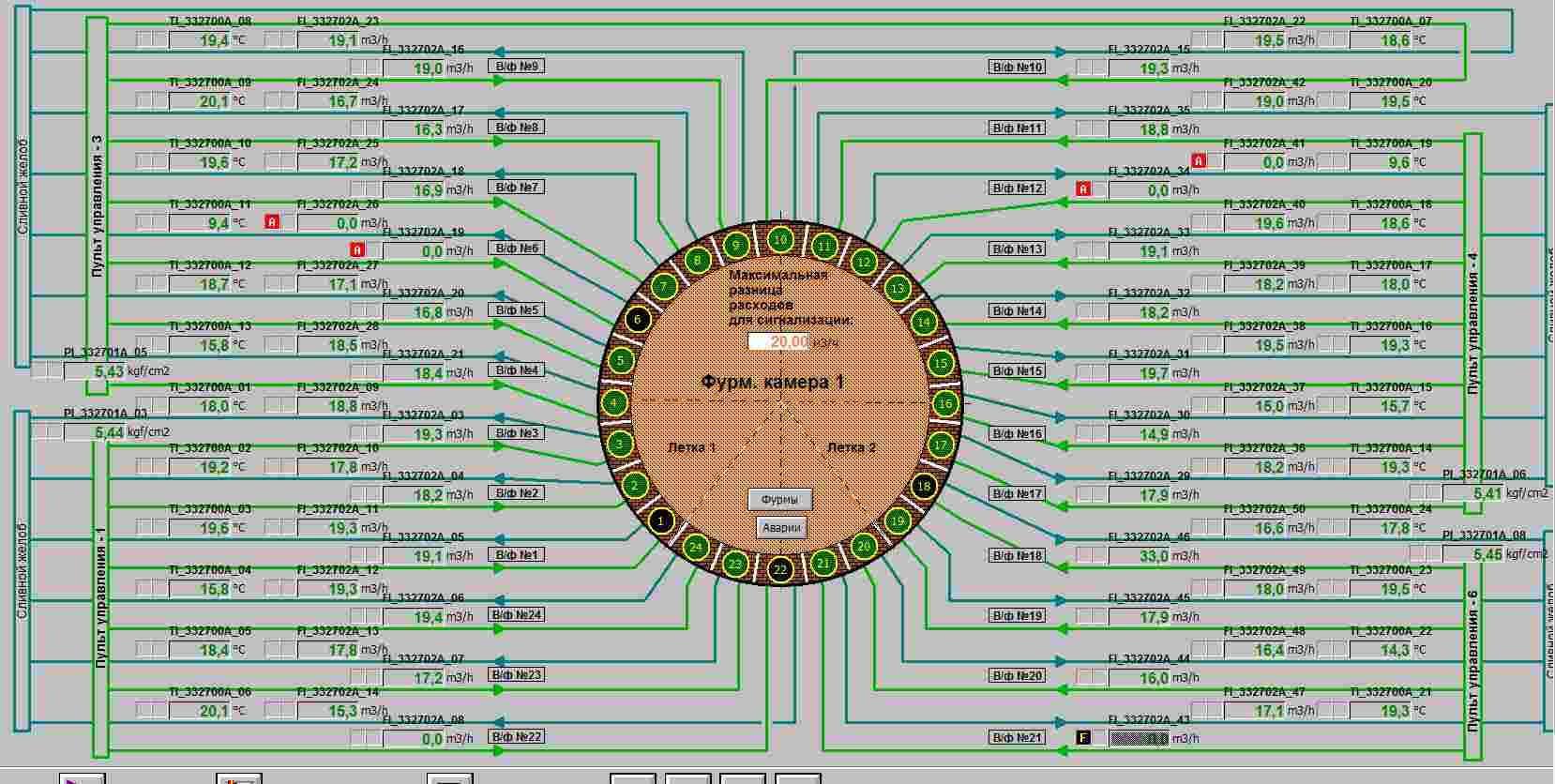

KROHNE Solution

As EMZ has been successfully using KROHNE flowmeters in the cooling system of the pan of a continuous casting machine, they also found the OPTIFLUX 2100 C to be the right solution for this application. The leak detection control system was equipped with more than 530 units of the electromagnetic flowmeter in DN 32 / 1¼", DN 40 / 1 ½”, DN 50 / 2” and DN 80 / 3”. The instruments were installed in the cooling lines of the blast furnace cooler, the tuyere zone as well as the blast furnace hearth and bottom, measuring the difference between supply and return. The readings of the OPTIFLUX 2100 C were transmitted to an automatic control system via a 4…20 mA HART communication. Whenever the difference in volume flow rate exceeds a certain limit, an alarm is triggered.

Customer benefits

The OPTIFLUX 2100 C flowmeter fully met the high demands of EMZ in terms of quality, reliability and repeatability. The very large number of more than 530 OPTIFLUX 2100 C flowmeters enabled the customer to implement a most advanced leakage monitoring system. As the coolant is only centimeters away from excessively heated molten material, the OPTIFLUX 2100 is key to inhibiting the development of explosive oxygen and hydrogen caused by leakage of coolant. Thus, the KROHNE flowmeter plays an essential role in maintaining process safety.

The diagnostic functions of the OPTIFLUX 2100 are a particular advantage here. The IFC 100 converter of the OPTIFLUX can check the performance of the sensor as well as its own functionality. It provides information on process conditions, problems with the conductivity of the medium or temperature as well as electrode errors.

EMZ also benefi tted from a thoughtful project management that enabled KROHNE to meet the desired delivery date of six weeks for the first 260 units of the flowmeter.